预约演示

更新于:2025-06-05

BSP Pharmaceuticals SpA

更新于:2025-06-05

概览

标签

肿瘤

泌尿生殖系统疾病

内分泌与代谢疾病

ADC

抗体融合蛋白

小分子化药

疾病领域得分

一眼洞穿机构专注的疾病领域

暂无数据

技术平台

公司药物应用最多的技术

暂无数据

靶点

公司最常开发的靶点

暂无数据

| 排名前五的药物类型 | 数量 |

|---|---|

| ADC | 10 |

| 小分子化药 | 2 |

| 单克隆抗体 | 1 |

| 抗体融合蛋白 | 1 |

关联

14

项与 BSP Pharmaceuticals SpA 相关的药物作用机制 微管蛋白抑制剂 [+1] |

原研机构 |

在研适应症 |

非在研适应症 |

最高研发阶段批准上市 |

首次获批国家/地区 美国 |

首次获批日期2025-05-14 |

靶点 |

作用机制 IL-23p19抑制剂 [+1] |

在研机构 |

原研机构 |

在研适应症 |

最高研发阶段批准上市 |

首次获批国家/地区 日本 |

首次获批日期2023-03-27 |

作用机制 FOLR1拮抗剂 [+1] |

在研机构 |

原研机构 |

在研适应症 |

最高研发阶段批准上市 |

首次获批国家/地区 美国 |

首次获批日期2022-11-14 |

17

项与 BSP Pharmaceuticals SpA 相关的临床试验CTR20241552

在二线含铂药物化疗联合贝伐珠单抗治疗后未出现疾病进展的FRα 高表达复发性铂类药物敏感上皮性卵巢癌、输卵管癌或原发性腹膜癌患者中评价mirvetuximab soravtansine 联合贝伐珠单抗对比贝伐珠单抗单药作为维持治疗的随机、多中心、开放性、III 期研究

主要目的为在铂类药物化疗(双药)联合贝伐珠单抗治疗后随机接受贝伐珠单抗联合mirvetuximab soravtansine(MIRV,第1 组)与贝伐珠单抗(第2 组)单药维持治疗的患者中,比较无进展生存期(PFS)

开始日期2024-09-03 |

申办/合作机构 |

CTR20240220

FONTANA:一项评估剂量递增的AZD5335单药治疗和与抗癌药物联合治疗在实体瘤受试者中的安全性、耐受性、药代动力学和初步疗效的I/IIa期、开放性、多中心模块化研究

1. 评估AZD5335单药治疗和与抗癌药物联合治疗在晚期实体瘤受试者中的安全性和耐受性。

2. 确定AZD5335单药治疗和与抗癌药物联合治疗进入II期研究的有效剂量(RP2D)。

3. 评估AZD5335单药治疗和联合抗癌药物治疗的初步抗肿瘤活性。

4. 表征AZD5335单药治疗和联合抗癌药物治疗时的PK。

5. 测定AZD5335的免疫原性。

开始日期2024-02-19 |

申办/合作机构 阿斯利康全球研发(中国)有限公司 [+2] |

CTR20233084

一项在中国骨髓增生异常综合征受试者中口服ASTX727和注射用地西他滨的开放、交叉、药代动力学和疗效桥接研究

主要目的:

1.评估中国骨髓增生异常综合征(MDS)受试者接受ASTX727治疗的有效性[完全缓解率(CR率)];

2.评估口服ASTX727与注射用地西他滨治疗5天后的主要药代动力学(PK)参数(地西他滨5天总暴露);

次要目的:

1.评估中国骨髓增生异常综合征受试者接受ASTX727治疗有效性的其他终点指标;

2.评估中国骨髓增生异常综合征受试者接受ASTX727治疗的安全性;

3.评估中国骨髓增生异常综合征受试者接受ASTX727与注射用地西他滨后的地西他滨、E7727和E7727-差向异构体PK参数。

开始日期2023-10-20 |

申办/合作机构 |

100 项与 BSP Pharmaceuticals SpA 相关的临床结果

登录后查看更多信息

0 项与 BSP Pharmaceuticals SpA 相关的专利(医药)

登录后查看更多信息

1

项与 BSP Pharmaceuticals SpA 相关的文献(医药)2024-09-01·INTERNATIONAL JOURNAL OF PHARMACEUTICS

Scalable microfluidic method for tunable liposomal production by a design of experiment approach

Article

作者: Oddone, Irene ; Verdone, Giuliana ; Barbarito, Chiara ; Pompei, Simona ; Secci, Daniela ; Buttitta, Giorgio ; Moliterno, Mauro ; Saito, Gabriele ; Bonacorsi, Simone ; Raimondi, Sergio

Liposomes constitute a widespread drug delivery platform, gaining more and more attention from the pharmaceutical industry and process development scientists. Their large-scale production as medicinal products for human use is all but trivial, especially when parenteral administration is required. In this study an off-the-shelf microfluidic system and a methodological approach are presented for the optimization, validation and scale-up of highly monodisperse liposomes manufacturing. Starting from a Doxil®-like formulation (HSPC, MPEG-DSPE and cholesterol), a rational approach (Design of Experiments, DoE) was applied for the screening of the process parameters affecting the quality attributes of the product (mainly size and polydispersity). Additional DoEs were conducted to determine the effect of critical process parameters "CPPs" (cholesterol concentration, total flow rate "TFR" and flow rate ratio "FRR"), thus assessing the formulation and process robustness. A scale-up was then successfully accomplished. The procedure was applied to a Marqibo®-like formulation as well (sphingomyelin and cholesterol) to show the generality of the proposed formulation, process development and scale-up approach. The application of the system and method herein presented enables the large-scale manufacturing of liposomes, in compliance with the internationally recognized regulatory standards for pharmaceutical development (Quality by Design).

13

项与 BSP Pharmaceuticals SpA 相关的新闻(医药)2024-07-26

·动脉网

国内注射笔市场即将大爆!

近两年,当GLP-1站在资本市场舞台中央的时候,在无人注意的角落,GLP-1配套的注射笔(笔式注射给药器)接连斩获了多个大单。

2023年,甘李药业的门冬胰岛素注射液和可重复使用的笔式胰岛素注射器先后在巴西、哈萨克斯坦签下大单。4月,其在巴西中标134万支门冬胰岛素注射液和6.7万支胰岛素重复注射笔;10月,两种产品又在哈萨克斯坦中标,中标量将满足哈萨克斯坦市场未来一整年的门冬需求量。

翰宇药业也在2023年拿下超亿元订单:11月,美国合作方向其采购1408.32万美元(约合1.03亿元人民币)的利拉鲁肽预填充注射笔制剂。据悉,该金额仅为首批订单的前端采购价部分,合作方还将根据产品净销售额50%进行分成。

此外,翰尔西医疗与国内多个知名上市药企签订了注射笔供销合作协议,签署金额近10亿元,将在未来五年内逐步交付。

不仅是注射笔企业,智能制造装备供应商均普智能也在2023年向瑞士糖尿病企业、丹麦医药企业成功交付了预装大容量可穿戴胰岛素注射笔、GLP-1受体激动剂自动注射电动笔等智能制造装备项目。此前,均普智能还为医药巨头赛诺菲交付了可年产400万件的智能化一次性胰岛素自动注射笔生产线。

事实上,国产GLP-1药物还未大规模放量,国产注射笔还处于即将爆发的阶段。而海外注射笔市场却由于司美格鲁肽、度拉糖肽等注射液的爆火而大卖。甚至于诺和诺德与礼来均在疯狂加强注射笔的供应。

2023年2月,诺和诺德在中国天津投资约11.8亿元建设预填充注射笔生产线及成品车间;8月,诺和诺德与赛默飞达成合作,赛默飞旗下子公司将为诺和诺德提供司美格鲁肽填充注射笔生产服务;11月,诺和诺德投资约23亿美元扩大在法国的生产,以提升GLP-1药物及注射笔的产量;2024年2月,诺和诺德控股股东以165亿美元收购CDMO龙头Catalent(康泰伦特),其中Catalent的两个生产基地将诺和诺德被用于灌装减重药物注射笔……

礼来也在2023下半年表示:将通过投资扩建工厂提高产能,并从2024年开始提供多剂量快速注射笔。

2024年3月,礼来与美国韧力公司(National Resilience)、意大利制药公司BSP Pharmaceuticals达成合作协议,由韧力公司、BSP公司为礼来提供注射笔的制剂灌装服务。礼来还表示,其将利用广泛的外部合同制造商组合加快生产。2024年4月,礼来宣布拟投资25亿美元建设一家工厂,用于生产注射药物和注射笔。

数十亿美元投建工厂、超百亿美元并购CDMO,对于注射笔、注射药物的扩产,诺和诺德与礼来不可谓不“疯狂”。

GLP-1的爆火在预料之内,而注射笔低调签单却瞒过了大多数人。从行业看,注射笔为何能大爆?其高增速能保持多久?更多企业入局背后,注射笔行业如何了?

注射笔爆发,不止是因为GLP-1

毫无疑问,注射笔的爆发,其中一个重要因素是GLP-1。

GLP-1是一类新型的药物,现阶段获批的适应症主要为治疗2型糖尿病和肥胖症,代表性药品包括司美格鲁肽、度拉糖肽、利拉鲁肽等。

自司美格鲁肽、度拉糖肽等重磅GLP-1药物获批以来,GLP-1市场就进入了超高速发展期。根据各上市企业年报统计,2022年,全球GLP-1药物总体销售额达到225亿美元。2023年,全球GLP-1药物销售额突破350亿美元。其中,仅司美格鲁肽针剂Ozempic的销售额就已达到138.9亿美元。

(2023年GLP-1代表药物销售情况)

之前,司美格鲁肽、度拉糖肽等GLP-1药物的应用场景主要为减重、降糖,需要消费者长期自我管理、自我给药。而这些药物此前的给药方式均是注射给药。

在多种注射给药方式中,玻璃针筒、一次性注射器等传统注射给药装置对操作者有一定的要求,需要专业的医护人员操作,且长期使用时患者依从度较低。

注射笔是将药物与注射装置合二为一,患者无需专业操作知识即可进行自我注射治疗,操作简单便捷,依从度更高。因此,司美格鲁肽注射液等GLP-1药物均配套了注射笔。而司美格鲁肽针剂、度拉糖肽针剂、替尔泊肽针剂等GLP-1产品的大卖,也带动了注射笔的销量大涨。

值得一提的是,近两年,国产GLP-1药物终于获批上市,且更多国产GLP-1即将获批。例如,2023年,华东医药的利拉鲁肽注射液分别获国家药监局批准了治疗成人2型糖尿病、肥胖或体重超重适应症;仁会生物的贝那鲁肽获批新适应证治疗肥胖或超重;2024年,正大天晴开发的利拉鲁肽注射液获得国家药监局批准上市,用于成人2型糖尿病患者控制血糖……

随着更多国产GLP-1产品的获批上市,GLP-1药物将进一步渗透市场。而这,也将促使国内注射笔市场进一步扩容。

近期,许多药企都开始扩产GLP-1产品。但是,注射笔的产量却少有人关注。根据统计,目前国内注射笔的年产量不超过1亿支,远远不能满足我国2025年6月以后的市场需求。这意味着国产GLP-1开始放量后,很可能会因注射笔的产量不足而缺货。而注射笔的扩产需要近10个月的准备期。因此,国内药企最好在2024年9月前确定注射笔合作方,确保未来注射笔的产量充足。

虽然GLP-1是注射笔大卖的重要因素,但不是唯一因素。GLP-1之外,胰岛素、重组人生长激素(矮小症用药)、特立帕肽(骨质疏松用药)、重组人促卵泡激素(不孕不育用药)等注射类药物的渗透率提升也刺激了注射笔市场。

以胰岛素药物为例,自2022年5月胰岛素国家专项集采在各省市陆续落地,国内市场上胰岛素产品价格明显下降,其渗透率也快速提升。如通化东宝的胰岛素类似物产品在2023年实现销量超60%增长。甘李药业基础胰岛素产品2023年的销售量同比增长32.47%,速效和预混胰岛素产品销售量同比增112.38%。

2024年3月,国家组织药品联合采购办公室再次开展胰岛素专项集采持续采购。此次接续集采的6类胰岛素首年采购需求超2.4亿支/瓶,其中制剂规格为笔芯或笔芯/预填充的产品采购量占总体采购量的95%以上。随着胰岛素的渗透率进一步提升,胰岛素注射笔的市场规模也在迅速扩大。

另外,相关企业还将注射笔产品的应用领域扩展到阿扑吗啡、利拉鲁肽、特立帕肽、阿达木单抗、贝伐珠单抗、纳武单抗、依那西普等新型药物中,进一步打开注射笔的市场空间,提升注射笔的市场增速。

除了应用场景扩展、渗透率提升外,国产注射笔也随着药企出海浪潮一同销往海外。例如,当国外胰岛素厂商在国际市场出现供应问题时,甘李药业趁机拓展客户,扩大海外订单。2023年,甘李药业胰岛素产品在海外市场的订单量增加,国际收入较上年同期翻倍增长。同时,伴随胰岛素的成功出海,甘李药业的注射笔也顺势在海外频频中标,销量大涨。

多种因素共同驱动下,注射笔市场高速增长、加速扩容。根据市场调研公司ReportLinker发布的研究报告,2021年全球注射笔市场规模预计为376亿美元,2026年将达到533亿美元,年均复合增长率7.2%。

国产注射笔大规模备产的背后,乱象渐起

规模变大、增速加快的注射笔行业,迅速吸引了更多入局者。同时,投机者、非专业人士的入局,也引发了一些行业乱象。

第一,注射笔企业在采购、选用材料方面存在乱象。一位注射笔行业资深人士表示:“许多注射类药物集采后,相关药企对降低成本提出了更高的要求。传递到注射笔端,药企们要求注射笔产品持续压缩成本、降低费用。而为了获得订单、赚取利润,有的注射笔企业通过使用工业级材料或劣质的改性塑料(回收废料的改进料)来降低成本。”

采用低端材料、劣质材料生产出的注射笔,在放置一段时间后通常会出现产品组件故障、润滑不良、推杆严重卡顿、产品寿命降低、无法注射或使用困难等问题。

同时,优质的注射笔可依靠高端材料的自润滑性实现传动注射;劣质的注射笔产品则由于采用了劣质材料,需额外使用润滑油等化工用剂来弥补产品核心组件的润滑性能。但是,这又带来新的问题:其不符合生物相容性要求。

在中国,由于注射笔尚属于创新产品,暂时缺乏相应的标准,此类产品仍可获批上市。但在欧洲等成熟市场,监管部门对注射笔的生物相容性及材料均有明确要求,应用低端材料、额外使用润滑油等化工用剂的注射笔产品,无法获得欧盟CE认证。

第二,注射笔产品在生产方面也存在乱象。现阶段,有的企业并未采用全自动生产线、全自动检测工艺,而是通过人工生产。这使得其注射笔产品的一致性较差。同时,有的企业在注射笔生产环节未进行过程化管控,使产品的质量不稳定,消费者可能买到这些企业生产的劣质品或残次品。

针对上述乱象,国家相关部门、行业协会应当发挥作用,牵头制定相关生产标准,并加强生产监管,确保注射笔产品符合市场要求、行业标准;注射笔企业也应以高标准要求自己,生产高品质产品。

第三,有的注射笔企业“唯客户论”“唯订单论”,只想赚快钱,不考虑长远。具体来说,当客户提出一些不符合行业标准的要求时,有的企业为了获得订单,选择迎合客户要求。

例如,注射笔需具备盲打功能,使患者能轻易知道、设置注射量。但是,有的客户提出了“柔顺注射”的要求,即主动弱化注射时的力反馈与声音反馈,使患者能更柔顺的完成注射。但是,这将导致患者不知道注射量,并失去盲打功能。很明显,这不符合患者需求,也不符合行业标准。

再如,有的客户会要求所需注射笔的手感与进口注射笔的手感一致。关于手感,每一个传动结构、核心部件都影响着注射笔的手感。若要手感一致,就需要完全仿制进口注射笔的结构、材料。但这必然会引发专利问题。

对于这些要求,有的注射笔企业并不会坚持原则,也不会给客户解释专利问题,而是为了获得订单,满足客户的所有要求。带来的危害是:药企后续可能遭遇专利官司,给海外企业赔付费用,并延期产品的上市时间、影响企业品牌。

一位业内人士表示:“海外巨头在国内的相关负责人曾透露,目前国产产品的销售量仍然较少,当产品放量后再进行专利诉讼,将获得更大利益。”

第四,国内注射笔市场卷价格,唯“低价论”。事实上,大部分市场都会区分高端、中端、低端。而注射笔市场,目前许多企业以价格为中心,并不考虑产品的其他性能。这使得有的注射笔企业通过低质材料、劣质生产、仿制海外产品(无创新、无专利)等方式压缩成本,获取订单。

一方面,这使得注射笔行业失去创新动力;另一方面,市场可能出现劣币驱逐良币的现象,中高端注射笔直接失去竞争力。

针对上述两种乱象,药企客户应当根据自身产品定位,自主选择高端、中端、低端注射笔产品,而不是唯低价论。同时,为了能够在欧美等市场推广产品,药企客户应当选择具有自主知识产权的注射笔产品,避免专利诉讼问题。注射笔企业也应当专注产品创新,以产品的品质、性能进行市场竞争,而不是单以价格。

第五,注射笔的市场准入也有一定乱象。注射笔按使用次数可分为一次性注射笔和重复使用注射笔。一次性注射笔供应药企,重复使用注射笔供应C端市场。两类产品准入制度的差异,给监管部门、注射笔企业、药企客户带来了许多困惑。

根据国家规定,重复使用注射笔属于二类医疗器械,需要通过国家药监局批准上市。一次性注射笔则属于药包材,只需备案即可。

但是,少部分地方部门对政策理解不深刻,给部分企业的一次性注射笔发放了注册证;而大部分地方部门并未给相关企业的一次性注射笔发放注册证,而是令其依照包材备案制度进行备案。

这导致市场出现不公平竞争。因为有的药企客户对注射笔行业不够了解,在采购时只选择拥有注册证的产品,而不考虑备案产品。

针对这种乱象,国家相关部门需要及时整改,严格按照相关产品的准入制度执行。对于已发放的注册证,应当宣布无效,减少不公平竞争的影响。

希望在药企、注射笔企业、监管部门、行业协会等多方共同努力下,注射笔行业能快速平息乱象,正向高速发展。

*封面图片来源:pexels

如果您认同文章中的观点、信息,或想进一步讨论,请与我们联系;也可加入动脉网行业社群,结交更多志同道合的好友。

近

期

推

荐

声明:动脉网所刊载内容之知识产权为动脉网及相关权利人专属所有或持有。未经许可,禁止进行转载、摘编、复制及建立镜像等任何使用。

动脉网,未来医疗服务平台

并购带量采购

2024-06-05

·动脉网

GLP-1持续火爆,不仅将开发GLP-1药物的企业推上浪尖,现在也为上游企业开出了资本市场门票。

5月31日,多肽CDMO泰德医药正式向港交所递交招股说明书,拟主板挂牌上市。成立至今,泰德医药已获得普华资本、海邦投资、钱塘产业集团、景盛资本等机构的投资。

泰德医药是中肽生化的母公司。2015年,中肽生化被信邦制药收购。2020年,浙江泰德从信邦制药手中将中肽生化回购。中肽生化成立于2001年,是知名多肽CDMO之一,在国内与美国均有研发与生产基地,客户涵盖多家MNC和Biotech。

因此,此次泰德医药申请IPO,可以看作是老牌多肽CDMO终于走向上市之路,也说明GLP-1的火热正在惠及上游——多肽产能紧缺已是行业共识,前不久礼来宣布将在印第安纳州生产基地额外投资53亿美元扩充GLP-1产能,是这家百年药企历史上最大的制造投资,也是美国历史上对合成药物API制造的最大一笔投资。

此外,药明康德、凯莱英等CDMO也在紧锣密鼓扩产并接连拿到订单。在仍然显得冷淡的生物医药市场中,国内多肽CDMO却越来越能打了?

老牌多肽CDMO生意如何?

在泰德医药的招股书中,2023年收入为3.37亿元人民币,占全球市场份额1.5%,弗若斯特沙利文根据销售数据将公司定义为全球第三大专注于多肽的CRDMO。

来源:泰德医药招股书

弗若斯特沙利文此份榜单定义专注于多肽的CRDMO公司,是指多肽CRDMO服务贡献逾50%收入的CRDMO公司,表中公司A、公司B分别为两家位于瑞士的多肽CDMO巨头:Bachem和PolyPeptide,泰德医药随之其后。

截至2023年1月1日,泰德医药的多肽项目管线包括249个CDMO项目及六个CMO项目。其亦于2023年获得72个CDMO项目及七个CMO项目。此外,于2023年全年,泰德医药已完成8728个CRO项目。泰德医药的项目覆盖超过50个国家,包括中国、美国、日本、欧洲、韩国及澳大利亚等主要市场。截至2024年5月27日,公司与七个开发GLP-1产品的客户有九个GLP-1药物开发项目。除了多肽外,泰德医药还开发了多元化的项目管线,专注于其他类别的TIDES药物,如POC、PDC和RDC。

但从营收来看,2021年至2023年,泰德医药的营收分别为2.82亿元、3.51亿元和3.37亿元;净调整净利润分别为1.08亿元、1.28亿元和1.01亿元。在多肽药物风生水起的2023年,其营收和利润反而出现了下降。

泰德医药在招股书中指出,其2023年的收入之所以有所下滑,主要是由于每名客户平均收入有所下跌,而每名客户平均收入减少主要归因于泰德医药三名主要客户因其自身多肽药物开发资源、计划及周期的变化而大幅减少对其服务的需求。

泰德医药的长处可能在于,旗下中肽生化深耕多肽领域多年,在多肽药物研发与开发上有更深刻的理解,和中美两地的药企都有良好的沟通。在未来长期的多肽生产竞赛中,泰德医药或许可以凭此占据一席之地。

国内多肽生产什么水平?

如果说谁真正吃到了GLP-1的生产福利,那必然还是几大CDMO巨头。

药明康德于2023年完成了常州和泰兴基地产能扩建工程,新产能已于2024年1月投入使用,多肽固相合成反应釜体积增加至32000L。礼来与药明合作生产替尔泊肽的一种关键成分,且礼来表示寻找替代供应商“可能不可行,或者可能需要很长时间”。

凭借产能优势,药明康德2023年TIDES业务(寡核苷酸和多肽)收入34.1亿元人民币,同比增长64.4%。截至2023年末,TIDES在手订单同比显著增长226%。

凯莱英则是信达生物和礼来共同开发的双靶点减肥药玛仕度肽的CDMO,这款GLP-1R/GCGR双重激动剂表现出了比司美格鲁肽、替尔泊肽都更优的减重效果,预计于今年或明年正式上市。此外凯莱英还拿下了礼来口服小分子订单,并推进礼来替尔泊肽的多肽订单,部分项目已进入验证生产环节。

为适配商业化项目需求,凯莱英正在加快多肽商业化产能建设,预计到2024年6月底达到14250L。

还有一些披露产能的公司,如翰宇药业已具备1000公斤产能;诺泰生物老产能技改后年产能达到400-500公斤。此次递表的泰德医药杭州多肽API年产能为500公斤,每批多肽产能为20公斤,能够处理多个100公斤级的多肽订单。

诺泰生物同欧洲大型药企客户签订了累计合同金额约1.02亿美元的cGMP医药高级中间体7年供货合同,供货开始时间为2024年。翰宇药业与海外客户签订了2.19亿元GLP-1多肽原料药合同。

接下来,司美格鲁肽国内专利2026年到期,大量国内仿制药企业已经布局,生产订单需求将进一步被激发,供需关系的不平衡仍将持续。沙利文数据显示,按销售收入计,全球多肽类药物市场规模预计将在2032年增长至2,612亿美元,中国多肽类药物市场规模将达到2,512亿元人民币。

市场广阔,但能迅速投入多肽生产战场并不容易。换言之,多肽CDMO是一个高壁垒行业。组合多肽合成方法复杂,考虑因素众多,且在合成过程中杂质生成复杂多样、纯化难度大。

目前国内多肽生产主要采用化学合成法,以液相合成和固相合成为主导。随着GLP-1类药物的爆发,行业开始优化生产工艺,呈现化学合成法与生物发酵法、酶解法融合发展的趋势,但多数企业的生物学技术积累还不够。

除了极少部分专注于多肽CDMO的公司,国内有能力实现多肽产能构建、应对繁多终端产品的,主要是由多肽原料药扩展至多肽CDMO的企业,以及本就实力雄厚的小分子CDMO企业。

国内部分代表性多肽CDMO,动脉网整理

能否参与全球竞争?

据沙利文,按销售收入计全球多肽类CDMO市场规模由2018年的16亿美元增加至2023年的31亿美元,复合年增长率为14.8%,并预计到2032年进一步增至188亿美元,复合年增长率为22.0%。

目前全球多肽CDMO市场份额排名第一的公司Bachem,2023年营收为6.44亿美元,其中多肽业务贡献的营收为4.31亿美元。Bachem仍在积极扩充产能,计划在2024年下半年投产,目标2026年收入达到9亿美元左右。

排名第二的PolyPeptide在2023年的营收为3.47亿美元,其中多肽业务贡献为3.13亿美元。

也就是说,在这个规模迅速扩张的市场,目前并没有绝对龙头。主营业务并非多肽的药明康德,2023年TIDES业务换算为美元约为4.74亿,与全球前两名比差距不大。且药明康德的订单还在增加,今年第一季度TIDES业务收入达到7.8亿元,同比增长43.1%。

国内多肽CDMO自然有成本与产业链优势,但考虑到未知的系统性风险与供应链安全问题,诺和诺德与礼来的产能之战并没有在国内大举布局,而是主要在欧美自建工厂或展开合作。例如诺和诺德计划从2022至2029年向其丹麦的生产基地投资约87亿美元,主要用于增加活性药物成分的生产。礼来为了补充原料和制剂的供应缺口,去年11月宣布投资25亿美元用于德国阿尔泽工厂建设,今年3月与National Resilience和意大利制药公司BSP Pharmaceuticals达成协议,4月从Nexus Pharmaceuticals购买工厂等等。

这限制了国内多肽CDMO充分参与全球竞争。不过随着原研药专利到期,国内市场的扩大会承接部分产能,国内多肽原料药的成本优势也会显现。根据沙利文,2023年中国多肽类CDMO市场规模38亿元人民币,并预计到2032年进一步增至人民币307亿元,复合年增长率为25.9%。

来源:泰德医药招股书

届时,中国多肽类CDMO的全球市场份额约为22%,而这一数字在2020年仅有5%左右。

多肽CDMO是“硬性需求”

多肽药物CDMO对相关药企可以说是一个“硬性需求”,多肽生产前期投入高、时间长,很少有药企能脱离CDMO进行开发。

“不同于小分子药物,小分子投资规模小,有1000L、2000L就可以做了。多肽药企想自己做生产几乎不可能,而且多肽CDMO其实是有规模效应的,能通过合适的合成方式把成本降下来。”有业内人士表示。

与小分子药物相比,多肽药物的结构更加复杂。在整个工艺流程中,多肽杂质控制是非常大的难点。不同于小分子药物的纯度可以达到98.5%以上,甚至99%,多肽能做到93%~94%的纯度已经很好,杂质种类繁多,质量标准制定非常复杂。通常,在小分子创新药企业中,如果从事工艺开发和分析的人员比例是1:1,多肽分析由于挑战很大,这个比例要扩大到1:2,甚至1:3。

多肽生产工艺放大也比较难。多肽药物的研发工艺和规模化生产存在较高的壁垒。此外,在多肽药物合成过程中,需要使用的保护剂种类繁多,而保护剂的选择和使用,已经成为环保组织关注的重点,如果仍采用传统溶剂,也会受到很大挑战,需要尝试用新型保护剂替代。

整体来说,国内多肽CDMO还不算成熟,尤其目前国内具备多肽专业背景,特别是对多肽药物生产有整体把控能力的高端人才储备不足。

以当下最热的GLP-1为例,GLP-1的产能规划错综复杂,需要结合销售预测、现金流、竞争对手反应等多方面因素综合考虑,先入场者适当超配产能有助于抢占市场,而后入场者则需要更加谨慎。

有CDMO相关负责人称:“在市场上能满足我们需求的人是非常少的。同样,一个创新药公司想招到有多肽背景的人,我相信难度也是非常大的。”

不过,多肽生产的高壁垒带来的是较高的回报。多肽药品临床前研究阶段就需要CDMO企业提供样品合成,后期新药上市更依赖CDMO企业在工艺研发、质量控制等方面的产业化经验,因此多肽CDMO客户对服务的依赖性往往更强。而多肽复杂的生产流程和较大的质控难度,使得通常需要在同一家企业内完成从初始物料到原料药的生产过程,难以从中间交接,一体化需求程度高。

随着市场对多肽药物的关注和投入,或许将出现GLP-1之外的新大单品的可能,多肽偶联药物也被寄予厚望。国内多肽药物CDMO公司有望在全球多肽药物的发展浪潮下找到具有影响力的站位——前提是拿到多肽生产的入场券且进化能力足够强。

参考资料:

1.国联证券:多肽药物前景广阔,CDMO/原料药需求增加

2.猎药人俱乐部,

https://mp.weixin.qq.com/s/7dNJSqIbbJpSwwV4Wr1B_A

*封面图片来源:壹图网

近

期

推

荐

声明:动脉网所刊载内容之知识产权为动脉网及相关权利人专属所有或持有。未经许可,禁止进行转载、摘编、复制及建立镜像等任何使用。

动脉网,未来医疗服务平台

并购IPO

2024-04-15

当前,抗体药物偶联物(ADC)已经对临床肿瘤治疗格局产生了深远的影响,它俨然成为肿瘤治疗领域中一颗璀璨的明星,多种新型的ADC药物如雨后春笋般涌现。随着更多ADC药物的临床试验数据逐渐公布,以及个体化和精准医疗理念的普及与推广,ADC将在肿瘤治疗的舞台上扮演更加举足轻重的角色。在近期举办的2024年美国癌症研究协会(AACR)年会上,多款来自BioBAY企业的ADC在研管线亮相,其中有大量新靶点ADC以及近期备受瞩目的双抗ADC。2024 AACR BioBAY企业部分ADC报告管线信达生物:单抗双抗ADC两手抓信达生物此次在大会上公布了旗下一系列肿瘤管线的多项最新临床前数据,其中包括IBI3001和IBI343两款ADC项目,并入选重磅研究(Late-Breaking Research)。IBI3001是一款潜在全球首创针对B7-H3和EGFR的双特异性ADC,采用经临床验证的SYNtecanE®定点偶联平台。IBI3001具有多重抗肿瘤的机制:(1)增强的EGFR信号阻断;(2)EGFR与B7-H3介导的药物内吞与细胞杀伤;(3)强效的ADC旁观效应。经过优化的B7-H3臂不但加强了EGFR信号阻断的效果,同时也降低了EGFR靶点的毒性。IBI3001在多个实体瘤的体内外模型中都显示强效的肿瘤杀伤效果,且有高耐受性,治疗窗口高达40倍。IBI343是一款具有全球首创潜力的靶向Claudin 18.2的ADC分子,基于Synaffix的GlycoConnect®实现了对细胞毒素Exatecan的糖基定点偶联。IBI343在多种不同表达量的肿瘤细胞系上展现了良好的Claudin 18.2特异性的体外杀伤活性,并在多种人源肿瘤异种移植小鼠模型上展现了良好的肿瘤抑制活性。基于糖基的定点偶联技术显著增强了整个ADC的稳定性。IBI343在恒河猴的GLP毒理实验中展现了良好的安全性,并在高至30 mg/kg的剂量下耐受性良好。目前,Claudin18.2 ADC 主要开发的适应症为二三线胃癌,现有疗法疗效有限。中国有2款进入注册三期,除IBI343外,还有康诺亚/阿斯利康合作开发的CMG901。2024年2月,信达生物在Clinicaltrials.gov网站注册了IBI343治疗Claudin18.2阳性、HER2阴性胃癌的三期临床试验,是全球首款进入三期临床阶段的Claudin18.2 ADC新药。2024年3月7日,阿斯利康在药品临床试验登记与信息公示平台网站上注册了CMG901二线或二线以上治疗晚期或转移性胃癌的三期临床试验。映恩生物:充分发挥平台优势此次大会,映恩生物公布了基于其自主研发的抗肿瘤ADC平台DITAC开发的DB-1310、DB-1311创新项目的研究成果。DB-1310是一款靶向HER3的ADC产品。其在临床前研究中表现出优异的肿瘤抑制效果和安全性。并且在与EGFR小分子抑制剂联合使用中表现出优秀的协同抑制肿瘤效果。作为新一代的ADC分子,其将有可能成为广大癌症患者的新治疗选择。DB-1310目前处于一项在晚期/转移性实体瘤受试者中评估安全性、耐受性、药代动力学和初步抗肿瘤活性的I/IIa期、多中心、开放性、非随机首次人体研究阶段。DB-1311是映恩生物靶向B7H3的第三代ADC产品,也是基于DITAC平台开发,在多种肿瘤模型中显示出强大的抗肿瘤活性,并且在临床前安全评估中展现出良好的安全性和药代动力学特征。DB-1311在未来临床应用中具有潜在的广阔治疗窗口。映恩生物目前正在开展一项评估DB-1311在晚期/转移性实体瘤受试者中的安全性、耐受性、药代动力学和初步抗肿瘤活性的I/IIa期、多中心、开放性、首次人体研究。宜联生物:YL211——罗氏与中国本土创新药企的重磅合作YL211是特异性靶向c-MET的下一代抗体偶联药物。c-MET为受体酪氨酸激酶(RTK)家族的成员之一,与肿瘤的形成、侵袭性生长和转移密切相关,是治疗上皮间质转化的关键靶点。YL211目前处于临床申报阶段,采用了宜联生物新一代TMALIN ADC平台技术,并配合以高特异性的c-MET抗体。YL211已在多种临床前肿瘤模型及安全性评价实验中展现出极具潜力的疗效及安全性。2024年1月2日,宜联生物与罗氏达成约10.5亿美元全球合作和许可协议,宜联生物将与罗氏中国创新中心(CICoR)共同合作推动YL211项目进入临床1期试验阶段,并交由罗氏负责后续全球范围内进一步开发和商业化工作。启德医药:GQ1010疗效优于DS1062和TrodvyGQ1010是基于启德医药独特的iLDC技术、可切割“开环”连接子以及新型拓扑异构酶I抑制剂开发的靶向Trop2创新ADC药物。临床前研究表明,在测试的各种Trop2+癌症细胞系中,GQ1010表现出比DS1062更强的体外细胞毒性和更强的旁观者杀伤力。在不同的CDX模型(包括TNBC、胃癌、头颈部(H&N)和胰腺癌)中进一步显示出强大的体内抗肿瘤活性,疗效优于DS1062和Trodvy,与体外数据一致。目前同类产品中,全球仅有Trodvy(吉利德)上市,DS1062(Dato-DXd,第一三共/阿斯利康)和SKB264(sacituzumab tirumotecan,科伦博泰/默沙东)已申报上市。2023年4月,启德医药已将GQ1010除大中华区(中国大陆、香港、澳门和台湾)外的全球开发和商业化权益独家授权给Pyramid,获得2000万美元的首付款和最高可达10亿美元的里程碑付款,以及基于净销售额计算的分级特许权使用费。2024年2月22日,CDE官网公示,启德医药自主研发的 Trop-2 ADC药物GQ1010注射液申报临床。普方生物:两个ADC披露靶点信息SLITRK6在某些上皮性肿瘤中高表达,包括尿路上皮、肺部、乳腺癌和胶质母细胞瘤,而在正常组织中表达微弱。目前布局该靶点的只有安斯泰来/Seagen的ADC药物Sirtratumab vedotin,已经在膀胱癌和尿路上皮癌中进行了概念验证,其中尿路上皮癌1期临床已完成,结果发表在2016年 ASCO 上,整体ORR为30%。PRO1106是由靶向SLITRK6的人源化IgG1和基于拓扑异构酶1抑制剂的连接子-载荷 sesutecan 组成,该链接子-载荷已经在之前多个新药的临床研究中经过验证。体外试验显示,PRO1106 的靶标结合能力优于Sirtratumab;在膀胱癌和食管鳞癌细胞来源异种移植模型中,PRO1106 显示出强大的肿瘤生长抑制作用。在动物模型中,表现出比 Sirtratumab vedotin 更稳定的PK,循环中毒素释放极小,且未观察到明显毒性。总之,PRO1106是建立在经临床验证的连接子-载荷基础上、针对经临床验证的靶点的ADC,且在临床前药理学研究中显示出有希望的数据。由于皮肤中SLITRK6的表达几乎可以忽略不计,与当前膀胱癌标准 ADC 疗法(enfortumab vedotin)在患者中导致显著的皮肤相关毒副作用相比,PRO1106 可能为该类患者提供一种新的选择。另一款PRO1286,靶点为EGFR/MET,目前同靶点ADC药物共有9款,进展最快的是阿斯利康/BSP Pharmaceuticals 的 AZD9592,已进入临床1期,其余8款均为国内企业研发,且均处于临床前阶段。新型抗体药物研发是BioBAY当下的重点招商方向之一。近年来,BioBAY围绕生物医药产业,重点布局抗体偶联药物(ADC)、核酸药物、细胞与基因治疗(CGT)、IT+BT等产业细分赛道,BioBAY药企创新实力愈发受到国际市场的持续关注。1月2日,宜联生物宣布与罗氏达成全球合作和许可协议,双方将合作开发靶向间质表皮转化因子(c-MET)的下一代抗体偶联(ADC)药物候选产品YL211,用于治疗实体瘤。根据协议条款,交易金额超过10亿美元。4月3日,普方生物(ProfoundBio)与丹麦哥本哈根和美国纳斯达克两地上市企业Genmab A/S与达成18亿美元全现金收购协议。普方生物成为了中国第一家被收购的ADC公司,18亿美元的收购价格也刷新了中国Biotech被收购价格的纪录。目前,BioBAY已聚集620余家生物医药高科技创新企业、35000名高层次科技人才,形成了创新药研发、高端医疗器械、生物技术三大重点产业集群。下一步,BioBAY将持续强化企业创新主体地位,以更高水平推动创新链、产业链、资金链、人才链深度融合,不断提升政策体系、产业生态、创新活力,全力打造国际一流生物医药创新策源地、世界级生物医药产业地标核心区。▌文章来源:网络信息整理责编:何文正审核:任旭推荐阅读18亿美元!国内Biotech收购价新纪录花落BioBAY涉及创新药!AACR会议上BioBAY企业惊艳亮相国产ADC出海交易TOP10,BioBAY独占5席!

抗体药物偶联物临床3期AACR会议临床2期

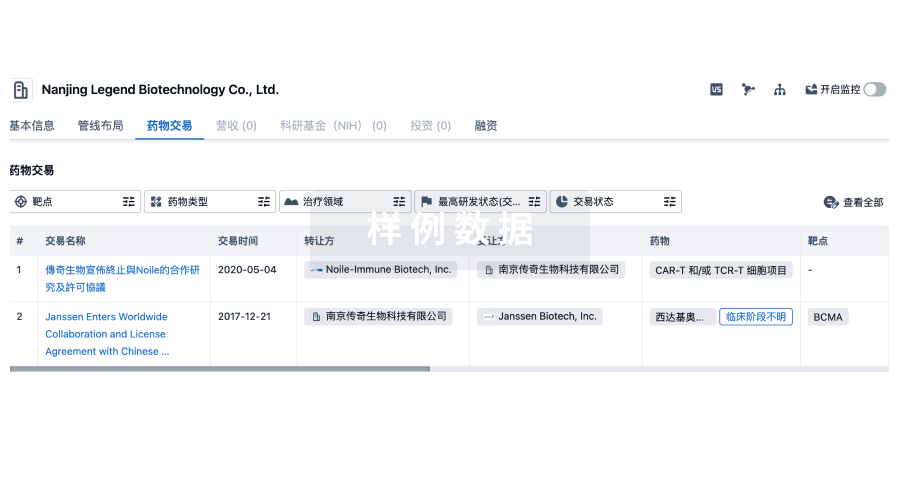

100 项与 BSP Pharmaceuticals SpA 相关的药物交易

登录后查看更多信息

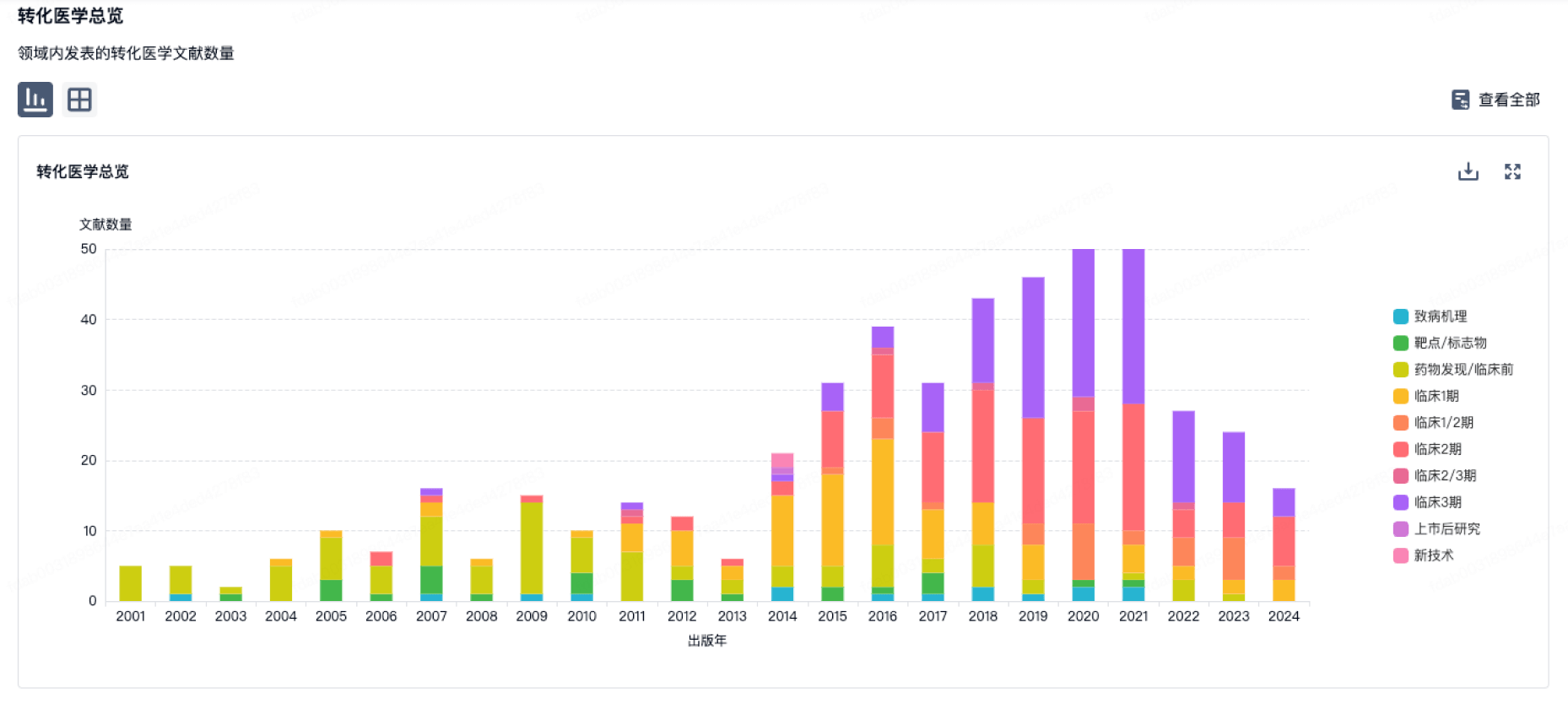

100 项与 BSP Pharmaceuticals SpA 相关的转化医学

登录后查看更多信息

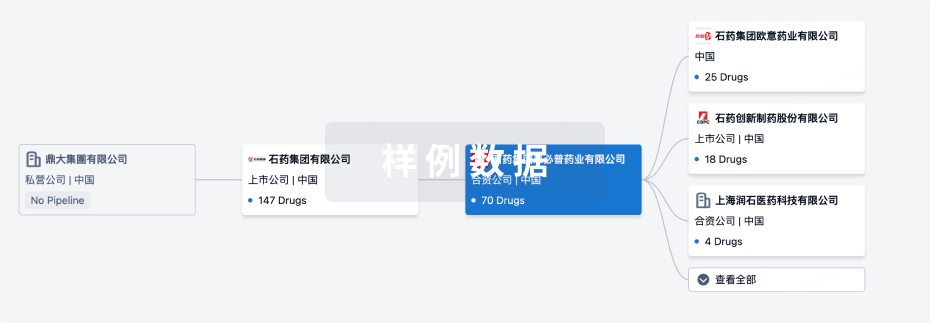

组织架构

使用我们的机构树数据加速您的研究。

登录

或

管线布局

2025年07月12日管线快照

管线布局中药物为当前组织机构及其子机构作为药物机构进行统计,早期临床1期并入临床1期,临床1/2期并入临床2期,临床2/3期并入临床3期

临床1期

1

6

临床2期

临床3期

3

4

申请上市

其他

6

登录后查看更多信息

当前项目

| 药物(靶点) | 适应症 | 全球最高研发状态 |

|---|---|---|

米吉珠单抗 ( IL-23p19 ) | 活动性重度溃疡性结肠炎 更多 | 申请上市 |

戈沙妥组单抗 ( Top I x Trop-2 ) | 三阴性乳腺癌 更多 | 临床3期 |

索米妥昔单抗 ( FOLR1 x Tubulin ) | 原发性腹膜癌 更多 | 临床3期 |

Telisotuzumab vedotin ( Tubulin x c-Met ) | 非鳞状非小细胞肺癌 更多 | 临床3期 |

维泊妥珠单抗 ( CD79B x Tubulin ) | 弥漫性大B细胞淋巴瘤 更多 | 临床3期 |

登录后查看更多信息

药物交易

使用我们的药物交易数据加速您的研究。

登录

或

转化医学

使用我们的转化医学数据加速您的研究。

登录

或

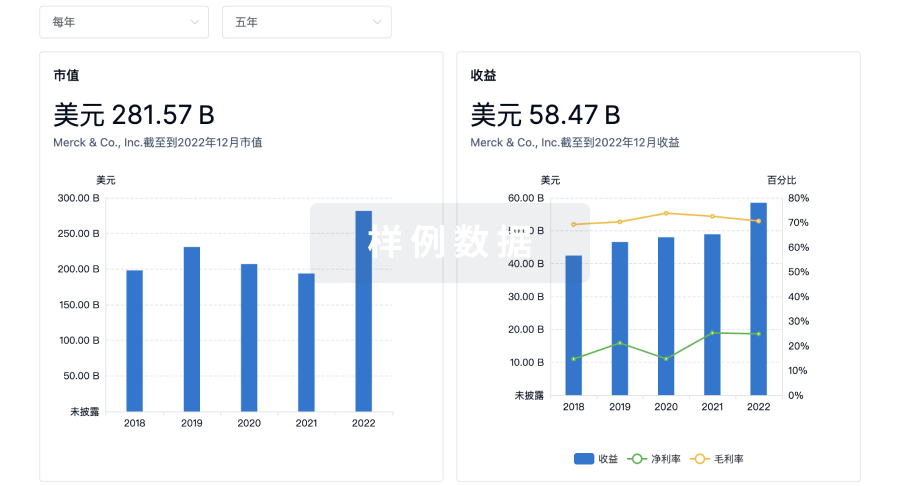

营收

使用 Synapse 探索超过 36 万个组织的财务状况。

登录

或

科研基金(NIH)

访问超过 200 万项资助和基金信息,以提升您的研究之旅。

登录

或

投资

深入了解从初创企业到成熟企业的最新公司投资动态。

登录

或

融资

发掘融资趋势以验证和推进您的投资机会。

登录

或

Eureka LS:

全新生物医药AI Agent 覆盖科研全链路,让突破性发现快人一步

立即开始免费试用!

智慧芽新药情报库是智慧芽专为生命科学人士构建的基于AI的创新药情报平台,助您全方位提升您的研发与决策效率。

立即开始数据试用!

智慧芽新药库数据也通过智慧芽数据服务平台,以API或者数据包形式对外开放,助您更加充分利用智慧芽新药情报信息。

生物序列数据库

生物药研发创新

免费使用

化学结构数据库

小分子化药研发创新

免费使用