预约演示

更新于:2025-08-14

Tianjin University

更新于:2025-08-14

概览

标签

肿瘤

神经系统疾病

其他疾病

小分子化药

单克隆抗体

诊断用放射药物

疾病领域得分

一眼洞穿机构专注的疾病领域

暂无数据

技术平台

公司药物应用最多的技术

暂无数据

靶点

公司最常开发的靶点

暂无数据

| 排名前五的药物类型 | 数量 |

|---|---|

| 小分子化药 | 3 |

| 诊断用放射药物 | 3 |

| 适配体药物偶联物 | 2 |

| 化学药 | 1 |

| 巨噬细胞疗法 | 1 |

关联

15

项与 天津大学 相关的药物靶点 |

作用机制 MAGL调节剂 |

在研适应症 |

非在研适应症- |

最高研发阶段临床前 |

首次获批国家/地区- |

首次获批日期- |

作用机制 α-synuclein调节剂 |

在研机构 |

原研机构 |

在研适应症 |

非在研适应症- |

最高研发阶段临床前 |

首次获批国家/地区- |

首次获批日期- |

9

项与 天津大学 相关的临床试验ChiCTR2500105417

Objective evaluation of cognitive efficacy in cochlear implant patients

开始日期2025-08-01 |

申办/合作机构 |

ChiCTR2500099071

Clinical study of a brain-controlled lower extremity hybrid exoskeleton rehabilitation system

开始日期2025-03-24 |

申办/合作机构 |

NCT06921980

Brain Function and Psychological Assessment in Patients With Autoimmune Hemolytic Anemia Undergoing Cell Therapy

Cell therapy is an innovative treatment with significant efficacy in hematologic and certain autoimmune diseases. Although it offers potential benefits for autoimmune hemolytic anemia (AIHA), it may result in cognitive and other potential impairments, which can adversely affect patients' cognition and behavior.

Brain function and psychological assessment are essential for the early detection of potential impairments, allowing timely interventions to prevent complications and ensure patient safety. This study aims to comprehensively evaluate the physical and psychological impacts of cell therapy on AIHA patients to develop safer and more effective treatment strategies that enhance their quality of life.

Brain function and psychological assessment are essential for the early detection of potential impairments, allowing timely interventions to prevent complications and ensure patient safety. This study aims to comprehensively evaluate the physical and psychological impacts of cell therapy on AIHA patients to develop safer and more effective treatment strategies that enhance their quality of life.

开始日期2025-02-25 |

申办/合作机构 |

100 项与 天津大学 相关的临床结果

登录后查看更多信息

0 项与 天津大学 相关的专利(医药)

登录后查看更多信息

72,051

项与 天津大学 相关的文献(医药)2026-02-01·BIOMATERIALS

Natural coagulation inspired RBCs-structural inheritance microgels hybrid featured with quasi-bicontinuous structure for junctional hemostasis

Article

作者: Dou, Mengjie ; Ji, Weijun ; Ma, Henan ; Yuan, Hao ; Li, Sidi ; Zhao, Jin ; Zhang, Lihai ; Lv, Faqin ; Yao, Fanglian ; Yuan, Xubo

Junctional hemorrhage is a major prehospital care challenge, causing 67 % of preventable deaths. In addition, the high risk of secondary hemorrhage during transportation remains a challenge for long-term wound protection. Present hemostatic materials can't simultaneously achieve "anti-high-pressure, fast hemostasis and stable blockage". Inspired by coagulation process, positively charged dense cross-linked structure-inherited microgels (PEDM) were prepared. PEDM hybrid blood form quasi-bicontinuous composite structure (Q-Bi CS), utilizing blood realize rapid anti-high-pressure hemostasis and stable protection. PEDM can self-gel within 15 s when contact with blood, mimicking primary hemostasis to form a quick mechanical blockage. Blood cells are concentrated within 50 s, which promotes the Q-Bi CS formed in 120 s. Compared to PEDM-PBS, the compression modulus of PEDM-blood is improved by 5.4 times, achieving robust blockage. Q-Bi CS showed stable dynamic adhesion with strength maintained at 90.1 % after 200 cycles. In the rabbit femoral artery hemorrhage model, PEDM can achieve rapid hemostasis within 61 s and prevent secondary hemorrhage. PEDM even controlled porcine iliac artery hemorrhage within 30 s. In this paper, the self-gelling of PEDM matches with coagulation process, and blood is incorporated as the reinforcing phase into the Q-Bi CS, overcoming the difficulty of junctional hemostasis.

2026-01-01·FUEL

CO2 adsorption capture for heavy duty trucks: Performance analysis and standardized evaluation

作者: Deng, Shuai ; Pang, Yujia ; Li, Jialin ; Li, Wanyang ; Huang, Zhiqiang ; Zhang, Xisheng ; Yao, Lixin ; Jia, Chenxi ; Meng, Weiwei

This study centers on curbing carbon emissions from heavy duty trucks (HDT) in operation.A compact Temperature Swing Adsorption (TSA) CO2 capture unit, powered by engine waste heat, is designed.The unit, featuring two parallel adsorption chambers for alternating adsorption and desorption, is tailored to HDT space limits with a three-folded double-layer pipe structure, measuring 860 mm x 800 mm x 600 mm.Using zeolite 13X-APG mol. sieve as a CO2 adsorbent and referencing common internal combustion engine parameters, simulations were performed at an intake temperature of 323.95 °C, a target adsorbent temperature during heating stage of 90 °C, and an exhaust gas mass flow rate of 0.2354 kg/s, with the exhaust gas composition assumed to be 75 % N2 and 15 % CO2.The results showed that it can process 20 % of HDT exhaust gas, attaining around 86.11 % CO2 recovery and 93.8 % purity.Addnl., a Vehicle Energy Efficiency Design Index (VEEDI) is proposed to gauge CO2 emissions across vehicle types.VEEDI encompasses CO2 emissions, transport workload, and factors like weather and energy efficiency technologies.It also accounts for the CO2 capture unit′s impact.Case calculations indicate that the CO2 capture unit can reduce VEEDI from 82.49 to 69.29, underscoring the Mobile Carbon Capture (MCC) technol.′s emission reduction potential.Amid stringent CO2 reduction policies, VEEDI can guide vehicle design and certification, offering a reference for vehicle environmental performance during operation and a quantifiable metric for emission reduction effects.

2026-01-01·BIOMATERIALS

A poly(lipoic acid)-based elastomer adhesive with synergistic activity of microenvironment regulation and peripheral neuropathy repair facilitates infectious diabetic wound healing

Article

作者: Fu, Feng ; Shao, Jiaxing ; Cui, Chunyan ; Yang, Rong ; Qi, Ying ; Zhang, Qian ; Wang, Jingjing ; Chen, Yueyang ; Liu, Wenguang ; Luo, Zhen ; Sun, Hongtao ; Song, Haotian

Diabetic wounds are notorious for their difficulty in healing and high recurrence rate, due to their harsh inflammatory microenvironment and the peripheral neuropathy caused by a hyperglycemic condition. However, current research often overlooks the impact of diabetic peripheral neuropathy on hindering wound healing. Here, we develop an adhesive elastomeric wound dressing by combining the natural active molecule lipoic acid (LA) with the clinically applied hypoglycemic drug metformin (Met), integrating the characteristics of remodeling the wound microenvironment and restoring peripheral nerve function, while stabilizing polyLA through the formation of strong salt bridge hydrogen bonds between guanidyl and carboxyl. The surface of the elastomeric dressing rich in adhesive carboxyl groups can achieve effective sealing protection for diabetic wounds by forming multiple hydrogen bonds or electrostatic interactions with the tissues, thereby resisting harmful bacterial invasion. The sustained targeted release of LA and Met at the wound site can effectively reduce local oxidative stress, increase collagen deposition and angiogenesis, and significantly upregulate neuroendocrine chemicals and nerve fiber markers, promoting the recovery of peripheral nerves around the lesion. In the diabetic infection model in rats, the polyLA-Met patch shows a significantly superior wound healing effect compared to the commercial 3M dressing.

287

项与 天津大学 相关的新闻(医药)2025-08-07

习近平总书记指出,“科学成就离不开精神支撑”,科学家精神已然成为新时代精神谱系中不可或缺的重要组成部分,是推动科技创新、引领时代发展的强大精神动力。

在此背景下,北京化工大学生命学院“弘扬科学家精神,赓续红色血脉”研究生实践团在7月-8月走进北京科学中心、中国科学家博物馆、天津大学和天津渤海化工集团海洋化工(侯德榜)展,感悟科学家们的初心与使命,汲取奋进力量,积极践行弘扬“爱国、创新、求实、奉献、协同、育人”科学家精神的使命担当。

中国科学家博物馆

踏入中国科学家博物馆,实践团在图文并茂的展板前久久驻足,于生动鲜活的视频影像中凝神沉思,在承载历史记忆的实物展品前细细端详。我们仿若登上了一座“生命科学时光机”,开启了一场跨越时空、与科学巨匠心灵对话的奇妙之旅。循着思想的指引,一步步走进科学家们波澜壮阔的精神世界,探寻那激励无数科研工作者奋勇前行的精神密码。

在设备简陋、资料匮乏年代,屠呦呦带领团队在380多次失败中“筛”出青蒿素。面对质疑,她以身试药,用中国药为全球疟疾治疗写下“东方方案”。她说:“科研不是为了争名夺利,而是要把任务完成。”这份“敢坐冷板凳、敢啃硬骨头”的求实与奉献,正是科学家精神最亮的注脚。

袁隆平坚持半个多世纪顶着烈日、踩着烂泥,只为让所有人远离饥饿。从“三系法”到超级稻,他把论文写在大地上,把中国人的饭碗牢牢端在自己手上。他叮嘱青少年:“节约粮食,从我做起。”这份“心怀天下、躬耕田畴”的家国情怀与创新担当,让科学家精神在稻浪中金黄闪耀。

向左滑动查看更多

北京科学中心

走进“传承”科学家精神主题展,我们仿佛踏上了一条由老、中、青三代科学家共同铺就的科学征途。这条道路,镌刻着他们矢志不渝的探索足迹,闪耀着勇于突破的创新光芒,承载着薪火相传的精神使命,更通向民族复兴的伟大梦想,旨在激励以科学家为楷模,将个人理想融入国家发展大局,同时激发全体公众的爱国情怀与民族自豪感,凝聚起奋进新时代的磅礴力量。

向左滑动查看更多

在科学教育展区,精心设计了流动科普体验展与科普阅读等专区专区,构建起一个沉浸式、互动式的科学探索空间。通过趣味横生的小游戏、直观生动的图文宣传等多元化形式,我们在轻松愉悦的氛围中走近科学、理解科学,感受科学知识的魅力与科学思想的深邃。这样的设计,让科学家精神突破了展柜的束缚,不再是遥不可及的奖章与荣誉,而是化作一颗颗可触可感、跃动不息的火种,点燃人们心中对科学的热爱与追求,激励更多人投身于科技创新的伟大实践,共同书写新时代的科学华章。

向左滑动查看更多

天津大学

走进天津大学卫津路校区,我们站在北洋广场仰望“实事求是”四字校训——这是1895 年北洋大学建校时便刻下的基因,也是百余年来无数中国科学家共同的价值坐标。天津大学校史馆,正是由当年的第一教学楼改建,它曾见证侯德榜“绿色制碱法”的雏形,也珍藏着茅以升“钱塘江大桥”的手稿。我们把脚步放慢,在校园里完成了一场“沉浸式校史课”——科学家精神,原来就刻在每一片砖瓦、每一道波纹里,等我们用青春去接力。

向左滑动查看更多

天津渤海化工集团海洋化工(侯德榜)展

天津赤峰道63号——1924年久大精盐厂旧址。青砖斑驳,却托举起中国海洋化工的“原点”:1917年,侯德榜带领“永久黄”团队在空地上搭棚建厂,用两年多时间炼出第一包“红三角”纯碱,一举打破洋碱垄断;1933年,他把苦心钻研的《纯碱制造》公之于世,让索尔维法第一次向东方敞开大门;战火中,他们又把实验室搬去四川,在竹棚里完成“侯氏制碱法”,只为“国家所需,拼命为之”。展馆里,150余件实物、150余幅照片,把“爱国、创新、求实、奉献”写进细节。站在侯德榜雕像前,我们忽然懂了:科学家精神不是遥远口号,而是把国家名字写进工业流程的底气;是把专利证书摊开给世界看的自信;是在最简陋的棚屋里也要做出世界领先技术的倔强。

我们深知,科学家精神是推动科技进步的强大动力,是激励我们奋勇前行的精神灯塔。在新时代的征程中,我们将以科学家们为榜样,汲取他们的精神力量,勇攀科学高峰,为实现中华民族伟大复兴的中国梦贡献自己的智慧和力量。

实践心得

向上滑动阅览

刘玲利

走进博物馆,“问天逐梦”影片先是震撼了我,古往今来世界都在不断探索无穷的宇宙,其中“科技的背后是人,每一代人都有每一代人的使命”的箴言,揭示了科技发展的规律与责任。我还被屠呦呦在无数次失败后坚持筛选青蒿素的故事深深震撼。作为一名生物专业的研究生,我们熟知“数据”和“结果”在实验中多么重要,但更应铭记支撑这些成果背后的是科研工作者坚韧不拔的毅力和“为人民健康服务”的初心使命。未来或许我们也将投身于药物研发、疾病防控、生命探索等前沿领域,我们更应传承这份“坐冷板凳、啃硬骨头”的科研品格,让科学成为有温度的事业,真正服务社会与人类。

郭璐源

在北京科学中心参观袁隆平院士的事迹展时,我久久驻足于那句耳熟能详却愈发动人的话:“把饭碗牢牢端在自己手上。”我深知“超级稻”背后不仅是实验数据的飞跃,更是半个世纪如一日扎根田野的执着与创新。而屠呦呦的事迹更让我深刻体会到,科研并不只是实验室里的试管和仪器,更是一种责任、一份担当。无论是面对实验失败,还是外界质疑,她始终坚定目标,不计得失,这份对科学的求实和对人民的奉献,正是“科学家精神”的真实写照。我们学习“协同与育人”的精神,不只是追求自己的科研突破,更是与时代同行,与社会共进。未来我希望将实验室的成果转化为现实方案,让“科学家精神”继续发光。

米雪晴

这一次实践,让我看到钱学森、华罗庚等数学与工程先驱的事迹,他们用一串串看似冰冷的公式、定理,解决的是国家最紧迫的技术难题,背后蕴含着的是家国情怀与使命担当。正如钱老所说:“搞科研不能只为自己,要为国家争口气。”在生物与数学交叉的科研方向上,我深刻体会到,数学模型可以为生物机制的揭示提供支撑,算法与计算也能加速生命科学的发展。而科学家精神给予我们的是一种穿越学科边界的引力——它鼓励我们求真、协作、创新,也敦促我们始终不忘初心,用理性拥抱未知,用信念点亮前路。在未来的科研道路上,我将以科学家们为榜样,不断增强数学服务生命科学的能力,让“精密计算”也拥有“温暖的灵魂”。

徐玄

走进天津大学北洋广场,我第一次如此近距离地体会到“实事求是”四个字的重量。它不仅是一句校训,更是一代又一代科学家严谨治学、勇于探索的精神源泉。从侯德榜孕育“绿色制碱法”的雏形,到茅以升亲笔绘制的钱塘江大桥手稿,这些珍贵史料让我意识到:科技的突破并非偶然,而是精神薪火的传承与积淀。创新精神、国际视野、家国情怀,正是科学家精神的内核写照。作为科研新生代,我们要明白,科研不只是追求“高精尖”,更要扎根于“实事求是”的态度之上,将学术理想与民族复兴同频共振。

赵瑛琪

在天津渤海化工集团海洋化工展,我们站在侯德榜雕像前,回望那段中国人“从零起步,自主炼碱”的峥嵘岁月。我仿佛看到一群青年,在空地上搭棚建厂、搬着试剂筒一路西迁、用毛笔书写下世界认可的《纯碱制造》——这些细节不仅令人动容,更让我重新认识了“科学家精神”的真正模样。它不是象牙塔里的空谈,而是把国家命运扛在肩上的担当;不是科研封闭的孤勇,而是让世界看到“中国制造”的自信。侯德榜“为国家所需,拼命为之”的一句话,更是诠释了“爱国、创新、求实、奉献”的科学家精神。

刘一帆

这次实践,我们在天大校园放慢脚步,站在一块块老砖前细读历史,才明白“沉浸式校史课”的意义。科学家精神,不只存在于历史人物的光环里,也藏在每一座老建筑、每一件旧器物之中,等待我们这代青年人用心触摸、用实践延续。作为一名研究生,我深刻体会到:科技自立自强,需要一代又一代的接续奋斗。从侯德榜的纯碱,到钱学森的导弹轨迹,再到今天的人工智能与交叉学科研究,科学家精神始终是一条主线,引领我们不为名利所动、不因艰难而退。我们要将青春融入科研,在最前沿的实验室、最真实的社会需求中接好“精神的接力棒”,用行动书写属于新时代科研工作者的答卷。

撰稿:林子瑜 刘玲利

编辑:耿海涛

审核:林子瑜 武新颖

2025-08-07

在现代医药的产业链中,动物实验扮演了重要承上启下的重要环节—在细胞和动物模型中开发出新药后,必须先在动物实验中了解代谢和毒理,才能进一步来到人体试验,评估对人类患者的安全性和有效性。

今年4月(2025年4月10日),美国食品药品管理局 (FDA) 宣布将取消单抗和其他药物的动物试验要求,转而使用包括基于人工智能的毒性计算模型、细胞系以及实验室环境下的类器官、器官芯片毒性测试等。

近年来,随着科技的飞速发展和伦理观念的日益增强,寻找动物实验的替代方案成为了科研领域的热门话题。器官芯片、类器官和诱导性多能干细胞(iPSC)模型等新兴技术的诞生与发张,为动物实验的替代方案提供了可能。

“器官芯片”是2010年诞生的一项变革性生物医学技术;2016年被达沃斯经济论坛列为“世界十大新兴技术”之一,在疾病机制研究(特定器官/微环境)、药物早期筛选与毒性测试(肝毒、心毒等)、个性化医疗、环境毒性测试等领域的作用日益凸显,为生命科学和医学研究提供一种系统性的解决方案。

器官芯片是一项多学科高度交叉的前沿技术,近年来,关于器官芯片相关的文章和基金课题呈现逐年上升的趋势。在疾病机制研究(特定器官/微环境)、药物早期筛选与毒性测试(肝毒、心毒等)、个性化医疗、环境毒性测试等领域的作用日益凸显,为生命科学和医学研究提供一种系统性的解决方案。同时,在个性化医疗领域,该技术可利用患者自己的细胞创建个性化的器官芯片,从而基于个体预测某种药物的作用。

目前,器官芯片OoC技术已日渐成熟,预计未来几年学术界和产业界将持续加大对OoC的研究投入。

器官芯片

器官芯片(Organ-on-a-Chip, OoC)是一种融合微流控技术、细胞生物学与材料科学的仿生系统,通过在微米级芯片上构建三维细胞培养环境,模拟人体器官的生理结构和功能。其核心在于利用生物材料构建支架,结合微流控通道模拟血液流动,整合生物传感器实时监测细胞反应,从而在体外重现器官级功能(如肺的气血屏障、肝脏代谢、心脏搏动等)。

器官芯片(OoC)主要组成部分

微流控通道:模拟血管或器官腔道,允许流体(血液/营养液)流动,传递机械力(如剪切力);

多孔生物膜:分隔不同细胞层(如肺泡上皮与血管内皮),实现物质交换模拟;

活细胞/组织:人源细胞(干细胞、原代细胞)在芯片内形成功能性组织;

集成传感器:实时监测细胞代谢、pH值、氧含量等生理参数(部分高端芯片)。

常见的器官芯片类型

器官芯片可以根据细胞来源分为普通器官芯片、类器官芯片;根据器官数量分为单器官芯片、多器官芯片;根据构建用途分为生理模型芯片、病理模型芯片等。

现已用器官芯片“重现”了人体的许多部位,如大脑、肺、肠道、肝脏、肾脏、胰岛、心脏和软骨等。这些模型在器官再生、疾病研究、药物筛选等方面显示出巨大的前景。

目前,器官芯片技术正逐渐形成从单一器官向多器官级联发展的趋势。串联芯片和人体芯片将研究层次提升至多器官互作和系统水平,为研究复杂疾病机制、预测药物系统效应、开发更安全有效的疗法提供了可能,是基础医学研究和转化医学领域的一项颠覆性技术。现如今主要投入应用的器官芯片如下:

器官芯片的优势

器官芯片(Organ-on-a-Chip)和类器官(Organoid)都是用于构建微型人体组织模型的快速发展的技术。类器官可提供细胞复杂性,芯片可提供动态环境,二者结合形成的类器官芯片(Organoids-on-chip, OrgOC),既能保留类器官的生物复杂性,又具备芯片平台的可控性,堪称新一代“人体替身”,可覆盖药物开发全流程。

类器官和器官芯片在使用过程中均需建立预测性验证框架。

目前,器官芯片技术被学术界和产业界广泛应用于各个领域,包括毒理学、免疫学、基因治疗和癌症研究。在学术界,器官芯片使研究人员能够开发出基因表达更接近人体的新模型,从而更好地了解人体生理和疾病机制。在产业界,该技术主要用于在临床试验前帮助确定候选药物的疗效和毒性,帮助提高进入临床的药物成功率。

相比传统模型、细胞模型和动物模型,器官芯片更贴近体内环境,可模拟人体器官结构、功能以及生理微环境,如细胞间相互作用、机械拉伸压缩、流体剪切等,为药物测试及疾病建模及个性化医疗提供更高的生理相关性。

器官芯片相关研究案例

案例一:肿瘤类器官芯片

为克服传统肿瘤模型难以模拟体内肿瘤微环境(特别是血管化)和转移过程的局限性。复旦大学刘妍君课题组开发了一种基于微流控芯片的个性化平台,将患者来源的肿瘤类器官与血管内皮细胞共培养,构建了具有功能性血管网络的血管化肿瘤类器官芯片模型。成功模拟了肿瘤细胞侵袭血管、内渗进入循环系统以及远处转移,为研究转移机制和筛选个体化治疗方案提供了有力工具。

案例二:类骨髓结构

现有研究方法难以在体外工程化构建并研究造血干细胞功能、模拟体内复杂细胞相互作用并展现天然免疫功能的自组织骨髓微环境,限制了体外技术在人类造血机制研究方面的潜力。美国宾夕法尼亚大学DanDongeun Huh课题组基于微流控器官芯片的技术,将人源血管内皮细胞和造血干细胞/祖细胞共培养于三维胶原基质中,利用流体流动诱导其自组织形成功能性结构。成功自组织形成包含功能性血管网络和造血生态位的类骨髓结构,首次在体外观察到由微环境产生的、具有关键免疫效应功能的天然免疫反应。

案例三:3D工程化心脏芯片

为了克服传统2D培养和动物模型在预测人类心脏药物反应(尤其毒性) 上的局限性,构建高保真、灌注式的人类心脏微环境,用于药物筛选。天津大学的姚斌团队整合熔融静电纺丝直写(构建各向异性微纤维支架引导细胞排列)与微流控技术(实现精确灌注培养和药物递送),接种hiPSC-CMs形成3D工程化心脏芯片。成功模拟了人类心脏结构/功能,显著提升了组织成熟度,并对多种心脏(毒性)药物展现出高敏感、高预测性的生理相关反应,证明了其在药物筛选中的优越性。

目前在生物医学研究和药物开发中,尚未有完全能替代动物实验的方法。

从生物医药产业的未来发展方向上,逐渐用更准确、更先进的人体模型来替代动物实验,是一个明确的方向。器官芯片、类器官技术作为一种新兴的生物医学工程技术,具有广泛的应用前景。但在短期内,要完全替代动物实验还很困难的。

但不管怎样,既然有这种风声出现,先人一步,卷在行业前列,还是很有必要的。

OTC2025论坛深度聚焦类器官与疾病建模、新药发现/研发、3D细胞培养、类器官培养及质控。OTC2026合作热线:王晨180 1628 8769

诊断试剂

2025-07-31

·乐威医药

近日,由国家工业信息安全发展研究中心主办“畅链援企”京津冀专场会议在天津大学顺利召开。此次会议聚焦提升企业供应链韧性与竞争力,汇聚各界力量共话发展,乐威医药作为京津冀医药产业协同发展的典型代表受邀参会。会上,天津大学校长柴立元、工业和信息化部规划司司长姚珺出席并发表会前讲话,国家及地方相关机构代表及企业代表围绕“产业政策解读、企业经验交流、应对措施指导、校企合作”等核心议程发表讲话。会后,围绕行业发展热点展开深度交流,通过政策、实践、协作等多维度探讨,为高质量发展凝聚共识、提供思路。作为京津冀协同发展战略的深度践行者,乐威医药“研发在津、生产在冀”的双基地协同模式深度契合区域一体化产业分工,成为京津冀医药产业联动发展的典型样本:其天津研发中心坐落于东丽区华明低碳产业基地,聚焦创新药路线设计、工艺开发及技术转移,是集团创新核心引擎;沧州GMP生产基地则落地河北沧州国家级临港经济技术开发区,依托6.6万平方米现代化生产基地、12条独立生产线及高压加氢专线,不仅具备OEB4级高活性药物专业生产能力,更完整覆盖小分子化合物合成到规模化生产的CDMO全链条服务。两地通过创新链与产业链的精准对接,实现技术成果快速转化与中试生产高效衔接,形成“研发-中试-生产”全周期协同体系;同时以数字化工艺优化、智能化设备升级及绿色工艺创新为支撑,持续提升全流程一站式CDMO服务,深度整合区域资源,为京津冀医药产业协同高质量发展注入新动能。此次参会,乐威医药不仅积极融入产业交流与政策解读中,更与各方探讨了创新链与产业链深度融合的路径。未来,乐威医药将持续以新技术赋能发展,推动研发与生产的高效协同,加速科技成果转化,在京津冀区域高质量发展中贡献更多力量,助力培育经济新动能。版权声明:本文内容及图片,如有侵权请联系删除。免责声明:本文内容仅作信息交流学习,并不反映任何意见及观点。往期推荐乐威医药荣获国际殊荣沧州GMP生产基地开展应急演练BIO International Convention 2025

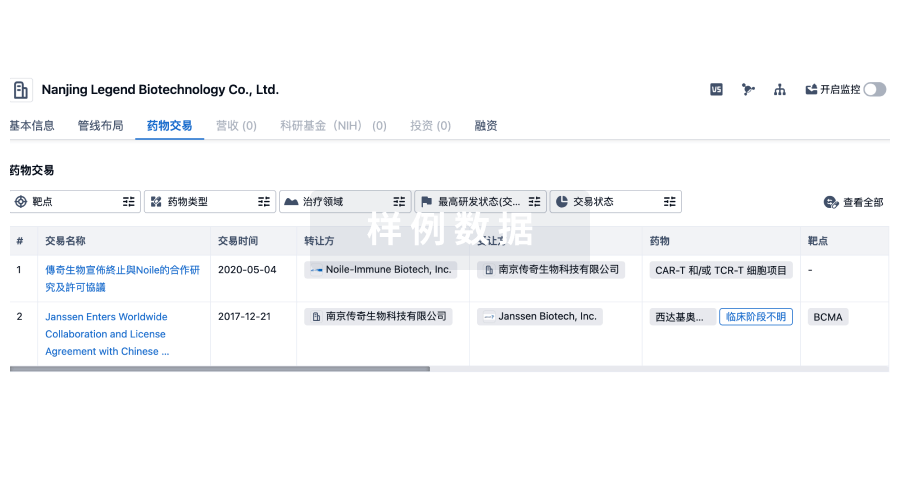

引进/卖出

100 项与 天津大学 相关的药物交易

登录后查看更多信息

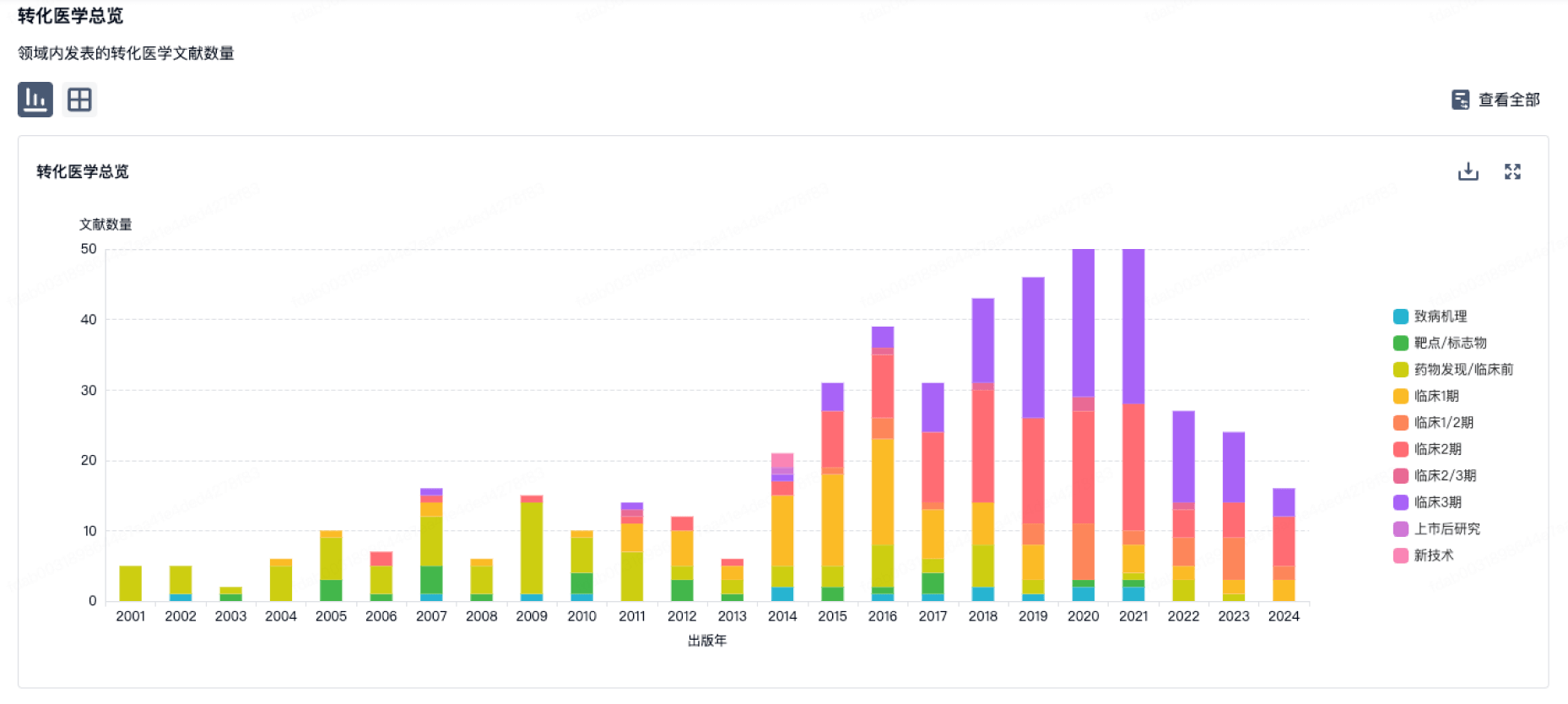

100 项与 天津大学 相关的转化医学

登录后查看更多信息

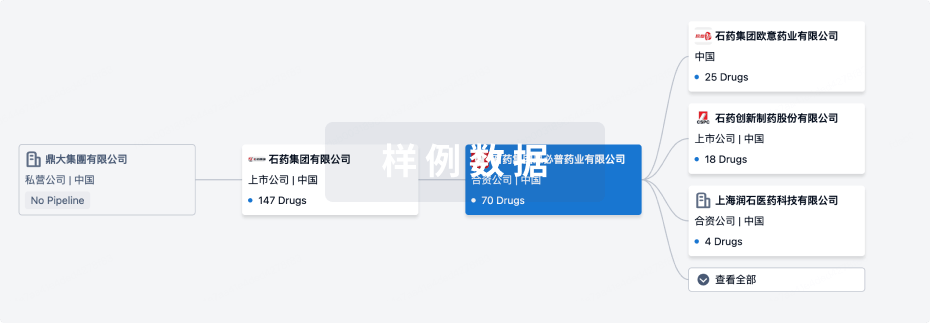

组织架构

使用我们的机构树数据加速您的研究。

登录

或

管线布局

2025年08月25日管线快照

管线布局中药物为当前组织机构及其子机构作为药物机构进行统计,早期临床1期并入临床1期,临床1/2期并入临床2期,临床2/3期并入临床3期

药物发现

5

10

临床前

登录后查看更多信息

当前项目

| 药物(靶点) | 适应症 | 全球最高研发状态 |

|---|---|---|

ICAM1靶向ADC(天津大学) ( ICAM-1 x Top I ) | 甲状腺癌 更多 | 临床前 |

11C-PAD ( MAGL ) | 肿瘤 更多 | 临床前 |

11C-MAGL-2-11 ( MAGL ) | 肿瘤 更多 | 临床前 |

HG1-9-MMAE(Tianjin University) | 胶质母细胞瘤 更多 | 临床前 |

TPA2PyPh-Loaded Macrophages(National University of Singapore) | 脓毒症 更多 | 临床前 |

登录后查看更多信息

药物交易

使用我们的药物交易数据加速您的研究。

登录

或

转化医学

使用我们的转化医学数据加速您的研究。

登录

或

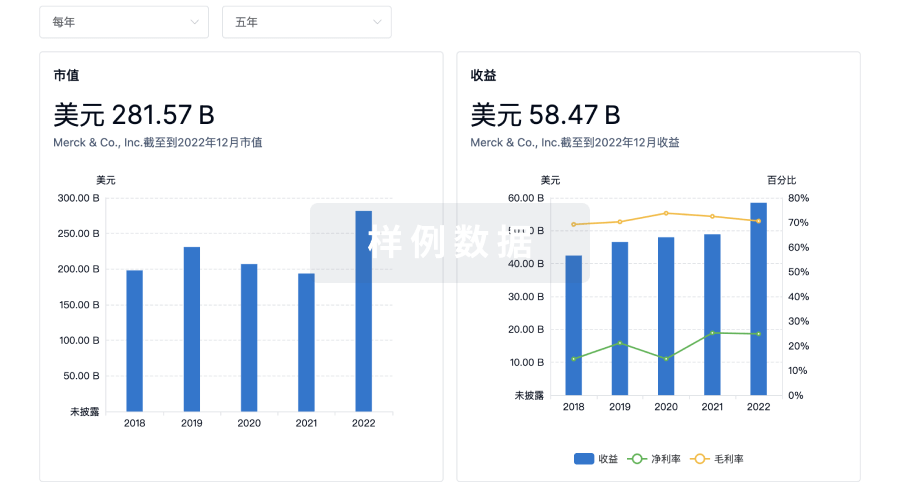

营收

使用 Synapse 探索超过 36 万个组织的财务状况。

登录

或

科研基金(NIH)

访问超过 200 万项资助和基金信息,以提升您的研究之旅。

登录

或

投资

深入了解从初创企业到成熟企业的最新公司投资动态。

登录

或

融资

发掘融资趋势以验证和推进您的投资机会。

登录

或

Eureka LS:

全新生物医药AI Agent 覆盖科研全链路,让突破性发现快人一步

立即开始免费试用!

智慧芽新药情报库是智慧芽专为生命科学人士构建的基于AI的创新药情报平台,助您全方位提升您的研发与决策效率。

立即开始数据试用!

智慧芽新药库数据也通过智慧芽数据服务平台,以API或者数据包形式对外开放,助您更加充分利用智慧芽新药情报信息。

生物序列数据库

生物药研发创新

免费使用

化学结构数据库

小分子化药研发创新

免费使用