预约演示

更新于:2025-08-29

Qingdao University

更新于:2025-08-29

概览

标签

神经系统疾病

肿瘤

其他疾病

小分子化药

合成多肽

mRNA

疾病领域得分

一眼洞穿机构专注的疾病领域

暂无数据

技术平台

公司药物应用最多的技术

暂无数据

靶点

公司最常开发的靶点

暂无数据

| 排名前五的药物类型 | 数量 |

|---|---|

| 小分子化药 | 15 |

| 合成多肽 | 4 |

| mRNA | 1 |

| 化学药 | 1 |

| 治疗性疫苗 | 1 |

关联

24

项与 青岛大学 相关的药物作用机制 BK channel激动剂 [+2] |

非在研适应症- |

最高研发阶段批准上市 |

首次获批国家/地区 中国 |

首次获批日期1993-01-01 |

靶点 |

作用机制 PDE4B抑制剂 |

最高研发阶段批准上市 |

首次获批国家/地区 意大利 |

首次获批日期1975-01-01 |

靶点- |

作用机制- |

非在研适应症- |

最高研发阶段批准上市 |

首次获批国家/地区- |

首次获批日期- |

72

项与 青岛大学 相关的临床试验ChiCTR2500096034

The Construction and Application Study of Salivary Intervention Plan Based on Symptom Management Theory for Parkinson's Disease Patients

开始日期2025-01-23 |

申办/合作机构 |

ChiCTR2400093643

A Study on the Application of Peer Education in Adolescent Sexual Health Education

开始日期2024-12-15 |

申办/合作机构 |

NCT06359977

The Effect of Quantitative Electroencephalography Combined With Ultrasound and Sputum Volume on Predicting Weaning Failure in Neurocritical Patients

Neurocritical patients often face the need for removal of endotracheal tubes. However, despite following the extubation criteria for general critical ill patients, neurocritical patients still exhibit a higher rate of weaning failure, significantly higher than that of general critical ill patients. The extubation criteria for general critical patients emphasize the assessment of lung conditions. However, neurological critical patients often have less severe lung damage, but factors such as consciousness level and coughing ability may significantly influence extubation. Quantitative EEG serves as an objective tool to reflect consciousness level status, while bedside ultrasound can assess respiratory muscle function. Additionally, sputum volume may reflect the condition of lung condition. Therefore, we believe that combination of these three indicators can better predict the success of extubation for neurocritical patients.

开始日期2024-04-15 |

申办/合作机构 |

100 项与 青岛大学 相关的临床结果

登录后查看更多信息

0 项与 青岛大学 相关的专利(医药)

登录后查看更多信息

18,651

项与 青岛大学 相关的文献(医药)2026-01-01·JOURNAL OF COLLOID AND INTERFACE SCIENCE

Remarkably improved electrochemical and safety performances of lithium-sulfur batteries via BaSO4@Ketjen black double-layer-modified separators

Article

作者: Zhang, Lianying ; Wu, Xiao ; Xia, Qingchao ; Jing, Maoxiang ; He, Qinggang ; Zhang, Qinghua ; Shen, Xiangqian ; Yuan, Weiyong

Ketjen black (KB) could be an ideal building block of the interlayer for modification of separators to greatly reduce the shuttling effect in lithium‑sulfur (Li-S) batteries, but it remains a formidable challenge to conformally and robustly coat them on the polyolefin separators. For the first time, a BaSO4@KB double-layer-modified polyethylene (PE) separator has been fabricated by uniformly depositing KB conductive carbon onto the PE separator via an intermediate layer of BaSO4 nanoparticles. The BaSO4 layer remarkably improves the mechanical properties of PE separator to effectively inhibit lithium dendrite formation and prevent separator puncture, and meanwhile effectively enhances the thermal stabilities of separator to reduce the risk of thermal runaway, thus greatly boosting the battery safety. The KB carbon layer, owing to KB's ultra-high specific surface area and branched nanochain structure, significantly enhances the binding with polysulfides and accelerates the charge transfer. The BaSO4@KB modified separator greatly improves the capacity and cyclability of Li-S batteries. When the sulfur loading of cathode is 3.0 mg cm-2, the initial discharge specific capacity of the cell with the modified separator reached 907 mAh g-1 at a current density of 0.5C. After 200 charge-discharge cycles, the remaining specific capacity was 772 mAh g-1, resulting in a capacity retention rate of 85.1 %. This work not only develops a novel high-performance carbon/ceramic double-layer-modified separator for practical Li-S battery applications, but offers scientific insights into the great effect of multifunctional separators on the performance enhancement of Li-S batteries.

2025-12-31·Journal of Maternal-Fetal & Neonatal Medicine

Risk factors for retinopathy of prematurity among preterm infants with bronchopulmonary dysplasia

Article

作者: Li, Lili ; Zhang, Xinkai ; Yu, Yu ; Liu, Dongyun ; Jiang, Yunhong ; Su, Linna ; Zhang, Haiyan

BACKGROUND:

This study was designed to investigate the risk factors for retinopathy of prematurity (ROP) among the preterm infants with bronchopulmonary dysplasia (BPD).

METHODS:

This retrospective study included 225 preterm infants with BPD who were admitted to our hospital between January 2016 and March 2022. These preterm infants were divided into ROP group and non-ROP group based on the presence of ROP. Logistic regression analysis was given to analyze the risk factors for ROP in the preterm infants with BPD. Spearman correlation analysis was performed to investigate the correlation between ROP severity and BPD.

RESULTS:

Logistic regression analysis indicated that noninvasive ventilation and oxygen therapy increased the risk of ROP among preterm infants with BPD. Low gestational age and low birth weight increased the risk of ROP among preterm infants with BPD. There was a positive correlation between severity of ROP and BPD.

CONCLUSIONS:

Low gestational age, low birth weight, noninvasive ventilation, oxygen therapy via mask and nasal catheter were risk factors for ROP among preterm infants with BPD.

2025-12-31·CANCER BIOLOGY & THERAPY

PINCH-1 promotes tumor growth and metastasis by enhancing DRP1-mediated mitochondrial fission in head and neck squamous cell carcinoma

Article

作者: Wang, Yaqi ; Song, Xicheng ; Tian, Ruxian ; Yuan, Ting ; Liu, Jiahui ; Li, Jiaxuan ; Song, Hao ; Li, Yumei

PURPOSE:

Abnormal expression of PINCH-1 has been observed in various types of human cancers. However, the clinical importance and mechanism underlying its role in head and neck squamous cell carcinoma (HNSCC) is yet to be fully elucidated.

METHODS:

This study evaluated the expression of PINCH-1 in HNSCC samples through immunohistochemical staining and Western blotting. AMC-HN-8, Cal27, and SCC7 cell lines were utilized for cellular function experiments, both in vivo and in vitro. CCK8, colony-formation assay, flow cytometry, wound-healing assay, and transwell assay were employed to investigate the effects of alterations in target proteins on the growth and metastasis of cancer cells. Mito-Tracker Deep Red FM was used to track mitochondrial morphology.

RESULTS:

PINCH-1 was found to be overexpressed in HNSCC and closely associated with lymph node metastasis and poor pathologic differentiation. Its upregulation promoted proliferation, inhibited apoptosis, and enhanced migration and invasion in HNSCC cells. It also promoted mitochondrial fission. We conducted a mechanism analysis, which showed that PINCH-1 knockdown inhibited mitochondrial fission by reducing the expression of DRP1. Furthermore, inhibition of mitochondrial fission could impede the proliferation and metastasis of HNSCC cells. Re-expression of DRP1 reversed the inhibitory effect of PINCH-1 knockdown on mitochondrial fission, cell proliferation, and metastasis in HNSCC cells.

CONCLUSIONS:

PINCH-1 plays a critical oncogenic role in HNSCC by enhancing DRP1-mediated mitochondrial fission, which may serve as a novel therapeutic target for HNSCC.

21

项与 青岛大学 相关的新闻(医药)2025-07-14

7月9日至11日,由中国环境诱变剂学会环境流行病学专业委员会、中国环境诱变剂学会生物标志物专业委员会、南京医科大学、贵州医科大学联合主办,环境污染与疾病监控教育部重点实验室(贵州医科大学)、贵州医科大学公共卫生与健康学院、贵州省环境诱变剂学会承办的中国环境诱变剂学会环境流行病学、生物标志物专委会联合学术会议暨第五届环境暴露与健康高端论坛在贵阳召开。来自国内外高等院校、科研单位、医疗与公共卫生机构从事环境与健康相关学科研究的专家、学者300余人参加。大会以“环境暴露与公众健康:风险防控、机制探索与创新实践”为主题,聚焦环境污染物、生物毒素、纳米材料等新兴环境诱变因素对人群健康的潜在威胁,围绕环境健康风险评估、环境流行病学大数据分析、分子生物学标志物筛选与验证等核心议题展开深入交流,为环境与健康领域的研究和实践注入新的活力与思路。大会开幕式上,校党委副书记、校长罗鹏教授对各位领导、专家、学者表示热烈欢迎和衷心感谢。他指出,本次会议是响应国家“健康中国”与“双碳”战略的生动实践,期待通过前沿报告与跨界对话,共同构筑更具韧性的健康安全屏障。他表示,贵州医科大学作为贵州省医学高等教育的重要基地,始终将“环境污染与疾病监控”作为公共卫生学科建设的核心方向,深耕地方性疾病防控、环境毒理机制与健康干预策略,希望与全球同仁一道分享贵州经验,共解环境健康治理难题。中国环境诱变剂学会理事长曹佳教授在致辞中表示,本次会议主题涉及环境科学、流行病学、毒理学、生物化学等多学科领域,有助于打破环境与健康各学科壁垒,实现资源共享、优势互补,为解决复杂的环境健康问题提供创新性方案。他指出,中国环境诱变剂学会将继续发挥学会平台优势,团结和带领广大环境与健康领域的科技工作者,积极投身于环境健康研究的伟大事业中,为守护公众健康、建设美丽中国贡献智慧和力量。会议主办方之一、南京医科大学副校长、贵州省卫生健康委副主任夏彦恺教授致辞并指出,本次会议内容围绕环境暴露组学、新型污染物毒理机制、生物标志物临床转化等国际学术前沿,探讨产学研协同创新的实现路径,推动构建面向未来的环境健康研究新范式。期待通过加强各领域之间的学术交流与务实合作,推动全球环境与健康研究迈向更高质量的发展。校党委委员、副校长洪峰教授主持开幕式及第一阶段大会主旨报告。大会主旨报告邀请了中国科学院生态环境研究中心江桂斌研究员、国家纳米科学中心陈春英研究员、陆军军医大学曹佳教授、青岛大学郑玉新教授、比利时安特卫普大学Adrian Covaci教授、贵州医科大学洪峰教授、中国疾病预防控制中心施小明研究员、新加坡南洋理工大学申小涛教授、武汉大学缪小平教授、重庆大学周舟教授、中国疾病预防控制中心李湉湉研究员,围绕新污染物暴露与健康效应、风险评估、生物监测及防控等核心方向展开深度探讨,分享了环境健康监测技术、风险预警模型及干预策略的创新进展,为跨学科、跨国界的学术交流搭建了高效平台,更对推动环境健康学科的理论创新、技术突破以及相关政策制定具有重要指导意义。会议设置了环境流行病学、生物标志物、环境暴露与健康三个专题分会场,31位专家学者聚焦新型污染物与健康结局、标志物筛选及转化、环境暴露健康风险评估技术革新等问题分享了前沿进展,为环境与健康领域理论深化和实践创新注入新动能。大会闭幕式上,中国环境诱变剂学会流行病学专委会主任委员阚海东教授、生物标志物专委会主任委员于典科教授作了总结发言。本次大会在热烈的学术氛围中圆满落幕,为环境与健康领域搭建了高水平交流平台,也进一步提升了我校在全国公共卫生与预防医学学科领域的学术影响力,是高水平公共卫生学院建设走深走实的具体体现。期待未来学界携手探索环境污染物暴露的深层机制、新型生物标志物的临床转化路径及跨区域健康风险协同防控策略,深化多学科交叉融合,推动科研成果向防控实践转化,为应对我国及全球环境健康挑战、守护人类生态与生命健康共同体贡献更多智慧与力量。来源:环境污染与疾病监控教育部重点实验室文字:马璐编辑:李菡逸一审:李牧二审:钱禾三审:陈颖往期回顾RECENTLY RELEASED祝贺!我校新增化学学科进入ESI全球前1%排名4个一等奖!我校学生作品在2025生物医学工程科普微视频大赛中获佳绩“金师”特辑·贵医非正式会谈黄静教授:培养有实践能力和创新精神的药学人贵州医科大学版权所有期待投稿合作邮箱:gmctougao@163.com

医药出海

2025-05-06

点击蓝字,关注我们编者按:日前,由中国临床肿瘤学会(CSCO)和北京市希思科临床肿瘤学研究基金会联合主办的2025 CSCO指南会在济南召开。此次会议作为肿瘤学界的重要学术盛会,汇聚了众多行业权威专家与前沿成果。会上,多部CSCO指南进行了发布,为肿瘤诊治注入了新的活力与规范。肿瘤瞭望特邀青岛大学附属医院王海波教授针对2025版CSCO BC指南早期乳腺癌新辅助治疗的更新内容、外科治疗领域乳腺癌患者的慢病化管理,以及资源受限地区如何兼顾指南标准化与患者个体化需求这一现实难题进行了观点分享。01肿瘤瞭望:请您从宏观角度介绍下,2025版CSCO BC指南早期乳腺癌新辅助治疗领域发生了哪些变化?王海波教授:2025版CSCO BC指南还是继续沿袭着分类、分型、分层的治疗推荐,我将按照分型进行介绍:激素受体阳性乳腺癌:新辅助化疗方面,此次更新还是以蒽环类化疗药物为主。并特别强调,对于需要术前新辅助治疗而又不适合化疗、暂时不适合手术或无须即刻手术,以及新辅助化疗不敏感或疗效欠佳的激素依赖型患者,可考虑新辅助内分泌治疗。当前,新辅助内分泌治疗还是以AI联合CDK4/6制剂为主,但新辅助内分泌治疗不能作为患者的主流治疗方案,应作为新辅助化疗的补充。HER2阳性乳腺癌:新辅助治疗方面,曲帕双靶联合化疗仍然是HER2阳性乳腺癌患者治疗的金标准。但基于HELEN-006临床研究及部分真实世界数据,I级推荐中,THP×6方案证据级别由2A调整为1A;随着小分子TKI吡咯替尼的数据增加,THP×4的证据级别不断下降:II级推荐中,THP×4方案与TH+吡咯替尼方案顺序调整。在指南更新前的专家投票中,我们也谈到了化疗是不是可以由双化疗减为单化疗,基于TCHP、THP等方案证据级别的提高及专家共识度指南进行了调整:原抗HER2联合紫杉的其他方案和科学合理的临床研究从II级推荐调整为III级推荐。三阴性乳腺癌:目前,三阴性乳腺癌患者的新辅助治疗仍然还是以化疗为主,TAC方案是目前新辅助化疗的主流方案。同时,指南中指出,适合新辅助治疗,同时无免疫治疗禁忌的患者,应优先考虑新辅助化疗+免疫治疗。基于KEYNOTE-522及CamRelief临床研究:TP-AC联合PD-1抑制剂成为唯一的I级推荐;基于国内外开展的NeoTENNIS,NeoPACT,cTRIO等多项II期临床研究:TP+PD-1抑制剂调整为II级推荐;基于现有的临床研究及专家共识推荐:III级推荐新增PD-1抑制剂联合紫杉类为基础的其他方案。02肿瘤瞭望:随着乳腺癌患者的生存期越来越长,乳腺癌进入到了“慢病化管理”时代,这一管理念对外科诊疗实践何影响?王海波教授:随着乳腺癌领域各类新理论、新药物、新技术的不断应用,患者生存期显著延长,生活质量大幅提高,乳腺癌确实已进入慢病化管理时代。慢病治疗体系需要政府与医疗机构携手合作,对疾病从筛查、诊断、治疗到后续随访康复的全过程进行精细化管理。就外科治疗而言,我们也相应作出了诸多调整。在技术层面,我们已从传统的改良根治手术发展到逐步向保乳手术过渡,并在保乳手术中融入了整形技术。此外,重建技术目前也在临床上得到了广泛应用,具体包括假体植入式重建、自体组织重建,以及自体组织联合假体植入重建等多种方式。针对局部晚期乳腺癌患者,我们还采用新辅助治疗策略。经过新辅助治疗降期后,在外科手术治疗方面,除了改良根治手术外,我们还可为患者提供保乳、重建等一系列治疗选择。在腋窝处理方面,我们现在能够通过前哨淋巴结活检技术,减少腋窝淋巴结清扫,从而降低患者上肢水肿的发生风险。另外,我们也在对部分患者进行精准筛选,即借助先进的诊断手段,探讨部分临床淋巴结阴性患者是否可以免于前哨淋巴结活检。当然,这一探讨仍在进行中。总体而言,我们外科医生正通过优化乳房与腋窝的局部处理措施,积极融入到乳腺癌患者的慢病化管理时代。03肿瘤瞭望:CSCO BC指南强调基于分子分型的分层、分类治疗策略,但临床实践中,不同层级医院的资源差异显著。您认为在资源受限地区,如何平衡指南的标准化要求与患者个体化需求?王海波教授:当前,CSCO BC指南的中国特色愈发显著。它以最新国际和国内数据为依据,结合临床专家共识,同时充分考虑了国内药物的可及性。在药物可及性方面,国产创新药物、仿制药以及自主研发药物越来越多地被纳入指南推荐。例如,2025版CSCO BC指南推荐中,基于中国原研药物和中国数据进行推荐的内容,已经超过了50%,这也就极大的解决了既往我们在临床中遇到的药物可及性的问题。此外,从某种程度上说,基层医生学习指南后,在治疗过程中能够使用相关治疗药物,也有助于缓解临床药物治疗的差异化问题。我们期望未来国内药企和新药研发公司,能推出更多原创药物和高质量仿制药物,为中国人乳腺癌的治疗贡献更多中国智慧与中国力量。王海波 教授医学博士 主任医师 博士研究生导师青岛大学附属医院乳腺病医院院长青岛大学附属医院乳腺病诊疗中心主任青岛大学实体肿瘤临床转化研究院院长中国临床肿瘤协会乳腺癌专家委员会副主任委员中国抗癌协会乳腺癌专业委员会常务委员中国医师协会乳腺专业培训专家委员会常务委员中国医师协会微无创委员会乳腺分会副主任委员中国医药教育协会乳腺疾病分会常务委员中国医学促进会乳腺整形分会常务委员山东省康复医学会乳腺疾病分会主任委员山东省临床肿瘤协会乳腺分会候任主任委员山东省医学会乳腺多学科协作分会副主任委员(来源:《肿瘤瞭望》编辑部)声 明凡署名原创的文章版权属《肿瘤瞭望》所有,欢迎分享、转载。本文仅供医疗卫生专业人士了解最新医药资讯参考使用,不代表本平台观点。该等信息不能以任何方式取代专业的医疗指导,也不应被视为诊疗建议,如果该信息被用于资讯以外的目的,本站及作者不承担相关责任。

CSCO会议临床2期临床3期

2025-04-08

TUESDAY, April 8, 2025 -- Blue laser vaporization alleviates lower urinary tract symptoms while preserving sexual function in patients undergoing

benign prostatic hyperplasia

(BPH) surgery, according to a study published online March 4 in

The Aging Male

.

Zun-Jie Hu, from The Affiliated Taian City Central Hospital of Qingdao University in China, and colleagues assessed the impact of 450-nm blue laser vaporization on sexual function in 67 patients (median age, 65 years) undergoing BPH surgery and followed for three months.

The researchers found that blue laser vaporization significantly improved International Prostate Symptom Score, quality of life, and International Consultation on Incontinence Modular Questionnaire for Male Lower Urinary Tract Symptoms (ICIQ-MLUTS) scores. Blue laser vaporization was also significantly associated with a reduction in postvoid residual volume. There were no significant changes seen in the International Index of Erectile Function 5 score, Male Sexual Health Questionnaire for Ejaculatory Dysfunction score, or ICIQ-MLUTS sex score, demonstrating preservation of sexual function after surgery.

"To determine the longevity of these effects, additional clinical data and extended follow-up periods are necessary," the authors write. "The findings present an effective surgical approach for safeguarding sexual function in BPH patients."

Abstract/Full Text

Whatever your topic of interest,

subscribe to our newsletters

to get the best of Drugs.com in your inbox.

临床结果放射疗法

100 项与 青岛大学 相关的药物交易

登录后查看更多信息

100 项与 青岛大学 相关的转化医学

登录后查看更多信息

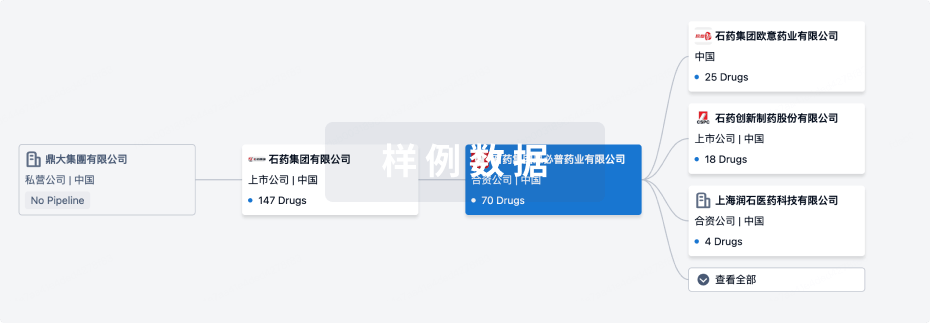

组织架构

使用我们的机构树数据加速您的研究。

登录

或

管线布局

2025年09月02日管线快照

管线布局中药物为当前组织机构及其子机构作为药物机构进行统计,早期临床1期并入临床1期,临床1/2期并入临床2期,临床2/3期并入临床3期

药物发现

6

18

临床前

其他

4

登录后查看更多信息

当前项目

| 药物(靶点) | 适应症 | 全球最高研发状态 |

|---|---|---|

NTP-217 (Qingdao University) | 肝癌 更多 | 临床前 |

ALN-OXA | 骨肉瘤 更多 | 临床前 |

α7 receptor agonists(Qingdao University) ( CHRNA7 ) | 精神分裂症 更多 | 临床前 |

QLS-81 ( Nav1.7 ) | 神经痛 更多 | 临床前 |

Sr-PTL-MCM ( JAK x MAPK x STAT ) | 骨病 更多 | 临床前 |

登录后查看更多信息

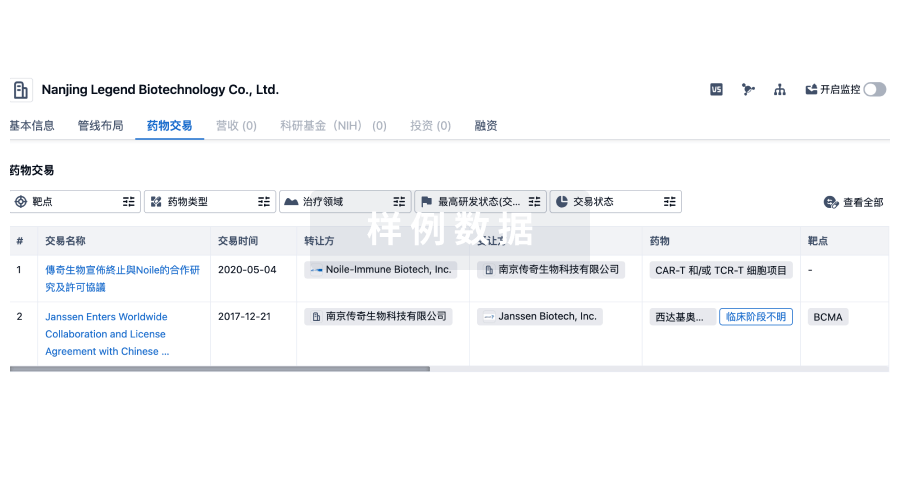

药物交易

使用我们的药物交易数据加速您的研究。

登录

或

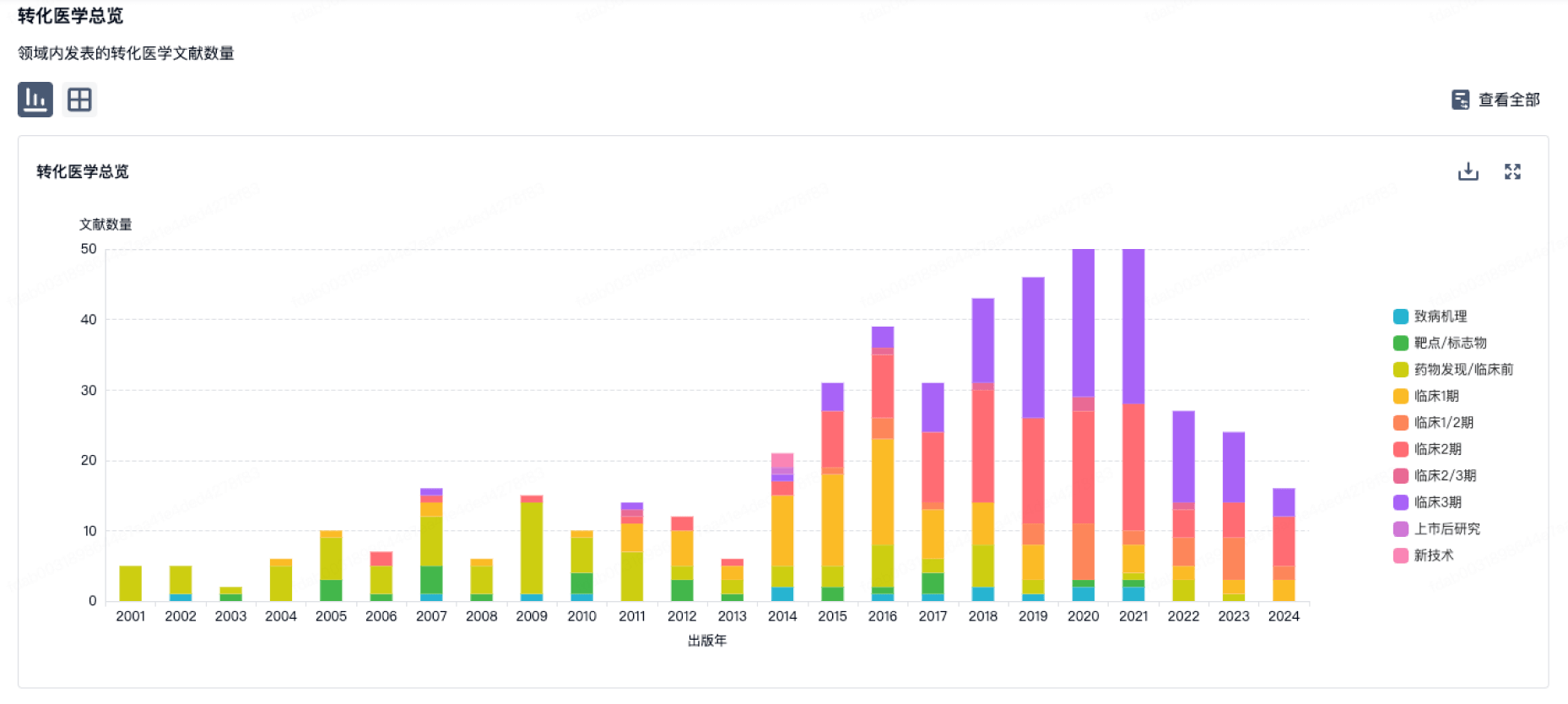

转化医学

使用我们的转化医学数据加速您的研究。

登录

或

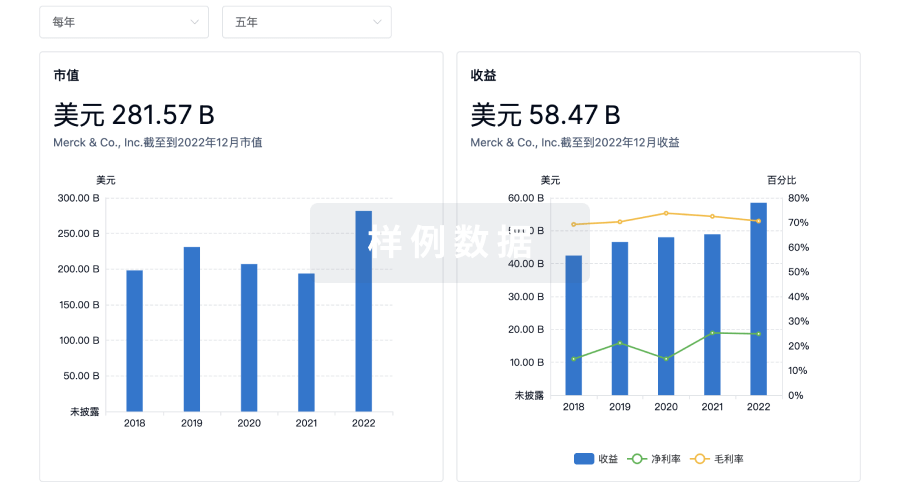

营收

使用 Synapse 探索超过 36 万个组织的财务状况。

登录

或

科研基金(NIH)

访问超过 200 万项资助和基金信息,以提升您的研究之旅。

登录

或

投资

深入了解从初创企业到成熟企业的最新公司投资动态。

登录

或

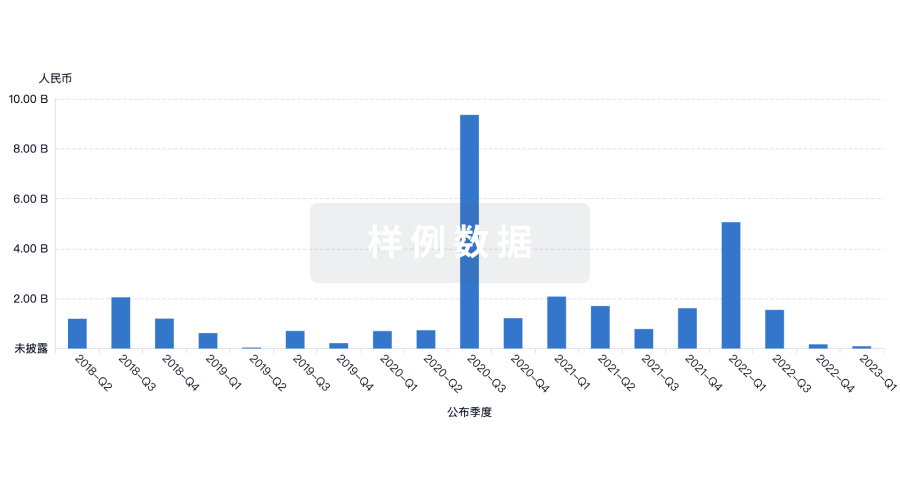

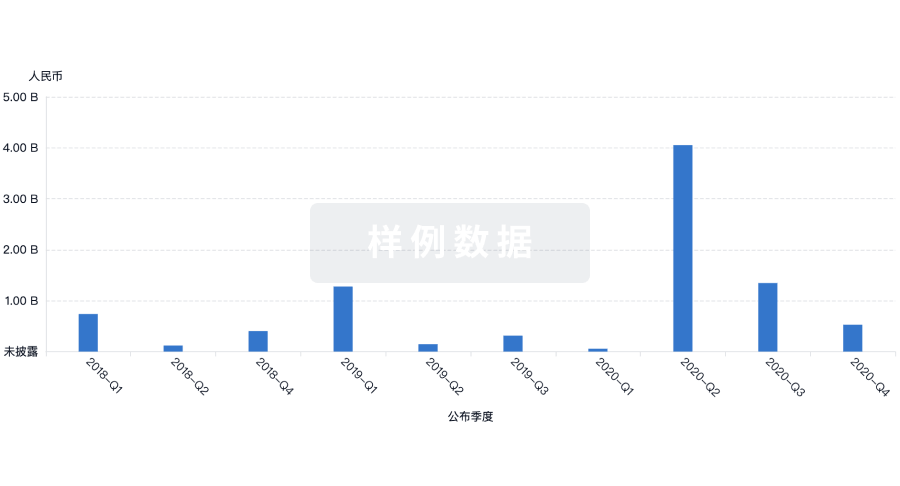

融资

发掘融资趋势以验证和推进您的投资机会。

登录

或

Eureka LS:

全新生物医药AI Agent 覆盖科研全链路,让突破性发现快人一步

立即开始免费试用!

智慧芽新药情报库是智慧芽专为生命科学人士构建的基于AI的创新药情报平台,助您全方位提升您的研发与决策效率。

立即开始数据试用!

智慧芽新药库数据也通过智慧芽数据服务平台,以API或者数据包形式对外开放,助您更加充分利用智慧芽新药情报信息。

生物序列数据库

生物药研发创新

免费使用

化学结构数据库

小分子化药研发创新

免费使用