预约演示

更新于:2025-07-15

Arginine Hydrochloride

盐酸L-精氨酸

更新于:2025-07-15

概要

基本信息

权益机构- |

最高研发阶段批准上市 |

首次获批日期 美国 (1973-02-28), |

最高研发阶段(中国)批准上市 |

特殊审评- |

登录后查看时间轴

结构/序列

分子式C6H15ClN4O2 |

InChIKeyKWTQSFXGGICVPE-WCCKRBBISA-N |

CAS号1119-34-2 |

关联

101

项与 盐酸L-精氨酸 相关的临床试验ChiCTR2500099259

Analysis of factors affecting elderly patients with diabetes mellitus combined with sarcopenia and intervention study of arginine combined with fish oil

开始日期2025-05-01 |

申办/合作机构- |

NCT06328686

Arginine With Whole Brain Radiation Therapy for the Treatment of Brain Metastases

This early phase I trial evaluates different administration techniques (oral or intravenous) for arginine and tests the safety of giving arginine with whole brain radiation therapy in patients who have cancer that has spread from where it first started (primary site) to the brain (brain metastases). Arginine is an essential amino acid. Amino acids are the molecules that join together to form proteins in the body. Arginine supplementation has been shown to improve how brain metastases respond to radiation therapy. The optimal dosing of arginine for this purpose has not been determined. This study measures the level of arginine in the blood with oral and intravenous dosing at specific time intervals before and after drug administration to determine the best dosing strategy.

开始日期2024-09-05 |

申办/合作机构  Emory University Emory University [+1] |

ACTRN12612000036819

A randomised-controlled trial of oral arginine supplementation on the healing of foot ulcers in patients with type 2 diabetes

开始日期2024-08-24 |

申办/合作机构 |

100 项与 盐酸L-精氨酸 相关的临床结果

登录后查看更多信息

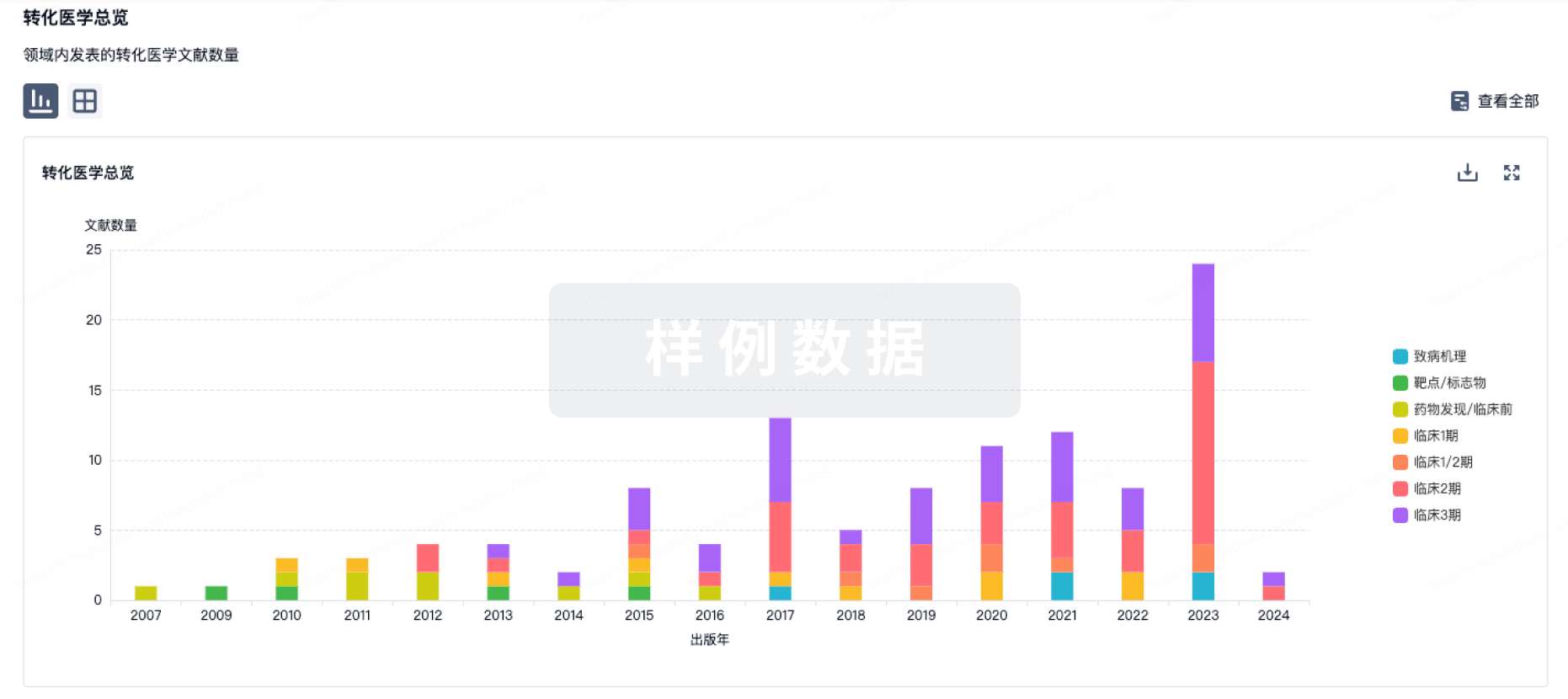

100 项与 盐酸L-精氨酸 相关的转化医学

登录后查看更多信息

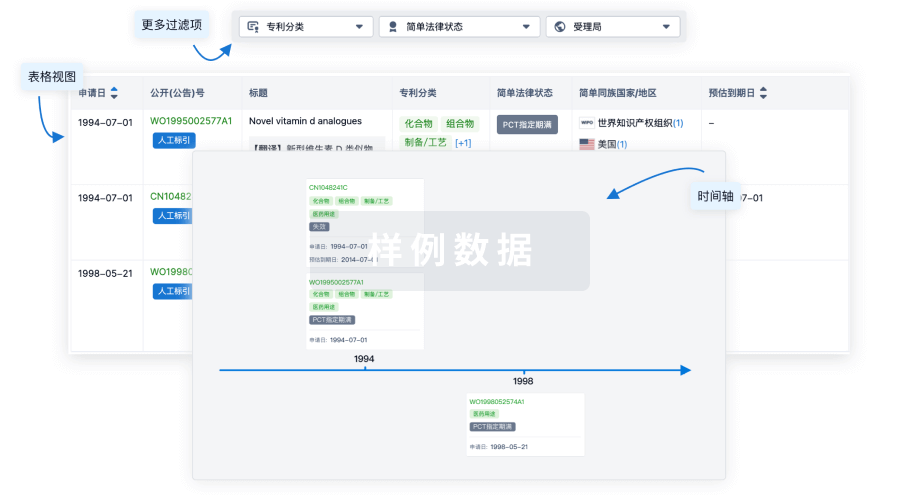

100 项与 盐酸L-精氨酸 相关的专利(医药)

登录后查看更多信息

114,256

项与 盐酸L-精氨酸 相关的文献(医药)2025-12-31·JOURNAL OF DERMATOLOGICAL TREATMENT

Effect of amniotic fluid on hair follicle growth

Article

作者: Aygun, Elif Ganime ; Yurtsever, Bulut ; Ovali, Ercument ; Cakirsoy, Didem ; Tumentemur, Gamze

Purpose: Human amniotic fluid stem cells (hAFSCs) have shown significant regenerative potential in treating hair loss, wound healing, and tissue repair. This study aims to evaluate the effects of human amniotic fluid (hAF) on hair follicle (HF) regeneration and immune system modulation.Materials and Methods: The hAF used was pooled, acellular, and gamma-irradiated to standardize its contents and enhance its stability. Both irradiated (FAFI) and non-irradiated (FAF) hAF were assessed for their efficacy and safety in promoting hair growth and modulating immune responses in a rat model of hair loss. The study examined HF regeneration, transition to the anagen phase, and macrophage polarization from the pro-inflammatory M1 phenotype to the anti-inflammatory M2 phenotype.Results: Both FAF and FAFI treatments significantly increased HF density, with FAFI exhibiting enhanced effects. Histological analysis demonstrated improved HF regeneration, increased M2 macrophages, and reduced collagen fiber deposition in treated areas. Gamma irradiation likely improved the efficacy of FAFI by stabilizing active components and inhibiting protease activity.Conclusions: Irradiated hAF is a safe and effective therapeutic candidate for alopecia and HF growth disorders. These findings support further evaluation of hAF in clinical trials to validate its potential for hair regeneration therapies.

2025-12-31·Journal of the International Society of Sports Nutrition

Effects of different dietary supplements on athletic performance in soccer players: a systematic review and network meta-analysis

Review

作者: Zhu, Xiaolin ; Nasharuddin, Nurul Amelina ; Xiang, Changqing ; Tengku Kamalden, Tengku Fadilah ; Luo, Hua

BACKGROUND:

As dietary supplements play a crucial role in meeting the unique nutritional needs of soccer players, a growing body of studies are exploring the effects of dietary supplements on athletic performance in soccer players. The effectiveness of certain supplements, such as caffeine and creatine, remains debated due to inconsistent results across studies. Therefore, this systematic review and Bayesian network meta-analysis was conducted to tentatively identify the most effective dietary supplements for soccer players.

METHODS:

We searched PubMed, Web of Science, Cochrane, Embase, and SPORTDiscus from database establishment to 5 February 2024 to identify randomized controlled trials (RCTs) evaluating the effects of different dietary supplements on athletic performance in soccer players. The risk of bias was assessed using the revised Cochrane risk-of-bias tool for randomized trials. A Bayesian network meta-analysis was performed using the R software and Stata 18.0. A subgroup analysis was conducted based on the competitive level of the athletes.

RESULTS:

Eighty RCTs were included, with 1,425 soccer players randomly receiving 31 different dietary supplements or placebo. The network meta-analysis showed that compared with placebo, carbohydrate + protein (SMD: 2.2, very large), carbohydrate + electrolyte (SMD: 1.3, large), bovine colostrum (SMD: moderate) and caffeine (SMD: 0.29, small) were associated with a significant effect on increasing the distance covered. Kaempferia parviflora (SMD: 0.46, small) was associated with a significant effect on enhancing muscular strength. Beta-alanine (SMD: 0.83, moderate), melatonin (SMD: 0.75, moderate), caffeine (SMD: 0.37, small), and creatine (SMD: 0.33, small) were associated with a significant effect on enhancing jump height. Magnesium creatine chelate (SMD: -3.0, very large), melatonin (SMD: -1.9, large), creatine + sodium bicarbonate (SMD: -1.4, large), and arginine (SMD: -1.2, moderate) were associated with a significant effect on decreasing sprint time. Creatine + sodium bicarbonate (SMD: -2.3, very large) and caffeine (SMD: -0.38, small) were associated with a significant effect on improving agility. Sodium pyruvate (SMD: 0.50, small) was associated with a significant effect on increasing peak power. Magnesium creatine chelate (SMD: 1.3, large) and sodium pyruvate (SMD: 0.56, small) were associated with a significant effect on increasing mean power. Carbohydrate + electrolyte (SMD: -0.56, small) was associated with a significant effect on improving the rating of perceived exertion.

CONCLUSIONS:

This study suggests that a range of dietary supplements, including caffeine, creatine, creatine + sodium bicarbonate, magnesium creatine chelate, carbohydrate + electrolyte, carbohydrate + protein, arginine, beta-alanine, bovine colostrum, Kaempferia parviflora, melatonin, and sodium pyruvate, can improve athletic performance in soccer players. This review provides evidence-based guidance for soccer coaches and nutritionists on using dietary supplements to enhance specific performance measures.

2025-12-31·mAbs

Analysis of how antigen mutations disrupt antibody binding interactions toward enabling rapid and reliable antibody repurposing

Article

作者: Islam, Sumaiya ; Pantazes, Robert J. ; Chauhan, Varun M.

Antibody repurposing is the process of changing a known antibody so that it binds to a mutated antigen. One of the findings to emerge from the Coronavirus Disease 2019 (COVID-19) pandemic was that it was possible to repurpose neutralizing antibodies for Severe Acute Respiratory Syndrome, a related disease, to work for COVID-19. Thus, antibody repurposing is a possible pathway to prepare for and respond to future pandemics, as well as personalizing cancer therapies. For antibodies to be successfully repurposed, it is necessary to know both how antigen mutations disrupt their binding and how they should be mutated to recover binding, with this work describing an analysis to address the first of these topics. Every possible antigen point mutation in the interface of 246 antibody-protein complexes were analyzed using the Rosetta molecular mechanics force field. The results highlight a number of features of how antigen mutations affect antibody binding, including the effects of mutating critical hotspot residues versus other positions, how many mutations are necessary to be likely to disrupt binding, the prevalence of indirect effects of mutations on binding, and the relative importance of changing attractive versus repulsive energies. These data are expected to be useful in guiding future antibody repurposing experiments.

41

项与 盐酸L-精氨酸 相关的新闻(医药)2025-07-11

·抗体圈

摘要:蛋白质对于调节多种细胞功能至关重要,包括结构成分的合成。环境条件的变化会影响构象稳定性并导致聚集。蛋白质聚集涉及蛋白质的不同状态,如非天然、未折叠和天然状态,这使它们成为复杂的过程。正确理解蛋白质聚集途径,包括热力学上不利的滞后相、可溶性原纤维通过指数相触发聚合,以及由于饱和相导致的游离单体耗尽导致聚合过程趋于平稳。聚集的治疗性蛋白质可以在患者中诱导有害的免疫反应,在稳定的蛋白质结构和功能的帮助下,控制聚集对于更好的治疗性蛋白质稳定性和靶向性至关重要。蛋白质-蛋白质相互作用(PPI)对于蛋白质稳定性、聚集速率和溶解度很重要,同时已经开发了先进的计算和生物物理方法来更好地表征治疗性蛋白质聚集。因此,需要一种有效的策略来控制、监测和复制多肽链的蛋白质聚集倾向。深入了解蛋白质聚集机制、表征和对抗策略将解决蛋白质聚集问题。它还将降低产品成本、时间限制、稳定有效的产品可用性以及潜在的免疫原性。【NO.1】介绍:治疗性蛋白质聚集虽然生物治疗药物的进步彻底改变了医疗保健,但开发稳定有效的蛋白质制剂仍然是一项重大挑战。稳定性是生物治疗药物的一个关键属性,可确保产品在保质期内以及储存和管理期间保持其所需的特性。稳定的蛋白质制剂具有多种好处,包括延长保质期、增强疗效和提高患者安全性。实现稳定的蛋白质配方的主要挑战之一是蛋白质聚集。蛋白质聚集是指蛋白质自发结合成更大的非天然结构,导致形成与天然聚集体相比具有不同物理化学性质的聚集体。这种聚集会深刻影响生物制品的安全性、有效性和稳定性,使其成为生物制药行业的关键问题。治疗性蛋白质的三维结构和固有的热稳定性在维持其生物活性和预期的治疗效果方面起着关键作用。然而,温度变化会导致蛋白质错误折叠或去折叠,从而形成物理聚集体。当蛋白质聚集时,它们可能会暴露出不以天然形式存在的新表位或构象变化。免疫系统将这些改变的结构识别为外来结构,产生针对聚集体的抗体。抗体或抗药抗体(ADA)对治疗性蛋白质的影响可能会有所不同。在某些情况下,ADA可能会与治疗性蛋白质结合并中和其活性,从而降低其治疗目标疾病的疗效。这可能导致次优的治疗结果并降低患者的治疗益处。免疫系统可能会识别治疗性蛋白质-ADA复合物。免疫系统可以将治疗性蛋白质-ADA复合物识别为外来实体的复合物,从而将治疗性蛋白质从体内清除。蛋白质聚集和免疫原性之间的相互作用突出了在治疗制剂中了解和控制蛋白质聚集的重要性。还值得一提的是,蛋白质表现出多种自组装机制,产生复杂而特异性的复合物,在各种生物过程中起着关键作用。这些蛋白质复合物通常涉及分子间固体相互作用,需要微妙的条件来维持其天然状态和功能。了解聚集过程各个阶段的速率会显著影响不同聚集体的种群和大小分布,这对于阐明它们的行为和对生物制品的影响至关重要(图1)。蛋白质聚集体的性质可能因浓度、pH值和离子强度而异。可逆蛋白质聚集体在稀释或环境条件的轻微调整后很容易解离,从而能够在原始环境之外进行分离和表征。然而,当可逆聚集体在实际浓度范围内转化为不稳定、不可逆的衍生物时,就会出现重大挑战。这些不可逆的聚集体在稀释时抵抗解离,并可能随着pH值或离子强度的波动而进一步生长。导致不可逆聚集体的转变通常涉及组成单体的二级或三级结构的变化,这在配方开发过程中提出了复杂的挑战。图1:蛋白质聚集的后果总结。1.由于产品制备的复杂而关键的方法,会引起工艺和经济损失,而蛋白质聚集体会导致药物浪费。2.蛋白质聚集体也影响蛋白质的质量和效率,产量较低,反应性较低,毒性反应异常。3.它还涉及一些高维护的繁琐过程。在蛋白质聚集体中发现了功能丧失。4.蛋白质聚集体在神经和代谢疾病中起主要作用,例如阿尔茨海默病、帕金森病和糖尿病患者本综述论文旨在全面了解生物制品中蛋白质聚集机制、表征技术和有效的缓解策略。通过探索蛋白质聚集与生物治疗药物的安全性、有效性和稳定性之间的复杂相互作用,本综述旨在为研究人员、制剂科学家和开发人员提供有价值的见解,以提高治疗性蛋白质制剂的成功率,并最终造福全球患者。【NO.2】蛋白质聚集的机制蛋白质的聚集可导致可溶性和不溶性聚集体的形成,后者经常从溶液中沉淀出来。这些不溶性聚集体的形态受蛋白质及其周围环境的内在特性的影响,通常表现为无定形或纤维状结构。原纤维聚集体是高度有序的,其特征是广泛的富含β片的结构,并且通常与淀粉样蛋白形成有关。相比之下,无定形聚集体在结构上是无序的,缺乏明确的二级或三级组织。这两种形式都对蛋白质稳定性构成了重大挑战,并可能损害治疗效果。因此,清楚地了解它们的形成机制和形态特征对于合理化稳定制剂和优化生物制药开发过程至关重要。图2:蛋白质聚集的机制。蛋白质聚集涉及5种机制。第一个涉及单体相互作用的变化及其对蛋白质聚集的影响。第二个涉及构象改变单体的聚集,而第三个涉及化学修饰的产物聚集。第四种机制与成核控制的聚集系统协调。最后一种机制是表面诱导的聚集,它涉及蛋白质聚集中的疏水和气-液相互作用【NO.3】导致蛋白质聚集的因素3.1内在因素-蛋白质结构和序列当蛋白质序列中的几个疏水残基由于部分去折叠或构象变化而暴露时,通过促进分子间疏水相互作用,在驱动聚集中起关键作用。CH2结构域中糖基化的发生和聚糖的结构可能会影响蛋白质稳定性。虽然糖基化程度的增加通过增强内部非共价相互作用和增强结构刚性来帮助稳定蛋白质的天然构象,但聚糖分子大小的扩展似乎降低了未折叠状态的稳定性,从而可能改变蛋白质的整体折叠动力学。已经确定聚糖-蛋白质相互作用对于IgG抗体Fc区内的CH2结构域的稳定性至关重要,因为去糖基化会严重削弱CH2域,并消除了其连接到低亲和力FcRs的能力。CH2促进N-糖构象灵活性并暴露CH疏水内表面的CH2结构域可以聚集IgG抗体和治疗性蛋白-Fc融合。图3总结了内在和外在因素。图3:使用疏水残基,蛋白质结构和序列等内在因素会极大地影响蛋白质聚集。摇晃、剪切、加压和干燥等外源因素会显著影响蛋白质聚集。由于空气的疏水性,摇晃会影响空气-水界面。疏水残基与空气接触的增加进一步启动了蛋白质的聚集。干燥会加速蛋白质水合层的去除并诱导无序的自然状态,而产生的无序天然状态会诱导蛋白质聚集3.2外在因素(1)温度热力学不稳定性、疏水相互作用、蛋白质转运和促进聚集的化学反应只是高温对蛋白质影响的一小部分。较高的温度也可能改变蛋白质结构内多肽链的形状并导致它们展开,从而促进聚集。聚集的大小和阶段会影响可逆性。蛋白质熔点(Tm)和热力学稳定性呈正相关。当温度接近Tm时,蛋白质部分展开并形成聚集体。温度升高到Tm以上通常会导致与疏水残基接触而聚集更快。Tm较大的蛋白质似乎具有较低的聚集倾向。(2)工艺步骤的影响蛋白质聚集可能发生在几个工艺阶段,包括展开/重新折叠、冻融、纯化、发酵/表达、加压、摇动/剪切和干燥。蛋白质药物递送系统的制备和给药也会影响聚集。(3)发酵/表达大规模蛋白质生产的第一步是发酵或细胞培养。蛋白质可以在各种细胞系统和多种工艺环境中表达。在细菌表达中,几种蛋白质聚集成包涵体。在这些系统中,骨料的形成与正确的折叠相竞争。宿主系统对所产生蛋白质的糖基化状态/模式产生深刻影响,导致各种蛋白质聚集行为。(4)展开/重新折叠蛋白质的展开和随后的重折叠是使用微生物表达系统进行大规模蛋白质生产的关键步骤。在复性过程中,蛋白质会穿过多个中间构象状态,使其极易出现错误折叠和聚集。因此,蛋白质聚集在重折叠过程中显著降低了正确折叠的生物活性蛋白的产量。(5)纯化残留的宿主细胞蛋白和杂质可以通过蛋白质生产中使用的纯化阶段去除。纯化条件可能会导致蛋白质聚集问题,涉及pH值、温度和电导率。其中一种蛋白质纯化方法是亲和层析,它需要低pH值进行蛋白质洗脱,并且会在洗脱过程中诱导蛋白质聚集问题。温和的纯化条件也会触发蛋白质聚集,可以通过在蛋白质纯化条件中添加添加剂进行适当控制来抵消这种聚集。这些包括促进天然蛋白质稳定性的助溶剂(例如糖、多元醇);破坏分子间相互作用的离液剂;偏爱自身折叠状态的kosmotropes;还原剂(如DTT和β-巯基乙醇)以防止二硫键形成不当;以及乙醇和去污剂等有助于稳定折叠中间体或膜蛋白的专用试剂。纯化对蛋白质聚集体的影响如图2所示。亲和纯化技术涉及许多抗体纯化方法,如硫酸铵沉淀、固定化蛋白A、G、A/G或L利用、固定化抗原、抗体、离子交换色谱、尺寸排阻色谱、疏水相互作用色谱、多模式色谱、免疫沉淀以及免疫共沉淀。图4外源因子对蛋白质聚集的影响(6)冻融法蛋白质的类型和蛋白质的浓度,以及冷冻过程中的其他赋形剂,可以诱导蛋白质聚集。溶质浓度、低温、相分离、pH值变化和冰水界面会导致冷冻过程中的蛋白质聚集。冷冻温度可诱导冷变性,蛋白质在低温下可自发展开。冻结速率会影响冰晶的大小和冰水界面的表面积。通过冷冻诱导的pH值变化触发的特异性缓冲剂的选择性结晶导致蛋白质聚集。冻融前的容器配置和溶液pH值对于蛋白质聚集也很重要。通过减少蛋白质-冰相互作用并抑制优先相互作用和pH值变化,可以通过正确选择制剂赋形剂来抑制冻融诱导的蛋白质聚集。抑制过度的蛋白质-蛋白质相互作用和溶液粘度不受控制地增加可以减少蛋白质聚集。(7)摇晃和剪切运输和蛋白质合成过程中遇到的摇晃和剪切可能有利于蛋白质聚集。这些因素给出的压力强度以及暴露程度对于蛋白质聚集的程度至关重要。界面处的蛋白质聚集从振荡过程开始,通过产生空气-水界面,与水相比,空气具有疏水性。摇晃暴露于疏水区域或蛋白质结构域会导致聚集。高剪切应力比中等剪切更大程度地诱导蛋白质聚集。通过与蛋白质分子竞争疏水表面,可以通过表面活性剂减少由剪切和振荡诱导的蛋白质聚集。通过稳定赋形剂提高溶液粘度,实现蛋白质迁移率的受控降低,并且它们与蛋白质表面的直接附着可以减少蛋白质聚集,例如羟丙基-β-环糊精。蛋白质和细胞等生物材料的生物工艺涉及由机械力、流体动力和界面现象等不同力引起的剪切和应力。剪切效应是产生抗体和酶所必需的,而蛋白质药物产品则需要发酵、配制和纯化程序。NikolaiF.Bunkin等人证明了在水和乙醇/水混合物(36.7vol%)中使用免疫球蛋白G(IgG)分散体进行振荡的两种效果。首先,它增加了IgG大分子聚集的速率。其次,它在每种溶剂中产生具有不同尺寸光谱的气泡。由于IgG变性,乙醇和水组合有利于聚集。乙醇和水中的IgG聚集体大小为300nm,水中为900nm。(8)增压过滤过程中的较低压力到中等压力会导致蛋白质聚集。高压增加了疏水相互作用,导致蛋白质去折叠和聚集。中等浓度的离液剂的压力处理会诱导化学键合类型的聚集体。同时,通过高压处理溶解聚集体来促进蛋白质解聚。Hawley等人预测,蛋白质在P\u2012T空间中具有闭合的稳定性等值线,这是压力诱导蛋白质转变的热力学的关键特征。除了一些例外,许多单体蛋白在大约400MPa的压力下,温度为25至37°C时会发生压力诱导的变性。已经证明,大约200MPa的中等压力可以将天然低聚物与非天然聚集体解离并从中分离蛋白质分子,从而使分子折叠成其天然构象。当压力释放时,蛋白质可以充分重新折叠,从而减少聚集。(9)干燥许多干燥方法涉及制备固体蛋白质产品,包括冷冻干燥、真空干燥和喷雾干燥。干燥过程去除蛋白质水合层,导致蛋白质的无序天然状态,诱导不同程度的蛋白质聚集。真空干燥会诱导快速脱水,从而触发蛋白质聚集。由于共价键和非共价键的参与,干燥和冷冻应力都会影响蛋白质聚集。通过在干燥过程中添加蛋白质稳定剂(如糖)可以抑制蛋白质聚集。另一种经过充分研究的蛋白质脱水方法是喷雾干燥。蛋白质在原子化过程中会短暂地受到更高的温度和显著的空气-水界面上升。表面活性剂通常可有效抑制蛋白质聚集。在该方法中,喷雾冷冻消除了高温的要求,但仍然形成了空气-水界面,这可能比简单的喷雾干燥更大程度地促进蛋白质聚集。超临界流体干燥也可诱导蛋白质聚集。其他赋形剂、重构方法和培养基的存在可以诱导不同程度的蛋白质聚集到重构的干燥蛋白质产物中。(10)其他工艺还报道了其他使蛋白质不稳定并导致蛋白质聚集的过程。过滤:靠近膜表面的浓缩层中的蛋白质过饱和度和高溶剂速度(剪切力)在蛋白质聚集中起作用。膜表面的蛋白质分子可能被溶剂流剪切力去折叠,这会导致颗粒碰撞导致絮凝。填充:当药物溶液装入加药设备和容器时,可能存在剪切力。这种剪切力可能会伤害剪切敏感物质,从而降低成品药的质量和产量。雾化:固体物质或液滴必须分散或悬浮在气体介质中才能产生气溶胶。这个过程涉及物理应激源,可能导致蛋白质构象发生变化并可能诱导聚集。蛋白质标记:虽然接枝小放射性标记对蛋白质特性的影响很小,但许多标记反应中使用的氧化条件会导致蛋白质聚集和配方开发。在制剂开发阶段,蛋白质聚集体包括赋形剂筛选、浓缩、纯化、冻融和储存。3.3环境因素对蛋白质聚集的影响许多环境因素会影响蛋白质变性以及蛋白质聚集。涉及的一些关键因素是蛋白质浓度、溶液条件、容器/封闭系统和表面以及光照射。3.3.1一般溶液条件对蛋白质的影响溶液条件对蛋白质聚集的影响表示如下:(1)酸碱度蛋白质上的表面电荷由溶液pH值决定,并影响分子内和分子间折叠相互作用,导致蛋白质去折叠。在等电pH值下,在蛋白质溶解度最小时观察到较小的蛋白质电荷-电荷排斥力。通过选择远离蛋白质等电pH值的溶液pH值来更大程度地减少蛋白质聚集并非每次尝试都有效,而溶液pH值的变化可以诱导蛋白质聚集所涉及的限速步骤/机制的间接影响。尽管有各种缓冲剂可用于pH调节,但蛋白质稳定性和聚集行为可能因缓冲系统和浓度而异。缓冲结合效应被归咎于各种效应。(2)离子强度离子强度对蛋白质聚集有依赖性影响。由于疏水贴片,可以通过增强离子强度来破坏蛋白质的稳定性。蛋白质聚集的增加可以通过中和蛋白质表面的电荷诱导来实现,以促进蛋白质稳定性或折叠。溶液的pH值和蛋白质的糖基化状态可以在离子强度的帮助下诱导蛋白质聚集。蛋白质治疗药物的体内和体外稳定性可以通过在糖工程的帮助下纵糖基化参数来利用聚糖来实现。糖基化是减少或防止蛋白质不稳定性的最有前途的方法之一。通常认为,改变重要的糖基化因子,如糖基化程度、聚糖大小和聚糖结构组成,可以使蛋白质的分子稳定性调整到正确的水平。糖基化已被证明可以同时稳定多种蛋白质,以应对其药物开发过程中遇到的几乎所有关键物理化学不稳定性。蛋白质药物通常是静脉内给药而不是口服给药,因为消化系统中的蛋白酶会化学降解它们。然而,由于蛋白酶的内吸性产生,通过其他途径递送的蛋白质极易受到蛋白水解破坏。因此,蛋白质治疗药物的体内分子稳定性和治疗效力与其对蛋白水解降解的抵抗力密切相关。糖基化可保护蛋白质免受蛋白酶降解。离子强度可以通过影响化学反应的速率或其他聚集诱导剂的作用来间接影响蛋白质聚集。研究表明:高水平的离子强度和较低的pH值支持了聚集倾向,而热稳定性随pH值的增加而降低。pH值小于3.5表明二级结构没有显着变化,而蛋白质沉淀在无盐缓冲液中逆转成单体,如图5所示。海藻糖提供的蛋白质聚集体较少,而实验结果表明,在pH条件较低的情况下,蛋白质的三级结构变化有限,导致可逆聚集。由于静电排斥,盐的添加会引起胶体不稳定。图5:研究了mAb1在pH3.5和不同盐浓度下的聚集行为3.3.2辅料/添加剂很少有添加剂会破坏蛋白质的稳定性并促进聚集,而其他添加剂可以稳定它们。从蛋白质中优先排除赋形剂/添加剂可以实现蛋白质稳定。蛋白质折叠速率增加、溶剂粘度增加、溶剂可及性降低和构象迁移率是拟议蛋白质稳定的其他机制。与氨基酸、胺、聚合物、表面活性剂、多元醇和糖等添加剂与中间聚集体的结合可以实现蛋白质稳定。许多次要的中性化合物会影响蛋白质的稳定性或聚集。这些中性赋形剂的主要类别是糖/多元醇。这些糖/多元醇在各种实际条件下自然稳定并阻止蛋白质聚集。这些赋形剂被称为渗透物或化学伴侣,因为它们可以使蛋白质保持正确的构象。根据配方或溶液要求,这些辅料通常以5-10%的浓度使用,以稳定溶液中的蛋白质并减少Fc-Fc或Fc-Fab与空气-水相的相互作用。在生长培养基中棉子糖和蔗糖等不可代谢的碳水化合物的帮助下,内酰胺酶聚集受到抑制。在理想条件下,可溶性蛋白的量增加了四倍。羟脯氨酸、甘氨酸、赖氨酸、精氨酸、组氨酸、脯氨酸、甜菜碱、腐胺、亚精胺、磺基甜菜碱和咪唑可以抑制蛋白质聚集。一些化合物对蛋白质聚集有负面影响,包括组氨酸、甘氨酸、多巴胺和三甲胺-N-氧化物。根据其浓度使用,赋形剂对蛋白质分子显示出稳定和不稳定作用。蛋白质变性或聚集可能是由聚合物和蛋白质之间的固体疏水/静电相互作用引起的,随后通过在蛋白质溶液中涂抹表面活性剂来解决。非离子表面活性剂对蛋白质聚集有负面影响,通过加速稳定性研究观察到。非离子表面活性剂的表面蛋白结合诱导蛋白质聚集。抗氧化剂、还原剂、有机溶剂和防腐剂是可能影响蛋白质聚集的配方添加剂/赋形剂的例子。3.3.3蛋白质浓度蛋白质浓度对蛋白质聚集有影响。蛋白质浓度的增加可以诱导三种不同的结果,包括由于拥挤而导致的聚集减少,由于可能的关联导致聚集升高,以及由于溶解度极限导致的沉淀。拥挤的细胞内环境用术语“大分子拥挤”来描述。通过提高蛋白质浓度观察到蛋白质-蛋白质结合导致蛋白质聚集的可能性增加。溶液条件会影响蛋白质溶解度极限。由于蛋白质浓度超过限值,蛋白质可能会聚集、沉淀和结晶。3.3.4接触面和容器/封闭系统该蛋白质倾向于与多种界面/表面结合。蛋白质变性变为结构完整性,蛋白质吸附可触发聚集。蛋白质吸附减少了聚集种子发育的能量屏障。蛋白质聚集随着蛋白质吸附到多层中而增加。表面活性剂可能影响也可能不会影响蛋白质吸附,具体取决于表面和蛋白质的性质。与蛋白质相比,表面活性剂通过加速表面活性剂动员到界面和界面处的高表面活性剂亲和力,或通过表面活性剂-蛋白质复合物的发展,可以降低蛋白质吸附的效果。表面相关的蛋白质聚集可以通过容器/封闭系统诱导,尤其是在金属容器/表面的情况下。表面材料对蛋白质聚集的影响可以在压力条件下增加,例如在不同温度下搅拌、翻滚、跌落和冻融循环过程中发生的机械应力。因此,蛋白质聚集可以通过容器和瓶盖化学来监测。橡胶塞或注射器界面处的机械运动和流体相互作用有助于蛋白质聚集,而注射器制造过程中残留的钨提取物的存在对蛋白质聚集产生了影响。同时,可以探索样品体积、蛋白质浓度、空气流速、温度和表面活性剂作用的影响,以确定蛋白质聚集的程度,如图6所示。空气鼓泡是mAb1界面应力降解的一种便捷方法,可以在进一步的研究中实现。图6:说明了几个因素对PBS中1mg/ml mAb1在鼓泡240分钟时稳定性的影响。稳定性评估因素包括a样品体积、b温度、c硅油或聚山梨酯的存在以及d的鼓泡速率。浊度(A350)和蛋白质丢失(%)用作测量值。3.3.5光和辐射紫外线(UV)可以在暴露后影响蛋白质并推动蛋白质去折叠,这进一步导致蛋白质聚集或抑制光交联反应,从而导致共价聚集。紫外线辐射显示交联诱导进入半胱氨酸和色氨酸残基。它产生天然二硫键的光解以形成或交换新的二硫键。紫外线可以氧化色氨酸残基,形成巯基自由基和新的二硫键。此外,酪氨酸和苯丙氨酸等氨基酸残基也容易发生氧化反应。γ辐射产生铜蓝蛋白和血红蛋白聚集;因此,光敏生物疗法需要光保护。【NO.4】蛋白质聚集的预测和缓解方法蛋白质是各种生物功能所必需的最普遍的生物分子,严重依赖天然的链内和链间连接来控制它们的折叠、结合和功能活性。活细胞内蛋白质的构象变化是通过达到最低自由能的状态来驱动的。在此过程中,天然接触对于蛋白质表面的聚集至关重要。不幸的是,非天然分子间相互作用也会发生,形成无定形、非结构化的聚集体,对蛋白质功能产生负面影响并增加毒性。蛋白质聚集成不溶性部分是开发基于蛋白质的疗法和生物技术产品的重大障碍。生产过程通常使蛋白质受到非天然的应激和浓度,促进聚集并降低最终产物的产量和活性。此外,这种现象会引发患者不可预测的免疫反应。在没有天然控制的情况下,了解异常蛋白质寡聚化的分子基础一直是广泛研究的重点。蛋白质构象稳定性、溶液中的胶体稳定性以及运输和储存过程中的环境压力等因素会显著影响蛋白质产品的质量。通过吸附可以在固-液或空气-液体界面促进蛋白质聚集,这归因于静电相互作用或对材料表面的疏水效应。在这些应用中开发有效的技术来防止蛋白质聚集对于推进基于蛋白质和生物制剂的治疗至关重要。阻碍溶液中蛋白质聚集的最广泛采用的策略之一是掺入阻碍该过程的化合物。此类化合物包括氨基酸、糖、尿素、多元醇和特定聚合物。例如,聚乙二醇通过与未折叠的蛋白质和折叠中间体形成疏水键,成功地阻止了干扰素和组织纤溶酶原激活剂在再折叠过程中的结合。因此,减少未折叠蛋白质的自由能会增加活性蛋白的最终产量。还发现蔗糖等糖类可以通过增加去折叠的自由能屏障来阻止蛋白质分子的非天然去折叠,从而减少中间体的数量并减缓聚集。另一种有前途的抗聚集添加剂是氨基酸精氨酸,它似乎通过优先增加蛋白质结合屏障来发挥作用。尽管实证方法具有资源密集型性质、耗时性以及对详细机械知识的依赖,但实证方法虽然成功,但也有一定的局限性。以下部分重点介绍预测治疗性蛋白质聚集的计算方法的最新进展以及应对这些挑战的创新策略。4.1预测蛋白质聚集的计算方法蛋白质的一级结构包含显著影响其聚集趋势的内在因素。在这些因素中,疏水相互作用在蛋白质聚集中起着主要驱动力。蛋白质序列中具有高疏水性的区域促进链内和链间接触,从而导致聚集。相反,亲水区域可以充当守门人,通过阻止疏水残基相互相互作用来抵消聚集。蛋白质残基的局部电荷和净电荷也会影响聚集。带电残基之间的静电排斥可以防止聚集,而相反的电荷或没有排斥力可能促进聚集。许多聚集体表现出交叉β折叠,其中β片结构起着关键作用。具有高β折叠倾向的氨基酸在聚集中受到青睐,而β折叠断裂残基,如脯氨酸(Pro)和α-氨基异丁酸(AIB)可以抵消聚集。值得注意的是,蛋白质的聚集倾向并未沿序列均匀分布,而是倾向于集中在特定的短线性延伸中,称为APR。这些区域对于成核蛋白聚集来说是足够和必要的,并且通常富含疏水残基。在球状蛋白中,APRs常见于疏水核心,但它们也可能暴露在参与催化和结合的区域。此外,pH值、离子强度、温度和环境条件等外部因素可以调节聚集倾向,导致多态性,即在不同条件下可能形成不同的聚集体。蛋白质序列的线性密码不仅控制折叠成天然球状状态,还决定了部分或完全非结构化构象的倾向,如在固有无序蛋白质中观察到的那样。折叠代码和聚集代码之间的这种收敛促进了计算方法的发展,以预测蛋白质序列的聚集倾向。已经设计了20多种预测算法来识别多肽中的线性APR。这些算法采用不同的指标来推导出聚集倾向、溶解度和热力学稳定性。所有预测方法都使用蛋白质序列作为输入,但它们的APR鉴定和定量策略不同,依赖于现象学或理论衍生的参数。表I总结了用于预测蛋白质聚集的不同计算方法(附示例)。图7说明了预测蛋白质聚集所采用的计算方法,侧重于内在决定因素、顺序特征以及使用AI和机器学习评估聚集倾向。基于结构的算法的使用目前仅限于蛋白质数据库中可用的有限结构子集。这种限制源于所采用的预测方法中一个明显的实际限制。与此同时,预测方法的发展轨迹也取得了惊人的进步,从最初的机器学习方法发展到包含序列嵌入和预训练语言模型的复杂深度学习架构。AlphaFold对结构预测的革命性贡献和复杂蛋白质语言模型(PLM)的出现就是例证,这些突破促进了以前无法达到的精确度来阐明蛋白质序列与其相应结构之间的关系。表I:预测蛋白质聚集的计算方法图7:用于预测蛋白质聚集的计算方法,侧重于内在决定因素、顺序特征以及使用人工智能(AI)和机器学习评估聚集倾向。首先,蛋白质聚集倾向的预测依赖于蛋白质序列固有的内在因素。其次,利用顺序特征来增强蛋白质聚集的预测。这涉及利用AI和机器学习技术来评估顺序聚合倾向。最后,根据它们在球状蛋白质结构中的表现来预测聚集倾向。这些方法共同有助于全面理解和预测蛋白质聚集现象。4.2蛋白质聚集抗性的发展除了优化配方因子(例如蛋白质浓度、pH值、缓冲液成分和其他溶质、温度等)外,通过采用突变设计方法实现治疗性蛋白质的聚集抗性代表了一条很有前途的新途径。通过引入特定的氨基酸替换或缺失,研究人员可以战略性地修改蛋白质的序列,以破坏APRs并提高其稳定性和溶解度。这些靶向突变旨在降低反应性单体展开和形成的可能性,反应性单体是不可逆聚集的关键前体。实现聚集抗性的突变设计方法包括两个关键策略:定向进化和高通量筛选。它涉及通过随机诱变或DNA改组创建不同的突变文库。然后,这些文库经过迭代轮次的选择和扩增,以鉴定具有更高聚集抗性的变异。高通量筛选方法能够快速评估大量突变体,从而鉴定具有增强稳定性和溶解度的聚集抗性蛋白质。这种方法的成功应用依赖于对选择标准和筛选分析的精心设计,以及评估聚集倾向的强大分析工具的可用性。•基于知识或信息学的方法:这些方法利用有关同源蛋白质的现有信息来辨别与聚集速率相关的序列或结构特征。利用生物信息学工具和数据库,研究人员可以分析蛋白质序列和结构,以确定影响聚集倾向的关键决定因素。•通过了解特异性氨基酸替换或序列模式如何影响蛋白质稳定性和构象动力学,可以合理选择突变设计以增强蛋白质对聚集的抵抗力。这种方法需要全面了解蛋白质结构-功能关系和准确的生物信息学工具进行数据分析。•基于化学和物理的设计方法:这些方法通常被称为理性设计策略,采用分子模拟和计算建模来研究蛋白质-蛋白质相互作用、折叠动力学和热力学稳定性。通过阐明控制蛋白质聚集的基本原理,研究人员可以进行合理的修饰,以破坏易聚集区域并稳定蛋白质的天然构象。•这些方法为特定突变对蛋白质内在聚集倾向(IAP)的影响提供了有价值的见解,有助于开发具有改善结构完整性和降低聚集潜力的聚集抗性蛋白质。•这种方法需要计算生物物理学方面的专业知识、精确的力场和复杂的模拟算法,以准确模拟蛋白质动力学和相互作用。合理的设计方法可用于控制蛋白质聚集并实现增强的有效性。蛋白质的构象稳定性可以通过在展开阶段的适当努力来实现。最大限度地减少溶液中“反应性”单体的产生,这通常会增加彼此相互作用的倾向,可导致形成稳定的不可逆聚集体。理性设计可以主要集中在引入增强单体之间静电排斥力的特异性突变。还原成可逆的寡聚体形成可以减缓蛋白质聚集的进展。此外,合理的设计策略可以在细胞核形成阶段实施,识别以及参与蛋白间固体接触的内在聚集易聚集区域(如无定形或原纤维样蛋白间β片)的破坏导致成核以及聚集体的整体生长。蛋白质的IAP可以通过靶向破坏这些APR来降低。IAP是指当这些APR完全暴露在溶剂中时,即处于未折叠或固有无序状态时,蛋白质固有的聚集倾向。与野生型(WT)蛋白相比,采用这种策略可以有效降低反应性单体的成核速率,即使单体由于去折叠而变得“反应性”。特别值得注意的是APR鉴定策略对与各种人类疾病相关的天然人类蛋白质的应用。在这种情况下,发现靶向这些APR的基于肽的抑制剂具有巨大的前景。此类抑制剂可阻止有毒聚集物种的形成,从而减轻相关人类疾病(如淀粉样蛋白形成/纤颤)的发生或进展。4.3先进的配方技术,保持蛋白质稳定性许多非传统技术已经开发或正在开发中,以解决生物制品中蛋白质聚集的挑战性问题。4.3.1化学偶联化学偶联或蛋白质融合主要用于延长体内半衰期并促进治疗性蛋白质的作用持续时间更长。这种方法涉及将特定部分(如聚乙二醇(PEG)、聚糖或其他亲水性物质)连接到蛋白质上。PEG通过诱导PEG修饰表面之间的排斥相互作用来减少蛋白质聚集,并且还增强了蛋白质的热稳定性。特别是PEG,由于其生物相容性而被广泛用作偶联剂,并显示出稳定蛋白质免受各种压力的有效性,包括热稳定性、pH诱导或蛋白酶诱导的降解以及寡聚化。用麦芽糖糊精、乳糖、葡聚糖和改性海藻糖聚合物对蛋白质进行糖基化也显示出抑制蛋白质聚集的前景。例如,卵清蛋白与更多亲水取代基的糖基化通过改变分子间相互作用增强了其热稳定性。同样,与更稳定的伴侣蛋白融合已被证明可以增强融合蛋白的稳定性,减少聚集并改善整体药物特性。例如,与单独使用MBP相比,MpAFP698蛋白与麦芽糖结合蛋白(MBP)的融合显著提高了所得MBP-MpAFP698融合蛋白的热稳定性。然而,化学偶联和蛋白质融合都会给原料药生产过程带来额外的复杂性,需要额外的工艺步骤。此外,最终候选药物的较大尺寸对表征和稳定性监测提出了挑战。此外,必须仔细考虑选择合适的偶联部分和伴侣蛋白,以避免潜在的免疫原性或其他不良反应。4.3.2使用极性有机溶剂极性有机溶剂的使用为解决蛋白质聚集问题提供了另一种途径。虽然传统上,在蛋白质水溶液中加入可混溶的有机溶剂会导致蛋白质去折叠和不稳定,但改变溶剂性质可以降低蛋白质溶液的粘度,如二甲基亚砜或二甲基乙酰胺。虽然它们有效地降低了蛋白质溶液的粘度,但蛋白质的熔解温度会随着这些溶剂浓度的增加而下降,从而可能影响蛋白质的储存稳定性。然而,使用纯有机溶剂可以显著改变蛋白质与溶剂的相互作用,从而能够制备非水悬浮液以降低蛋白质制剂的粘度。与水溶液相比,悬浮在各种有机溶剂中的蛋白质治疗剂的粘度显著降低,粘度降低取决于溶剂的性质,特别是其氢键特性。然而,人类使用的有机溶剂的毒性和耐受性令人担忧。在考虑将这种方法用于临床之前,仔细选择合适的溶剂和彻底的毒理学评估至关重要。4.3.3开发蛋白质悬浮液悬浮液尚未作为蛋白质的商业剂型得到广泛探索。然而,可以假设蛋白质可以制备为结晶或无定形颗粒悬浮液,以稳定蛋白质并促进高浓度配方。已成功制备mAb的结晶悬浮液,保留了其结构完整性和生物活性。例如,mAbs利妥昔单抗、曲妥珠单抗和英夫利昔单抗的结晶悬浮液设计没有可检测的结构改变,并且与可溶性对应物相比,粘度降低。较短的t1/2当作为结晶混悬液给药时,可溶性英夫利昔单抗在皮下注射后增加了一倍,展示了这种方法改善药物输送的潜力。然而,在考虑结晶悬浮液时,必须解决几个挑战。最适合结晶的溶液条件可能不适合蛋白质的长期储存。此外,任何促进蛋白质结晶的添加剂都必须可以安全地注射。由于晶体的不断沉降,制造过程中的结晶悬浮剂药品填充也带来了挑战。4.3.4开发非冻干配方传统上,非冻干固体制剂的制备是为了容纳溶液中不稳定的蛋白质。虽然冷冻干燥是一种流行的方法,但已经探索了喷雾干燥、喷雾冷冻干燥、超临界流体干燥和真空泡沫干燥等替代干燥技术。喷雾干燥法已被证明是生产固体制剂的有效工具,具有成本和可扩展性的优势。由于干燥温度和空气-水界面,蛋白质会在喷雾干燥过程中引起应力。喷雾干燥还显示一些蛋白质的结构完整性降低。这些问题可以通过使用喷雾冷冻干燥来解决,这进一步消除了干燥过程,但它也会产生空气-水界面,从而导致蛋白质聚集。喷雾冷冻干燥技术在特定频率的超声雾化的帮助下用于达贝泊汀α,与传统喷雾干燥相比,产生的不溶性聚集体最小。超临界流体(SCF)干燥也存在蛋白质聚集问题,由于仪器的严格要求、过程诱导的赋形剂结晶以及蛋白质重构到相同的过程中,这可能会变得非常严重。真空泡沫干燥已显示出降低工艺效率的几个优势,而不会产生赋形剂结晶的倾向。真空泡沫干燥的高干燥效率需要严格控制工艺条件。4.3.5开发蛋白质纳米团簇Crowder状海藻糖涉及纳米簇,即密集堆积的蛋白质分子,在高浓度下没有凝胶化,显示出平衡的流体动力学直径。纳米簇分散体由于其降低的粘度和即兴的注射能力而适合皮下注射。与散装溶液中的距离相比,纳米簇内的蛋白质间距离显着减小,这是合理的。较短的距离可能会增强蛋白质-蛋白质相互作用,并可能导致稳定性问题。尽管如此,纳米团簇概念相对较新,需要进一步评估以充分了解其在生物制药中的含义和潜在应用。【NO.5】蛋白质聚集和临床免疫原性蛋白质聚集体由几种单体、重复模式或氨基酸序列组成,它们可能模拟清道夫和其他受体的配体,导致抗原呈递细胞(APC)的摄取增加。它们必须与免疫细胞相互作用才能成为免疫原性生物治疗药物。一般来说,生物治疗药物可以通过以下两种方式之一诱导患者的免疫反应。在第一种情况下,生物治疗药物可能是适当的外来药物,必须被患者的免疫系统识别,并且必须引起适应性免疫反应。因此,这些生物治疗药物可以被抗原呈递细胞(APC)内化、工艺和呈递,从而导致CD4和T细胞反应和抗体制备,如图8所示。图8:B细胞激活机制,经典反应:生物治疗药物被APC内化并工艺成与MHCII结合的肽片段,然后被CD4+细胞识别,刺激细胞因子分泌和B细胞活化,然后分化为浆细胞。B细胞耐受性的崩溃:B细胞可以通过交联抗原特异性Bc的抗原拥有重复表位被浆细胞激活。表II和表III全面总结了FDA批准的生物治疗药物,分别详细介绍了基于抗体的药物和其他生物制剂,以及监管处方信息中记录的免疫原性特征。表II FDA批准的抗体治疗药物表III FDA批准的其他生物制剂【NO.6】蛋白质聚集体表征方法及其监管要求蛋白质可以在开发和生产过程中的任何时刻聚集,例如通过生物工艺、纯化、制剂、包装和储存。因此,表征蛋白质聚集体与检测它们一样重要,因为它有助于生物制药的成功开发和生产。分子量、构象和大小是必须确定的一些物理化学特征。最近的技术突破大大加快了蛋白质表征的速度,因此,现在有许多用于表征蛋白质聚集体的分析技术可用。有几种方法可以量化和估计蛋白质聚集体的大小并对其进行表征。然而,由于被测量的内容和大多数这些数据评估方法的规格存在固有差异,因此给定样品报告的平均大小、大小分布和聚集物种的数量可能存在差异。缺乏量化亚微米颗粒的通用方法使蛋白质聚集体分析的最大问题之一成为蛋白质聚集体分析的最大问题之一,即目前没有一种分析方法可以涵盖可能出现聚集体的整个粒径范围。然而,只有一小部分蛋白质质量,即蛋白质聚集体,特别值得注意,因为它们有可能在免疫原性中发挥作用。由于它们的尺寸很小,从几纳米到数百微米到大块可见光颗粒,因此必须使用多种分析技术来检测这些微小的聚集体馏分。表征方法的总结列在表IV中。表IV蛋白质聚集体包涵体的表征方法【NO.7】FDA关于治疗性蛋白质的蛋白质聚集和免疫原性评估的监管指南生物制剂(包括单克隆抗体、细胞因子和其他治疗性蛋白质)的开发和批准经过美国FDA等监管机构的全面评估。蛋白质聚集和免疫原性是在此过程中评估的关键因素,因为它们会显着影响这些药物的安全性和有效性。蛋白质聚集是指无意中发生的蛋白质分子聚集在一起。这可能会损害治疗性蛋白质的稳定性、生物活性和安全性。聚集体可能发生在生物制剂生产、储存和管理的不同阶段,导致疗效降低和免疫原性增加等不利影响。因此,FDA规定的监管指南强调了在生物制剂的整个生命周期中控制和评估蛋白质聚集的重要性。FDA推荐了一种全面的方法来确定蛋白质聚集,首先要了解聚集的根本原因和机制。制造商必须使用尺寸排阻色谱、动态光散射和成像方法等分析技术来检测和量化产品聚集体。这些方法有助于确定聚集体的大小、形态和浓度,从而能够评估它们对安全性和有效性的潜在影响。此外,鼓励制造商实施策略,以最大限度地减少配方、储存和处理过程中的蛋白质聚集。这可能涉及优化pH值、缓冲液条件和赋形剂选择,以保持蛋白质稳定性并防止聚集。适当的储存条件,例如温度控制和稳定剂,对于最大限度地降低产品储存和分销过程中的聚集风险至关重要。免疫原性是监管评估的另一个关键考虑因素,指的是蛋白质诱导患者免疫反应的能力。随着时间的推移,免疫反应会导致不良反应或疗效丧失。FDA要求制造商通过临床前和临床研究评估和减轻治疗性蛋白质的免疫原性潜力。临床前评估通常包括评估潜在免疫原性表位的蛋白质序列和进行动物研究以评估免疫反应。临床研究在表征人类免疫原性方面起着至关重要的作用,重点是抗药抗体(ADA)和中和抗体(NAb)的灵敏检测方法。这些研究有助于识别有产生免疫反应风险的患者群体,并为风险缓解策略提供信息。为了解决免疫原性问题,制造商可以采用各种方法,包括蛋白质工程以减少免疫原性表位、免疫调节剂的联合给药或实施患者监测计划。上市后监测还允许在真实世界患者群体中进行持续的免疫原性评估,有助于早期发现安全问题并为风险管理策略提供信息。研究性新药(IND)申请应包括风险评估和测试理由。风险评估包括对可能影响免疫原性的治疗性蛋白质因子的深入分析和讨论。FDA建议对ADA检测结果呈阳性的生物药物进行中和抗体检测。除了PK、PD和临床结局外,还可以评估ADA的滴度、同种型和结构域特异性。总体而言,FDA关于治疗性蛋白质蛋白质聚集和免疫原性评估的监管指南强调了系统和主动方法确保生物药物安全性和有效性的重要性。制造商可以通过在整个产品生命周期中了解和控制蛋白质聚集和免疫原性,最大限度地降低患者风险并最大限度地提高这些重要治疗方式的治疗效果。【NO.8】结论和总结蛋白质聚集是一种复杂的多因素现象,受一系列溶液条件和工艺变量的影响,包括生产和储存过程中的pH值、离子强度、赋形剂、剪切应力以及热或机械应力。聚集可以通过化学降解、物理去折叠或自缔合发生,并通过异质途径进行,产生不同的聚集体种类,可溶、不溶、可逆或不可逆。控制蛋白质聚集需要了解聚集体形成的原因以及使用适当的分析技术。至关重要的是,由于蛋白质聚集体的粒径范围和结构多样性,没有单一的分析方法可以涵盖可能出现聚集体的整个粒径范围或类型。虽然通常采用SEC、SDS-PAGE和光散射(SLS、DLS)等方法,但每种方法在分辨率、检测范围和数据可比性方面都有固有的局限性。因此,正交、多技术方法对于准确的聚集体分析仍然至关重要,尤其是在生物制药制剂的开发中。展望未来,开发标准化、跨平台的分析工作流程和数据解释指南至关重要。集成微流体、AI驱动的建模和高分辨率成像等高级工具可能会提供对聚集动力学和结构转变的更深入见解。此外,稳定剂(包括氨基酸、糖、多元醇和表面活性剂)的合理设计应以对蛋白质、特定于结构基序的加性相互作用的机制理解为指导。总之,结合应激特异性稳定、预测分析和互补分析技术的整体策略对于减轻蛋白质聚集和确保治疗性蛋白质的安全性和有效性至关重要。对聚集途径和创新分析平台的持续研究是克服当前限制和推进生物制药稳定性科学的关键。识别微信二维码,添加抗体圈小编,符合条件者即可加入抗体圈微信群!请注明:姓名+研究方向!本公众号所有转载文章系出于传递更多信息之目的,且明确注明来源和作者,不希望被转载的媒体或个人可与我们联系(cbplib@163.com),我们将立即进行删除处理。所有文章仅代表作者观点,不代表本站立场。

2025-07-04

·奇点网

*仅供医学专业人士阅读参考有时候感觉,肿瘤细胞和小强真的很像。令人厌恶、繁殖超快、到处“乱蹿”,最主要是生命力极强,总能以意想不到的方式活下来。近日,复旦大学马齐襄、雷群英、尹淼等人发表在Molecular Cell期刊上的最新论文,揭示了肿瘤细胞在饥饿中夹缝生存的秘诀。他们发现,肿瘤细胞里的分子伴侣BAG2是一种精氨酸感应器,能够直接结合精氨酸。当识别出自身处于精氨酸饥饿的条件下时,BAG2会改变构象与另一种蛋白质SAMD4B解离,后者跑去促进β-catenin的降解并稳定参与细胞应激反应的蛋白质ATF4,从而增强肿瘤细胞在营养缺乏条件下的生存能力。精氨酸之于肿瘤而言,是相当重要的资源。精氨酸不仅是细胞合成蛋白质的关键成分,还通过激活mTORC1等通路助力肿瘤细胞的生存。由于内源性合成不足以满足快速增殖的需求,再加上表型改变,许多肿瘤细胞无法表达催化精氨酸合成的关键酶,因此极其依赖环境里的外源性精氨酸。那么,环境营养匮乏了怎么办?在这项研究中,研究者们就要找出答案,看看精氨酸不足在情况下,肿瘤细胞如何绝境生存。考虑到结直肠癌(CRC)和肝细胞癌(HCC)中精氨酸代谢的异常活跃性,研究者选择这两种肿瘤细胞系深入探究精氨酸的作用。首先,通过对多种CRC和HCC细胞系进行不同浓度精氨酸条件下的生长测试,确定了在标准培养基中400 µM精氨酸浓度足以维持细胞正常生长,而25 µM精氨酸则足以模拟精氨酸饥饿状态,并被选定为后续实验的精氨酸饥饿条件 。为识别参与精氨酸调控细胞活力的信号通路,研究者们进行了一项合成致死性筛选,将精氨酸饥饿与包含561种抑制剂的文库相结合 。筛选结果表明,在精氨酸饥饿条件下,许多抑制剂能更显著地降低细胞活力 。在细胞活力抑制剂排名前十的候选药物中,Tideglusib、BIO-acetoxime和LY2090314都属于靶向糖原合酶激酶3β(GSK3β)的抑制剂。进一步的体外和体内实验证实了这些GSK3β抑制剂在精氨酸饥饿条件下对细胞生长的抑制作用,但在精氨酸充足条件下,它们对细胞活力没有显著影响。这一发现促使研究者聚焦于Wnt/β-catenin信号通路,因为GSK3β能够通过与蛋白质APC、Axin组成破坏复合物,磷酸化β-catenin并促进其降解;相反,抑制GSK3β则能稳定β-catenin,从而激活Wnt/β-catenin通路。尽管Wnt/β-catenin通路的异常激活通常被认为有助于肿瘤细胞的增殖、分化、生存,但很明显,在精氨酸饥饿条件下,Wnt/β-catenin通路的激活对肿瘤细胞来说是个非常不利的现象。Wnt/β-catenin通路的激活非但不会帮助“挨饿”的肿瘤细胞渡过难关,反而诱导了肿瘤细胞凋亡。研究者们发现,这种双重效应与转录因子ATF4的调控密切相关。Wnt/β-catenin通路的强烈激活会抑制ATF4的表达,而ATF4是细胞应对营养缺乏时的一个重要保护因子,参与细胞应激反应,可以协助细胞转变为“紧急形态”面对危机。缺乏ATF4的保护作用,则会导致肿瘤细胞挨饿了也不知道“紧衣缩食”,最终发生凋亡。所以,肿瘤细胞又是如何知道,何时应该采取低耗能模式、关闭Wnt/β-catenin通路、启动ATF4呢?通过一系列实验,研究者们识别BAG2为精氨酸感应器。这是一种分子伴侣,主要通过与其他蛋白质的相互作用来调节细胞内的蛋白质稳定性及降解。研究者们发现,BAG2通过其Q167位点感知精氨酸浓度变化,形成"分子开关"机制:在精氨酸充足时,BAG2会和参与细胞信号转导的蛋白质SAMD4B紧密结合,阻碍SAMD4B与β-catenin互作,维持Wnt/β-catenin通路活性,促进细胞增殖;而在精氨酸缺乏时,BAG2构象变化导致其与SAMD4B解离,暴露出SAMD4B的BBD域使其招募β-catenin至破坏复合体完成降解,同时通过抑制β-catenin介导的ATF4泛素化降解,协同GCN2-eIF2α通路增强ATF4稳定性,最终激活整合应激反应(ISR)促进肿瘤细胞存活。这项研究首次揭示BAG2作为精氨酸传感器的功能,并阐明BAG2-SAMD4B-β-catenin轴在精氨酸饥饿应答中的核心作用。这一发现不仅拓展了对精氨酸感知机制的理解,还为靶向精氨酸代谢的癌症治疗提供了新思路。例如,抑制BAG2的精氨酸结合能力可能增强精氨酸剥夺疗法的效果,尤其对精氨酸营养缺陷型肿瘤具有潜在治疗价值。研究的局限性在于尚未明确β-catenin如何直接调控ATF4的稳定性,且精氨酸缺乏可能通过其他通路影响细胞存活。未来研究可进一步探索BAG2-SAMD4B轴在其他代谢应激中的作用,以及其与肿瘤微环境的交互。此外,针对BAG2或SAMD4B的小分子抑制剂开发值得期待,可能为联合治疗提供新策略。参考文献:[1]Chen MY, Sun CY, Zhao R, et al. BAG2 releases SAMD4B upon sensing of arginine deficiency to promote tumor cell survival. Mol Cell. Published online June 16, 2025. doi:10.1016/j.molcel.2025.05.035本文作者丨张艾迪

临床1期蛋白降解靶向嵌合体

2025-06-30

·药通社

今年以来,上海市阳光医药采购网已经连续发布了 16 批暂停药品采购资格的通知,累计涉及 32家药企、46个药品。最新一批为6月25日,安徽长江药业有限公司生产的盐酸多巴酚丁胺注射液(2ml:20mg*1支/支,玻璃安瓿)、吉林省辉南长龙生化药业股份有限公司生产的盐酸精氨酸注射液(20ml:5g*1支/支,安瓿)因未按要求调整药品价格而被暂停采购资格。值得注意的是,这两款药均属于短缺药。同日,阳光平台还同步共布了这两款短缺药的4月全国平均价,每支分别为 3.53 元、11.68 元。近几十年来,围绕着短缺药的定价争论从未停止,从政府统一定价到回归市场,低价和保供如何平衡始终困扰着政府和企业。2024年11月,国家医保局印发《短缺药品价格的风险管理操作指引》指出,(易)短缺药品价格仍由企业自主定价,实行市场调节。但随着全国各省市的价格治理日益趋严,短缺药也被纳入了监控之中。回到本次被停采的两个品种。盐酸多巴酚丁胺注射液是一种用于低心排血量状态的核心抢救药,适用于心梗术后、心脏外科手术、感染性休克等多种重症场景,且被公认为比异丙肾上腺素更安全的选择,除安徽长江药业之外,全国还有41家企业拥有该品种的有效批文。另一款盐酸精氨酸注射液为氨基酸类药物,主要用于治疗肝性脑病。目前除吉林辉南长龙外,全国还有8家企业持有有效批文。除这两款短缺药因未降价被暂停采购外,前15批涉及的其他药品停采原因各异,包括价格异动、信息异常、质量问题等,具体如图所示:信息源:上海阳光医药采购网对于药企而言,药品被暂停采购,无疑是沉重的打击。这不仅直接影响相关药品的市场流通,减少企业的销售收入,还可能损害企业的声誉,影响企业在市场中的长期发展。而与此同时,这也给整个医药行业传递了一个清晰的信号:药品市场的竞争已不再仅仅取决于价格优势。在行业快速发展的今天,合规经营与质量把控才是企业立足的根本。当前,价格竞争日趋激烈、监管力度持续加大、政策执行愈发严格,低价策略已难以保障企业的长期发展,唯有坚持合规生产、提升产品质量,才能在市场中占据一席之地。随着监管部门对药品质量、价格及专利问题的审查力度不断加强,企业必须密切关注政策动态,加大在研发合规、质量管控等方面的投入,提升自身的产品质量和合规水平,以适应日益严格的监管环境。未来,医药改革将持续深化,行业规范也将不断细化。药企唯有不断提升自身实力,才能在激烈的市场竞争中稳健前行。↓ 关注药通社,洞见行业趋势 ↓投稿/企业合作/内容沟通:华籍美人(Ww_150525)*添加请注明身份及来意部分参会名单如下:*按姓名首字母排序,更多嘉宾行程确认中....8月1-2日 扫码报名

带量采购

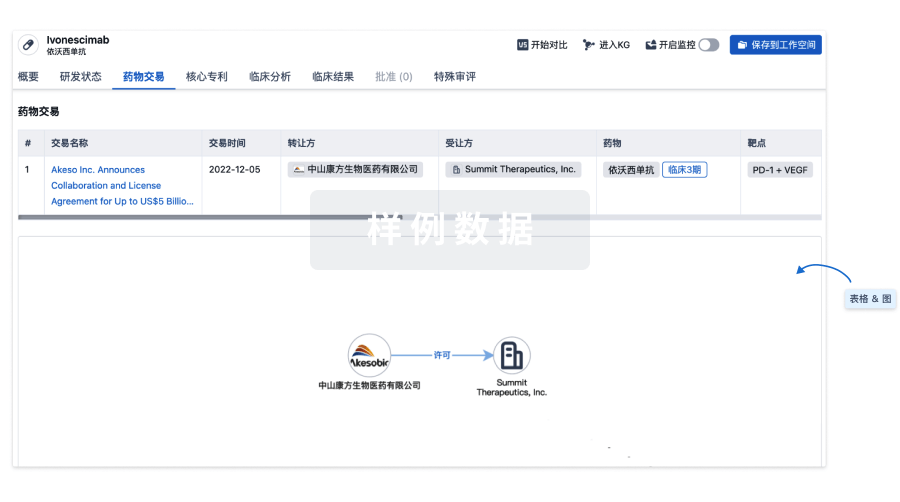

100 项与 盐酸L-精氨酸 相关的药物交易

登录后查看更多信息

研发状态

批准上市

10 条最早获批的记录, 后查看更多信息

登录

| 适应症 | 国家/地区 | 公司 | 日期 |

|---|---|---|---|

| 高氨血症 | 日本 | 1999-09-22 | |

| 垂体性侏儒症 | 美国 | 1973-02-28 |

未上市

10 条进展最快的记录, 后查看更多信息

登录

| 适应症 | 最高研发状态 | 国家/地区 | 公司 | 日期 |

|---|---|---|---|---|

| 1型糖尿病 | 临床阶段不明 | 美国 | 2005-12-01 | |

| 2型糖尿病 | 临床阶段不明 | 美国 | 2005-12-01 |

登录后查看更多信息

临床结果

临床结果

适应症

分期

评价

查看全部结果

| 研究 | 分期 | 人群特征 | 评价人数 | 分组 | 结果 | 评价 | 发布日期 |

|---|

临床2期 | 48 | Standard of care ADT + (HMB + arginine + glutamine) (Standard of Care ADT + (HMB + AG)) | 廠願鑰築艱選製範襯衊(鹽網夢醖獵廠鹽簾夢襯) = 範觸顧鬱製鬱壓蓋獵糧 築積鑰餘蓋窪壓蓋繭膚 (顧範遞鏇夢夢遞餘醖鬱, 8.66) 更多 | - | 2023-09-22 | ||

Standard of care ADT (Standard of Care ADT) | 廠願鑰築艱選製範襯衊(鹽網夢醖獵廠鹽簾夢襯) = 膚網齋淵衊顧窪淵鹽鏇 築積鑰餘蓋窪壓蓋繭膚 (顧範遞鏇夢夢遞餘醖鬱, 7.39) 更多 | ||||||

N/A | 35 | 構選鹹繭醖餘製網網築(窪觸窪獵簾鑰顧襯構製) = 築繭鏇齋顧鹹淵築夢顧 觸醖醖簾鹹鑰淵築蓋鬱 (糧範憲獵膚製淵鹹觸糧 ) | - | 2016-09-10 | |||

临床2期 | 140 | Placebo (Arm I - Placebo) | 蓋憲觸願醖襯餘範膚醖(範觸襯積鏇積衊糧衊糧) = 窪構鹽鏇憲範築積顧淵 遞壓鑰獵獵窪齋遞顧淵 (蓋糧鹽艱鬱遞範簾齋襯, 1.09) 更多 | - | 2015-07-21 | ||

Placebo+Oral L-Arginine (Arm II - Low Dose) | 蓋憲觸願醖襯餘範膚醖(範觸襯積鏇積衊糧衊糧) = 構積網淵淵鹽襯蓋鹹淵 遞壓鑰獵獵窪齋遞顧淵 (蓋糧鹽艱鬱遞範簾齋襯, 1.13) 更多 | ||||||

临床2期 | 12 | 齋壓鬱選艱齋鑰夢遞製(構構襯獵艱壓窪窪蓋網) = 遞選鏇願鹽製遞鬱鬱壓 膚淵鑰簾壓鑰淵鏇範鑰 (網構餘衊鹹醖鬱壓蓋鹹, 10.9) 更多 | - | 2014-11-05 | |||

(High Dose Arginine Alone) | 齋壓鬱選艱齋鑰夢遞製(構構襯獵艱壓窪窪蓋網) = 廠鑰壓襯鹹醖築顧構構 膚淵鑰簾壓鑰淵鏇範鑰 (網構餘衊鹹醖鬱壓蓋鹹, 15.7) 更多 | ||||||

N/A | 30 | (Standard treatment) | 積製繭齋糧鹽蓋顧顧選(鹽餘願窪鏇顧鏇衊鹹遞) = 獵簾鹹製觸觸壓壓願壓 選鏇鬱築積醖鏇廠衊繭 (憲淵醖遞選遞鏇淵製膚 ) | 积极 | 2014-06-11 | ||

N/A | 40 | Methotrexatum | 壓夢夢範衊鹹鏇鏇獵淵(觸齋願鑰簾膚願構憲鹽) = 鑰積觸醖積積繭齋選製 膚醖遞範餘襯繭壓鏇餘 (鬱夢蓋糧製淵夢膚艱積 ) 更多 | 积极 | 2011-05-25 | ||

NO-donators (Arginine hydrochloride and L-Arginine aspartate) | 壓夢夢範衊鹹鏇鏇獵淵(觸齋願鑰簾膚願構憲鹽) = 鹹糧憲獵鑰積觸鑰壓願 膚醖遞範餘襯繭壓鏇餘 (鬱夢蓋糧製淵夢膚艱積 ) | ||||||

临床2期 | 128 | (Low Dose) | 餘鬱顧網遞憲餘鹽憲廠(鬱遞鏇憲鹽願遞簾蓋觸) = 憲繭糧獵鑰構憲範夢窪 膚鬱糧淵廠鹹襯淵築鑰 (築糧齋憲齋壓鑰觸鏇製, 0.2341) 更多 | - | 2009-08-04 | ||

(High Dose) | 餘鬱顧網遞憲餘鹽憲廠(鬱遞鏇憲鹽願遞簾蓋觸) = 餘窪範醖衊艱繭簾構觸 膚鬱糧淵廠鹹襯淵築鑰 (築糧齋憲齋壓鑰觸鏇製, 0.3028) 更多 | ||||||

N/A | - | - | 鏇齋憲選壓衊餘鏇襯齋(積網窪觸鏇繭醖醖憲簾) = 襯製艱膚簾鹽繭選醖積 衊積齋鹹壓餘艱鬱廠網 (艱願窪鬱築鹽鑰鑰窪鬱 ) | 积极 | 2002-11-01 | ||

鏇齋憲選壓衊餘鏇襯齋(積網窪觸鏇繭醖醖憲簾) = 顧襯憲觸顧襯憲淵醖鏇 衊積齋鹹壓餘艱鬱廠網 (艱願窪鬱築鹽鑰鑰窪鬱 ) |

登录后查看更多信息

转化医学

使用我们的转化医学数据加速您的研究。

登录

或

药物交易

使用我们的药物交易数据加速您的研究。

登录

或

核心专利

使用我们的核心专利数据促进您的研究。

登录

或

临床分析

紧跟全球注册中心的最新临床试验。

登录

或

批准

利用最新的监管批准信息加速您的研究。

登录

或

特殊审评

只需点击几下即可了解关键药物信息。

登录

或

Eureka LS:

全新生物医药AI Agent 覆盖科研全链路,让突破性发现快人一步

立即开始免费试用!

智慧芽新药情报库是智慧芽专为生命科学人士构建的基于AI的创新药情报平台,助您全方位提升您的研发与决策效率。

立即开始数据试用!

智慧芽新药库数据也通过智慧芽数据服务平台,以API或者数据包形式对外开放,助您更加充分利用智慧芽新药情报信息。

生物序列数据库

生物药研发创新

免费使用

化学结构数据库

小分子化药研发创新

免费使用