预约演示

更新于:2025-09-09

Tsinghua University

更新于:2025-09-09

概览

标签

肿瘤

血液及淋巴系统疾病

免疫系统疾病

小分子化药

蛋白水解靶向嵌合体(PROTAC)

重组蛋白

疾病领域得分

一眼洞穿机构专注的疾病领域

暂无数据

技术平台

公司药物应用最多的技术

暂无数据

靶点

公司最常开发的靶点

暂无数据

| 排名前五的药物类型 | 数量 |

|---|---|

| 蛋白水解靶向嵌合体(PROTAC) | 39 |

| 小分子化药 | 27 |

| 治疗性疫苗 | 3 |

| 纳米抗体 | 2 |

| 重组蛋白 | 2 |

关联

85

项与 清华大学 相关的药物作用机制 病毒蛋白抑制剂 [+2] |

在研机构 |

原研机构 |

在研适应症 |

非在研适应症- |

最高研发阶段临床1期 |

首次获批国家/地区- |

首次获批日期- |

102

项与 清华大学 相关的临床试验ChiCTR2500107745

Investigating the Impact of Task Adjustment Strategies on Emotion and Training Performance Differences in Human-Computer Interaction

开始日期2025-08-18 |

申办/合作机构  清华大学 清华大学 [+2] |

NCT07163819

Effect of Probiotic Intervention on Travel-Related Health Conditions During Short-Term Overseas Travel

International travel disrupts gut health through dietary changes, microbial exposure, and stress, often causing gastrointestinal symptoms like traveler's diarrhea and sleep disturbances. These shifts may increase antibiotic resistance risks. Probiotics may help stabilize gut microbiota and improve well-being during travel. This randomized, double-blind, placebo-controlled trial investigated whether probiotic supplementation mitigates gut microbiota perturbations, gastrointestinal symptoms, and sleep issues in adults traveling abroad. We also assessed changes in anxiety, well-being, gut immunity, microbial function, and antibiotic resistance genes.

开始日期2025-07-31 |

申办/合作机构 |

NCT07076225

A Ultrashort Regimen for Drug-susceptible Pulmonary Tuberculosis in Elderly Patients: A Multicenter Randomized Controlled Trial

Tuberculosis (TB) remains one of the leading global public health concerns and is among the top ten causes of death from a single infectious agent. China ranks third worldwide in total TB burden, with a substantial proportion of cases classified as drug-susceptible TB (DS-TB). Despite the availability of effective standard treatment regimens, the current 6-month therapy duration poses challenges in terms of patient adherence, resource allocation, and overall treatment success.

In recent years, ultrashort-course regimens for DS-TB have been proposed and evaluated in clinical studies, showing promising results in improving adherence, reducing treatment duration, and maintaining or even enhancing treatment efficacy. However, these regimens have primarily been studied in younger populations, with limited data available for elderly patients. Older adults often present with age-related physiological changes, multiple comorbidities, and an increased risk of adverse drug reactions, which may affect both the efficacy and safety of treatment.

Therefore, this study aims to assess the therapeutic effectiveness and safety profile of a novel ultrashort-course regimen for drug-susceptible pulmonary TB specifically in patients aged 65 years and older.

In recent years, ultrashort-course regimens for DS-TB have been proposed and evaluated in clinical studies, showing promising results in improving adherence, reducing treatment duration, and maintaining or even enhancing treatment efficacy. However, these regimens have primarily been studied in younger populations, with limited data available for elderly patients. Older adults often present with age-related physiological changes, multiple comorbidities, and an increased risk of adverse drug reactions, which may affect both the efficacy and safety of treatment.

Therefore, this study aims to assess the therapeutic effectiveness and safety profile of a novel ultrashort-course regimen for drug-susceptible pulmonary TB specifically in patients aged 65 years and older.

开始日期2025-07-25 |

申办/合作机构  复旦大学 复旦大学 [+4] |

100 项与 清华大学 相关的临床结果

登录后查看更多信息

0 项与 清华大学 相关的专利(医药)

登录后查看更多信息

96,846

项与 清华大学 相关的文献(医药)2026-12-01·Nano-Micro Letters

Tackling Challenges and Exploring Opportunities in Cathode Binder Innovation

Review

作者: Wang, Yude ; Bhayo, Adnan Murad ; Lai, Tingrun ; He, Xiangming ; Wang, Li ; Liu, Zhibei

Abstract:

Long-life energy storage batteries are integral to energy storage systems and electric vehicles, with lithium-ion batteries (LIBs) currently being the preferred option for extended usage-life energy storage. To further extend the life span of LIBs, it is essential to intensify investments in battery design, manufacturing processes, and the advancement of ancillary materials. The pursuit of long durability introduces new challenges for battery energy density. The advent of electrode material offers effective support in enhancing the battery's long-duration performance. Often underestimated as part of the cathode composition, the binder plays a pivotal role in the longevity and electrochemical performance of the electrode. Maintaining the mechanical integrity of the electrode through judicious binder design is a fundamental requirement for achieving consistent long-life cycles and high energy density. This paper primarily concentrates on the commonly employed cathode systems in lithium-ion batteries, elucidates the significance of binders for both, discusses the application status, strengths, and weaknesses of novel binders, and ultimately puts forth corresponding optimization strategies. It underscores the critical function of binders in enhancing battery performance and advancing the sustainable development of lithium-ion batteries, aiming to offer fresh insights and perspectives for the design of high-performance LIBs.

2026-03-01·BIOMATERIALS

Porous microscaffold enables spontaneous hematopoietic cell differentiation and continuous macrophage production from hPSCs for therapy

Article

作者: Li, Wenjing ; Ding, Shuangyuan ; Liu, Jintao ; Liang, Yong ; Zhu, Yonglin ; Zhang, Jing-Ren ; Du, Yanan ; Li, Tianjie ; Fu, Yangxin ; Chen, Xia ; Zhang, Xingwu ; Qiu, Hui ; An, Haoran ; Zhou, Xinyao ; Qu, Kengyuan ; Li, Mengda ; Guo, Jianying ; Wang, Peiliang ; Zhang, Yaxuan ; Yan, Li ; Chen, Danyu ; Liu, Jinyang ; Na, Jie

Macrophages play critical roles in various physiological and pathological processes, yet their scalable production for therapeutic applications remains a challenge. Here, we present a porous microscaffold (PMS) that enables robust hematopoietic differentiation from human pluripotent stem cell (hPSC)-derived mesoderm. Within PMS, mesoderm cells self-organize into vascular structures reminiscent of the early aorta-gonad-mesonephros (AGM) niches, promoting efficient endothelial-to-hematopoietic transition with minimal cytokine supplementation. Additionally, endothelial-cell-modified PMS enriches paracrine signals and activates key genes involved in macrophage proliferation and self-renewal. Multi-omics analyses delineate the gene network driving enhanced macrophage expansion within this 3D microenvironment. Functionally, PMS-derived macrophages exhibit potent therapeutic potential by effectively alleviating drug-resistant Streptococcus pneumoniae infections in mice. These results establish PMS as a cost-effective and scalable platform for producing functional macrophages, paving the way for off-the-shelf cell-based therapies.

2026-03-01·BIOMATERIALS

Tumor-activated nanocomplex reprograms cancer and macrophage metabolism in opposite directions to overcome immune suppression

Article

作者: Song, Hao ; Yang, Yannan ; Zhang, Ming ; Shi, Yiru ; Wang, Runming ; Dai, Zan ; Yu, Chengzhong ; Wang, Qiaoyun ; Johannessen, Bernt ; Zhen, Xu

Immunotherapy efficacy is hindered by the immunosuppressive metabolism of cancer cells and tumor-associated macrophages (TAMs), yet their opposite metabolic programs complicate synchronized modulation of tumor microenvironment. Here, we report an acid-activated Fe-Zn nanocomplex (FZNC) that transforms into spiky FeOOH nanoparticles within the tumor microenvironment. This transformation enhances cellular uptake and enables selective scavenging of hydrogen sulfide (H2S)-a metabolite that promotes glycolysis in cancer cells and oxidative phosphorylation (OXPHOS) in TAMs. Local H2S depletion by FZNCs induces a bidirectional metabolic shift: cancer cells are redirected from glycolysis to OXPHOS, while TAMs switch from OXPHOS to glycolysis. This dual reprogramming enhances tumor immunogenicity with increased dendritic cell maturation and M1 polarization in vitro, and enhanced cytotoxic T-cell infiltration in vivo. FZNCs treatment suppresses tumor growth and metastasis, with synergistic effects when combined with PD-L1 blockade. This work introduces a materials-based strategy to spatially coordinate opposing metabolic programs for improved antitumor immunity.

1,674

项与 清华大学 相关的新闻(医药)2025-09-09

·同写意

9月9日,驯鹿生物与赛桥生物正式签署全球战略合作协议,共同推动国产先进细胞治疗药物产业链一体化出海。赛桥生物创始人、董事长兼首席执行官商院芳博士与驯鹿生物创始人、董事长兼首席执行官张金华共同出席签约仪式。

签约现场合影(前排左一驯鹿生物首席商务官张华,右一赛桥生物免疫细胞业务线总裁陈静,后排左四驯鹿生物创始人、董事长兼首席执行官张金华,右四赛桥生物创始人、董事长兼首席执行官商院芳博士,及双方管理团队代表)

秉持“让天下没有治不起的病”的发展愿景,赛桥生物聚焦细胞治疗领域“工艺即产品、工具即工艺”的行业特性,以及“交不出、用不起”的行业核心痛点,与行业客户深度协同。通过工艺-工具一体化技术创新,推动细胞制备从传统手工开放模式,逐步升级为单机自动封闭化、流程集成化、床旁智能化的全新生产范式,实现自体细胞药物生产成本降低5-10倍、异体细胞药物生产成本降低数十倍的突破。核心产品及解决方案已覆盖全球10余个国家、超100条细胞治疗管线,累计装机量近1000台,成功支撑中国首款MSC上市药物及多款CAR-T上市药物的研发与生产,成为全球前三覆盖早研、临床至商业化全阶段且具备完全自主知识产权的细胞治疗工具平台。

本次驯鹿生物与赛桥生物达成战略合作,标志着双方正式启动“驯鹿生物细胞生产工艺+赛桥生物智能制造”的全球协同模式,加速国产细胞治疗产业链一体化的输出,满足国际市场对先进治疗技术的需求。合作将从技术协同与市场拓展两个维度深入推进:在技术层面,双方将共同建立工艺开发机制,结合驯鹿生物在CAR-T药物研发方面的深厚经验与赛桥生物在高端装备适配领域的核心能力,协同提升细胞治疗产品的生产可行性;在市场层面,将整合彼此的国际渠道资源,推动整体解决方案在海外市场的落地与应用。此次合作不仅是两家企业之间的资源互补,更为中国细胞治疗产业链上下游协同出海提供了重要实践范例,有望进一步增强中国先进治疗技术在全球市场的影响力。

关于赛桥生物

赛桥生物成立于2020年3月,由清华大学精密仪器系博士、德国国家工程院院士张友明教授联合创办,核心团队曾负责国家生物仪器重大专项,拥有10+年仪器工程与生物相关技术积累,是国内最早深耕细胞处理与自动化装备的专业团队。

秉持“让天下没有治不起的病”的发展愿景,赛桥生物聚焦细胞治疗领域“工艺即产品、工具即工艺”的行业特性,以及“交不出、用不起”的行业核心痛点,与行业客户深度协同。通过工艺-工具一体化技术创新,推动细胞制备从传统手工开放模式,逐步升级为单机自动封闭化、流程集成化、床旁智能化的全新生产范式,实现自体细胞药物生产成本降低5-10倍、异体细胞药物生产成本降低数十倍的突破。核心产品及解决方案已覆盖全球10余个国家、超100条细胞治疗管线,累计装机量近1000台,成功支撑中国首款MSC上市药物及多款CAR-T上市药物的研发与生产,成为全球前三覆盖早研、临床至商业化全阶段且具备完全自主知识产权的细胞治疗工具平台。

关于驯鹿生物

驯鹿生物成立于2017年,是一家行业领先的专注于研发、生产和销售创新细胞疗法的生物制药公司。公司以开发血液肿瘤细胞类药物为创新基石,并向自身免疫性疾病领域和抗体类药物拓展,拥有完整的从早期药物发现、临床研发、注册申报到商业化的全流程能力。公司现有10余款处于不同研发阶段的创新药物品种,其中由驯鹿生物自主研发的全球首个全人源CAR-T产品,靶向BCMA的伊基奥仑赛注射液(福可苏®)已于2023年6月获中国国家药品监督管理局(NMPA)批准上市,用于治疗既往经过至少3线治疗后进展(至少使用过一种蛋白酶体抑制剂及免疫调节剂)的复发或难治性多发性骨髓瘤(R/R MM)成人患者。其前线适应症用于治疗2-3线多发性骨髓瘤(MM)已进入III期临床。此外,伊基奥仑赛注射液在中国和美国已获得多个自身免疫性疾病的新药临床试验申请(IND)许可。

同时,针对淋巴瘤的双靶点(CD19/CD22)产品CT120即将进入II期临床。另一款靶向GPRC5D用于治疗复发难治多发性骨髓瘤的产品IASO118已在中国获得IND许可。除细胞疗法产品外,公司的全人源靶向CD19抗体产品IASO-782,已在中国和美国获得治疗多个自身免疫性疾病的IND许可,同时仍在探索更多的自身免疫性疾病适应症。公司先后和海外细胞治疗公司Sana Therapeutics、Cabaletta Bio及Umoja Biopharma达成全球商业拓展授权或研发合作,积极探索新一代细胞疗法产品的开发。驯鹿生物依托其强大的管理团队、创新的产品管线、自有的GMP生产和先进的临床开发能力,全力以赴为中国及全球患者带来变革性、可及的创新疗法和治愈的希望。

关于同写意

同写意论坛是中国新药研发行业权威的多元化交流平台,二十一年来共举办会议论坛百余期。“同写意新药英才俱乐部”基于同写意论坛而成立,早已成为众多新药英才的精神家园和中国新药思想的重要发源地之一。同写意在北京、苏州、深圳、成都设立多个管理中心负责同写意活动的运营。

尊享多重企业/机构会员特权

● 分享庞大新药生态圈资源库;

● 同写意活动优享折扣;

● 会员专属坐席及专家交流机会;

● 同写意活动优先赞助权;

● 机构品牌活动策划与全方位推广;

● 秘书处一对一贴心服务。

入会请联系同写意秘书处

同写意创新链盟机构

(上下滑动查看更多)

瀚枢生物 | 深势科技 | 新天地药业 | 快舒尔医疗 | 华赛伯曼 | 艾里奥斯 | 药明合联 | 皓元医药 | 希格生科 | 纽瑞特医疗 | 夸克医药 | 石药集团 | 源生生物 | 君赛生物 | 达尔文生物 | 浩博工程 | 怀雅特 | 赛立维 | 科伦博泰 | 赛隽生物 | 安升达/金唯智 | 卡替医疗 | 达科为生物 | 沙利文 | 天广实 | 拜耳 | 楚天科技 | 三生制药 | 三启生物 | 国通新药 | 通瑞生物 | 科济药业丨立迪生物 | 森西赛智 | 汇芯生物 | 申科生物 | 方拓生物 | 东抗生物 | 科盛达 | 依利特 | 翊曼生物丨锐拓生物丨复百澳生物丨圆因生物丨普洛斯丨华润三九丨皓阳生物丨人福医药丨广生堂药业丨澳宗生物丨妙顺生物 | 荣捷生物丨行诚生物 | 宜联生物 | 生命资本 | 恒诺康丨斯丹姆 | 益诺思 | 深圳细胞谷丨佰诺达生物 | 沃臻生物 | 金仪盛世 | 朗信生物 | 亦笙科技 | 中健云康 | 九州通 | 劲帆医药 | 沙砾生物 | 裕策生物 | 同立海源 | 药明生基 | 奥浦迈 | 原启生物 | 百力司康 | 宁丹新药 | 上海细胞治疗集团 | 滨会生物 | FTA | 派真生物 | 希济生物 | 优睿赛思 | 血霁生物 | 优睿生物 | 邦耀生物 | 华大基因 | 银诺生物 | 百林科医药 | 纳微科技 | 可瑞生物 | 夏尔巴生物 | 金斯瑞蓬勃生物 | 健元医药 | 星眸生物 | 格兰科医药 | 莱羡科学仪器 | 明度智云 | 玮驰仪器 | 康源久远 | 易慕峰 | 茂行生物 | 济民可信 | 欣协生物 | 泰楚生物 | 泰澧生物 | 谱新生物 | 思鹏生物 | 领诺医药 | 宜明生物 | 爱科瑞思 | 阿思科力 | 博格隆生物 | 百吉生物 | 迈邦生物 | 多宁生物 | 万邦医药 | ASCT | 为度生物 | 比邻星创投 | 赛桥生物 | 吉美瑞生 | 荣泽生物 | 科金生物 | 汉超医药 | 康日百奥 | 汉腾生物 | 力品药业 | 安必生 | 博瑞策生物 | 中盛溯源 | 深研生物 | 东方略 | 赛赋医药 | 克睿基因 | 安润医药 | 镁伽科技 | 科锐迈德 | 和元生物 | 申基生物 |楷拓生物| 森松生命科技 | 凯理斯 | 尚德药缘 | 晟国医药 | 健新原力 | 纽福斯 | 华东医药 | 士泽生物 | 影研医疗科技 | 新格元生物 | 依生生物 | 腾迈医药 | 汉欣医药 | 恒驭生物 | 盛诺基 | 序祯达生物 | 乐纯生物 | 速石科技 | 耀海生物 | 新合生物 | 华龛生物 | 恺佧生物 | 成都凡微析 | 正帆科技 | 大橡科技 | 博雅辑因 | 因美纳 | 博雅控股集团 | 近岸蛋白 | 依科赛生物 | 利穗科技 | 东南科仪 | 倍谙基 | 辉诺医药 | 圣诺制药 | 埃格林医药 | 科镁信 | 爱思益普 | 复星医药 | 齐鲁制药 | 捷思英达丨荣昌生物丨泽璟制药丨奕安济世丨礼新医药丨维立志博丨派格生物丨赛生药业丨呈源生物丨启德医药丨双运生物丨宝船生物丨曙方医药丨澳斯康生物丨普莱医药丨维健医药丨海昶生物丨征祥医药丨智核生物丨望石智慧丨博生吉医药丨南京诺丹丨四星玻璃丨艾米能斯丨霁因生物丨普瑞康生物丨映恩生物丨康哲生物丨霍德生物丨海慈药业丨沃生生物丨睿健医药丨矩阵元丨斯微生物丨则正医药丨预立创投丨东立创新丨博安生物丨伟德杰生物丨星奕昂生物丨耀乘健康科技丨琅钰集团丨康德弘翼 | 原力生命科学丨上海科洲丨特瑞思丨药源丨健艾仕生物丨冠科美博丨微境生物丨天境生物丨合源生物丨泛生子丨创胜集团丨加科思药业丨丹诺医药丨凌科药业丨偶领生物丨凯斯艾生物丨成都圣诺丨松禾资本丨清普生物丨和其瑞丨开拓药业丨科兴制药丨玉森新药丨水木未来丨分享投资丨植德律所丨奥来恩丨乐明药业丨东曜药业丨君圣泰丨海创药业丨天汇资本丨再鼎医药丨济煜医药丨百英生物丨基石药业丨君实生物丨Sirnaomics,Inc.丨亦诺微丨博腾股份丨思路迪诊断丨艾博生物丨普瑞金生物丨未知君生物丨尚健生物丨阿诺医药丨有临医药丨赛业生物丨睿智医药丨博济医药丨晶泰科技丨药明康德丨创志科技丨奥星集团丨苏雅医药丨科贝源丨合全药业丨以岭药业丨科睿唯安丨DRG丨博瑞医药丨丽珠医药丨信立泰药业丨步长制药丨华素制药丨众生药业丨上海医药丨高博医疗集团丨药渡丨君联资本丨集萃药康丨诺思格丨精鼎医药丨百利药业丨Pfizer CentreOne丨默克中国创新中心丨奥来恩丨瑞博生物丨新通药物丨广东中润丨医普科诺丨诺唯赞丨康利华丨国信医药丨昆翎丨博纳西亚丨缔脉丨一品红丨和泽医药丨博志研新丨凯莱英医药丨汉佛莱丨英派药业丨京卫制药丨海思科药业丨宏韧医药丨开心生活科技丨哈三联丨Premier Research丨宣泰医药丨先声药业丨海金格丨普瑞盛医药丨Informa丨科特勒丨谋思医药丨HLT丨莱佛士丨辉瑞丨科林利康丨冠科生物丨科文斯丨卫信康丨龙沙(Lonza)丨美迪西丨阳光诺和丨润东医药丨勃林格殷格翰(中国)丨艾苏莱生物丨领晟医疗丨驯鹿医疗丨燃石医学丨中肽生化丨鸿运华宁丨泰格医药丨易迪希丨希麦迪丨百奥赛图丨迪纳利丨青云瑞晶丨鼎丰生科资本丨中源协和丨维亚生物丨青松医药丨中科谱研丨长风药业丨艾欣达伟丨鼎康生物丨中晟全肽丨海步医药丨勤浩医药丨奥萨医药丨太美医疗科技丨生特瑞丨东富龙丨Cytiva丨优辰实验室丨苏桥生物丨君达合创丨澎立生物丨南京澳健丨南京科默丨东阳光丨亚盛医药丨杰克森实验室丨上海科州丨三优生物丨三迭纪丨泰诺麦博丨Cell Signaling Technology丨PPC佳生丨澳斯康丨先为达丨智享生物丨锐得麦丨宜明昂科丨明济生物丨英百瑞丨六合宁远丨天津天诚丨百拓生物丨星药科技丨亓上生物丨真实生物丨引光医药丨方达医药丨高博医疗集团丨赞荣医药丨国投创新丨药明生物丨康哲药业丨高特佳投资丨普瑞基准丨臻格生物丨微谱医药丨和玉资本 | 倚锋资本

细胞疗法免疫疗法

2025-09-09

·驯鹿生物

9月9日,驯鹿生物与赛桥生物正式签署全球战略合作协议,共同推动国产先进细胞治疗药物产业链一体化出海。驯鹿生物创始人、董事长兼首席执行官张金华与赛桥生物创始人、董事长兼首席执行官商院芳博士共同出席签约仪式。

签约现场合影(前排左一驯鹿生物首席商务官张华,右一赛桥生物免疫细胞业务线总裁陈静,后排左四驯鹿生物创始人、董事长兼首席执行官张金华,右四赛桥生物创始人、董事长兼首席执行官商院芳博士,及双方管理团队代表)

作为细胞治疗领域的领军企业,驯鹿生物具备从早期药物发现、临床开发、CMC开发、注册申报到商业化的全流程能力。为使全球更多患者早日获益,驯鹿生物正以创新和多元的方式,积极与国际不同领域的伙伴探索多样合作模式,致力于以最符合各地政策与市场条件的形式输出先进治疗方法。除加快在多个国家和地区的药品注册与市场准入进程外,推动细胞治疗产业链中不同原料、工艺、技术和服务“组团出海”,也成为一种新的合作路径。

本次与赛桥生物达成战略合作,标志着双方正式启动“驯鹿生物细胞生产工艺+赛桥生物智能制造”的全球协同模式,加速国产细胞治疗产业链一体化的输出,以满足国际市场对先进治疗技术的需求。合作将从技术协同与市场拓展两个维度深入推进:在技术层面,双方将共同建立工艺开发机制,结合驯鹿生物在CAR-T药物研发方面的深厚经验与赛桥生物在高端装备适配领域的核心能力,协同提升细胞治疗产品的生产可行性;在市场层面,将整合彼此的国际渠道资源,推动整体解决方案在海外市场的落地与应用。此次合作不仅是两家企业之间的资源互补,更为中国细胞治疗产业链上下游协同出海提供了重要实践范例,有望进一步增强中国先进治疗技术在全球市场的影响力。

关于驯鹿生物

驯鹿生物成立于2017年,是一家行业领先的专注于研发、生产和销售创新细胞疗法的生物制药公司。公司以开发血液肿瘤细胞类药物为创新基石,并向自身免疫性疾病领域和抗体类药物拓展,拥有完整的从早期药物发现、临床研发、注册申报到商业化的全流程能力。公司现有10余款处于不同研发阶段的创新药物品种,其中由驯鹿生物自主研发的全球首个全人源CAR-T产品,靶向BCMA的伊基奥仑赛注射液(福可苏®)已于2023年6月获中国国家药品监督管理局(NMPA)批准上市,用于治疗既往经过至少3线治疗后进展(至少使用过一种蛋白酶体抑制剂及免疫调节剂)的复发或难治性多发性骨髓瘤(R/R MM)成人患者。其前线适应症用于治疗2-3线多发性骨髓瘤(MM)已进入III期临床。此外,伊基奥仑赛注射液在中国和美国已获得多个自身免疾性疾病的新药临床试验申请(IND)许可。

同时,针对淋巴瘤的双靶点(CD19/CD22)产品CT120即将进入II期临床。另一款靶向GPRC5D用于治疗复发难治多发性骨髓瘤的产品IASO118已在中国获得IND许可。除细胞疗法产品外,公司的全人源靶向CD19抗体产品IASO-782,已在中国和美国获得治疗多个自身免疫性疾病的IND许可,同时仍在探索更多的自身免疫性疾病适应症。公司先后和海外细胞治疗公司Sana Therapeutics、Cabaletta Bio及Umoja Biopharma达成全球商业拓展授权或研发合作,积极探索新一代细胞疗法产品的开发。驯鹿生物依托其强大的管理团队、创新的产品管线、自有的GMP生产和先进的临床开发能力,全力以赴为中国及全球患者带来变革性、可及的创新疗法和治愈的希望。

关于赛桥生物

赛桥生物成立于2020年3月,由清华大学精密仪器系博士、德国国家工程院院士张友明教授联合创办,核心团队曾负责国家生物仪器重大专项,拥有10+年仪器工程与生物相关技术积累,是国内最早深耕细胞处理与自动化装备的专业团队。

秉持“让天下没有治不起的病”的发展愿景,赛桥生物聚焦细胞治疗领域“工艺即产品、工具即工艺”的行业特性,以及“交不出、用不起”的行业核心痛点,与行业客户深度协同。通过工艺-工具一体化技术创新,推动细胞制备从传统手工开放模式,逐步升级为单机自动封闭化、流程集成化、床旁智能化的全新生产范式,实现自体细胞药物生产成本降低5-10倍、异体细胞药物生产成本降低数十倍的突破。核心产品及解决方案已覆盖全球10余个国家、超100条细胞治疗管线,累计装机量近1000台,成功支撑中国首款MSC干细胞上市药物及多款CAR-T上市药物的研发与生产,成为全球前三覆盖早研、临床至商业化全阶段且具备完全自主知识产权的细胞治疗工具平台。

细胞疗法上市批准免疫疗法引进/卖出ASH会议

2025-09-09

·智药邦

2025年9月3日,AI蛋白质设计公司途深智合完成千万级人民币天使+轮融资,由上海天使会联合投资,老股东诚美资本连投。本轮融资将进一步加速公司前沿技术的产业转化速度。

途深智合致力于通过AI超智能加速科学领域产品研发,应用于高价值蛋白等周边产品的设计与产业化。公司打造了多模态大模型+垂直模型+干湿实验全流程的一体化平台,大幅度缩短新品设计的周期和效率。

核心团队:汇聚顶尖的AI×生物人才,核心团队来自上海交通大学、约翰霍普金斯大学、清华大学、剑桥大学等国内外知名高校和研究机构,团队具备丰富的人工智能科研与产业化经验。

项目背景及意义

全球AI+新药研发市场规模持续增长,预计2034年将达到164.9亿美元。截至2024年,新药平均研发成本高达24亿美元,其中临床前平均研发成本为11亿美元。传统药物研发面临成本高昂、周期漫长、成功率低等痛点。

途深智合洞察到AI超级智能体在药物研发领域的巨大潜力。通过AI驱动的药物研发,临床前研发成本有望大幅降低。同时,通过靶点预测和药物分子预测,新药通过PCC失败率可降低70%以上,临床成功率将大幅提升。

途深智合的解决方案

构建聚焦生物医药的科学智能体平台,实现抗体设计智能化、自动化。其拥有独特优势:包含ProteinNova蛋白设计AI科学家、蛋白表达测试两大智能体平台。基于国产芯片超智能技术,自研多款蛋白设计闭源模型,深度优化多款垂直开源SOTA模型。通过AscendC算子优化和软硬协同保证优秀的推理速度。

在下游产业化应用中,途深智合在兔单克隆抗体亲和力改造的成果已超越欧洲头部医药公司的商用抗体;在酶改造方面,氧化还原酶活性AI首轮设计即提高380%,核酸酶的活性提高 800%。

途深智合创始人、上海交大副教授王宇光:“2024年的诺贝尔化学奖授予了蛋白质AI设计领域的相关团队,这一成就充分展示了AI技术在蛋白质工程和生物制药中的巨大潜力。作为AI For Science领域的创新者,途深智合自主研发的AI超智能平台,正是应对这一技术革新的成果。

通过该平台,我们能够利用对话式AI模型,在短时间内以纯干实验方式生成大量具有巨大潜力的蛋白质序列,显著提升蛋白质的活性、稳定性和产量。

实现Vibe Protein Coding

我们的技术已经在食品、医美和医药等多个领域广泛应用,助力新产品的设计与开发。展望未来,我们将持续推动人工智能驱动的蛋白质工程与生物制药领域的创新发展。”

途深智合部分产品Pipeline

诚美资本创始合伙人王飞雪:“作为天使投资人,最重要的就是相信途深智合,同时整合市场里他们所需要的客户、平台和生态资源,不会干预企业自身发展。”

此次融资标志着市场对途深智合技术实力与发展潜力的高度认可。未来,途深智合将融资资金进一步投入AI蛋白质平台的研发,持续加速产品创新、扩展客户服务范围、助力产业升级。

本文转自【途深智合】公众号

--------- End ---------

感兴趣的读者,可以添加小邦微信加入读者实名讨论微信群。添加时请主动注明姓名-企业-职位/岗位或姓名-学校-职务/研究方向。

引进/卖出

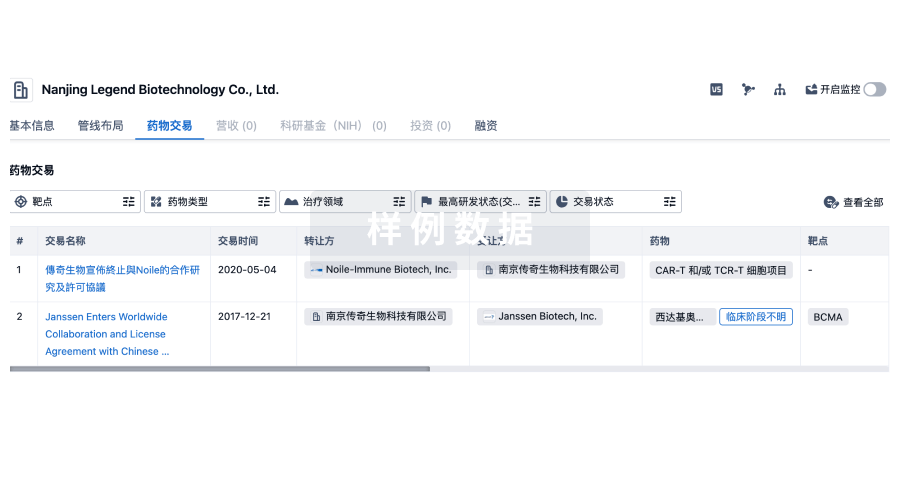

100 项与 清华大学 相关的药物交易

登录后查看更多信息

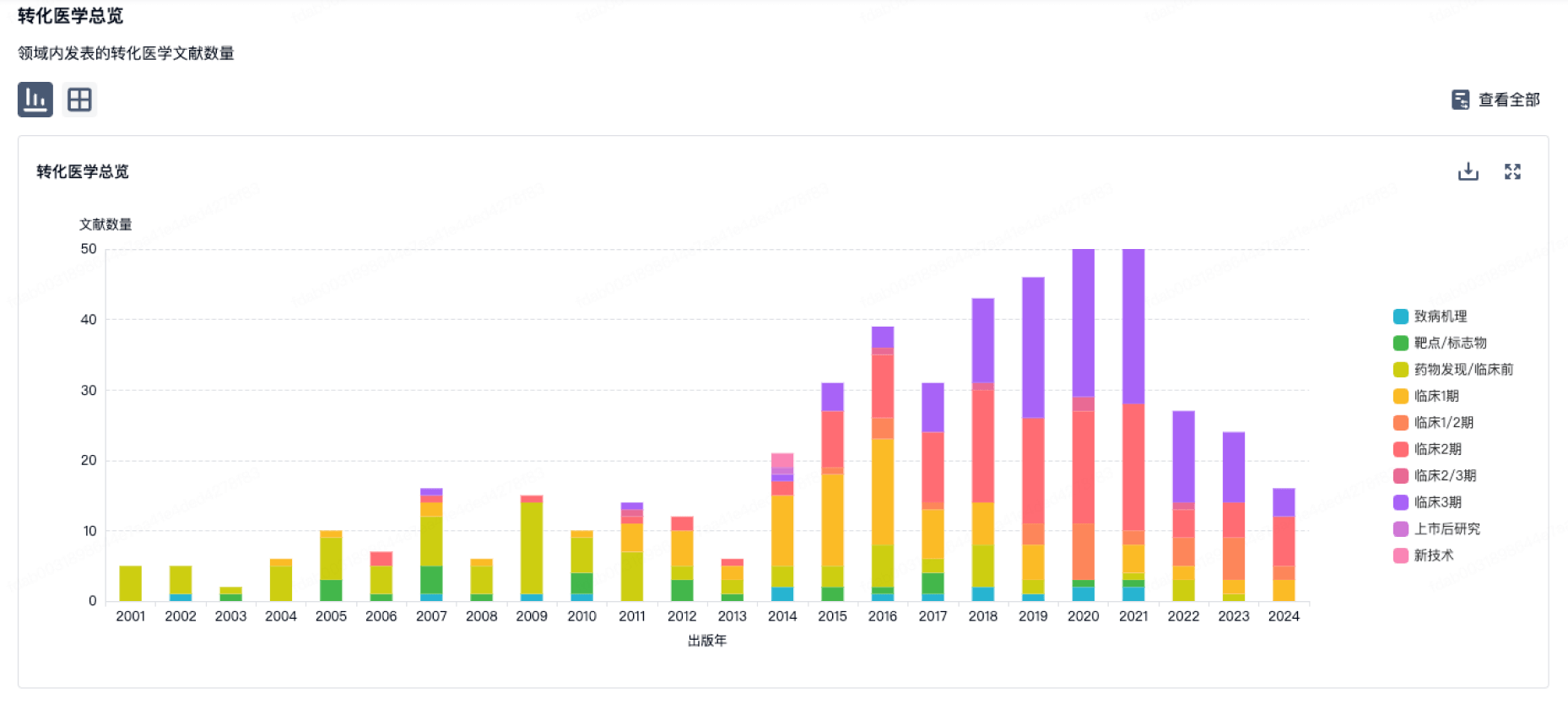

100 项与 清华大学 相关的转化医学

登录后查看更多信息

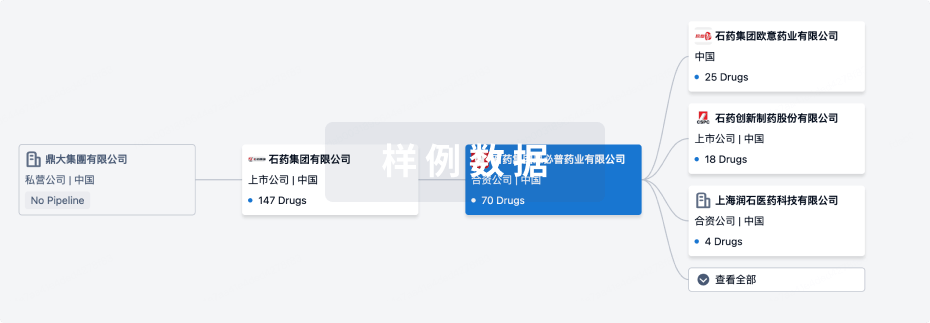

组织架构

使用我们的机构树数据加速您的研究。

登录

或

管线布局

2025年11月13日管线快照

管线布局中药物为当前组织机构及其子机构作为药物机构进行统计,早期临床1期并入临床1期,临床1/2期并入临床2期,临床2/3期并入临床3期

药物发现

18

64

临床前

临床申请批准

1

2

临床1期

临床3期

1

110

其他

登录后查看更多信息

当前项目

| 药物(靶点) | 适应症 | 全球最高研发状态 |

|---|---|---|

Insulin enteric-coated(Tsinghua University) | 1型糖尿病 更多 | 临床3期 |

聚乙二醇重组人血管内皮抑制素 (清华大学) ( VEGFR ) | 非鳞状非小细胞肺癌 更多 | 临床1期 |

HL-21 ( SARS-CoV-2 PLpro ) | 新型冠状病毒感染 更多 | 临床申请批准 |

NOD1 antagonists(Tsinghua University) ( NOD1 ) | 幽门螺杆菌感染 更多 | 临床前 |

RS-47 ( RELB ) | 结直肠癌 更多 | 临床前 |

登录后查看更多信息

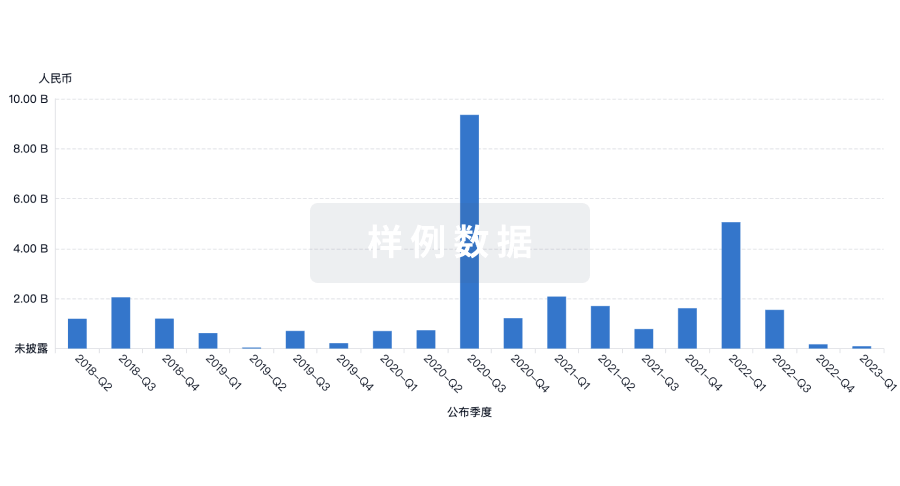

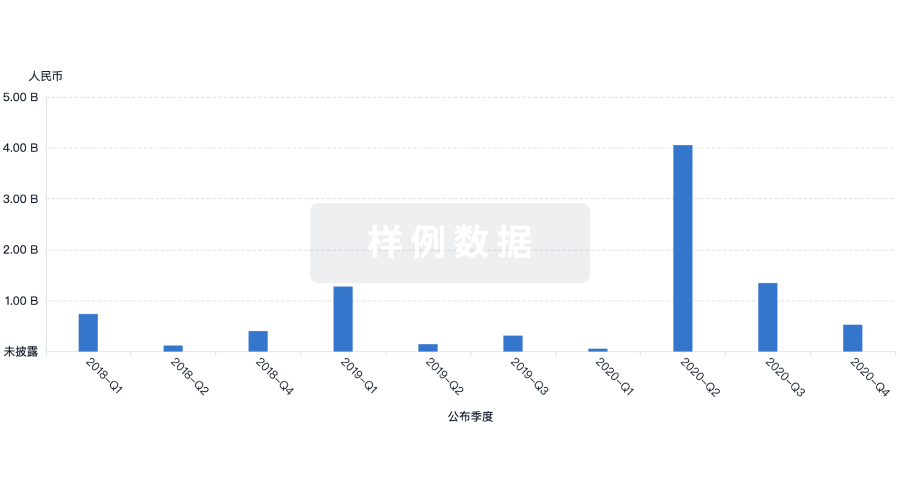

药物交易

使用我们的药物交易数据加速您的研究。

登录

或

转化医学

使用我们的转化医学数据加速您的研究。

登录

或

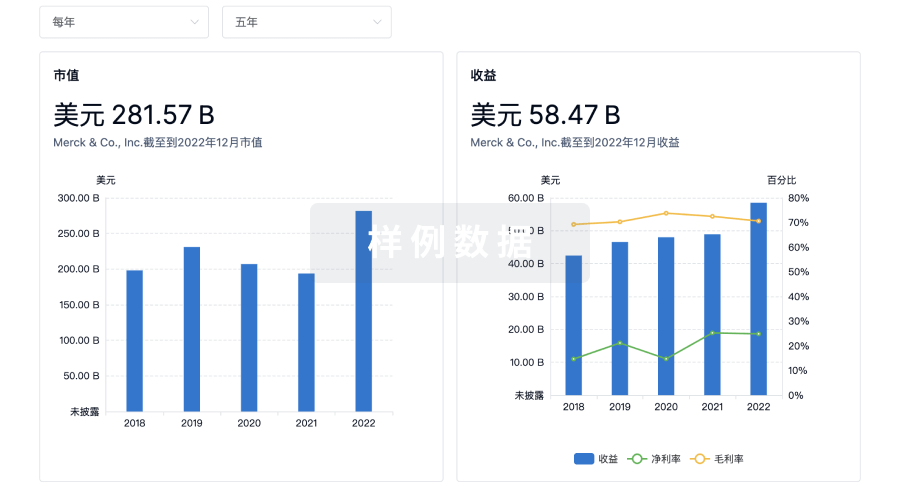

营收

使用 Synapse 探索超过 36 万个组织的财务状况。

登录

或

科研基金(NIH)

访问超过 200 万项资助和基金信息,以提升您的研究之旅。

登录

或

投资

深入了解从初创企业到成熟企业的最新公司投资动态。

登录

或

融资

发掘融资趋势以验证和推进您的投资机会。

登录

或

生物医药百科问答

全新生物医药AI Agent 覆盖科研全链路,让突破性发现快人一步

立即开始免费试用!

智慧芽新药情报库是智慧芽专为生命科学人士构建的基于AI的创新药情报平台,助您全方位提升您的研发与决策效率。

立即开始数据试用!

智慧芽新药库数据也通过智慧芽数据服务平台,以API或者数据包形式对外开放,助您更加充分利用智慧芽新药情报信息。

生物序列数据库

生物药研发创新

免费使用

化学结构数据库

小分子化药研发创新

免费使用