预约演示

更新于:2025-08-29

Hunan University

更新于:2025-08-29

概览

标签

肿瘤

神经系统疾病

其他疾病

小分子化药

重组多肽

合成多肽

疾病领域得分

一眼洞穿机构专注的疾病领域

暂无数据

技术平台

公司药物应用最多的技术

暂无数据

靶点

公司最常开发的靶点

暂无数据

| 排名前五的药物类型 | 数量 |

|---|---|

| 小分子化药 | 8 |

| 重组多肽 | 3 |

| 合成多肽 | 2 |

| 适配体 | 1 |

| 化学药 | 1 |

关联

20

项与 湖南大学 相关的药物作用机制 HSPH1调节剂 [+1] |

在研机构 |

原研机构 |

在研适应症 |

非在研适应症- |

最高研发阶段临床前 |

首次获批国家/地区- |

首次获批日期- |

1

项与 湖南大学 相关的临床试验NCT06366373

Reducing Stigma Through a Mental Health Art Exhibition and Its Printed Brochure: an Social-contact Intervention Study

Mental health art exhibitions, as an intervention strategy integrating artistic expression and social contact, have the potential to positively impact the elimination of stigma and discrimination associated with mental health problems. Based on a two-phase experimental design, this study aims to evaluate the effect of a real-world mental health art exhibition (Phase One) and its printed brochure (Phase Two) on stigma/discrimination and related outcomes, such as mental health literacy. The evaluation will encompass three categories of people: those with lived experience of mental disorders, family members and friends of those with lived experience, and the general public. Qualitative methods, such as in-depth interviews, will also be used for the evaluation.

开始日期2024-04-12 |

申办/合作机构  湖南大学 湖南大学 [+1] |

100 项与 湖南大学 相关的临床结果

登录后查看更多信息

0 项与 湖南大学 相关的专利(医药)

登录后查看更多信息

24,724

项与 湖南大学 相关的文献(医药)2026-01-01·TALANTA

An asymmetric double-strand displacement amplification strategy by a side-shifted hybrid chain reaction for the ultrasensitive detection of let-7a

Article

作者: Li, Hongbo ; Lai, Yiling ; Wang, Suqin ; Xu, Jun ; Yu, Ruqin

MicroRNA (miRNA) plays a crucial role in a great number of human cancers so that the detection of miRNA has been widely acknowledged as an effective strategy for the early discovery and diagnosis of cancer. Building upon conventional strand displacement amplification, the study was introduced a dual strand displacement process to enhance primer amplification efficiency. Additionally, we designed a lateral displacement assembly-based DNA nanostructure, expanding on traditional hairpin structures, and constructed a side-shifted hybrid chain reaction (SHCR) strategy for dual amplification of primer sequences. This approach yielded a three-way junction (3WJ) DNA nanostructure, providing optimal molecular recognition sites. The SHCR facilitated the assembly of fluorescent probes through a straightforward hybridization chain reaction. The target-triggered double strand displacement amplification (DSDA) exhibited high specificity for miRNA-let-7a with the rang from 50 fM to 50 nM, and the biosensor's limit of detection is 22 fM. Moreover, the sensor system performed exceptionally well in detecting real samples, such as cell lysates. Therefore, this work offers a novel strategy for early cancer screening.

2026-01-01·SPECTROCHIMICA ACTA PART A-MOLECULAR AND BIOMOLECULAR SPECTROSCOPY

Graphitic nanozyme for visual ascorbic acid sensing in commercial beverages

Article

作者: Wang, Shen ; Li, Shengkai ; Sun, Xiaoyuan ; Gui, Guofeng

Ascorbic acid (AA), an essential micronutrient that cannot be endogenously synthesized in humans, plays vital roles in various physiological processes and must be obtained through dietary intake. However, AA is prone to oxidative degradation during food processing, storage, and transportation, leading to significant loss of its bioactivity. These factors underscore the critical need for developing simple, rapid, and accurate methods for AA quantification in food products. Recently, nanozyme-mediated colorimetric sensing has emerged as a promising approach for AA detection, combining the advantages of nanozymes (including cost-effectiveness, high catalytic activity, excellent stability, and scalable production) with the simplicity of colorimetric analysis that enables equipment-free visual detection. Most nanozymes demonstrate optimal catalytic activity exclusively under acidic conditions, while simultaneously exhibiting poor stability in such environments. To address this limitation, we developed an ultra-stable peroxidase (POD)-like CoPt graphitic nanozyme (CoPt@G) through a one-pot chemical vapor deposition (CVD) method and constructed a robust colorimetric AA detection platform. The proposed biosensor exhibits a linear range of 5-60 μM and the detection limit (S/N = 3) of 1.4 μM, with results comparable to most of the related works. Additionally, the proposed sensor demonstrates good selectivity and promising practical application potential for AA detection in commercial beverages. This study develops a simple, rapid visual AA detection method, offering valuable guidance for scientifically informed dietary decisions.

2026-01-01·TALANTA

Merocyanine-based near-infrared molecular rotor for monitoring viscosity changes in living cells

Article

作者: Wang, Lingyan ; Wang, Fenglin ; Ding, Xu ; Bai, Hailin ; Jiang, Jianhui ; Peng, Zhihong ; Liu, Feng

Abnormal intracellular viscosity is closely associated with cellular dysfunctions and various diseases. The development of reliable tools for monitoring intracellular viscosity changes has garnered significant attention. Herein we designed a series of novel merocyanine-based molecular rotors featuring an electron acceptor-donor-acceptor (A-D-A) system for highly sensitive detection and imaging of viscosity in live cells. The molecular rotors with extended π-conjugated systems were engineered by introducing electron-withdrawing groups at the γ-position of trimethine merocyanines. It was demonstrated that all the fluorophores exhibited weak emission in aqueous media but showed highly sensitive responses to viscosity changes. Among them, the benzothiazolium acetonitrile-merocyanine fluorophore (BAMCy) represents the first merocyanine-derived molecular rotor capable of viscosity-specific detection with high signal-to-noise ratio (45-fold) in the near-infrared window. These outstanding properties enabled no-wash and specific imaging of viscosity changes in living cells under various stimulation conditions. Furthermore, using this probe, we observed an increase in cellular viscosity during ferroptosis process. This probe represents a valuable tool for investigating the physiological processes and pathological mechanisms underlying diseases related to intracellular viscosity.

49

项与 湖南大学 相关的新闻(医药)2025-08-10

·智药邦

蛋白质是生命活动的“分子机器”,而蛋白质之间的相互作用(PPIs)更是细胞运转的核心机制——从免疫反应到代谢调控,从疾病发生到药物研发,几乎所有生命过程都离不开PPIs的精密协作。然而,传统实验手段解析PPIs成本高、周期长,如何通过AI技术高效预测PPIs的类型和亲和力,一直是生物信息学领域的重大挑战。

近日,来自湖南大学曾湘祥团队携手腾讯生命科学实验室,延世大学,和阿里国际提出了一种名为LLaPA(Large Language and Protein Assistant)的多模态大语言模型,为破解这一难题提供了全新方案。该模型不仅在蛋白质相互作用预测任务中刷新了当前最优性能,更解决了传统方法难以处理未知蛋白质、多蛋白质复合物的痛点。该工作已经正式发表在ACL 2025。

现有方法的三大局限性

过去几年,深度学习技术已广泛应用于PPIs预测,但现有方法始终存在三大局限:

一是过度简化任务难度。传统基于PPI网络的模型(如GNN-PPI)在训练和测试时,会保留测试集中蛋白质对的连接信息,相当于“提前剧透”了待预测的相互作用关系。但现实中,蛋白质间的连接信息需要大量实验验证才能获得,这种“作弊式”预测在实际场景中根本行不通。

二是对“新面孔”蛋白质束手无策。当遇到未出现在已知PPI网络中的“未知蛋白质” 时,传统模型无法利用网络拓扑信息,就像失去导航的船,预测准确度大幅下降。

三是无法处理“多人协作”。许多关键生物过程依赖多蛋白质复合物(如抗原-抗体复合物由3条链组成),但传统模型架构固定,只能处理两个蛋白质的相互作用,面对更多蛋白质时便“力不从心”。

图(a)(b)(c)现有方法将测试蛋白对之间的连接信息输入到了图编码器,导致预测任务被过度简化;(d)(e)(f)移除这些连接信息之后许多蛋白质在网络中变成孤立结点,无法从PPI网络中获得有效信息,这些孤立蛋白质也等同于“未知蛋白质”。

LLaPA:让大语言模型学会“解读”蛋白质网络

LLaPA的核心创新在于将蛋白质序列、PPI网络拓扑信息与大语言模型(LLM)深度融合,通过三大关键设计突破传统局限:

图LLaPA的模型架构。

1.把PPI网络变成“可查询的知识库”

LLaPA创造性地将PPI网络视为“外部知识”,通过检索增强生成(RAG)技术,像查字典一样调用网络信息。例如,当预测两个蛋白质的相互作用时,模型会自动从PPI网络中提取它们的拓扑特征(如邻居蛋白质、连接模式),并将这些信息转化为自然语言提示输入给LLM,让模型结合蛋白质序列和网络背景综合判断。

2.给“未知蛋白质”找个“参照物”

针对未知蛋白质,LLaPA借鉴了生物学中“多序列比对”的思路:为未知蛋白质匹配 PPI网络中序列相似的“近亲”,用“近亲”的拓扑信息作为替代。比如,若一个新蛋白质与网络中某已知蛋白质的序列相似度达90%,就借用已知蛋白质的网络关系辅助预测,大幅提升对未知蛋白质的处理能力。

3.构建更全面的“蛋白质社交网络”

团队还整合了STRING、PDBBind、SAbDab三大数据库,构建出包含26180个独特蛋白质、594216条相互作用的“统一PPI网络(UPPIN)”。这个更庞大、更多样的 “社交网络”,让模型能接触到更丰富的蛋白质“人际关系”,进一步提升泛化能力。

性能大比拼:刷新多项任务最优记录

在严格的实验验证中,LLaPA展现出碾压性优势:

表1 LlaPA在多分类蛋白质蛋白质相互关系预测上的性能。

在多标签PPI类型预测任务中,面对SHS27k和SHS148k两个权威数据集,无论采用随机、DFS还是BFS数据划分方法,LLaPA的预测精度(micro-F1)均远超DPPI、PIPR等传统方法。尤其在更接近真实场景的DFS和BFS划分下(含大量未知蛋白质对),LLaPA的性能领先第二名多达12个百分点。

在多蛋白质亲和力预测任务中,针对包含2到16个蛋白质的复合物,LLaPA在 PDB2020数据集上的平均绝对误差(MAE)和皮尔逊相关系数(PCC)均优于专用模型。即使面对6个蛋白质组成的复杂复合物,其预测精度仍能保持稳定,而传统模型只能处理2个蛋白质的简单情况。

消融实验进一步证明:UPPIN网络的引入能使性能提升26%,而蛋白质与网络信息的对齐机制可额外提升3%,充分验证了各模块的有效性。

未来展望:从“预测”到“理解”生命机制

LLaPA的突破不仅限于PPIs预测。凭借大语言模型的灵活性,它还能通过自然语言指令处理多种蛋白质任务——例如输入“预测这三个蛋白质的结合强度”,模型就能直接返回结果。这种“懂生物+懂语言”的能力,为生物学家提供了更直观的研究工具。

当然,LLaPA目前仍有局限:无法处理需要氨基酸级信息的任务(如结合位点预测),且对已有大量文献的知名蛋白质,尚未充分利用文本信息。但随着更大规模PPI网络的构建和多模态能力的深化,未来的蛋白质大模型有望从“预测相互作用”升级为“理解生命机制”,为疾病机理研究和新药研发开辟全新路径。

论文地址:

https://aclanthology.org/2025.acl-long.554.pdf

--------- End ---------

感兴趣的读者,可以添加小邦微信加入读者实名讨论微信群。添加时请主动注明姓名-企业-职位/岗位或姓名-学校-职务/研究方向。

孤儿药

2025-08-09

如何精确指挥细胞执行特定任务,是合成生物学发展的关键挑战。近日,中国科学院深圳先进技术研究院(简称“深圳先进院”)陈业团队联合湖南省农业科学院单杨院士团队在基因线路设计领域取得重要突破,他们建立了一套全新的生物信号处理框架,能够精准“解码”细胞感知的复杂信号。该研究成果以A Framework for Complex Signal Processing via Synthetic Biological Operational Amplifiers 为题,发表于Nature Communications。该研究的核心是建立了一个可拓展的、解决复杂信号处理问题的通用基因线路解决方案,并成功设计出生物学“运算放大器”(OA)作为实现该框架的物理载体,为解决多维信号调控难题提供了创新的工程化思路。

挑战:工程目标与细胞本能的矛盾

生物在亿万年的演化中,发展出了一套精密复杂的信号感知与响应系统。细胞能够同时感知环境中多种信号(如营养、温度、种群密度),并将这些信号整合、互作,从而做出最有利于自身生存的复杂决策。这种信号的复杂性和相互作用,对于生物适应多变的环境至关重要,是其生存智慧的重要体现。

然而,当研究人员尝试将细胞改造为“细胞工厂”或“传感器”以执行特定的生产或识别任务时,这种天然的复杂性反而可能成为障碍。对于工程化目标而言,信号间的相互干扰(串扰)和不可预测的互作,会严重影响基因线路的稳定性、调控精度和后续信号强化,使得细胞无法精准地执行人工设计的程序。

突破:从“编码”到“解码”的信号处理新框架

为解决这一核心矛盾,陈业团队从模拟电子电路的核心组件——运算放大器(OA)中获得启发,创新性地提出了一套全新的解决方案。团队首先建立了一个通用信号“解码”框架,将细胞感知复杂环境并调整自身基因表达的过程视为一个 “编码”过程——细胞将多种输入信号“编码”成一个混合的、非正交的响应信号。而该工作通过运算放大器实现的信号处理方案,则扮演了“解码器”的角色。可对细胞生成的混合信号进行精确线性运算,将其“解码”为多个相互正交的干净信号,从而让工程师能够清晰地理解细胞状态,并施以精准、有效的下游调控。

图1 运算放大器设计和应用示意图

应用验证:无诱导剂的动态调控与高维信号分解

该框架的强大功能在两项关键应用中得到了验证:

1. 实现了无诱导剂的动态调控:在生物制造中,团队利用该框架,使大肠杆菌能够“智能”地感知自身所处的生长阶段(如指数期或平台期),并自主切换基因表达模式——在成长期专注生长,在生产期高效合成目标产物(如莽草酸)。整个过程无需添加昂贵诱导剂,实现了过程自动化和生产高效化。

图3 无诱导剂的动态调控

2. 实现了高维信号分解:面对三种常见的细菌群体感应(QS)信号相互“串扰”的复杂情况(包括受体蛋白和DNA识别序列两类串扰),该框架成功将三维混合信号分解并消除串扰,实现了三个清晰独立的正交输出。这充分证明了该框架在处理多维、高复杂度信号系统中的强大能力。

未来展望

这项研究建立的信号处理框架,为合成生物学领域提供了一个强大的底层技术。它通过“解码”细胞的内在状态,使得对复杂生物系统的精准、可预测调控成为可能。这一基础性突破不仅为解决当前生物制造中的诸多瓶颈问题提供了新思路,也为未来设计更加智能、鲁棒的“细胞计算机”,应用于医药健康、环境治理和可持续能源等领域铺平了道路。

深圳先进院陈业研究员、湖南省农业科学院单杨院士以及深圳先进院博士后刘莉莉为本文的通讯作者。深圳先进院与湖南大学联合培养博士生操文军、深圳先进院博士后刘莉莉为本文共同第一作者。

原文链接:

https://www-nature-com.libproxy1.nus.edu.sg/articles/s41467-025-62464-9

制版人: 十一

学术合作组织

(*排名不分先后)

战略合作伙伴

(*排名不分先后)

·

转载须知

【非原创文章】本文著作权归文章作者所有,欢迎个人转发分享,未经作者的允许禁止转载,作者拥有所有法定权利,违者必究。

BioArt

Med

Plants

人才招聘

近期直播推荐

点击主页推荐活动

关注更多最新活动!

核酸药物

2025-08-06

编辑 | 萝卜皮

近年来深度生成模型的进步,使得科学家可以相对精准地设计靶向难成药位点的治疗性肽,但是却低估了蛋白质相互作用(PPI)中分子表面的关键影响——就像找到了锁芯却忽略了开门的正确角度,这极大阻碍了治疗性肽的设计与发现。

为了弥补这一差距,分子之心许锦波团队、斯坦福大学Jure Leskovec团队联合湖南大学曾湘祥教授团队合作提出了一种全设计肽生成范例,称为 SurfFlow,这是一种基于表面的新型生成算法,可以对肽的序列、结构和表面进行全面的共同设计。

SurfFlow 采用多模态条件流匹配 (CFM) 架构来学习表面几何形状和生化特性的分布,从而提高肽结合的准确性。

在全面的 PepMerge 基准测试中,SurfFlow 在所有指标上均始终优于全原子基线。这些结果展现了在从头肽发现中考虑分子表面的优势,并展示了整合多种蛋白质模态以更有效地发现治疗性肽的潜力。

该研究的相关技术论文已被数据挖掘领域最具影响力的国际会议KDD(ACM SIGKDD Conference on Knowledge Discovery and Data Mining,国际知识发现与数据挖掘大会)2025 收录。

研究背景

肽是由大约2至50个氨基酸组成的短链蛋白质,在各种生物过程中发挥着关键作用,包括细胞信号传导、酶催化和免疫反应。

肽是药理学中必不可少的介质,因为它们能够以高亲和力和特异性结合细胞表面受体,例如具有低毒性、低免疫原性且易于递送的细胞内效应。

传统的肽发现方法依赖于物理能量函数的频繁计算,但由于肽设计空间庞大,这种方法效率较低,因此推动了计算方法的快速发展。

近年来,在研究蛋白质-蛋白质相互作用(PPI)时,分子表面越来越受到关注,因为 PPI 很大程度上取决于相互作用蛋白质表面的互补性。表面的静电势和疏水性是决定 PPI 强度和特异性的关键因素,而其几何形状(例如突起、凹槽和裂缝)则能够实现特异性结合所必需的「锁钥」或「诱导契合」机制。

图示:有无表面约束的全原子肽设计的比较。(来源:论文)

这些表面充当着决定蛋白质如何相互识别和结合的基本界面。由于这些原因,在肽生成过程中同时考虑所有分子模式(序列、结构和表面)至关重要,从而增强所谓的全设计各个方面的一致性。

SurfFlow

为了实现这一目标,斯坦福大学及分子之心团队提出了一种名为 SurfFlow 的新型全设计生成算法。

它将多模态流匹配 (FM) 应用于内部结构和分子表面,这些结构和表面由表面点位置和单位范数向量表示,并作为 SE(3) 中的刚性框架。

由于仅靠互补的表面几何形状并不能保证成功的结合——结合界面的精确性和电荷、极性和疏水性的放置也是必要的,因此 SurfFlow 将这些生物化学性质的约束纳入其中。

图示:SurfFlow 工作流程用于肽全方位设计,它考虑了生成过程中序列、结构和分子表面之间的多模态一致性。(来源:论文)

具体来说,它利用离散FM(DFM)来处理一些分类表面特征的离散数据空间,并使用连续时间马尔可夫链(CTMC)。

此外,考虑到以可扩展的方式捕捉不规则表面几何形状、多尺度特征和蛋白质间相互作用的挑战,研究人员提出了一种等变表面几何网络(ESGN),它可以动态地模拟异构表面图,同时独特地结合表面内和表面间的相互作用。

鉴于环状性和二硫键等关键肽属性会影响稳定性和结合亲和力,他们将这些因素作为附加条件,从而增强 SurfFlow 的容量和泛化能力。

性能评估

该团队全面评估了 SurfFlow 在非条件和条件序列结构协同设计任务以及侧链填充问题上的表现。为了进行基准测试,他们使用了源自 PepBDB 和 Q-BioLip 的 PepMerge 数据集。评估结果如以下图表所示,它在所有指标上均始终优于全原子基线。

表:评估序列结构协同设计任务中不同方法的优劣,并针对 SurfFlow 关键组件进行消融研究。最佳结果和次优结果以粗体和下划线标记。(来源:论文)

图示:设计和天然肽的结合能分布,越低越好。(来源:论文)

图示:通过 DL 算法和参考文献设计的肽(左);具有循环条件的肽设计。(右)。(来源:论文)

虽然 SurfFlow 机制在原有的全原子设计机制上有所改进,但仍有进一步探索的空间。例如,如果将受体表面信息纳入联合分布模型,可以期待进一步的优化。此外,RFDiffusion 的成功表明,在 PDB 中对常规蛋白质进行预训练是有益的。

尽管如此,SurfFlow 模型是一种能够同时生成所有蛋白质模态(序列、结构和表面)的新型模型。研究人员应用 SurfFlow 解决了一个特定的肽设计难题,并将循环性和二硫键等关键特征整合到生成过程中。

据说团队很快会上线 SurfFlow,感兴趣的朋友可以期待一下。

转载自ScienceAI公众号

参考资料

Fang Wu, Zhengyuan Zhou, Shuting Jin, Xiangxiang Zeng, Jure Leskovec, and Jinbo Xu. 2025. Surface-based Molecular Design with Multi-modal Flow Matching. In Proceedings of the 31st ACM SIGKDD Conference on Knowledge Discovery and Data Mining V.2 (KDD '25). Association for Computing Machinery, New York, NY, USA, 3192–3203.

https://doi-org.libproxy1.nus.edu.sg/10.1145/3711896.3737139

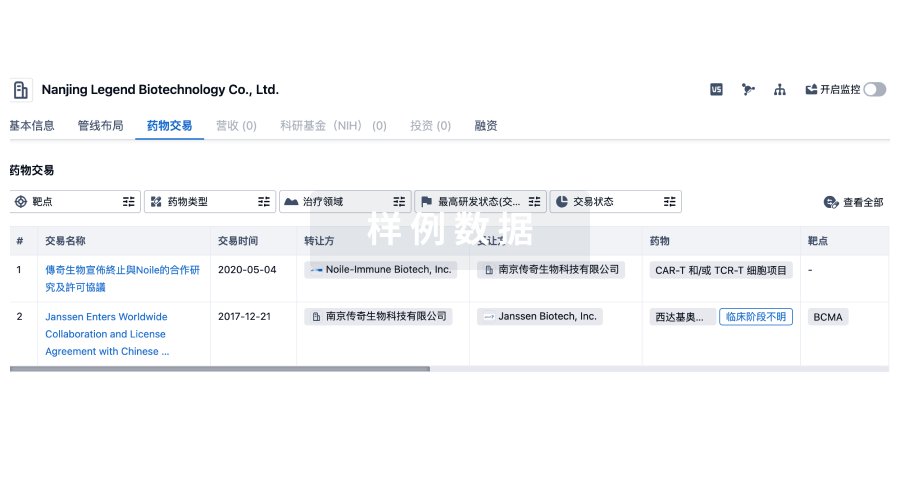

100 项与 湖南大学 相关的药物交易

登录后查看更多信息

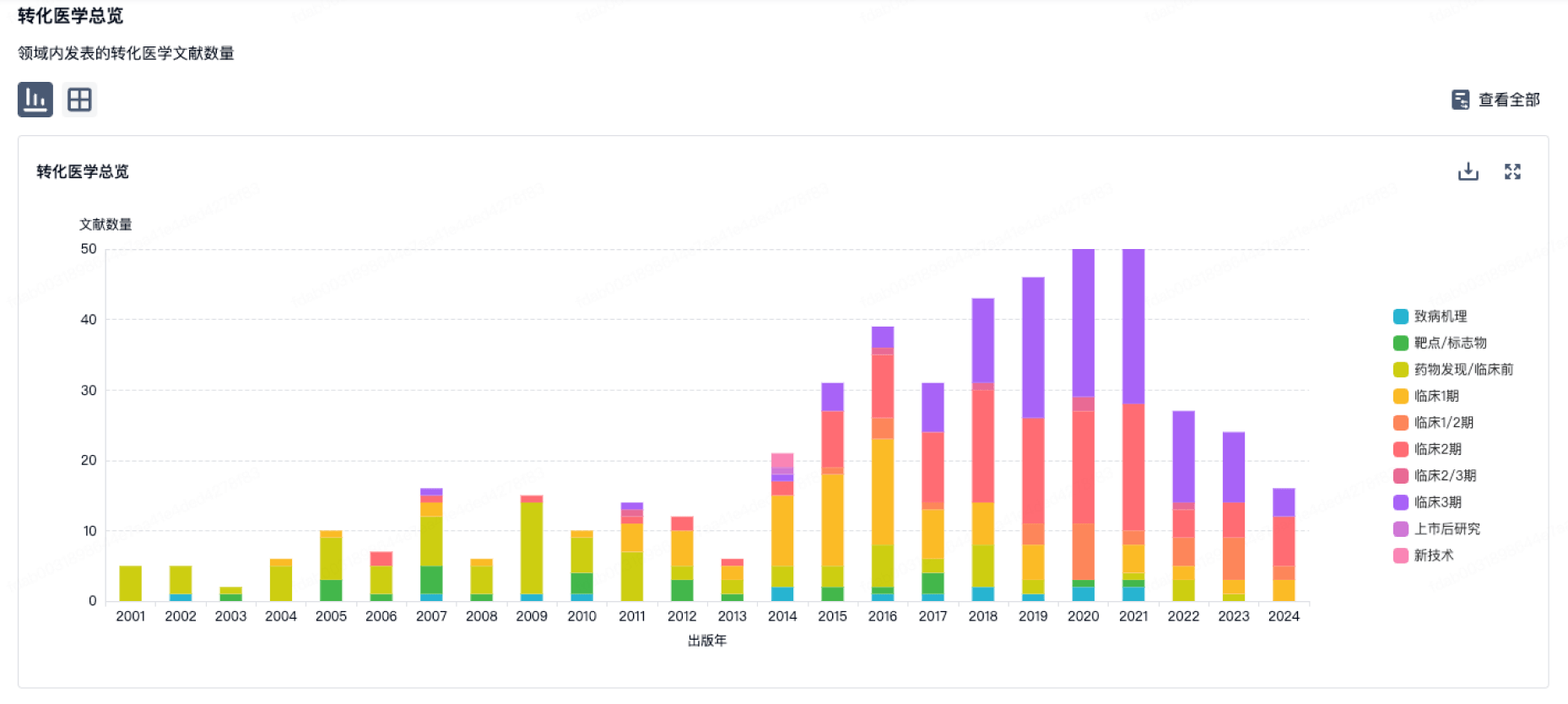

100 项与 湖南大学 相关的转化医学

登录后查看更多信息

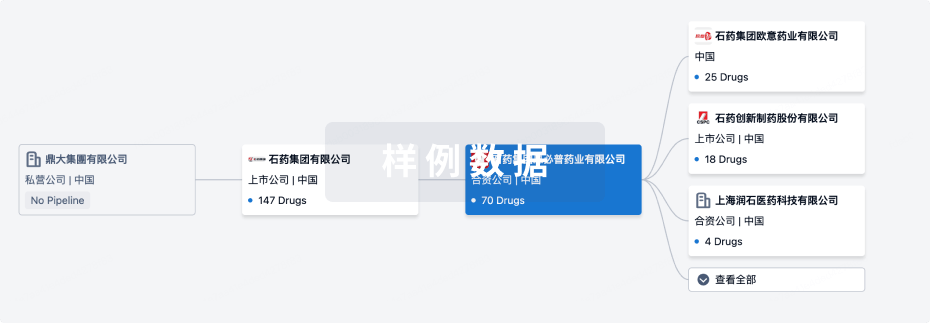

组织架构

使用我们的机构树数据加速您的研究。

登录

或

管线布局

2025年09月05日管线快照

管线布局中药物为当前组织机构及其子机构作为药物机构进行统计,早期临床1期并入临床1期,临床1/2期并入临床2期,临床2/3期并入临床3期

药物发现

13

7

临床前

其他

3

登录后查看更多信息

当前项目

| 药物(靶点) | 适应症 | 全球最高研发状态 |

|---|---|---|

Furamidine | 锥虫病 更多 | 临床前 |

iCDN(Hunan University) ( STING ) | 肿瘤 更多 | 临床前 |

Pyridine-bis(benzimidazole) ( G4 ) | 肿瘤 更多 | 临床前 |

aptamer d3(湖南大学) | 肿瘤 更多 | 临床前 |

ZL-216 ( NCL ) | 乳腺癌 更多 | 临床前 |

登录后查看更多信息

药物交易

使用我们的药物交易数据加速您的研究。

登录

或

转化医学

使用我们的转化医学数据加速您的研究。

登录

或

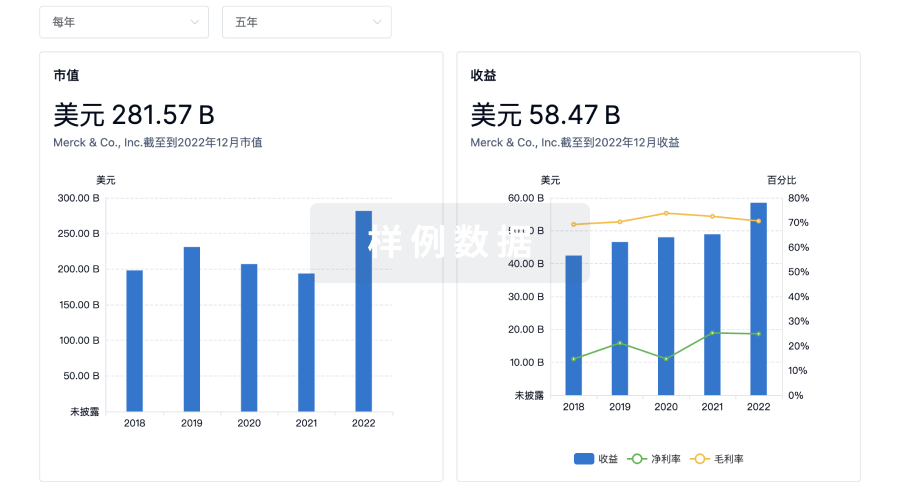

营收

使用 Synapse 探索超过 36 万个组织的财务状况。

登录

或

科研基金(NIH)

访问超过 200 万项资助和基金信息,以提升您的研究之旅。

登录

或

投资

深入了解从初创企业到成熟企业的最新公司投资动态。

登录

或

融资

发掘融资趋势以验证和推进您的投资机会。

登录

或

Eureka LS:

全新生物医药AI Agent 覆盖科研全链路,让突破性发现快人一步

立即开始免费试用!

智慧芽新药情报库是智慧芽专为生命科学人士构建的基于AI的创新药情报平台,助您全方位提升您的研发与决策效率。

立即开始数据试用!

智慧芽新药库数据也通过智慧芽数据服务平台,以API或者数据包形式对外开放,助您更加充分利用智慧芽新药情报信息。

生物序列数据库

生物药研发创新

免费使用

化学结构数据库

小分子化药研发创新

免费使用