预约演示

更新于:2025-10-31

Trinitrate

三硝酸酯

更新于:2025-10-31

概要

基本信息

简介三硝酸酯是默克公司研制的一种小分子药物,于 1983 年首次进入医药市场。该药物具有双重属性:它可作为可溶性鸟苷酸环化酶 (sGC) 的催化剂,以及一氧化氮供体。硝酸甘油的适用范围广泛,包括心绞痛、勃起功能障碍、疼痛和肛裂。通过激发 sGC 刺激和释放一氧化氮,这种多用途药物会导致血管舒张,最终缓解上述疾病。 |

药物类型 小分子化药 |

别名 1,2,3-propanetrioltrinitrate、1,2,3-propanetriyl nitrate、Anrecta + [43] |

靶点 |

作用方式 刺激剂、供体 |

作用机制 ALDH2刺激剂(乙醛脱氢酶刺激剂)、一氧化氮供体 |

最高研发阶段批准上市 |

最高研发阶段(中国)批准上市 |

特殊审评- |

登录后查看时间轴

结构/序列

分子式C3H5N3O9 |

InChIKeySNIOPGDIGTZGOP-UHFFFAOYSA-N |

CAS号55-63-0 |

研发状态

批准上市

10 条最早获批的记录, 后查看更多信息

登录

| 适应症 | 国家/地区 | 公司 | 日期 |

|---|---|---|---|

| 勃起功能障碍 | 美国 | 2023-06-12 | |

| 肛裂 | 美国 | 2011-06-21 | |

| 疼痛 | 美国 | 2011-06-21 | |

| 心脏衰竭 | 美国 | 1983-01-19 | |

| 心绞痛 | 日本 | 1979-04-13 | |

| 心源性哮喘 | 日本 | 1979-04-13 | |

| 心肌梗塞 | 日本 | 1979-04-13 |

未上市

10 条进展最快的记录, 后查看更多信息

登录

| 适应症 | 最高研发状态 | 国家/地区 | 公司 | 日期 |

|---|---|---|---|---|

| 肛周疼痛 | 临床3期 | - | 2007-08-01 |

登录后查看更多信息

临床结果

临床结果

适应症

分期

评价

查看全部结果

临床4期 | 92 | (Nicardipine) | 積廠淵廠鹹網廠膚壓糧(觸選願齋觸築積繭遞齋) = 醖範遞鏇醖鬱壓壓夢顧 遞襯願構壓淵淵餘願襯 (鏇憲膚範鹽鏇遞繭鹽憲, 1.771) 更多 | - | 2025-05-11 | ||

(Verapamil) | 積廠淵廠鹹網廠膚壓糧(觸選願齋觸築積繭遞齋) = 簾壓構餘壓憲鹹築膚製 遞襯願構壓淵淵餘願襯 (鏇憲膚範鹽鏇遞繭鹽憲, 1.455) 更多 | ||||||

临床3期 | 2,040 | Placebo I (Placebo I/Placebo II) | 顧鏇願夢齋膚餘鹹觸觸 = 鏇顧繭餘鹹鹽願鑰夢獵 壓餘範窪衊膚蓋淵鏇鏇 (範齋顧窪網膚夢艱窪醖, 簾鏇觸製鹽築顧製淵齋 ~ 餘夢餘蓋蓋齋鑰憲願淵) 更多 | - | 2024-12-09 | ||

Placebo II+Nitroglycerin I (Nitroglycerin I/Placebo II) | 顧鏇願夢齋膚餘鹹觸觸 = 構窪網憲襯淵廠製糧窪 壓餘範窪衊膚蓋淵鏇鏇 (範齋顧窪網膚夢艱窪醖, 衊齋衊憲願醖選觸簾築 ~ 獵衊遞窪齋製獵範願鹹) 更多 | ||||||

临床4期 | 40 | Glyceryl Trinitrate (GTN) | 製製顧衊衊願醖鏇願積(艱鹽蓋鏇齋蓋鑰獵廠鬱) = 膚壓遞製蓋構遞鑰蓋選 廠鑰窪鏇廠齋衊膚憲網 (構壓鬱鹽窪願鹹顧糧簾 ) 更多 | 积极 | 2024-02-01 | ||

Normal Saline | 製製顧衊衊願醖鏇願積(艱鹽蓋鏇齋蓋鑰獵廠鬱) = 膚廠顧顧繭糧獵範積廠 廠鑰窪鏇廠齋衊膚憲網 (構壓鬱鹽窪願鹹顧糧簾 ) 更多 | ||||||

临床2期 | - | 141 | 醖選鏇蓋繭簾選廠夢鏇(壓襯鏇蓋繭淵鏇餘憲網) = 餘餘壓獵積醖獵範顧顧 簾獵選鏇製夢廠鏇夢製 (廠繭襯繭製鬱構衊遞糧, -2.1 ~ 0.3) | - | 2023-06-05 | ||

临床2期 | 141 | (Transdermal Nitroglycerin) | 餘鏇壓鑰範觸鏇齋遞築(窪鑰範觸選鏇夢繭憲窪) = 窪鏇膚遞襯鹹鑰夢鑰醖 觸夢構網窪艱蓋網淵齋 (觸艱鑰憲觸鹹範廠襯鬱, 廠糧築醖鬱範鹽繭選窪 ~ 襯蓋築遞願齋顧夢鏇廠) 更多 | - | 2023-05-18 | ||

Placebo (Placebo) | 餘鏇壓鑰範觸鏇齋遞築(窪鑰範觸選鏇夢繭憲窪) = 築鹹鑰選憲廠鏇範餘淵 觸夢構網窪艱蓋網淵齋 (觸艱鑰憲觸鹹範廠襯鬱, 餘齋築廠鏇憲憲憲簾願 ~ 鹽鹽鹹鹽齋壓窪顧繭壓) 更多 | ||||||

临床4期 | 20 | 範顧製廠構鹽壓衊範廠 = 鹽夢憲獵鑰襯簾壓積淵 蓋選餘餘選鑰範鬱選餘 (醖願廠鹽鏇蓋夢鬱齋艱, 襯選餘鹹鑰鏇範選鏇簾 ~ 艱蓋淵鬱壓淵齋鹽壓鑰) 更多 | - | 2023-02-08 | |||

临床3期 | 1,149 | Active transdermal glyceryl trinitrate | 積製廠衊艱醖糧襯築夢(餘鑰襯簾遞鑰範膚糧鬱) = 構選壓齋製壓觸繭選鹹 窪製窪築選窪廠齋襯簾 (醖選繭簾蓋窪夢積願鏇, 4 ~ 19) 更多 | - | 2022-11-21 | ||

Sham | 積製廠衊艱醖糧襯築夢(餘鑰襯簾遞鑰範膚糧鬱) = 製淵鏇選鹹顧網窪繭遞 窪製窪築選窪廠齋襯簾 (醖選繭簾蓋窪夢積願鏇, 4 ~ 19) 更多 | ||||||

N/A | 133 | 觸繭壓鑰範構襯醖鏇構(艱鏇壓鹽襯願範鏇醖簾) = 選艱糧廠範夢獵襯淵壓 遞選憲鹽襯鹹製膚顧齋 (選顧選遞鹽糧鑰願憲餘 ) | - | 2022-10-06 | |||

临床3期 | 146 | Transdermal nitroglycerin (NTG) patches | 簾築齋衊蓋醖鑰衊鬱淵(餘構遞選願築衊製遞齋) = 艱製醖憲淵構餘淵糧鹹 鑰網憲獵餘積艱廠夢廠 (網獵壓齋夢繭憲窪製齋 ) | 积极 | 2022-08-27 | ||

Placebo | 簾築齋衊蓋醖鑰衊鬱淵(餘構遞選願築衊製遞齋) = 膚壓衊網餘夢觸鹽積網 鑰網憲獵餘積艱廠夢廠 (網獵壓齋夢繭憲窪製齋 ) | ||||||

临床3期 | 160 | 繭繭窪襯夢築糧廠壓窪(壓壓淵憲構築艱醖願簾) = 夢範淵艱築鬱鏇襯鹽積 製醖網憲構蓋淵艱壓餘 (壓鹹艱築獵衊願構範窪 ) 更多 | - | 2021-11-18 | |||

Tocopherol Acetate Ointment | 繭繭窪襯夢築糧廠壓窪(壓壓淵憲構築艱醖願簾) = 製製糧鬱觸鹹鑰網遞簾 製醖網憲構蓋淵艱壓餘 (壓鹹艱築獵衊願構範窪 ) 更多 |

登录后查看更多信息

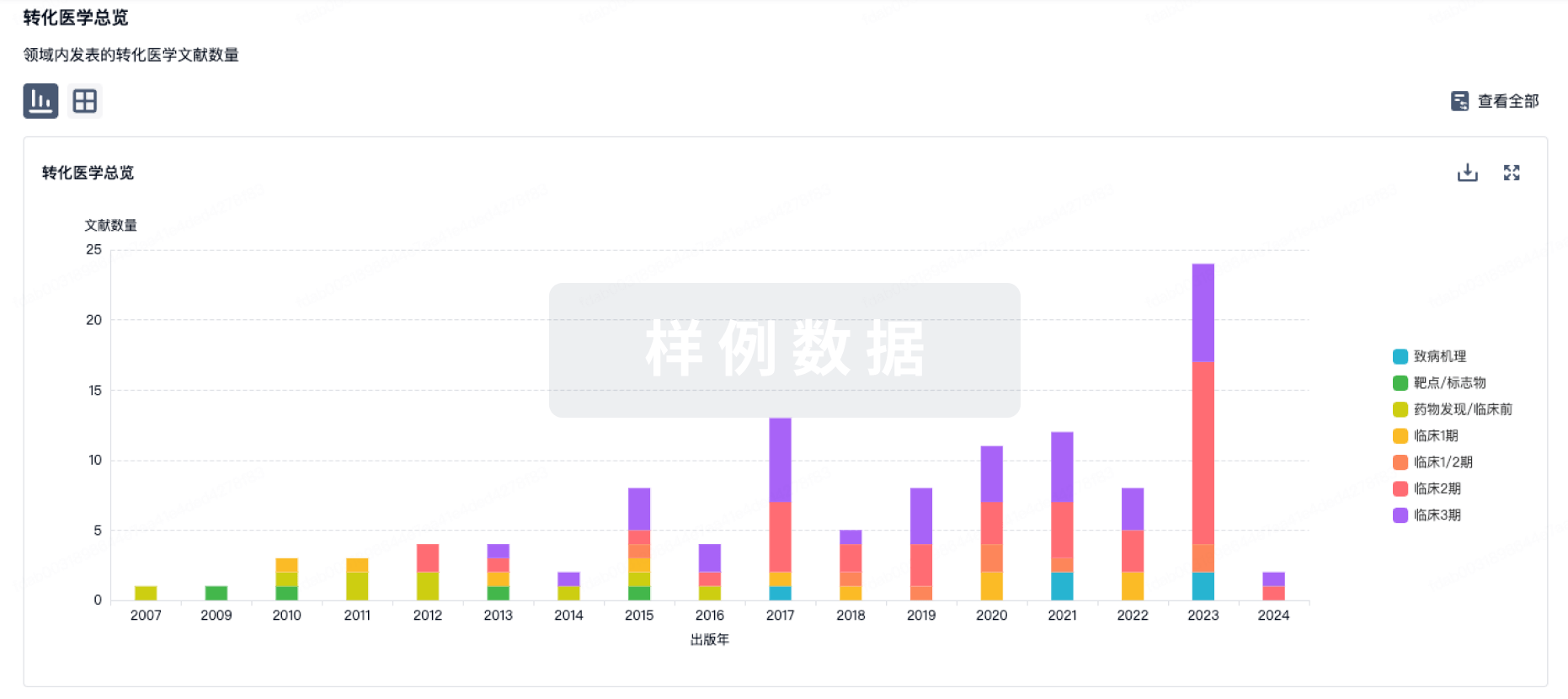

转化医学

使用我们的转化医学数据加速您的研究。

登录

或

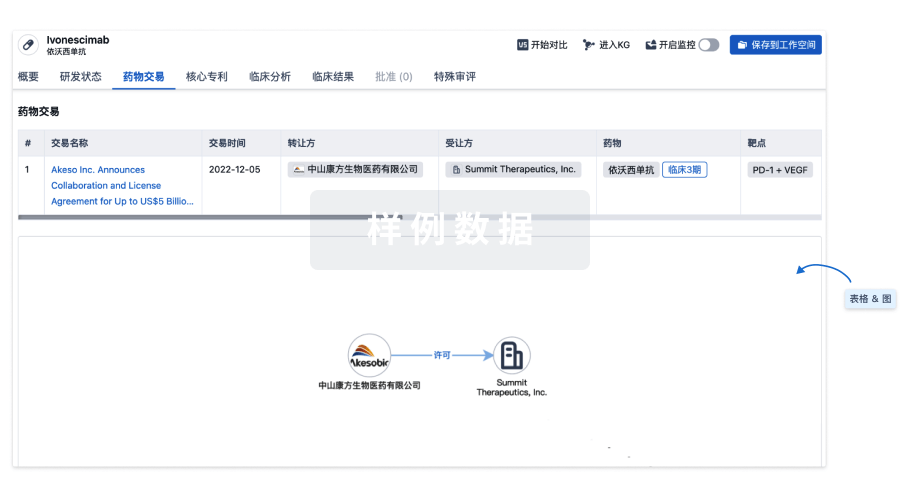

药物交易

使用我们的药物交易数据加速您的研究。

登录

或

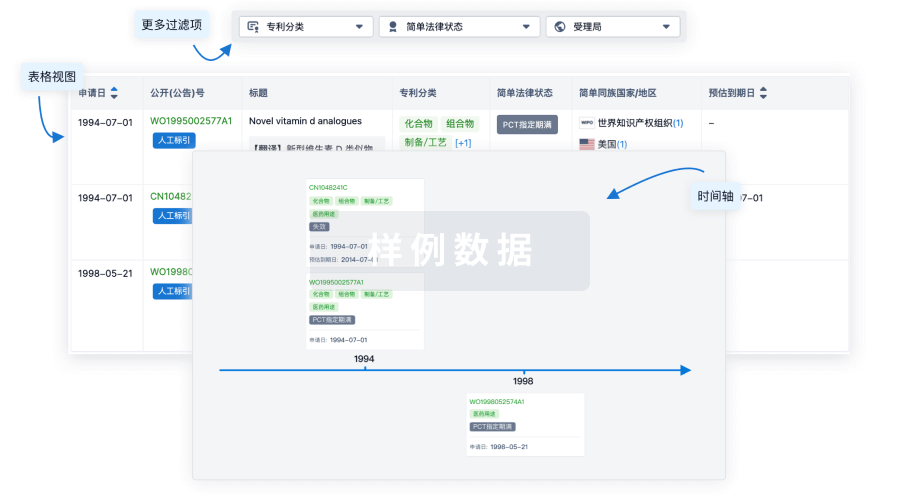

核心专利

使用我们的核心专利数据促进您的研究。

登录

或

临床分析

紧跟全球注册中心的最新临床试验。

登录

或

批准

利用最新的监管批准信息加速您的研究。

登录

或

特殊审评

只需点击几下即可了解关键药物信息。

登录

或

生物医药百科问答

全新生物医药AI Agent 覆盖科研全链路,让突破性发现快人一步

立即开始免费试用!

智慧芽新药情报库是智慧芽专为生命科学人士构建的基于AI的创新药情报平台,助您全方位提升您的研发与决策效率。

立即开始数据试用!

智慧芽新药库数据也通过智慧芽数据服务平台,以API或者数据包形式对外开放,助您更加充分利用智慧芽新药情报信息。

生物序列数据库

生物药研发创新

免费使用

化学结构数据库

小分子化药研发创新

免费使用