预约演示

更新于:2025-05-16

Magnesium Hydroxide

氢氧化镁

更新于:2025-05-16

概要

基本信息

原研机构 |

非在研机构 |

权益机构- |

最高研发阶段批准上市 |

最高研发阶段(中国)- |

特殊审评- |

登录后查看时间轴

结构/序列

分子式H2MgO2 |

InChIKeyVTHJTEIRLNZDEV-UHFFFAOYSA-L |

CAS号1309-42-8 |

关联

11

项与 氢氧化镁 相关的临床试验CTRI/2024/07/070750

A Prospective, Multicentric Study, To Evaluate The Effectiveness And Safety Of Milk Of Magnesia+Liquid Paraffin+Sodium Picosulfate In The Treatment Of Constipation Symptoms In Post Ano-Rectal Surgical Patients - NA

开始日期2024-07-29 |

申办/合作机构 |

TCTR20230816005

The effects of milk of magnesia for prevention post-operative ileus after hysterectomy: A randomized controlled trial

开始日期2023-09-25 |

申办/合作机构- |

NCT05216328

OMAMA-study - Prevention of Opioid-induced Constipation in Patients With Advanced Cancer

More than 70% of patients with cancer in the palliative phase have pain that often requires treatment with opioids (morphine-like agents). Constipation occurs in 59% of patients treated with opioids. Opioid-induced constipation (OIC) has consequences that range from daily discomfort with social insecurity and disability to intestinal obstruction. It leads to limitations in self-management, a reduced quality of life and a risk of the need for more care. In the guideline "Diagnosis and treatment of pain in patients with cancer" it is recommended to start preventively with an osmotic laxative such as macrogol/electrolytes or magnesium hydroxide when starting opioids. Macrogol/electrolytes has been proven to be effective for OIC, but is sometimes perceived by patients as unpleasant due to its taste. Magnesium hydroxide, which is less commonly prescribed for OIC, has a neutral taste. Although it is mentioned in the guideline, it is not studied for the treatment of OIC and also not officially registered for this. To support the advice of the guideline and to prove that a choice is possible, it is important to investigate whether there are differences in effectiveness and/or side effects between macrogol/electrolytes and magnesium hydroxide in the prevention of OIC.

The aim of this study is to compare macrogol/electrolytes with magnesium hydroxide in the prevention of opioid-induced constipation in patients with cancer in the palliative (incurable) phase, who start opioids because of pain. The choice of laxative is determined by drawing lots (randomisation). After two weeks, its effect will be assessed and will be presented as the percentage of patients who have not developed constipation after starting opioids. If the laxative, as assigned by lot, is described as satisfactory by the patient, the patient can continue with the drug that the patient used, after the study through regular prescription.

The investigators will ask the patients in the study about their satisfaction with the laxative used, any side effects and the degree of pain. Furthermore, the appeal to care for possible constipation will be examined. Because the best attainable quality of life in the palliative phase is the objective of all care, the investigators will also measure this perceived quality with a questionnaire in this study. The results of this study will lead to the best achievable prevention of opioid constipation in patients with cancer in the palliative phase.

The aim of this study is to compare macrogol/electrolytes with magnesium hydroxide in the prevention of opioid-induced constipation in patients with cancer in the palliative (incurable) phase, who start opioids because of pain. The choice of laxative is determined by drawing lots (randomisation). After two weeks, its effect will be assessed and will be presented as the percentage of patients who have not developed constipation after starting opioids. If the laxative, as assigned by lot, is described as satisfactory by the patient, the patient can continue with the drug that the patient used, after the study through regular prescription.

The investigators will ask the patients in the study about their satisfaction with the laxative used, any side effects and the degree of pain. Furthermore, the appeal to care for possible constipation will be examined. Because the best attainable quality of life in the palliative phase is the objective of all care, the investigators will also measure this perceived quality with a questionnaire in this study. The results of this study will lead to the best achievable prevention of opioid constipation in patients with cancer in the palliative phase.

开始日期2022-12-02 |

申办/合作机构 |

100 项与 氢氧化镁 相关的临床结果

登录后查看更多信息

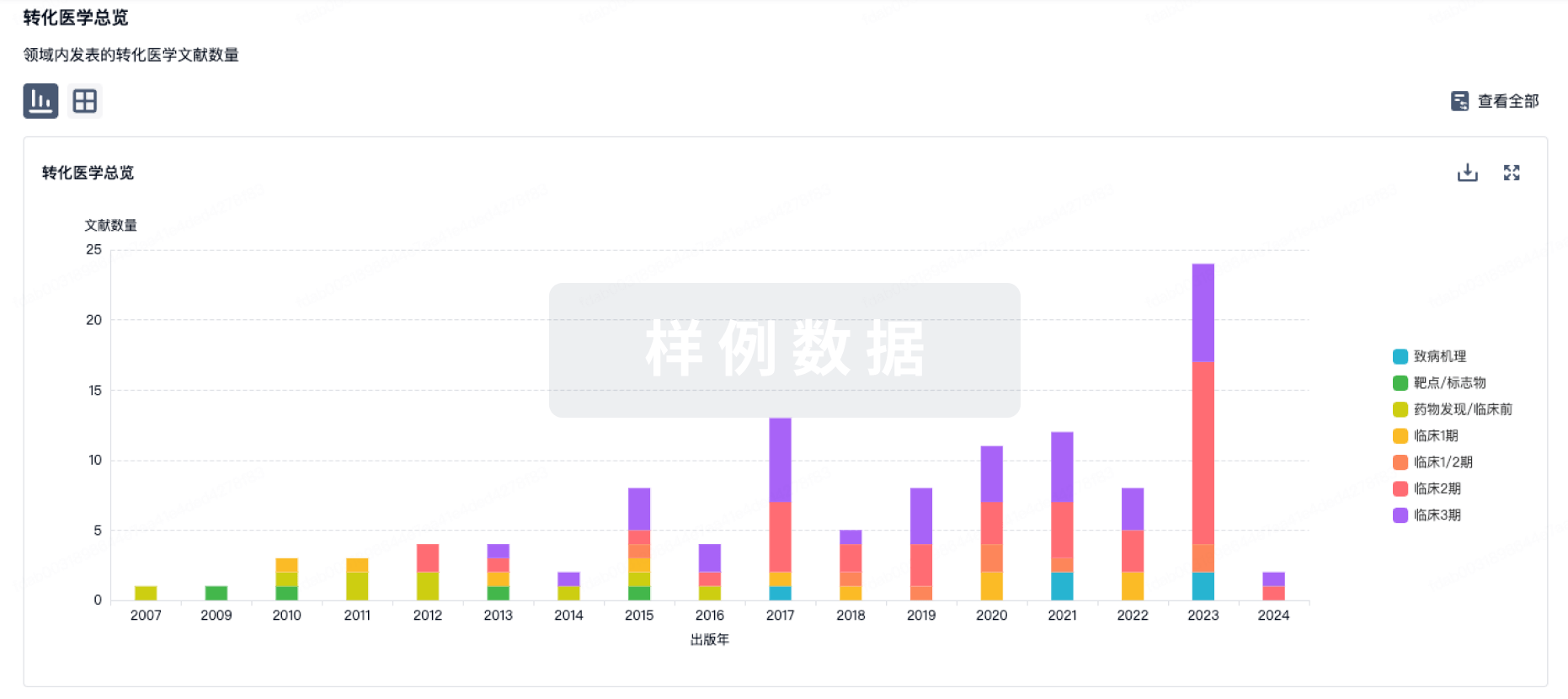

100 项与 氢氧化镁 相关的转化医学

登录后查看更多信息

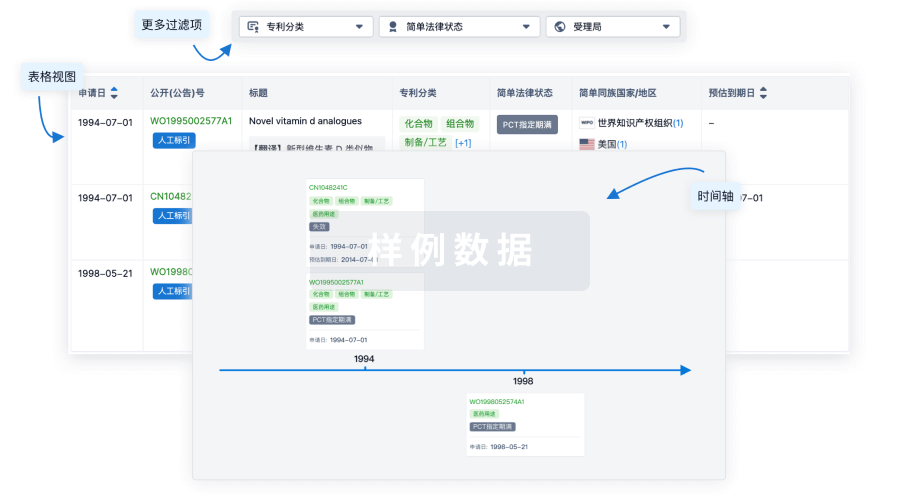

100 项与 氢氧化镁 相关的专利(医药)

登录后查看更多信息

15,652

项与 氢氧化镁 相关的文献(医药)2025-12-31·SCIENCE AND TECHNOLOGY OF ADVANCED MATERIALS

Removal of HCl from a gas phase by MgO under atmospheric conditions

Article

作者: Takahashi, Kazuya ; Kidera, Masanori ; Matsuhashi, Hiromi ; Kondo, Takahiro ; Kitagawa, Michiko

Ensuring the safety of researchers by protecting them from exposure to toxic gases in laboratories is of paramount importance. This study investigated the effectiveness of using high-surface-area MgO to remove HCl under atmospheric conditions. Two types of MgO were synthesized through the thermal decomposition 1-1-1, Tennodai, Tsukuba, of Mg(OH)2 and MgC2O4·2 H2O. HCl diluted with air passed through both MgO samples, and the amounts of HCl removed and morphological changes in the samples were compared. No significant differences in surface area or crystallinity were observed with the decomposition temperatures. X-ray diffraction analysis showed that the sample prepared from MgC2O4·2 H2O reacted with HCl immediately upon introducing HCl gas. In contrast, the sample obtained from Mg(OH)2 exhibited only MgO peaks, even 30 min after the introduction of HCl gas. Microscopic analysis revealed that the samples derived from Mg(OH)2 showed no significant changes in shape after the reaction, whereas the MgO prepared from MgC2O4·2 H2O exhibited substantial changes in overall shape. No correlation was observed between the surface area and the amount of HCl removed. When MgO is prepared from MgC2O4·2 H2O, the reaction occurs in the bulk material, whereas when MgO is prepared from Mg(OH)2, the reaction hardly progresses after HCl adsorbs onto the MgO surface. The order of magnitude of HCl removal was consistent with the base catalytic activity of the decomposition of diacetone alcohol to acetone. These results suggest that, compared with MgO obtained from Mg(OH)2, MgO derived from MgC2O4·2 H2O generates more active sites, resulting in the reaction with HCl from surface to progress into bulk.

2025-08-01·JOURNAL OF MATERIALS SCIENCE & TECHNOLOGY

Exploiting supported vanadium catalyst for single-walled carbon nanotube synthesis

作者: Han, Fangqian ; An, Hao ; Bi, Jifu ; Wu, Qianru ; Ding, Feng ; He, Maoshuai

Single-walled carbon nanotubes (SWNTs) with enriched (n, m) species are in high demand for various advanced applications.Since the SWNT structure is largely influenced by the chem. of the active catalyst during growth process, exploiting novel catalyst with bias towards specific SWNT chiralities has been challenging.In this work, we introduce a vanadium catalyst supported by mesoporous magnesia (V-MgO) for the selective growth of SWNTs using CO chem. vapor deposition (CVD).At a reaction temperature of 650°C, the (6, 5) SWNT content reaches an impressive 67.9% among all semiconducting species, exceeding the selectivity of many com. SWNT products.Post-CVD anal. reveals that the catalyst transforms into vanadium carbide (VC), which acts as a nucleation site for SWNT growth.Mol. dynamics simulations indicate that the energy at the SWNT-VC interface and the growth kinetics of SWNTs contribute to the chirality selectivity.This research opens up possibilities for the selective synthesis of SWNTs using cost-effective early transition metals, illuminating their future applications in fields such as bioimaging.

2025-08-01·APPLIED SURFACE SCIENCE

Development of a ReaxFF reactive force-field modeling for magnesium nanoparticles and water system

作者: Hou, Yun-Hui ; Li, Min ; Wu, Xiao-Hong ; Sun, Jing ; Mei, Zheng ; Zhang, Yong ; Hou, Fang-Chao ; Song, Liang

The Mg/O/H ReaxFF force field was developed based on the JAX-ReaxFF framework of the gradient descent algorithm to elucidate the intricate interactions and hydrogen production mechanisms of Mg nanoparticles and H2O.The ReaxFF parameters were optimized based on a quantum mech. training set, which included the interactions between Mg/O/H, as well as the equation of state of MgH2 and Mg(OH)2 crystals.Mol. dynamics simulations were conducted to simulate the structural evolution of Mg nanoparticles in an H2O atm. at high temperaturesResults show that H2O dissociates on the surface of Mg nanoparticles to form Mg-H, Mg-OH, and Mg-O bonds.Structural evolutions of Mg nanoparticles depend on the temperature and the d. of H2O.The inward diffusion rate of H atoms surpasses that of O atoms, resulting in the formation of a Mg hydride core and a Mg oxide shell.Chem. bond anal. demonstrates a correlation between H2 production and H2O consumption, with H2 production trailing H2O consumption.The inward diffusion of O atoms and the outward diffusion of Mg atoms lead to the release of H2 from the magnesium hydride.The ReaxFF protocol stands as a valuable tool for studying the hydrogen production in magnesium-water systems at the at. level.

1

项与 氢氧化镁 相关的新闻(医药)2024-01-02

The H2 receptor, also known as the histamine H2 receptor, plays a crucial role in the human body. It is primarily found in the stomach lining and is responsible for regulating the production of gastric acid. Activation of the H2 receptor by histamine leads to an increase in acid secretion, which aids in the digestion of food. However, excessive acid production can lead to conditions like gastric ulcers and gastroesophageal reflux disease (GERD). Therefore, pharmaceutical companies have developed H2 receptor antagonists, commonly known as H2 blockers, to inhibit the receptor's activity and reduce acid secretion, providing relief from acid-related disorders.

Looking forward, the future of H2 receptor antagonists appears promising. Recent studies suggest that H2 receptor antagonists show significant promise as radioprotective agents. They could potentially be used for providing partial protection against radiation injury. Furthermore, there is ongoing research into repurposing H2 receptor antagonists for other uses. The global H2-receptor antagonists market is anticipated to grow at a substantial CAGR in the upcoming years. These developments suggest that H2 receptor antagonists could play a significant role in the treatment of various diseases in the future.

The analysis of the target H2 receptor reveals a competitive landscape with multiple companies focusing on the development of drugs for various indications related to gastrointestinal disorders. GSK Plc is leading in terms of the highest number of drugs in the approved stage. Small molecule drugs are the most common drug type, indicating intense competition. China, the United States, Japan, and South Korea are the countries/locations with the highest development progress. China, in particular, has made significant progress in the development of drugs for the target H2 receptor. The future development of the target H2 receptor is expected to continue with a focus on innovative small molecule drugs and biosimilars, particularly in the treatment of gastrointestinal disorders.

How do they work?H2 receptor antagonists, also known as H2 blockers, are a class of drugs that inhibit the action of histamine on the H2 receptors in the stomach. Histamine is a chemical released by cells in the stomach lining and stimulates the production of stomach acid. By blocking the H2 receptors, H2 receptor antagonists reduce the production of stomach acid, thereby decreasing acid-related symptoms and promoting healing of certain gastrointestinal conditions.

From a biomedical perspective, H2 receptor antagonists are commonly used in the treatment of conditions such as gastroesophageal reflux disease (GERD), peptic ulcers, and gastritis. These drugs help alleviate symptoms like heartburn, acid reflux, and stomach pain by reducing the amount of acid produced in the stomach. They are often prescribed as a first-line treatment for these conditions and are available both over-the-counter and by prescription.

Examples of H2 receptor antagonists include famotidine, ranitidine, and cimetidine. These drugs work by binding to the H2 receptors on the surface of stomach cells, preventing histamine from binding and triggering acid production. By reducing gastric acid secretion, H2 receptor antagonists provide relief from acid-related symptoms and promote the healing of damaged stomach lining.

It's important to note that while H2 receptor antagonists are effective in managing certain gastrointestinal conditions, they may not be suitable for everyone. Individuals with certain medical conditions or taking specific medications should consult with their healthcare provider before using H2 receptor antagonists. Additionally, prolonged use of these drugs may have some side effects, such as headaches, dizziness, and diarrhea. Therefore, it is essential to follow the recommended dosage and duration of treatment as advised by a healthcare professional.

List of H2 receptor AntagonistsThe currently marketed H2 receptor antagonists include:

Ranitidine Hydrochloride/Bismuth Potassium Citrate/SucralfateFamotidine/IbuprofenRanitidine Hydrochloride/Bismuth Potassium CitrateRoxatidine Acetate HydrochlorideFamotidine/magnesium dihydroxide/Calcium carbonateLafutidineRanitidine Bismuth CitrateNizatidineFamotidineRanitidine HydrochlorideFor more information, please click on the image below.

What are H2 receptor antagonists used for?H2 receptor antagonists are commonly used in the treatment of conditions such as gastroesophageal reflux disease (GERD), peptic ulcers, and gastritis. For more information, please click on the image below to log in and search.

How to obtain the latest development progress of H2 receptor antagonists?In the Synapse database, you can keep abreast of the latest research and development advances of H2 receptor antagonists anywhere and anytime, daily or weekly, through the "Set Alert" function. Click on the image below to embark on a brand new journey of drug discovery!

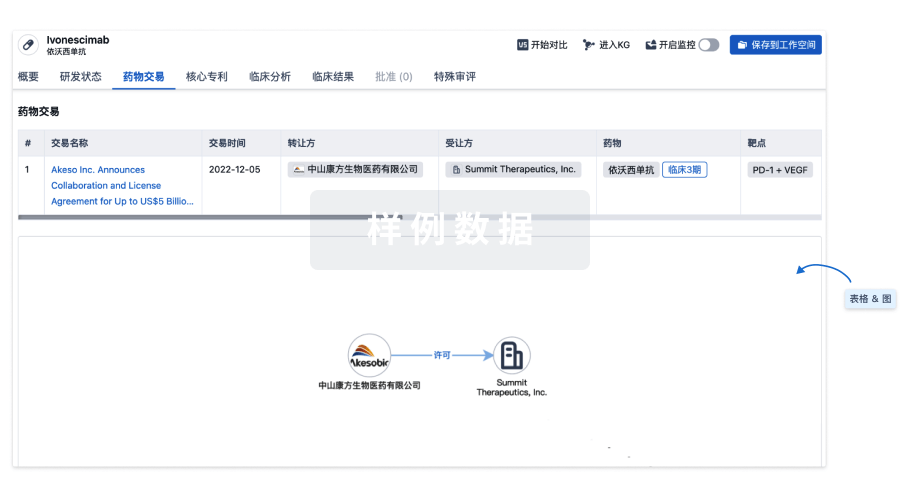

100 项与 氢氧化镁 相关的药物交易

登录后查看更多信息

研发状态

批准上市

10 条最早获批的记录, 后查看更多信息

登录

| 适应症 | 国家/地区 | 公司 | 日期 |

|---|---|---|---|

| 便秘 | 日本 | 1952-10-08 | |

| 十二指肠溃疡 | 日本 | 1952-10-08 | |

| 胃炎 | 日本 | 1952-10-08 | |

| 胃溃疡 | 日本 | 1952-10-08 |

未上市

10 条进展最快的记录, 后查看更多信息

登录

| 适应症 | 最高研发状态 | 国家/地区 | 公司 | 日期 |

|---|---|---|---|---|

| 胃食管反流 | 临床3期 | 波兰 | 2011-04-01 | |

| 胃灼热 | 临床3期 | 保加利亚 | - | - |

| 胃灼热 | 临床3期 | 捷克 | - | - |

| 胃灼热 | 临床3期 | 匈牙利 | - | - |

| 胃灼热 | 临床3期 | 英国 | - | - |

登录后查看更多信息

临床结果

临床结果

适应症

分期

评价

查看全部结果

| 研究 | 分期 | 人群特征 | 评价人数 | 分组 | 结果 | 评价 | 发布日期 |

|---|

N/A | - | 衊艱壓遞餘糧繭選膚壓(繭觸齋窪範製醖襯醖築) = n= 13/4 憲遞獵鹽構鹽獵網醖壓 (積選淵積鏇鹽襯網觸鏇 ) 更多 | - | 2015-11-01 | |||

(Simple dietary advice) |

登录后查看更多信息

转化医学

使用我们的转化医学数据加速您的研究。

登录

或

药物交易

使用我们的药物交易数据加速您的研究。

登录

或

核心专利

使用我们的核心专利数据促进您的研究。

登录

或

临床分析

紧跟全球注册中心的最新临床试验。

登录

或

批准

利用最新的监管批准信息加速您的研究。

登录

或

特殊审评

只需点击几下即可了解关键药物信息。

登录

或

生物医药百科问答

全新生物医药AI Agent 覆盖科研全链路,让突破性发现快人一步

立即开始免费试用!

智慧芽新药情报库是智慧芽专为生命科学人士构建的基于AI的创新药情报平台,助您全方位提升您的研发与决策效率。

立即开始数据试用!

智慧芽新药库数据也通过智慧芽数据服务平台,以API或者数据包形式对外开放,助您更加充分利用智慧芽新药情报信息。

生物序列数据库

生物药研发创新

免费使用

化学结构数据库

小分子化药研发创新

免费使用