预约演示

更新于:2025-09-09

National Tsing-Hua University

更新于:2025-09-09

概览

标签

肿瘤

消化系统疾病

其他疾病

小分子化药

miRNA

化学药

疾病领域得分

一眼洞穿机构专注的疾病领域

暂无数据

技术平台

公司药物应用最多的技术

暂无数据

靶点

公司最常开发的靶点

暂无数据

| 排名前五的药物类型 | 数量 |

|---|---|

| 小分子化药 | 4 |

| miRNA | 1 |

| 化学药 | 1 |

| 酶 | 1 |

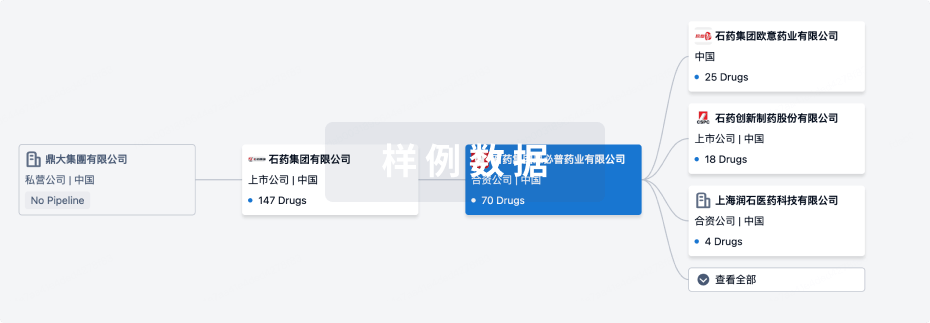

关联

7

项与 国立清华大学 相关的药物10

项与 国立清华大学 相关的临床试验NCT06157515

Inhaled Dose Analysis Using a Breath Actuated Nebulizer in Healthy Subjects

The goal of this crossover study is to compare urine drug concentrations using a continuous vibrating mesh nebulizer versus a breath-actuated vibrating mesh nebulizer in healthy volunteers. The main questions it aims to answer are:

* Whether breath-actuation nebulizer delivers higher inhaled drug dose, resulting in higher urine drug concentrations compared to continuous nebulization.

* Whether the different nebulizer modes deliver inhaled drug resulting in different effects on physiological parameters, including heart rate, respiratory rate, blood pressure, and blood oxygen saturation.

Participants will

* Inhale one dose (2.5mg) of salbutamol via continuous vs. breath-actuated nebulize mode.

* collect urine samples at multiple timepoints before and after nebulization to quantify drug elimination.

Researchers will compare the continuous and breath-actuated modes of vibrating mesh nebulizers to determine if breath-actuation improves drug delivery efficiency compared to continuous nebulization.

* Whether breath-actuation nebulizer delivers higher inhaled drug dose, resulting in higher urine drug concentrations compared to continuous nebulization.

* Whether the different nebulizer modes deliver inhaled drug resulting in different effects on physiological parameters, including heart rate, respiratory rate, blood pressure, and blood oxygen saturation.

Participants will

* Inhale one dose (2.5mg) of salbutamol via continuous vs. breath-actuated nebulize mode.

* collect urine samples at multiple timepoints before and after nebulization to quantify drug elimination.

Researchers will compare the continuous and breath-actuated modes of vibrating mesh nebulizers to determine if breath-actuation improves drug delivery efficiency compared to continuous nebulization.

开始日期2024-03-13 |

申办/合作机构  长庚大学 长庚大学 [+3] |

NCT06656741

Neurological Evidence of Diverse Self-Help Breathing Trainings with Virtual Reality and Bio-Feedback Assistance: an Extensive Exploration of EEG Markers

The goal of this research is to learn about the neuro-mechanism beneath breath training, mindfulness meditation, or periods of idleness. This research also focuses on the use of virtual reality (VR) and bio-feedback (BF) integrated assistance system in breath training, and seeks for the potential of generalizing breath training in public.

The main questions it aims to answer are:

Whether and how people's neuro-mechanism (indicated by EEG indexes) changes when they are performing different breath training techniques (i.e., mindful breathing, guided breathing, and breath counting).

Researchers will compare the neuro-markers when participants perform different styles of breath training.

Participants will:

* Participants will equip an EEG system, a VR headset, a respiratory belt, and a heartbeat sensor.

* Participants will perform resting state task, mindful breathing task, guided breath task, and breath counting task respectively.

* EEG activity, breath rate, reaction time, accuracy, and HRV will be recorded. Each session will last approximately two hours.

The main questions it aims to answer are:

Whether and how people's neuro-mechanism (indicated by EEG indexes) changes when they are performing different breath training techniques (i.e., mindful breathing, guided breathing, and breath counting).

Researchers will compare the neuro-markers when participants perform different styles of breath training.

Participants will:

* Participants will equip an EEG system, a VR headset, a respiratory belt, and a heartbeat sensor.

* Participants will perform resting state task, mindful breathing task, guided breath task, and breath counting task respectively.

* EEG activity, breath rate, reaction time, accuracy, and HRV will be recorded. Each session will last approximately two hours.

开始日期2021-05-11 |

申办/合作机构  国立清华大学 国立清华大学 [+1] |

NCT04248790

Design and Development of a Mobile App to Improve Adherence to Pre-exposure Prophylaxis in Men Who Have Sex With Men: A Pilot Study

This study is testing feasibility and acceptability of a theoretically based mobile application (app), UPrEPU, to increase adherence to pre-exposure prophylaxis (PrEP) among men who have sex with men (MSM) to prevent human immunodeficiency virus (HIV).

开始日期2020-05-25 |

申办/合作机构  国立成功大学 国立成功大学 [+3] |

100 项与 国立清华大学 相关的临床结果

登录后查看更多信息

0 项与 国立清华大学 相关的专利(医药)

登录后查看更多信息

26,502

项与 国立清华大学 相关的文献(医药)2026-02-01·BIOMATERIALS

Endogenous macrophages as "Trojan horses" for targeted oral delivery of mRNA-encoded cytokines in tumor microenvironment immunotherapy

Article

作者: Peng, Sheng-Yao ; Chang, Wan-An ; Guo, Jhih-Syuan ; Chen, Yin-Hsu ; Luo, Po-Kai ; Chang, Hsiao-Huang ; Wei, Hao-Chi ; Lai, Po-Liang ; Chuang, Ya-Han ; Nguyen, Lam-Duc-Huy ; Chu, Li-An ; Sung, Hsing-Wen ; Wang, Kuan-Lin

Macrophages (MΦ) in the tumor microenvironment (TME) are often skewed toward the M2 phenotype, which suppresses immune responses and supports tumor progression. Interferon-γ (IFN-γ) plays a pivotal role in reprogramming MΦ toward a pro-inflammatory M1-like phenotype, thereby enhancing anti-tumor immunity. This study introduces a targeted oral immunotherapy strategy using IFN-γ mRNA-loaded lipid nanoparticles conjugated with β-glucans (IFN-γ mRNA@βGlus-LNPs), evaluated in a mouse model of triple-negative breast cancer. Following oral administration, the nanoparticles target transcytotic M cells in Peyer's patches, are taken up by endogenous MΦ in intestinal lymphoid tissues, and transported via lymphatic and systemic circulation to the tumor site. In the TME, the nanoparticles induce transient, localized IFN-γ expression, reprogramming both infiltrating and resident MΦ toward an M1-like phenotype and activating cytotoxic T cell responses. By harnessing the natural tumor-homing ability and biocompatibility of MΦ, this "Trojan horse" approach offers a promising platform for effective, safe mRNA-based cancer immunotherapy.

2026-01-01·BIOMATERIALS

Polydopamine nanoparticle-enhanced stem cell spheroid-derived decellularized extracellular matrix with antioxidant and tissue-adhesive properties for brain repair

Article

作者: Huang, Chieh-Cheng ; Yang, Pei-Ching ; Liu, Shao-Wen ; Ho, Chia-Hsin ; Huang, Shih-Chen ; Chen, Linyi ; Chen, Grace H ; Kao, Ying-Chi ; Lee, Peng-Ying ; Lin, Yu-Ping

The use of implantable biomaterials has emerged as a promising therapeutic strategy for managing traumatic brain injury (TBI). We have previously demonstrated that mesenchymal stem cell (MSC) spheroid-derived three-dimensional decellularized extracellular matrix (3D dECM), enriched with stem cell secretome, serves as an effective biomaterial for promoting post-TBI brain repair. However, its limited antioxidant capacity and inadequate tissue adhesion remain significant challenges. To overcome these limitations, in the present study, we functionalized 3D dECM with polydopamine nanoparticles (PDANPs), renowned for their inherent antioxidant and adhesive properties, to enhance free radical scavenging and tissue adhesion. PDANP decoration imparted significant reactive oxygen/reactive nitrogen species-scavenging capacity to 3D dECM, thereby enhancing its neuroprotective potential and reducing oxidative stress-induced neuronal cell death in vitro. In a mouse TBI model, PDANP-decorated 3D dECM demonstrated robust adhesion to cortical tissues, effectively addressing post-TBI secondary injury by mitigating oxidative damage and suppressing neuroinflammation, ultimately promoting neuronal cell survival. The adhesive, antioxidant, and immunomodulatory properties together led to improved recovery of neurological function and reduced lesion volume in vivo. Overall, our findings highlight the potential of PDANP-decorated 3D dECM as a multifunctional and clinically translatable therapeutic platform for TBI management, while underscoring the adaptability of MSC spheroid-derived 3D dECM to be precisely tailored for diverse therapeutic applications.

2026-01-01·BIOMATERIALS

In situ incorporation of boronate into carbonized alginate nanogels for targeted inhibition of triple-negative breast cancer metastasis by inducing cytoskeletal disruption, cell growth arrest, and apoptosis

Article

作者: Sarkar, Saumyadip ; Hean, Li Er ; Tang, Yu ; Chou, C Perry ; Huang, Ruo-Yi ; Wang, Chen-Yow ; Shih, Ren-Hong ; Anand, Anisha ; Chen, Pin-Yuan ; Hsu, Pang-Hung ; Lin, Chin-Jung ; Chen, Shiow-Yi ; Unnikrishnan, Binesh ; Huang, Chih-Ching

Metastasis is the primary cause of cancer mortality, and its prevention is particularly challenging due to the complex tumor microenvironment. Carbon nanomaterials are well known to act as drug delivery systems for therapeutics. Nonetheless, their inherent capabilities in combating tumor cells remain underexplored. In this study, we report the synthesis and characterization of novel boronate-incorporated alginate carbon nanogels (Bor/Alg-CNGs) as promising anti-metastatic agents for effectively suppressing migration and invasion of triple-negative breast cancer (TNBC) cells, while triggering cell-cycle arrest. Notably, Bor/Alg-CNGs decreased cell viability of TNBC cells through disorganization of F-actin, a critical factor mediating cellular migration. In an in vivo study, Bor/Alg-CNGs reduced metastatic lung nodules in a tumor-induced mouse model by >85 %, compared to the untreated controls. Transcriptomics and proteomics analyses further validated the in vivo results with an in-depth understanding of the role of Bor/Alg-CNGs in the stress response of reactive oxygen species-induced cells and downregulation of the phosphatidylinositol 3-kinase/protein kinase B (PI3K/Akt) signaling pathway, leading to metabolic breakdown, cell growth arrest, and apoptosis. These findings underscore the potent anti-metastatic properties of Bor/Alg-CNGs based on their multifunctional role in inhibiting cellular mechanisms essential for metastasis. Compared to many existing carbon nanomaterials, Bor/Alg-CNGs offer enhanced specificity and efficiency in targeting metastatic pathways. Their ability to target and disrupt metastatic processes while minimizing side effects holds the potential for development as a new class of anti-metastatic agents in cancer therapy, warranting further mechanistic and clinical investigations to realize their full therapeutic potential.

9

项与 国立清华大学 相关的新闻(医药)2025-03-10

In our recent Nitinol Knowledge webinar with Ming Wu, the retired Edwards Lifesciences SVP of engineering, we had more questions from our audience than we could answer at the time.

But we promised we’d get back to everyone with answers to their nitinol questions as soon as we could. With the on-demand replay now available for that free webinar, below are the questions we couldn’t get to and answers from Wu. (If you asked a question and don’t see it here, please check your email, because in some cases we followed up privately.)

If you haven’t watched our webinar presentation and don’t know who Wu is, he joined the structural heart device developer and manufacturer as VP of engineering in 2006 and retired in 2023. Before Edwards, he was at Memry Corp. for two decades, where he rose from director of engineering and chief metallurgist to VP of technology. Wu has three degrees in materials science and engineering from National Tsing Hua University (bachelor of science) and the University of Illinois Urbana-Champaign (master of science degree and a Ph.D.).

Nitinol basics: What is nitinol and where is it used?

The following has been lightly edited for space and clarity.

When you decided to use nitinol from a different supplier, were there any tests that could be conducted on the nitinol itself to predict whether it would be a good fit before conducting a feasibility test on the actual product?

The first step is to ensure the alternate source meets the material specification. One could also perform testing on transformation temperatures (in both fully annealed condition and final shape-set device condition) and mechanical properties to ensure reasonable equivalency to those of the original material. Depending on the stage of product development cycle, design verification tests may need to be repeated with change of material sourcing.

Would medtech benefit from nitinol standardization in industry, and how would you do it?

Over the last several decades, the ASTM F04 Committee has already developed several standard specifications and test methods for nitinol for medical device applications. However, these specifications tend to be fairly open to accommodate different grades of materials from all suppliers. There is room to be more specific on some attributes, such as cleanliness and inclusion, for high-risk implantable device applications. There are also opportunities to develop better guidance on fatigue testing, structural durability risk analysis and finite element analysis for nitinol implantable medical devices.

Regarding the metallurgy of nitinol, is the R-phase a stable phase or is it a metastable phase? How does it impact a medical implant?

R-phase is a stable phase below its transformation temperature. Similar to martensitic transformation, R-phase can be stress-induced at temperatures above its transformation temperature. When stress-induced R-phase occurs during the elastic deformation (before stress-induced martensite that give rise to the superelastic plateau in the stress-strain curve), the elasticity will appear to be softened, i.e., the “effective modulus” is reduced due to the presence of stress-induced R-phase transformation.

Save the date: The MDO Min-Vasive Medtech webinar series returns in August 2025

How does the precipitate phase contribute to superelasticity? Specifically, does the reduction in transformation stress due to precipitation enhance superelasticity? At the same time, since precipitates are generally considered nontransformable, do they reduce the overall recovery capability of the alloy?

In most heat-treated conditions of superelastic nitinol in medical devices, the nickel-rich precipitate is on the nanometer scale, which is much smaller than that of the martensite. Hence, the precipitate phase has minimal effects on superelasticity. However, the precipitation does eventually enrich the titanium concentration in the matrix and raises R-phase and martensitic transformation temperatures.

Is there a reliable way to remove or prevent R-phase? Is R-phase more common in certain types of ingot (VIM versus VAR)?

Adding ternary alloying elements such as copper, gold, platinum or palladium can eliminate R-phase transformation. For superelastic binary nitinol, the only way to remove R-phase is to fully anneal the material. However, fully annealing significantly compromises mechanical properties and makes the alloy less useful for medical device applications.

R-phase is not an issue in device design. Superelastic binary nitinol can be heat treated properly to impart desirable mechanical properties for the application regardless of the R-phase.

The melting process, whether vacuum induction melting (VIM) or vacuum arc melting (VAR), does not affect the R-phase transformation.

How do you view the development of single crystal nitinol and nickel-free analogues to nitinol?

In theory, a single-crystal nitinol could exhibit multiple stage superelasticity with recoverable strain going way beyond 6% when deformed along certain crystal orientations. The challenge is in the development of a viable single crystal growth and subsequent fabrication process.

There were multiple studies on nickel-free superelastic compositions. These studies were mostly focusing on beta titanium alloys such as TiNb-X, TiV-X and TiMo-X series of compositions. These alloys require solution treatment at relatively high temperatures to impart superelastic properties. The resulting superelastic plateau strain was around 3%, far less than the 6% in nitinol. Heat treating these beta titanium alloys at intermediate temperatures (as a potential shape-setting process) could introduce omega phase precipitation which causes embrittlement.

What is a clear overview and step-by-step guide for designing a stent-like endovascular device? I am finding it difficult to create a robust framework and would appreciate a structured approach to understand and guide the design process effectively.

Conceptualize design based on design inputs and functional requirements.

Iterate design in finite element (FEA) simulations by applying possible deformation modes of anatomical interactions to ensure the worst-case in-vivo deformation is within the constant life of material fatigue durability.

Collaborate with delivery system (DS) R&D to ensure the structure can be loaded and deployed with reliable DS-device interface.

Seek manufacturing feedback to ensure the device can be manufactured with stable processes.

Repeat FEA to finalize design.

Run animal studies and critical pre-DV (design verification) testing including full device DFM (dynamic failure mode) tests to ensure the device meets design intent and that any failure occurs at load and locations consistent with the FEA simulation and material fatigue constant life.

Start design verification testing.

Is it possible for the Medtronic Evolut platform and the Abbott Navitor platform to have the same radial force given the difference in valve cells/amount of scaffolding?

It is possible only if cell design and amount of scaffold are allowed to be modified. If not, the only two options are 1) adjust strut thickness and 2) modify heat treat condition. Both options have limited room to manipulate the radial force.

Any guidance on how to develop good compression data for a tube or wire sample?

Compression tests of small diameter tubes and wires are quite challenging. Large diameter specimens (> 5 mm) would be more practical. Make sure to keep the aspect ratio (height/diameter) low and deform to a small strain before buckling or barreling starts to develop.

How many cycles of loading would you consider “run-out” for nitinol?

There is no run-out in nitinol fatigue. It is critical to run sufficient tests to the required life cycle and analyze survival and failure distributions.

Which acid is good for nitinol oxide removal?

Hydrofluoric and nitric acid solution, or hydrochloric and sulfuric acid solution.

We are currently implanting a nitinol valve with 0° austenite finish (Af) temperature. In order to ease the crimp difficulty, the crimp is performed inside an ice bath. We are exploring a small increase in Af temperature in the future, but meanwhile we want to know the effect of crimping in room temperature on the recoil after deploy (clearly yes) and its implications over the material’s endurance properties.

Crimping at room temperature compared to an ice bath would likely induce a higher permanent set. In any case, the device will experience 37° C in its crimped state as it goes through the delivery procedure inside the cardiovascular system. The temperature difference between the body temperature and the Af temperature is another factor that will contribute to permanent set.

The implication on the material’s endurance properties will depend on the orientation of the residual stress. Compressive residual stress induced by tension deformation in crimped state may help in prolonging fatigue endurance. Tensile residual stress induced by compressive deformation in the crimped state may negatively influence the fatigue endurance.

Are R-phase transformations not usually introduced in the constitutive models in FE simulation?

R-phase transformation is generally not included in the FEA constitutive model. However, a good FEA practice should include mechanical testing of specimens that are representative of the final device at body temperature. The test results should then be used to construct the FEA constitutive model.

How do you minimize burrs while milling nitinol?

Proper selection of lubricant, and optimize feeding and cutting speed.

Are there differences right now for review of nitinol devices in the U.S. versus the EU?

FDA has specific guidance for the nonclinical assessment of medical devices containing nitinol.

For high-risk implantable devices such as TAVR, FDA requires 600 million cycles structural fatigue durability assessment, while the EU requires 400 million durability analysis

In EU, regulatory review is going through notifying bodies, such as TUV, DEKRA, etc. Current EU MDR requires documentation on the RoHS (restriction of hazardous substances) compliance.

Visit the Medical Design & Outsourcing Nitinol Hub for more nitinol know-how.

临床结果高管变更

2024-10-22

·药智网

10月7日,2024年诺贝尔生理学或医学奖颁布给了Victor Ambros和Gary Ruvkun两位科学家,以表彰其发现了microRNA(简称miRNA)及其在转录后基因调控中的作用,并阐明了控制基因活动的基本原则。

图片来源:诺贝尔生理学或医学奖委员会

虽然,在此之前,大众对诺贝尔医学奖的猜测大多集中于glp-1等产业应用较广泛的领域,但其实miRNA无论是学术意义,还是现阶段的产业落地速度,都并不逊色于前者,而诺贝尔官方将医学奖颁给miRNA或许某种程度上也不失为对未来作为创新疗法的潜力认可。

那么,miRNA究竟是何方神圣,目前全球产业界的布局又推进至何种程度了呢?

获奖实至名归

miRNA参与人类1/3的基因调节

其实,在过去很长一段时间里,人们一直遵循的都是由佛朗西斯·克里克1958年提出的中心法则,即遗传信息必须从DNA传递给RNA,再从RNA传递给蛋白质,再由蛋白质执行各种生命功能。

而随着科学家对人类基因的探索愈发深入,人们却逐渐意识到RNA原来可以分为两种:一种是参与编码蛋白质的编码RNA,仅占全部RNA的2%左右;另一种则是不参与编码蛋白质的非编码RNA,占全部RNA的98%,而miRNA正是“非编码RNA”的主要代表之一。

miRNA在翻译过程中的作用不同于大多数同类,其主要执行的是监督、调节编码RNA与效应蛋白的作用,可以将其想象成工地里的“施工员”,几乎参与了所有的生物学功能,以至于人类近1/3的基因均由miRNA进行调节。

而也正是因此,miRNA在近20年里一直都是科学界的研究热点,期间全球各大期刊发布了不低于18万篇相关的科学研究文章,仅就连国内与之相关的研究论文也多达2万余篇,充分彰显了这个“新大陆”的辽阔与前景。

堪比siRNA

miRNA趋势性同样明显

众所周知,在新药蓬勃发展的今天,小核酸药物被认为是将带来“除小分子药和抗体药之外的第三次制药浪潮”的关键,而对于目前的小核酸药物开发,目前主要的思路有三种:

可以针对细胞内的mRNA、非编码RNA(ncRNA)等,沉默抑制该基因的表达,以影响最终蛋白的表达,即RNA干扰疗法。

对于由蛋白缺乏导致的疾病,也可引入上调目标基因的表达,通过saRNA实现。

直接引入mRNA表达新的所需的蛋白,比如大家熟悉mRNA疫苗(所以说是子集) 。

其中,RNA干扰疗法是目前小核酸领域最受关注的存在,而其中除了熟知的siRNA外,miRNA也是该疗法中的主要构成之一。

只不过siRNA的研究进度更为靠前,其在抑制效率已足够优秀的情况下,miRNA就显得没那么亮眼了。但其实,miRNA与siRNA两者在很多方面均存在着较明显的差异点:

表1. siRNA与miRNA的主要区别点

分类

siRNA

miRNA

体内作用

RNA干扰

RNA干扰

序列长度

21-23nt

19-25nt

结构

双链RNA

单链RNA

互补程度

完全互补

部分互补

来源

人工体外合成

内源

Dicer酶加工过程

对称加工

不对称加工

作用位置

任何部位

靶标基因3′-UTR区

作用方式

下调

上调+下调

靶标RNA数量

一对一

一对多

数据来源:公开数据来源

其中,miRNA对比siRNA在功能上的特定优势主要有三点,分别是:

可同时靶向多个基因,miRNA对序列的匹配要求不高,不需要像siRNA那样完全与目标基因匹配,因此原则上可以结合并抑制多种靶mRNA,以此形成庞大而复杂的调控网络。

靶点选择广泛,miRNA非编码RNA的特性导致其在靶点选择比ASO等疗法范围更广,理论上可治疗的疾病也更多。

多样化的调节方式,与单纯降低基因表达的siRNA不同,miRNA既可以下调也可以上调mRNA的表达水平。

因此,miRNA在原理上的成药空间并不低,只是受限于相关研究的不足,以及产业界对miRNA的认知不足,其领域内的发展速度较siRNA更为缓慢,但随着miRNA的基础研究水平上升,其与多种疾病的关联性被确定,未来其在肿瘤、心血管疾病、代谢性疾病(如糖尿病等)、免疫疾病、神经类疾病、传染病等领域,都有着极大的应用空间。

甚至已有不少创新Biotech企业开始布局。

三足鼎立

miRNA海外格局初成

虽然,原则上miRNA的发现时间不长,目前也并无任何一款相关新药上市,但其产业化落地速度却是极快,尤其是海外领域。

其中,基于miRNA的诊断方法应用最广泛,比如将miRNA用于肿瘤转移、肿瘤恶性程度,或肿瘤的早期诊断就是目前miRNA最被看重的板块,此外,循环miRNA也可以用于心血管疾病、肾病和神经退行性疾病的诊断等等。

排除miRNA在疾病诊断方面的广泛应用,如肿瘤转移、肿瘤恶性程度与肿瘤的早期诊断等,在miRNA作为药物治疗靶点方面,目前已有不少突破性进展,如利用基因编辑技术针对 miRNA 治疗疾病,目前已有多种经过临床试验的 miRNA 分子靶向药物面世。

统计miRNA领域全球在研新药,目前共有92项miRNA疗法在研,虽其中绝大部分管线尚处于临床前阶段,但仍有7款创新疗法率先进入临床,且初步展现出一定的临床优势,其中:

Causeway针对肱骨外上髁炎的CWT-001研究进展最快,已推进至临床II期。

Apic Bio的APB-102、UniQure的AMT-260与AMT-130目前已进入临床I/II期。

InteRNA针对实体瘤的INT-1B3处于临床I期。

JBT-miR2与APB-101处于临床申请阶段。

表2. 全球部分临床阶段的“miRNA”疗法(点击查看大图)

数据来源:公开数据来源

而其中,Causeway、Apic Bio与UniQure作为现阶段miRNA领域的技术三巨头,几乎占据了该领域绝大多数的技术推进力,未来也大概率将是MNC推进相关产业合作的首选。

miRNA先驱:UniQure

UniQure于1998年在荷兰成立,其致力于治愈性基因疗法在肝脏代谢、中枢神经系统和心血管领域的开发应用,是基因治疗领域的先行者,同样也是miRNA领域的技术龙头之一。

目前,该企业全球员工超400人,经历多轮融资之后,已于美国纳斯达克成功上市,并且在资金与人才的双重助力之下,成功建立了独有的两大技术核心平台。

其中miQURETM技术是UniQure专有的下一代基因沉默平台,旨在降解致病基因,而不产生脱靶毒性,并通过继发性外泌体介导的递送诱导整个靶器官的沉默。

使用该技术设计的基因治疗候选药物结合了专有的治疗性miRNA,并通过AAV递送,能够提供持久的活性。在临床上展现出众多优势,如组织特异性的增强、细胞核基因的改善、未产生与miRNA或mRNA相关的不良影响等。

目前,UniQure共有5条miRNA相关管线,其中AMT-260与AMT-130的临床推进最为迅速,目前已进入了临床Ⅰ/Ⅱ期,是UniQure最核心的临床管线之一。

表3. UniQure共有5条miRNA相关管线

药品成分

研发机构

全球最高状态

全球适应症在研状态

疾病领域

项目最新进展时间

项目最新进展

AMT-260

UniQure biopharma,Corlieve Therapeutics

临床I/II期

临床I/II期: 颞叶癫痫发作

神经系统疾病

2023年11月15日

NCT06063850开始招募

AMT-130

UniQure biopharma

临床I/II期

临床I/II期: 亨廷顿舞蹈病

神经系统疾病,罕见病

2024年10月3日

NCT04120493招募完成

AMT-240

UniQure biopharma

临床前

临床前: 阿尔兹海默病

神经系统疾病,精神障碍疾病

2021年12月21日

阿尔兹海默病临床前 (进行中)

AMT-161

UniQure biopharma

临床前

临床前: 肌萎缩侧索硬化症

罕见病,骨骼肌肉系统疾病,神经系统疾病

2023年5月18日

肌萎缩侧索硬化症

AMT 150

UniQure biopharma

临床前

临床前: 脊髓小脑性共济失调

神经系统疾病,罕见病

2021年12月21日

脊髓小脑性共济失调临床前 (进行中)

数据来源:公开数据来源

AMT-260,是2016年UniQure收购Corlieve所获得的项目资产。作为一种拟用于治疗颞叶癫痫的AAV基因疗法,其采用了miRNA沉默技术来靶向抑制颞叶癫痫(TLE)患者海马体中异常表达的kainate受体,能有效地减少了皮质神经元中GluK2的表达。

在临床前数据显示,AMT-260能有效降低癫痫样活性和过度扩张,阻断患者异常放电。目前其关于内侧颞叶癫痫适应症的II期试验正在进行,计划将于2026年完成主要临床数据的收集。

AMT-130,是UniQure利用了其专有的miQURETM沉默技术设计的,由microRNA和载体AAV5组成,递送入脑后能够抑制突变亨廷顿蛋白的产生。

在一项AMT-130治疗亨廷顿舞蹈症I/II期临床试验低剂量队列中,AMT-130耐受性良好,未发生与AMT-130相关的严重不良事件,且MRI成像未显示任何具有临床意义的安全性信号。后续12月随访中,接受AMT-130治疗的患者在12个月时脑脊液中的神经丝轻链(NfL)接近基线,相较于对照组有较好改善。

miRNA黑马:Causeway

从数据上看,Causeway是现阶段全球领域miRNA疗法研究推进最快的企业之一,作为一家2017才成立的biotech企业,其致力于开发新型microRNA疗法,专注于常见的肌肉骨骼和年龄相关疾病,并始终相信miRNA疗法几乎有无限的治愈潜力。

其认为,递送是miRNA靶向技术用于治疗的主要障碍。虽然,肝脏是寡核苷酸疗法能够可靠递送的唯一器官。然而,一个值得注意的例外是局部递送,其拥有用药量小、有限的系统吸收、更高安全性与更低的商业化成本等诸多优势,这也是为何Causeway会选择肌肉骨骼和年龄相关疾病的根本原因。

目前,该公司管线进展最快的是CWT-001(临床Ⅱ期),是一种化学合成的microRNA-29a(miR29a)模拟物,针对肌腱病,在之前一项针对网球肘患者进行的1b期临床试验中,替诺米似乎安全且耐受性良好;一项具有疗效终点(肘关节功能、疼痛和肌腱再生)的多中心2期研究已于2023年夏季开始招募。

图片来源:Causeway官网

另外,据其公司官网数据显示,其miRNA管线中还有针对骨关节炎、皮肤老化的OsteoMiR与DermaMiR,有望继CWT-001之后,迅速进入临床阶段。

miRNA大拿:Apic Bio

Apic Bio是一家创新型基因治疗公司,致力于推动罕见病的基因疗法发展。2017年由麻省大学医学院(UMMS)衍生而来,并于之后几年连续获得多次融资。

Apic Bio主打方向为腺相关病毒(AAV)基因疗法,核心管线主要有APB-102与APB-101等多款创新疗法,而在miRNA领域,现阶段Apic共有四款创新疗法涉及,其中APB-102推进最快,目前已处于临床Ⅰ/Ⅱ期,APB-101正处于临床申请阶段,CNS disease与APB-105则尚处于临床前阶段。

表4. 腺相关病毒(AAV)基因疗法

药品成分

研发机构

全球最高状态

全球适应症在研状态

疾病领域

项目最新进展时间

项目最新进展

APB-102

Apic Bio,UniQure biopharma

临床I/II期

临床I/II期: 肌萎缩侧索硬化症

罕见病,骨骼肌肉系统疾病,神经系统疾病

2024年08月1日

NCT06100276首例入组

APB-101

Apic Bio,UMass Chan Medical School(大学)

申请临床

申请临床: α-1抗胰蛋白酶缺乏症

消化系统疾病,呼吸系统疾病,罕见病

2021年12月2日

α-1抗胰蛋白酶缺乏症临床研究 (申请中)

CNS disease(Apic Bio)

Apic Bio

临床前

临床前: 中枢神经系统疾病

神经系统疾病

2021年12月2日

中枢神经系统疾病临床前 (进行中)

APB-105

Apic Bio

临床前

临床前: 肌萎缩侧索硬化症

罕见病,骨骼肌肉系统疾病,神经系统疾病

2021年12月2日

肌萎缩侧索硬化症临床前 (进行中)

数据来源:公开数据来源

作为Apic的 主打产品,APB-102是一款针对遗传性肌萎缩侧索硬化症(SOD1-ALS)的基因疗法,由重组AAVrh10载体表达组成,该载体表达微核糖核酸(miRNA),miRNA旨在敲低SOD1的表达,减缓或逆转有SOD1突变的患者的ALS进展。临床前概念性研究已经证明APB-102可抑制突变SOD1基因活性。

在SOD1-ALS小鼠模型的临床前研究表明,APB-102大大提高了患病小鼠的生存率。在啮齿类动物和非人灵长类动物中,在建议的临床剂量下,脊髓运动神经元的SOD1也有相关减少。APB-102已于2021年4月获批临床,并先后获得 FDA 的孤儿药和快速通道指定,Apic Bio预计将在今年下半年启动相关临床Ⅰ/Ⅱ期试验。

2023年1月23日,Apic Bio与UniQure达成合作,后者引进了Apic的APB-102,并成功获得了该药的开发和商业化权利。

继续观望

国内miRNA落地尚需时日

相较于国外,国内miRNA赛道发展相对更慢,布局企业主要的方向还主要集中于诊断方向,如觅瑞集团致力于miRNA及其他非编码RNA作为生物标志物的诊断产品创新及临床转化等。

至于miRNA治疗领域方面,国内现阶段相关管线基本尚处于临床前阶段,且绝大多数相关疗法均为国内大学、研究机构发起的研究,企业对该领域的兴趣存在较大的缺失,导致国内相关临床管线推进相对缓慢。

而如此差异的根本原因,主要是海内外新药研究的格局不同所致,就目前而言,国内新药产业仍多以fast follow为主,对于miRNA之类在海外没有明确临床数据验证的情况下,国内短期内的兴趣不会有所提升,也很难看到新玩家的加入。

表5.国内部分“miRNA疗法”涉及管线

药品成分

靶点

研发机构

全球最高状态

全球适应症在研状态

T-155

(云海生物)

miR-155

成都云海四面体生物科技有限公司,四川大学(大学)

临床前

临床前: 脉络膜新生血管,免疫系统疾病

miR-22

(云海生物)

miR-22

成都云海四面体生物科技有限公司,四川大学(大学)

临床前

临床前: 视神经疾病

miR-200c

(复旦)

HSPA9

复旦大学(大学)

临床前

临床前: 卵巢上皮癌

miR-708

NRAS

国立清华大学(大学)

临床前

临床前: 肿瘤

ARVN601

-

极目生物有限公司

临床前

临床前: 青光眼

AAV9-hSMN1-dual-amiR(纽欧申)

SOD1

纽欧申医药(上海)有限公司

临床前

临床前: 肌萎缩侧索硬化症

AAV therapy to treat C9orf72 HRE-caused ALS(纽欧申)

C9orf72

纽欧申医药(上海)有限公司

临床前

临床前: 肌萎缩侧索硬化症

T-155

(云海生物)

miR-155

成都云海四面体生物科技有限公司,四川大学(大学)

临床前

临床前: 脉络膜新生血管,免疫系统疾病

miR-22

(云海生物)

miR-22

成都云海四面体生物科技有限公司,四川大学(大学)

临床前

临床前: 视神经疾病

miR-200c

(复旦)

HSPA9

复旦大学(大学)

临床前

临床前: 卵巢上皮癌

miR-708

NRAS

国立清华大学(大学)

临床前

临床前: 肿瘤

ARVN601

-

极目生物有限公司

临床前

临床前: 青光眼

AAV9-hSMN1-dual-amiR(纽欧申)

SOD1

纽欧申医药(上海)有限公司

临床前

临床前: 肌萎缩侧索硬化症

AAV therapy to treat C9orf72 HRE-caused ALS(纽欧申)

C9orf72

纽欧申医药(上海)有限公司

临床前

临床前: 肌萎缩侧索硬化症

数据来源:公开数据来源

或许,在大多数国内企业看来,现阶段入局miRNA风险过大,无论是成药性,还是商业化可能都还存在较大的局限性,短期内很难看到较为明显的投资回报,与其不断试错,不如继续观望来得更稳健一点。

小结

显而易见,miRNA虽有诺奖加持,且也基本符合核酸药物引领产业变革的大势,但就目前而言,我们对其的了解仍相对早期,miRNA要成功走向产业化,仍有诸多研究与开发上的挑战。

在研究层面,疾病机制的突破、关键工艺合成技术、递送技术的革新、序列设计与优化、工艺工程放大等问题仍需全球各界一同努力。

在商业化层面,要想将该疗法推进至全球,单纯靠创新biotech企业明显不现实,过程中一定需要MNC与全球各地本土企业的加入。

只有兼顾成药性与商业化趋势之后,miRNA才算是迈出了成功的第一步。在不久的将来才有希望成为精准医疗领域的后起之秀,在小核酸领域绽放光芒,为医药产业带来一场全新的革命。

来源 | 博药(药智网获取授权转载)

撰稿 | 弎

责任编辑 | 八角

声明:本文系药智网转载内容,图片、文字版权归原作者所有,转载目的在于传递更多信息,并不代表本平台观点。如涉及作品内容、版权和其它问题,请在本平台留言,我们将在第一时间删除。

商务合作 | 王存星 19922864877(同微信)

阅读原文,是受欢迎的文章哦

疫苗siRNA信使RNA核酸药物临床1期

2024-01-30

Nanoclusters (NCs) of transition metals like cobalt or nickel have widespread applications in drug delivery and water purification, with smaller NCs exhibiting improved functionalities. Downsizing NCs is, however, usually challenging. Now, scientists have demonstrated functional NC formation with atomic-scale precision. They successfully grew cobalt NCs on flat copper surfaces using molecular arrays as traps. This breakthrough paves the way for advancements like single-atom catalysis and spintronics miniaturization.

Nanoclusters (NCs) are crystalline materials that typically exist on the nanometer (10-9 m) scale. They are composed of atoms or molecules in combination with metals like cobalt, nickel, iron, and platinum, and have found several interesting applications across diverse fields, including drug delivery, catalysis, and water purification. A reduction in the size of NCs can unlock additional potential, allowing for processes such as single-atom catalysis. In this context, the coordination of organic molecules with individual transition-metal atoms shows promise for further advancement in this field.

An innovative approach to further reduce the size of NCs involves introducing metal atoms into self-assembled monolayer films on flat surfaces. However, it is crucial to exercise caution in ensuring that the arrangement of metal atoms on these surfaces does not disrupt the ordered nature of these monolayer films. Now, in a recent study featured in the Journal of Materials Chemistry C, Dr. Toyo Kazu Yamada from the Graduate School of Engineering at Chiba University, along with Masaki Horie from the Department of Chemical Engineering at National Tsing Hua University, Satoshi Kera from the Institute for Molecular Science, and Peter Krüger also from the Graduate School of Engineering at Chiba University, have showcased the surface growth of cobalt atoms on molecular ring arrays at room temperature.

Talking to us about this advancement. Dr. Yamada says, "This advanced method of functional nanocluster formation with atomic-scale precision can be utilized in the development of highly efficient catalysts or in quantum computing."

In the study, the team used ring-shaped molecular structures called "crown ethers," which contain benzene and bromine rings. These structures were used to trap and grow cobalt NCs on flat copper surfaces. The resulting cobalt NCs were of two sizes, 1.5 nm and 3.6 nm. To understand their properties and structure further, various techniques were employed, including low-temperature scanning tunneling microscopy and spectroscopy (STM and STS), angle-resolved photoelectron spectroscopy (ARPES) with low energy electron diffraction (LEED), and density functional theory (DFT) calculations.

The analysis revealed the formation of stable surface sites to which the cobalt atoms could attach. In addition, the formation of these stable surface sites was found to be influenced by the electronic hybridization (mixing) between the crown ethers and cobalt. Once the cobalt atom was trapped, it acted like a nucleation center, attracting other cobalt atoms to form an NC. Additionally, unlike the usual behavior of crown ether molecules in solution, these molecules did not trap the metal atom at the center of the crown ring. Instead, the metal atom was at the edge, because of the presence of bromine atoms at that location. Discussing the long-term potential of these findings, Dr. Yamada says, "The use of this approach in applications such as single-atom catalysis, miniaturization of spintronics media, and quantum computing will contribute to the development of an information-based society in a way that reduces carbon dioxide (CO2) production."

In summary, the team successfully demonstrated the growth of cobalt NCs by exploiting the trapping potential of two-dimensional crown ether molecules on a copper surface. The chemical behavior of the crown ether molecules deviated from typical interactions observed in solution, by trapping cobalt atoms at the edge, and not the center. Importantly, the method demonstrated effective and large-scale production of NCs with well-defined size and morphology at room temperature.

100 项与 国立清华大学 相关的药物交易

登录后查看更多信息

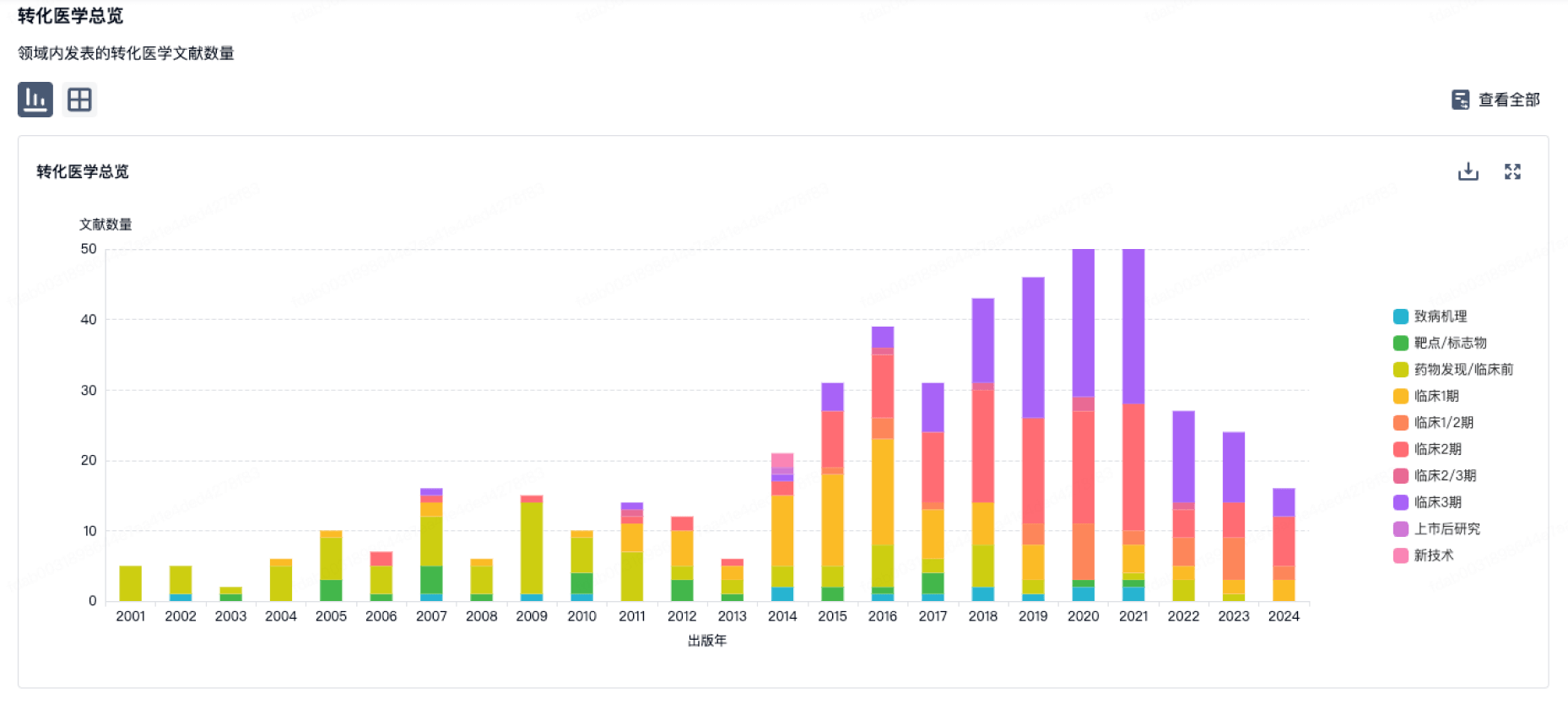

100 项与 国立清华大学 相关的转化医学

登录后查看更多信息

组织架构

使用我们的机构树数据加速您的研究。

登录

或

管线布局

2025年11月05日管线快照

管线布局中药物为当前组织机构及其子机构作为药物机构进行统计,早期临床1期并入临床1期,临床1/2期并入临床2期,临床2/3期并入临床3期

药物发现

2

5

临床前

其他

1

登录后查看更多信息

当前项目

| 药物(靶点) | 适应症 | 全球最高研发状态 |

|---|---|---|

Compound 12(National Tsing Hua University) ( PANX1 ) | 炎症性肠病 更多 | 临床前 |

Withangulatin A ( PHGDH ) | 肿瘤 更多 | 临床前 |

Lanzyme | 肿瘤 更多 | 临床前 |

Peroxynitrite-Activation of Probe 1(National Tsing Hua University) ( CAs ) | 肿瘤 更多 | 临床前 |

miR-708 ( NRAS ) | 肿瘤 更多 | 临床前 |

登录后查看更多信息

药物交易

使用我们的药物交易数据加速您的研究。

登录

或

转化医学

使用我们的转化医学数据加速您的研究。

登录

或

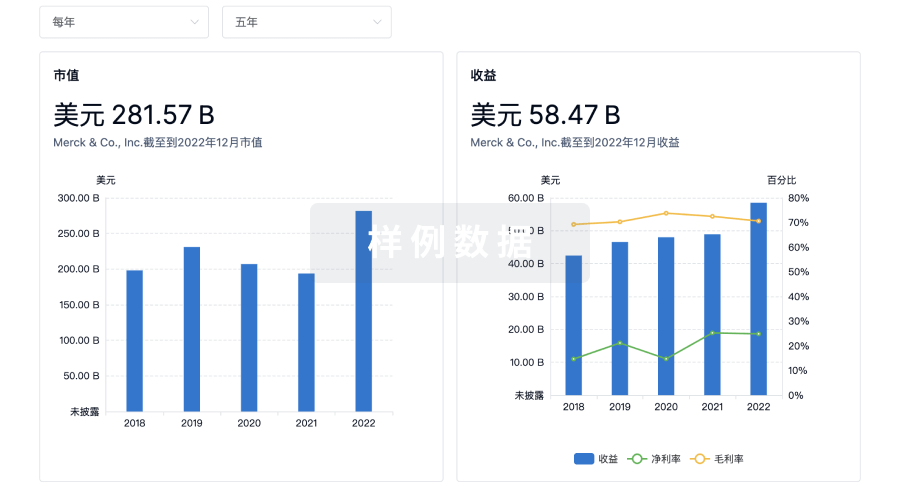

营收

使用 Synapse 探索超过 36 万个组织的财务状况。

登录

或

科研基金(NIH)

访问超过 200 万项资助和基金信息,以提升您的研究之旅。

登录

或

投资

深入了解从初创企业到成熟企业的最新公司投资动态。

登录

或

融资

发掘融资趋势以验证和推进您的投资机会。

登录

或

生物医药百科问答

全新生物医药AI Agent 覆盖科研全链路,让突破性发现快人一步

立即开始免费试用!

智慧芽新药情报库是智慧芽专为生命科学人士构建的基于AI的创新药情报平台,助您全方位提升您的研发与决策效率。

立即开始数据试用!

智慧芽新药库数据也通过智慧芽数据服务平台,以API或者数据包形式对外开放,助您更加充分利用智慧芽新药情报信息。

生物序列数据库

生物药研发创新

免费使用

化学结构数据库

小分子化药研发创新

免费使用