预约演示

更新于:2025-05-07

Pfizer Global Manufacturing

子公司|Connecticut, United States

子公司|Connecticut, United States

更新于:2025-05-07

概览

标签

神经系统疾病

其他疾病

心血管疾病

小分子化药

疾病领域得分

一眼洞穿机构专注的疾病领域

暂无数据

技术平台

公司药物应用最多的技术

暂无数据

靶点

公司最常开发的靶点

暂无数据

| 排名前五的药物类型 | 数量 |

|---|---|

| 小分子化药 | 7 |

关联

8

项与 Pfizer Global Manufacturing 相关的药物靶点 |

作用机制 VDCCs阻滞剂 |

最高研发阶段批准上市 |

首次获批国家/地区 美国 |

首次获批日期2003-10-31 |

靶点 |

作用机制 5-羟色胺重摄取抑制剂 |

原研机构 |

非在研适应症- |

最高研发阶段批准上市 |

首次获批国家/地区- |

首次获批日期1990-01-01 |

作用机制 L-type calcium channel阻滞剂 |

在研机构 |

原研机构 |

非在研适应症 |

最高研发阶段批准上市 |

首次获批国家/地区 英国 |

首次获批日期1989-03-01 |

1

项与 Pfizer Global Manufacturing 相关的临床试验EUCTR2004-000954-22-LV

A 1-Year Open-Label Safety Extension Study of Pregabalin (CI-1008) in Patients With Anxiety Disorders

开始日期2004-09-23 |

申办/合作机构 |

100 项与 Pfizer Global Manufacturing 相关的临床结果

登录后查看更多信息

0 项与 Pfizer Global Manufacturing 相关的专利(医药)

登录后查看更多信息

3

项与 Pfizer Global Manufacturing 相关的文献(医药)Chimica Oggi

Process analytical chemistry as a tool for green chemistry. Perspectives from an API plant

作者: Berry, L. ; Sistare, F. ; Mojica, C. A.

Cleaning validation by direct swab NIR analysis

作者: Grout, Bronwyn

Journal of Process Analytical Chemistry

A chemical sensor based scheme to evaluate packaging containment effectiveness. Part 2: scale-up and qualification of the inspection scheme

作者: Webster, Gregory K. ; Farrand, Douglas A. ; Litchman, Mark A.

100 项与 Pfizer Global Manufacturing 相关的药物交易

登录后查看更多信息

100 项与 Pfizer Global Manufacturing 相关的转化医学

登录后查看更多信息

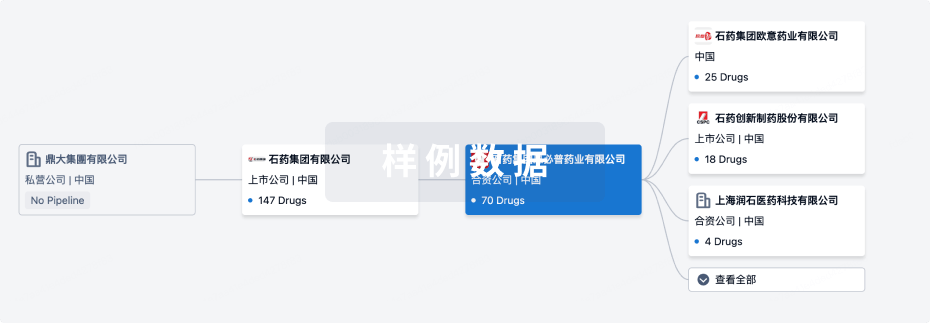

组织架构

使用我们的机构树数据加速您的研究。

登录

或

管线布局

2025年09月30日管线快照

管线布局中药物为当前组织机构及其子机构作为药物机构进行统计,早期临床1期并入临床1期,临床1/2期并入临床2期,临床2/3期并入临床3期

临床前

2

5

批准上市

其他

1

登录后查看更多信息

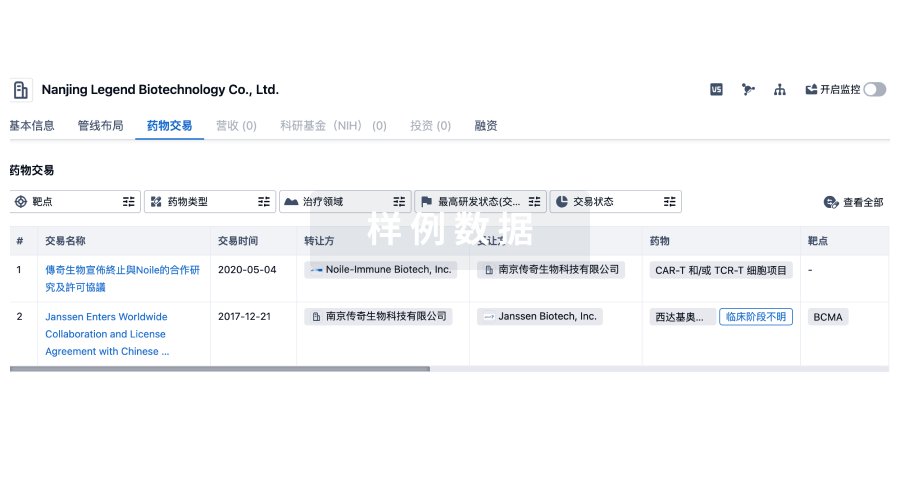

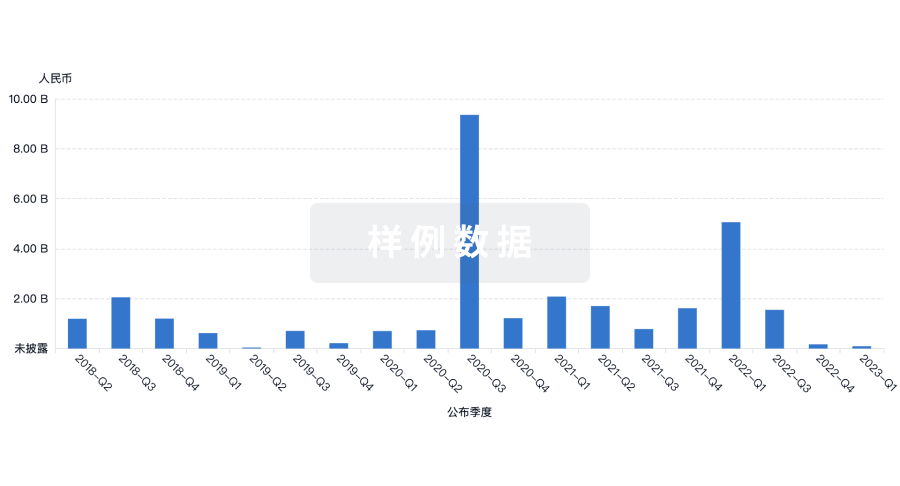

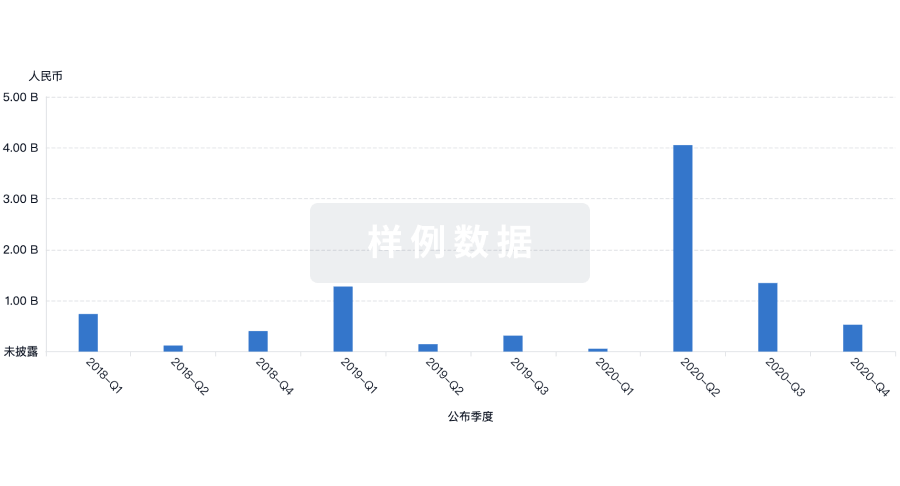

药物交易

使用我们的药物交易数据加速您的研究。

登录

或

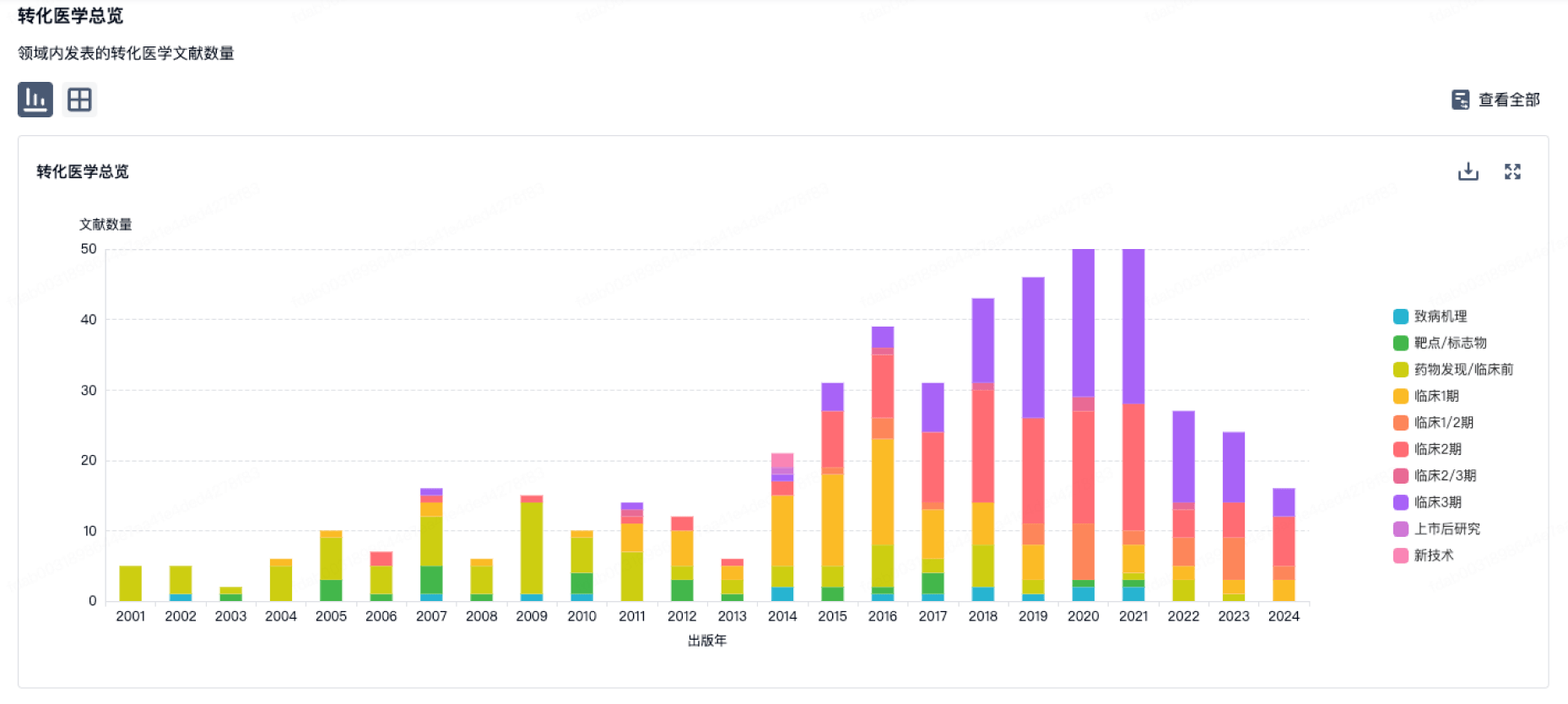

转化医学

使用我们的转化医学数据加速您的研究。

登录

或

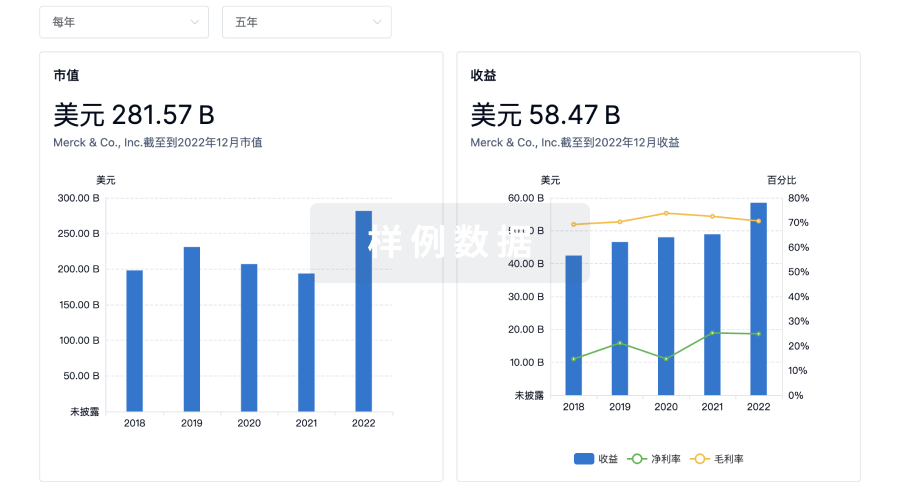

营收

使用 Synapse 探索超过 36 万个组织的财务状况。

登录

或

科研基金(NIH)

访问超过 200 万项资助和基金信息,以提升您的研究之旅。

登录

或

投资

深入了解从初创企业到成熟企业的最新公司投资动态。

登录

或

融资

发掘融资趋势以验证和推进您的投资机会。

登录

或

Eureka LS:

全新生物医药AI Agent 覆盖科研全链路,让突破性发现快人一步

立即开始免费试用!

智慧芽新药情报库是智慧芽专为生命科学人士构建的基于AI的创新药情报平台,助您全方位提升您的研发与决策效率。

立即开始数据试用!

智慧芽新药库数据也通过智慧芽数据服务平台,以API或者数据包形式对外开放,助您更加充分利用智慧芽新药情报信息。

生物序列数据库

生物药研发创新

免费使用

化学结构数据库

小分子化药研发创新

免费使用