预约演示

更新于:2025-05-07

GlaxoSmithKline Biologicals SAS

私营公司|1986|France

私营公司|1986|France

更新于:2025-05-07

概览

标签

感染

神经系统疾病

免疫系统疾病

预防性疫苗

小分子化药

减毒活疫苗

疾病领域得分

一眼洞穿机构专注的疾病领域

暂无数据

技术平台

公司药物应用最多的技术

暂无数据

靶点

公司最常开发的靶点

暂无数据

| 排名前五的药物类型 | 数量 |

|---|---|

| 预防性疫苗 | 2 |

| 小分子化药 | 1 |

| 减毒活疫苗 | 1 |

| 重组亚单位疫苗 | 1 |

| 排名前五的靶点 | 数量 |

|---|---|

| ALK5(转化生长因子β受体1) | 1 |

关联

4

项与 GlaxoSmithKline Biologicals SAS 相关的药物靶点 |

作用机制 ALK5抑制剂 |

在研适应症 |

非在研适应症- |

最高研发阶段临床前 |

首次获批国家/地区- |

首次获批日期- |

2

项与 GlaxoSmithKline Biologicals SAS 相关的临床试验CTR20240406

一项Ⅲ期、开放性、随机、对照研究,用以评估在中国健康婴儿中脊髓灰质炎灭活疫苗(IPV)与无猪圆环病毒(PCV)的口服人轮状病毒(HRV)减毒活疫苗液体制剂联合接种时的免疫原性和安全性

本研究的目的是在6~10周龄(入组年龄)的中国健康婴儿中,评价脊髓灰质炎灭活疫苗(IPV)与葛兰素史克生物制品公司(GSK)的无猪圆环病毒(PCV)的口服人轮状病毒(HRV)减毒活疫苗液体制剂联合接种时的免疫原性和安全性。

- 证明IPV与无PCV的Rotarix疫苗联合接种相较于IPV单独接种的免疫学非劣效性。

- 评估IPV在与无PCV的Rotarix联合接种时和单独接种时的免疫原性。

- 评估无PCV的Rotarix在与IPV联合接种时和单独接种时的免疫原性。

- 根据征集性全身性事件,评价无PCV的Rotarix疫苗和IPV疫苗的反应原性。

- 根据非征集性不良事件(AE)和严重不良事件(SAE)评估无PCV的Rotarix疫苗的安全性,根据SAE评估IPV的安全性。

开始日期2024-03-22 |

申办/合作机构 |

EUCTR2009-014275-53-BE

An open, single centre study to evaluate the long-term antibody persistence and immune memory between 16 and 20 years after the primary study HAB-028 (208127/021) in which healthy adults were vaccinated with Twinrix? Adult following a three-dose schedule. - HAB-028 Ext Year 16-20

开始日期2009-10-06 |

100 项与 GlaxoSmithKline Biologicals SAS 相关的临床结果

登录后查看更多信息

0 项与 GlaxoSmithKline Biologicals SAS 相关的专利(医药)

登录后查看更多信息

24

项与 GlaxoSmithKline Biologicals SAS 相关的文献(医药)2017-01-01·PDA Journal of Pharmaceutical Science and Technology

PDA Points To Consider: Technical Product Lifecycle Management: Communication and Knowledge Exchange between Marketing Authorization Holders and Health Authorities

Review

作者: Munk, Morten ; Seymour, Melissa ; Ramnarine, Emma ; Busse, Ursula ; Skeens, Lisa ; Colao, Marcello ; Vinther, Anders ; Edwards, Julia ; Simianu, Mihaela ; Jornitz, Maik

2017-01-01·PDA Journal of Pharmaceutical Science and Technology

PDA Points to Consider: Technical Product Lifecycle Management. Pharmaceutical Quality System Effectiveness for Managing Post-approval Changes

Review

作者: Munk, Morten ; Simianu, Mihaela ; Seymour, Melissa ; Ramnarine, Emma ; Jornitz, Maik ; Busse, Ursula ; Colao, Marcello ; Vinther, Anders ; O'Donnell, Kevin ; Edwards, Julia ; Skeens, Lisa

2017-01-01·PDA Journal of Pharmaceutical Science and Technology

PDA PAC iAM 2017 Survey on Post Approval Change: Is the Regulatory Environment Hindering Much-Needed Innovation in the Pharma Industry?

Article

作者: Munk, Morten ; Gale, Karolyn ; Jornitz, Maik ; O'Donnel, Kevin ; Ramnarine, Emma ; Busse, Ursula ; Edwards, Julia ; Kiani, Suzanne ; Baker, Denyse ; Follman, Kara ; Vinther, Anders ; Colao, Marcello ; Good, Kassidy ; Simianu, Mihaela ; Seymour, Melissa ; Levy, Rich ; Skeens, Lisa

100 项与 GlaxoSmithKline Biologicals SAS 相关的药物交易

登录后查看更多信息

100 项与 GlaxoSmithKline Biologicals SAS 相关的转化医学

登录后查看更多信息

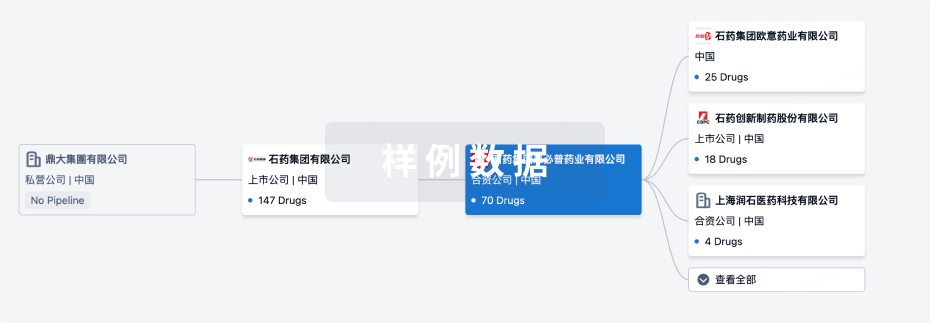

组织架构

使用我们的机构树数据加速您的研究。

登录

或

管线布局

2025年07月18日管线快照

管线布局中药物为当前组织机构及其子机构作为药物机构进行统计,早期临床1期并入临床1期,临床1/2期并入临床2期,临床2/3期并入临床3期

临床前

1

1

临床3期

申请上市

1

1

其他

登录后查看更多信息

当前项目

| 药物(靶点) | 适应症 | 全球最高研发状态 |

|---|---|---|

重组带状疱疹(GlaxoSmithKline Plc) | 带状疱疹 更多 | 申请上市 |

人轮状病毒减毒活疫苗(GSK) | 轮状病毒引起的病毒性胃肠炎 更多 | 临床3期 |

GW-788388 ( ALK5 ) | 肾纤维化 更多 | 临床前 |

GW6604 ( ALK5 ) | 肝纤维化 更多 | 无进展 |

登录后查看更多信息

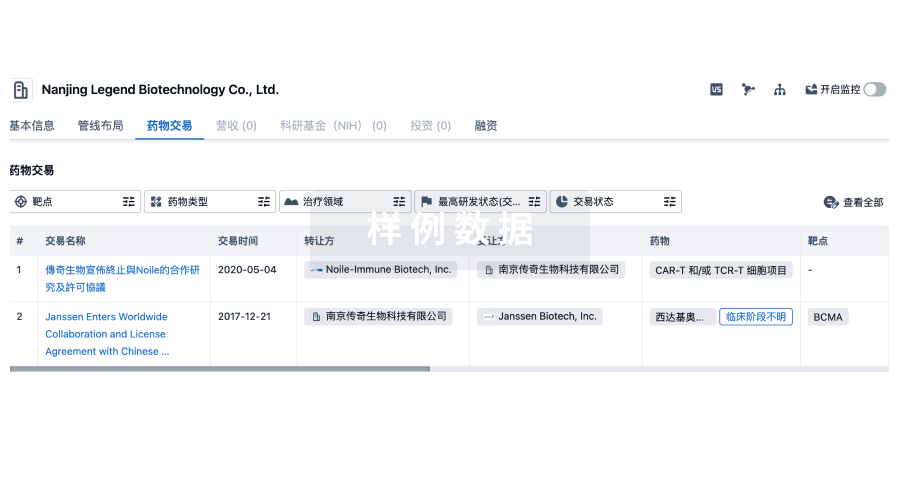

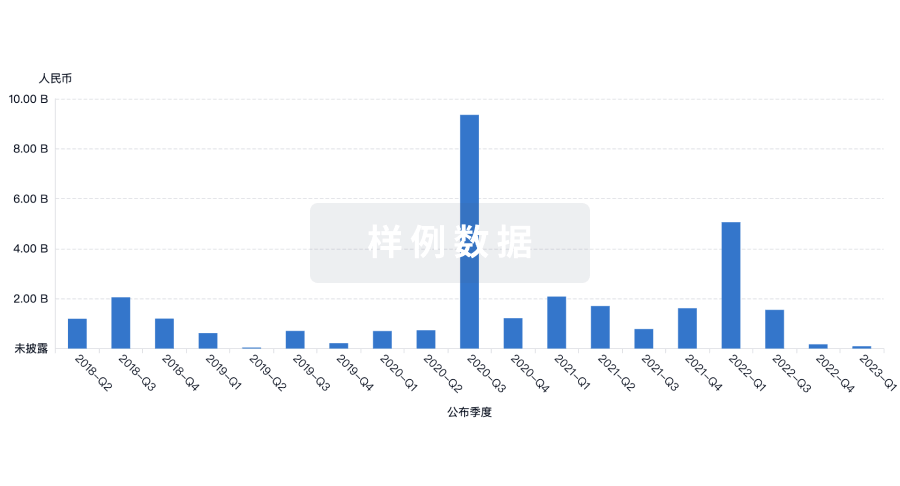

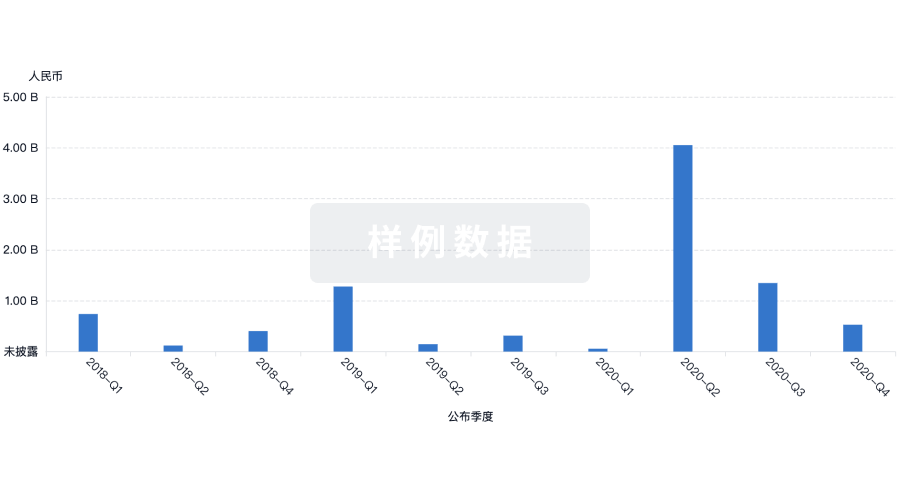

药物交易

使用我们的药物交易数据加速您的研究。

登录

或

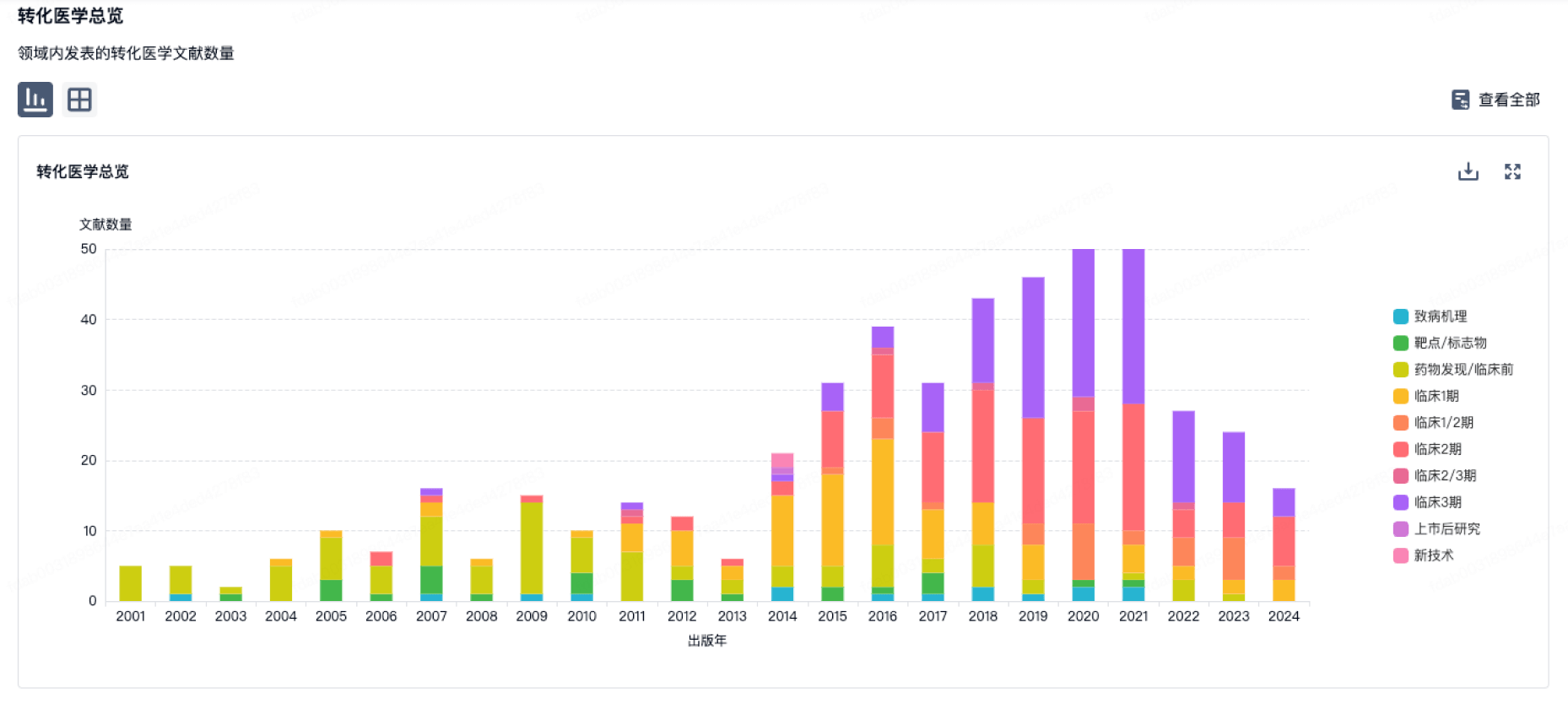

转化医学

使用我们的转化医学数据加速您的研究。

登录

或

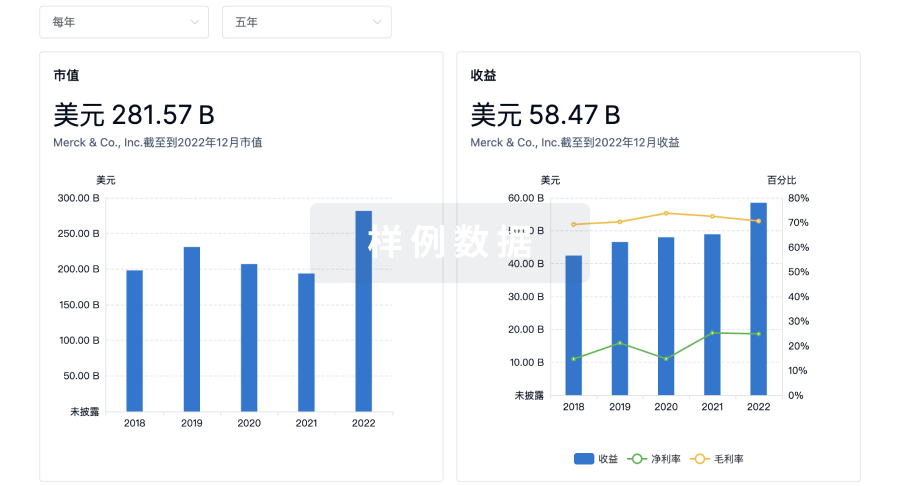

营收

使用 Synapse 探索超过 36 万个组织的财务状况。

登录

或

科研基金(NIH)

访问超过 200 万项资助和基金信息,以提升您的研究之旅。

登录

或

投资

深入了解从初创企业到成熟企业的最新公司投资动态。

登录

或

融资

发掘融资趋势以验证和推进您的投资机会。

登录

或

Eureka LS:

全新生物医药AI Agent 覆盖科研全链路,让突破性发现快人一步

立即开始免费试用!

智慧芽新药情报库是智慧芽专为生命科学人士构建的基于AI的创新药情报平台,助您全方位提升您的研发与决策效率。

立即开始数据试用!

智慧芽新药库数据也通过智慧芽数据服务平台,以API或者数据包形式对外开放,助您更加充分利用智慧芽新药情报信息。

生物序列数据库

生物药研发创新

免费使用

化学结构数据库

小分子化药研发创新

免费使用