预约演示

更新于:2025-07-31

Flurbiprofen Sodium

氟比洛芬钠

更新于:2025-07-31

概要

基本信息

原研机构 |

在研机构 |

权益机构- |

最高研发阶段批准上市 |

首次获批日期 美国 (1986-12-31), |

最高研发阶段(中国)批准上市 |

特殊审评- |

登录后查看时间轴

结构/序列

分子式C15H13FNaO2 |

InChIKeyCGCMNXTUJNJYIY-UHFFFAOYSA-N |

CAS号56767-76-1 |

关联

2

项与 氟比洛芬钠 相关的临床试验ISRCTN10047986

Pain-relieving plaster versus flurbiprofen cataplasms in terms of pain, stiffness, functional activities, joint swelling, quality of life, and safety for knee osteoarthritis treatment: a multi-center, randomized, controlled, non-inferiority clinical trial.

开始日期2024-10-01 |

申办/合作机构 |

CTR20212329

评估受试制剂氟比洛芬凝胶贴膏(规格:40mg)与参比制剂(泽普思® )(规格:40mg)在健康成年受试者外用条件下的单中心、开放、随机、单剂量、两周期、两序列、交叉生物等效性研究。

主要目的:研究外用条件下单次给予受试制剂氟比洛芬凝胶贴膏(规格:40 mg,乐明药业(苏州)有限公司)与参比制剂氟比洛芬凝胶贴膏(泽普思®,规格:40 mg;日本三笠制药株式会社)在健康受试者体内的药代动力学特征,评价外用条件下给予两种制剂的生物等效性。 次要目的:1、研究受试制剂氟比洛芬凝胶贴膏(规格:40 mg)和参比制剂氟比洛芬凝胶贴膏(泽普思®)(规格:40 mg)在健康受试者中的安全性。 2、研究受试制剂氟比洛芬凝胶贴膏(规格:40 mg)和参比制剂氟比洛芬凝胶贴膏(泽普思®)(规格:40 mg)在健康受试者中的黏附性。

开始日期2021-11-10 |

申办/合作机构 |

100 项与 氟比洛芬钠 相关的临床结果

登录后查看更多信息

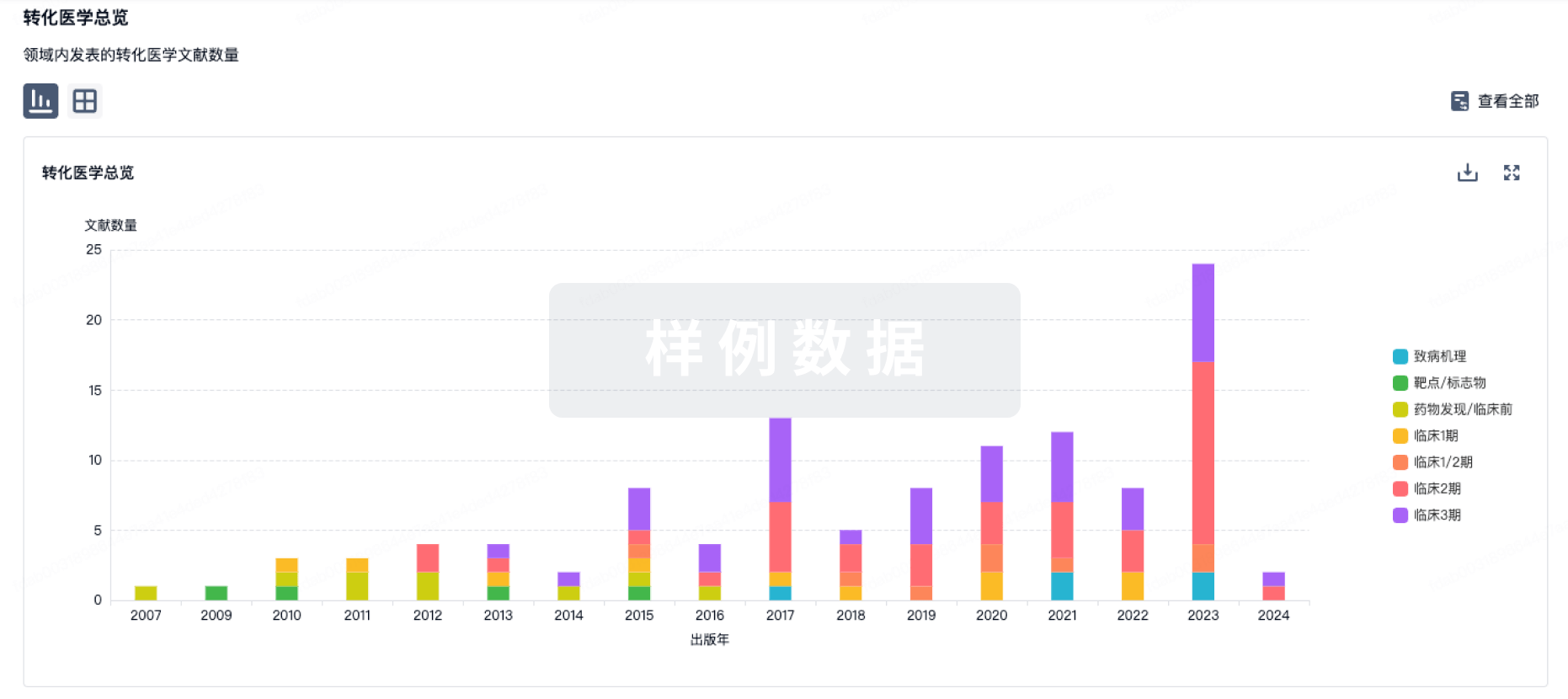

100 项与 氟比洛芬钠 相关的转化医学

登录后查看更多信息

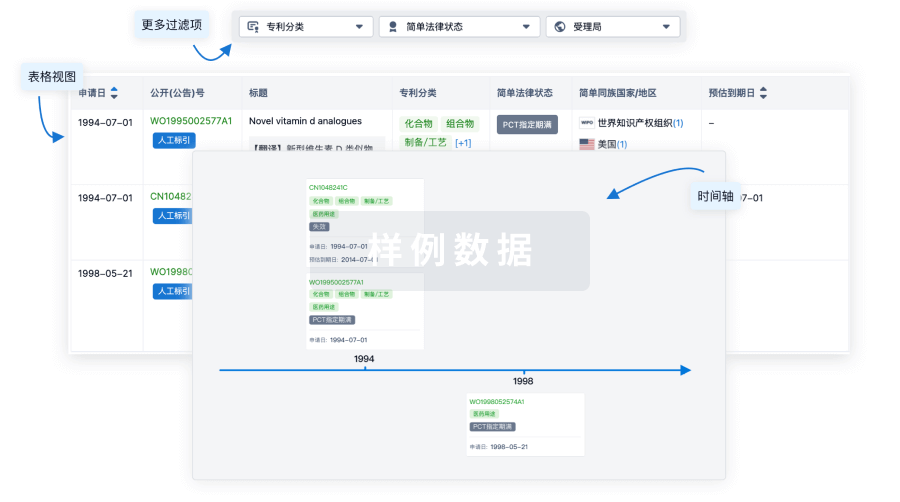

100 项与 氟比洛芬钠 相关的专利(医药)

登录后查看更多信息

4,341

项与 氟比洛芬钠 相关的文献(医药)2025-11-01·SEPARATION AND PURIFICATION TECHNOLOGY

Experimental characterization and QSAR modeling of maximum uptake and distribution factor for neutral and ionic micropollutants on granular activated carbon in artificial and real wastewaters

作者: Cho, Chul-Woong ; Park, Si-Hyeon ; Lee, Kwan-Yong ; Cho, Bo-Gyeon ; Jin, Se-Ra ; Cheon, Jeong-Min

Granular activated carbon (GAC)-based adsorption treatment for micropollutant removal is known to be cost-effective and environmentally sustainable.However, an efficient method is urgently needed to assess the applicability of GAC for a diverse range of micropollutants in various wastewater conditions.Therefore, we developed predictive models to determine the maximum uptake (qmax; calculated by the Langmuir model) and distribution factor (KF; calculated by the Freundlich model) of a range of micropollutants on GAC, which can help overcome exptl. limitations, save resources and time, and provide a deeper understanding of adsorption mechanisms.Exptl. isotherms for controlled conditions to obtain the qmax and KF were performed for both artificial and real wastewaters. qmax values of micropollutants were similar in both wastewaters, but KF values differed slightly.Exptl. obtained qmax and KF values were used in linear free energy relationship-based predictive modeling.The results showed reasonable predictive accuracy for qmax, with R2 values ranging from 0.844 to 0.875 and standard errors between 0.144 and 0.072 log units for both artificial and real wastewater conditions.For KF, the model showed R2 values between 0.803 and 0.762, with standard errors ranging from 0.189 to 0.163 log units.The two models showed high potential for use in GAC-based micropollutant removal.

2025-08-01·COMPUTERS & CHEMICAL ENGINEERING

Solvent selection, sustainability analysis, technoeconomic evaluation and optimisation of batch cooling crystallisation for flurbiprofen production

作者: Gerogiorgis, Dimitrios I. ; Blair, Matthew

Selecting suitable solvents for the crystallization of pharmaceuticals can be a challenging task, given the vast number of solvents that we can choose from.To simplify this problem, we can use principles from solid-liquid equilibrium (SLE) alongside established thermodn. models to identify promising candidates prior to conducting experimentsThis study addresses the batch cooling crystallization of flurbiprofen - a non-steroidal anti-inflammatory drug (NSAID) used to treat arthritis - using a simple model framework implemented within MATLAB.The Apelblat equation is employed to describe the thermophys. behavior of flurbiprofen over a wide temperature range (283.15-323.15 K) in twelve (12) solvents: three alkanes (n-hexane, n-heptane, n-octane); two (iso-Pr, methyl-tert-butyl) ethers; five alcs. (n-propanol, isopropanol, n-butanol, isobutanol, isopentanol); an ester (iso-Pr acetate); and a nitrile (acetonitrile).Moreover, we have used green metrics (E-factor, Scope 1 and 2 carbon emissions) with established process economics models to determine the most promising solvent (n-propanol) for an environmentally friendly and economical manufacturing process.

2025-08-01·EUROPEAN JOURNAL OF MEDICINAL CHEMISTRY

Aromatic group-induced self-assembly of short antimicrobial peptides: unveiling exceptionally potent antimicrobial efficacy

Article

作者: Gou, Sanhu ; Wang, Yu ; Ba, Zufang ; Ouyang, Xu ; Yang, Tingting ; Yu, Zhongwei ; Yan, Pengyi ; Zhang, Yun ; Ren, Bingqian ; Liu, Yao ; Xu, Qingyang ; Yuan, Liru ; Zhao, Yuhuan ; Li, Beibei ; Zhong, Chao ; Liu, Hui ; Ni, Jingman ; Liu, Xueting

Self-assembled antimicrobial peptides (AMPs) have superior antimicrobial properties from their supramolecular nanostructures. A systematic study is needed to determine which AMPs can generate more significant self-assembled structures for antimicrobial activity. In this study, thirty-six self-assembled AMPs were systematically designed by combining six hexapeptide sequences with five aromatic groups, exploring the contributions of different sequences and groups to self-assembly and antimicrobial properties. Most peptides had broad-spectrum antimicrobial and self-assembly capabilities. Moderate self-assembly can endow these new AMPs with excellent antimicrobial properties. Candidate peptides Nap-f5f6 and Npx-f5f6 had outstanding antimicrobial activity, low toxicity, and high selectivity. This may be due to their self-assembly into nanofibers and nanospheres via π-π stacking provided by C- and N-terminal aromatic groups. Their membrane-disrupting bactericidal mechanism gives a rapid effect and prevents antibiotic resistance. Also, in infected mouse skin wounds, Nap-f5f6 and Npx-f5f6 had low toxicity, reduced bacterial load, and accelerated wound healing.

15

项与 氟比洛芬钠 相关的新闻(医药)2025-06-02

·信狐药迅

本周药品注册受理数据,分门别类呈现,一目了然。(5.26-6.1)新药上市申请药品名称企业注册分类受理号伊托法替布软膏明慧医药(杭州)有限公司1CXHS2500058洛布替尼片广州麓鹏制药有限公司1CXHS2500057洛布替尼片广州麓鹏制药有限公司1CXHS2500056ACYW???群脑膜炎球菌多糖结合疫苗北京智飞绿竹生物制药有限公司3.2CXSS2500056注射用STSP-0601江苏贝捷泰生物科技有限公司1CXSS2500057重组人源化单抗MIL62注射液北京天广实生物技术股份有限公司1CXSS2500054新药临床申请药品名称企业注册分类受理号BGB-16673片百济神州(苏州)生物科技有限公司1CXHL2500526BGB-16673片百济神州(苏州)生物科技有限公司1CXHL2500525HSK47388片海思科医药集团股份有限公司1CXHL2500521SZ2001片苏中药业集团股份有限公司1CXHL2500524SZ2001片苏中药业集团股份有限公司1CXHL2500523HSK47388片海思科医药集团股份有限公司1CXHL2500522RO7840734罗氏(中国)投资有限公司1CXHL2500519RO7840734罗氏(中国)投资有限公司1CXHL2500518SYN818片杭州圣域生物医药科技有限公司1CXHL2500511SYN818片杭州圣域生物医药科技有限公司1CXHL2500510富马酸奥比特嗪肠溶微丸胶囊深圳市真兴医药技术有限公司1CXHL2500512HEC20002胶囊广东东阳光药业股份有限公司2.2CXHL2500527CZ006注射液浙江萃泽医药科技有限公司2.2CXHL2500520硫酸阿托品滴眼液湖南迈欧医疗科技有限公司2.2CXHL2500516KEM2417缓释干混悬剂深圳珐玛易药品科技有限公司2.2CXHL2500515KEM2417缓释干混悬剂深圳珐玛易药品科技有限公司2.2CXHL2500514硫酸阿托品滴眼液湖南迈欧医疗科技有限公司2.2CXHL2500517MZ-01吸入溶液成都米子生物医药科技有限公司2.2;2.4CXHL2500513鼻喷重组呼吸道合胞病毒疫苗(5型副流感病毒载体)广州思安信生物技术有限公司1.1CXSL2500430重组呼吸道合胞病毒疫苗(CHO细胞)(佐剂)江苏中慧元通生物科技股份有限公司1.2CXSL2500429三价流感病毒裂解疫苗(MDCK细胞)兰州百灵生物技术有限公司2.2CXSL2500428注射用YL201苏州宜联生物医药有限公司1CXSL2500441注射用BAT8008百奥泰生物制药股份有限公司1CXSL2500440BAT1308注射液百奥泰生物制药股份有限公司1CXSL2500438SM2275注射液珠海烁星生物医药科技有限公司1CXSL2500443注射用YL202苏州宜联生物医药有限公司1CXSL2500437注射用HB0043上海华奥泰生物药业股份有限公司1CXSL2500431注射用YL201苏州宜联生物医药有限公司1CXSL2500436IBI363信达生物制药(苏州)有限公司1CXSL2500435IBI363信达生物制药(苏州)有限公司1CXSL2500434注射用MHB088C明慧医药(杭州)有限公司1CXSL2500433注射用MHB039A明慧医药(杭州)有限公司1CXSL2500432HEC-301注射液东莞市东阳光生物药研发有限公司1CXSL2500426注射用BL-B01D1成都百利多特生物药业有限责任公司1CXSL2500424重组人PD-L1/CD3 双抗溶瘤II型单纯疱疹病毒注射液(Vero细胞)武汉滨会生物科技股份有限公司1CXSL2500425注射用RMMV疫苗长春康悦生物科技有限公司1CXSL2500423注射用IMD303亲合力(成都)药业有限公司1CXSL2500422BAT4706注射液百奥泰生物制药股份有限公司2.4CXSL2500439注射用重组A型肉毒毒素乐普健糖药业(重庆)有限公司2.4CXSL2500427仿制药申请药品名称企业注册分类受理号利伐沙班颗粒广州大光制药有限公司3CYHS2501949利伐沙班颗粒广州大光制药有限公司3CYHS2501948硫酸沙丁胺醇注射液亚邦医药股份有限公司3CYHS2501947氟比洛芬贴剂湖南九典制药股份有限公司3CYHS2501944硫酸妥布霉素注射液湖北华鸿医药有限公司3CYHS2501943辅酶Q10片海南元盈医药科技有限公司3CYHS2501942维生素B6注射液上海禾丰制药有限公司3CYHS2501936复方氨基酸注射液(20AA-Ⅱ)内蒙古白医制药股份有限公司3CYHS2501930复方氨基酸注射液(20AA-Ⅱ)内蒙古白医制药股份有限公司3CYHS2501929维生素B6注射液南京海鲸药业股份有限公司3CYHS2501927盐酸氨溴索滴剂浙江赛默制药有限公司3CYHS2501926盐酸氨溴索滴剂浙江赛默制药有限公司3CYHS2501925富马酸酮替芬口服溶液安徽茂康药业有限公司3CYHS2501921中性腹膜透析液(碳酸氢盐-G4.25%)石家庄四药有限公司3CYHS2501913注射用盐酸头孢替安/氯化钠注射液湖南科伦制药有限公司3CYHS2501904盐酸昂丹司琼片南京海鲸药业股份有限公司3CYHS2501901盐酸昂丹司琼片南京海鲸药业股份有限公司3CYHS2501900盐酸普萘洛尔注射液安徽美来药业股份有限公司3CYHS2501895氨磺必利口服溶液福安药业集团湖北人民制药有限公司3CYHS2501908利伐沙班口腔崩解片山东新时代药业有限公司3CYHS2501884利伐沙班口腔崩解片山东新时代药业有限公司3CYHS2501883奥美拉唑碳酸氢钠干混悬剂(II)裕松源药业有限公司3CYHS2501882复方聚乙二醇电解质散(II)湖南润兴药业有限公司3CYHS2501876腺苷钴胺胶囊济南中渔润医药科技有限公司3CYHS2501874乙酰半胱氨酸注射液长春澜江医药科技有限公司4CYHS2501957洛索洛芬钠贴剂津药达仁堂集团股份有限公司新新制药厂4CYHS2501956洛索洛芬钠贴剂津药达仁堂集团股份有限公司新新制药厂4CYHS2501955巴瑞替尼片广州大光制药有限公司4CYHS2501954脂肪乳氨基酸(17)葡萄糖(19)注射液瑞阳制药股份有限公司4CYHS2501953盐酸尼卡地平注射液赤峰源生药业有限公司4CYHS2501952盐酸尼卡地平注射液赤峰源生药业有限公司4CYHS2501951乙酰半胱氨酸注射液湖北津药药业股份有限公司4CYHS2501950氟伐他汀钠缓释片浙江百代医药科技有限公司4CYHS2501946乙酰半胱氨酸注射液合肥启旸生物医药科技有限公司4CYHS2501945聚乙烯醇滴眼液湖南华纳大药厂股份有限公司4CYHS2501941环索奈德吸入气雾剂上海上药信谊药厂有限公司4CYHS2501937硫酸特布他林雾化吸入用溶液上海旭东海普药业有限公司4CYHS2501938注射用伏立康唑湖北午时医药研究院有限公司4CYHS2501935瑞巴派特片浙江浙北药业有限公司4CYHS2501934磷酸西格列汀片云鹏医药集团有限公司4CYHS2501933西格列汀二甲双胍片(II)江西施美药业股份有限公司4CYHS2501932达可替尼片北京康立生医药技术开发有限公司4CYHS2501931依达拉奉右莰醇注射用浓溶液陕西丽彩药业有限公司4CYHS2501928恩他卡朋双多巴片(II)复星万邦(江苏)医药集团有限公司4CYHS2501940盐酸乙哌立松片西洲医药科技(浙江)有限公司4CYHS2501939玻璃酸钠滴眼液润尔眼科药物(广州)有限公司4CYHS2501918蒙脱石散成都恒瑞制药有限公司4CYHS2501916比拉斯汀片新乡市常乐制药有限责任公司4CYHS2501914乌帕替尼缓释片广东华润顺峰药业有限公司4CYHS2501912非诺贝特酸胆碱缓释胶囊苏州特瑞药业股份有限公司4CYHS2501911氟比洛芬钠滴眼液广州大光制药有限公司4CYHS2501910布瑞哌唑片杭州和康药业有限公司4CYHS2501924布瑞哌唑片杭州和康药业有限公司4CYHS2501923布瑞哌唑片杭州和康药业有限公司4CYHS2501922乙酰半胱氨酸注射液浙江赛默制药有限公司4CYHS2501920乙酰半胱氨酸注射液四川科伦药业股份有限公司4CYHS2501919乙酰半胱氨酸注射液广州大光制药有限公司4CYHS2501917乙酰半胱氨酸注射液广州君博医药科技有限公司4CYHS2501915克林霉素磷酸酯过氧苯甲酰凝胶江苏知原药业股份有限公司4CYHS2501905依折麦布阿托伐他汀钙片(II)山东创新药物研发有限公司4CYHS2501903依折麦布阿托伐他汀钙片(I)山东创新药物研发有限公司4CYHS2501902艾普拉唑肠溶片江苏和晨药业有限公司4CYHS2501899结构脂肪乳注射液(C6-24)成都国为生物医药有限公司4CYHS2501898盐酸左布比卡因注射液河南普瑞药业有限公司4CYHS2501897盐酸左布比卡因注射液河南普瑞药业有限公司4CYHS2501896硫酸氨基葡萄糖胶囊福州闽海药业有限公司4CYHS2501894左甲状腺素钠片江苏德源药业股份有限公司4CYHS2501893左甲状腺素钠片江苏德源药业股份有限公司4CYHS2501892氧云县长隆工业气体有限公司4CYHS2501891达格列净片陕西君可力医药科技有限公司4CYHS2501890达格列净片陕西君可力医药科技有限公司4CYHS2501889硫酸氨基葡萄糖胶囊唐山利康药业有限责任公司4CYHS2501888盐酸阿罗洛尔片长春海悦药业股份有限公司4CYHS2501907克立硼罗软膏山东达冠医药科技有限公司4CYHS2501906盐酸尼卡地平注射液湖南赛隆药业(长沙)有限公司4CYHS2501909地夸磷索钠滴眼液海南斯达制药有限公司4CYHS2501887阿达帕林过氧苯甲酰凝胶江苏知原药业股份有限公司4CYHS2501886阿达帕林过氧苯甲酰凝胶江苏知原药业股份有限公司4CYHS2501885氯吡格雷阿司匹林片湖南尚众合生物医药有限公司4CYHS2501881苹果酸奈诺沙星氯化钠注射液广州大光制药有限公司4CYHS2501880阿达帕林凝胶乐泰药业(兰西)有限公司4CYHS2501879酒石酸美托洛尔片山东普瑞曼药业有限公司4CYHS2501878酒石酸美托洛尔片山东普瑞曼药业有限公司4CYHS2501877阿司匹林肠溶片赤峰万泽药业股份有限公司4CYHS2501875雷珠单抗注射液杭州中美华东制药有限公司3.3CXSS2500055硫酸特布他林注射液广东万泰科创药业有限公司3CYHL2500102氨苯砜凝胶深圳珐玛易药品科技有限公司3CYHL2500101去氧胆酸注射液江苏润恒制药有限公司3CYHL2500099卡麦角林片长春金赛药业有限责任公司3CYHL2500098倍氯米松福莫特罗吸入气雾剂鲁南贝特制药有限公司4CYHL2500100冻干b型流感嗜血杆菌结合疫苗艾美坚持生物制药有限公司3.3CXSL2500442进口申请药品名称企业注册分类受理号甲苯磺酸纳地美定片Shionogi & Co., Ltd.5.1JXHS2500060伊奈利珠单抗注射液Horizon Therapeutics Ireland DAC2.2JXSS2500070注射用维泊妥珠单抗Roche Pharma (Schweiz) AG2.2JXSS2500069注射用维泊妥珠单抗Roche Pharma (Schweiz) AG2.2JXSS2500068比奇珠单抗注射液UCB Pharma S.A.3.1JXSS2500067比奇珠单抗注射液UCB Pharma S.A.3.1JXSS2500066比奇珠单抗注射液UCB Pharma S.A.3.1JXSS2500065比奇珠单抗注射液UCB Pharma S.A.3.1JXSS2500064恩他卡朋片Aurobindo Pharma Limited5.2JYHS2500024GIREDESTRANTGenentech, Inc.1JXHL2500122PF-08046047Pfizer Inc.1JXSL2500085Mosunetuzumab Injection (Subcutaneous Injection)F. Hoffmann-La Roche Ltd.2.1JXSL2500084Mosunetuzumab Injection (Subcutaneous Injection)F. Hoffmann-La Roche Ltd.2.1JXSL2500083中药相关申请药品名称企业注册分类受理号桃红四物汤颗粒瑞阳制药股份有限公司3.1CXZS2500023健脾疏肝固本颗粒江苏康缘药业股份有限公司1.1CXZL2500032JMZ-2102胶囊江西济民可信药业有限公司1.2CXZL2500034JMZ-2102江西济民可信药业有限公司1.2CXZL2500033注:绿色字体部分为潜在首仿品种;不包含原料药、医用氧、注射用水、氯化钠或葡萄糖注射液等申请,不包含再注册、一次性进口、技术转移、复审申请。

疫苗申请上市

2025-02-14

·米内网

精彩内容

近日,国家药监局官网显示,南京海科瑞医药申报的4类仿制药维生素B12滴眼液获批生产,为国内首家视同过评,该产品2024上半年在中国三大终端六大市场(统计范围详见本文末)的销售额增速约达172%。目前31个眼科用药已有企业过评或视同过评,欧康维视、兴齐眼药、齐鲁制药等领跑。

维生素B12滴眼液可用于缓解调节性眼疲劳症状。在南京海科瑞医药之前,有4家企业拥有维生素B12滴眼液生产批文,该产品2024上半年在中国三大终端六大市场的销售额增速约达172%。

13家企业的维生素B12滴眼液以新注册分类报产,南京海科瑞医药的产品顺利获批并首家视同过评,浙江莎普爱思药业、四川禾亿制药、成都普什制药、广州大光制药等企业的产品报产在审。

近年来随着人口老龄化进程加快、生活方式变化、电子产品的普及等,眼部疾病的发病率及用药需求均在不断提升。米内网数据显示,2023年中国三大终端六大市场眼科用药(化学药)销售额超过150亿元,2024上半年有略微回落。

近年来中国三大终端六大市场眼科化药销售情况(单位:万元)来源:米内网综合数据库

目前有31个眼科用药已有企业过评或视同过评,玻璃酸钠滴眼液、盐酸莫西沙星滴眼液2个品种竞争激烈,目前均有40家及以上的企业过评或视同过评。此外,氟比洛芬钠滴眼液、盐酸西替利嗪滴眼液、盐酸奥布卡因滴眼液、曲伏噻吗滴眼液等13个品种目前仅1家企业过评或视同过评。

眼科用药过评情况

来源:米内网中国申报进度(MED)数据库

从企业过评情况看,欧康维视生物、沈阳兴齐眼药、齐鲁制药、远大健康、中山万汉制药等领跑,目前分别有10个、9个、8个、8个、8个眼科用药过评或视同过评。

资料来源:米内网数据库、国家药监局官网等

注:米内网《中国三大终端六大市场药品竞争格局》,统计范围是:城市公立医院和县级公立医院、城市社区中心和乡镇卫生院、城市实体药店和网上药店,不含民营医院、私人诊所、村卫生室,不含县乡村药店;上述销售额以产品在终端的平均零售价计算。数据统计截至2月14日,如有疏漏,欢迎指正!

本文为原创稿件,转载请注明来源和作者,否则将追究侵权责任。投稿及报料请发邮件到872470254@qq.com稿件要求详询米内微信首页菜单栏商务及内容合作可联系QQ:412539092

【分享、点赞、在看】点一点不失联哦

2025-01-05

·米内网

摘要

abstract

2024年12月,7个1类新药、10个改良型新药申报上市;320个品种按新分类仿制申请申报,其中63个品种暂无国内仿制获批,富马酸伏诺拉生片有11家企业提交仿制申请,石家庄四药仿制申报品种数最多,有11个;45个存量品种有企业申报一致性评价,其中1个品种为首次申报;8个1类新药、1个新剂型改良型新药获批上市,8个品种获批新适应症;17个品种首家过评,其中11个为首仿。

创新药品种申报情况

2024年12月,200个创新药品种(药品注册分类为“1”的品种)获CDE承办。7个品种申请上市:HH-003注射液(华辉安健(北京)生物)、Rilzabrutinib片(健赞)、培来加南喷雾剂(江苏普莱医药)、仁术健胃颗粒(南京中山制药)、伊诺格鲁肽注射液(杭州先为达生物)、伊坦长效重组人生长激素注射液(YI-MAB BIOTECH)、重组质粒-肝细胞生长因子注射液(武汉光谷人福生物医药)。2024年12月创新药上市申请承办情况2024年12月创新药临床申请承办情况

改良型新药品种申报情况

2024年12月,48个改良型新药品种获CDE承办。伯瑞替尼肠溶胶囊(北京浦润奥生物)、布西珠单抗注射液(诺华)、马来酸噻吗洛尔凝胶(北京梅尔森医药)、赛沃替尼片(和记黄埔医药(上海))、替尔泊肽注射液(礼来)、乌帕替尼缓释片(艾伯维)、注射用玛贝兰妥单抗(葛兰素史克)7个品种为新适应症上市申请。2024年12月改良型新药上市申请承办情况2024年12月改良型新药临床申请承办情况

新分类仿制药品种申报情况

2024年12月,320个品种仿制申请获CDE承办,其中63个品种在中国境内暂无仿制药获批。富马酸伏诺拉生片申报企业最多,有11家。此外,石家庄四药申报品种最多,有11个。2024年12月新分类仿制药品种申报情况

存量品种一致性评价申报情况

2024年12月,45个品种的一致性评价补充申请获CDE承办。盐酸吡格列酮分散片首次有企业按补充申请申报。2024年12月存量品种一致性评价申报情况

获批情况

2024年12月有8款1类新药首次获批上市,9个品种获批新适应症,1个新剂型获批。190个品种按新分类仿制申请获批并视同过评,43个品种按存量品种一致性评价补充申请过评。其中,17个品种首家过评,阿帕他胺片、艾曲泊帕乙醇胺干混悬剂、巴氯芬口服溶液、碘比醇注射液、氟比洛芬钠滴眼液、精氨酸培哚普利片、聚乙二醇钠钾散、培哚普利氨氯地平片(Ⅲ)、曲伏噻吗滴眼液、司来帕格片、小儿法罗培南钠颗粒等11个品种为首仿品种。2024年12月主要注册类型品种获批情况

数据来源:米内网中国申报进度数据库(MED)、CDE、NMPA;相关统计字段按药品名称统计,申报企业数按主申报企业统计,时间截至2024年12月31日;获批品种按NMPA发布时间统计;药物作用靶点以及适应症整理自公开资料;首仿品种指中国内地首仿品种。

本文为原创稿件,转载请注明来源和作者,否则将追究侵权责任。

投稿及报料请发邮件到872470254@qq.com

稿件要求详询米内微信首页菜单栏

商务及内容合作可联系QQ:412539092

【分享、点赞、在看】点一点不失联哦

一致性评价上市批准

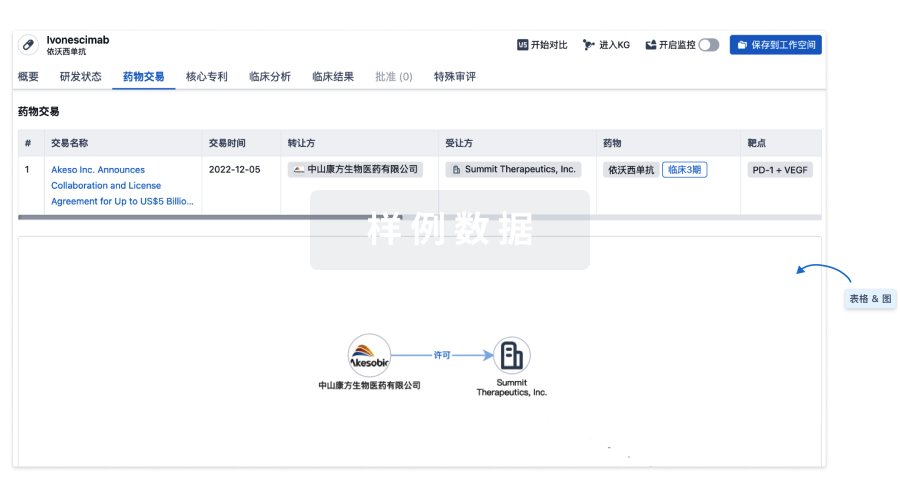

100 项与 氟比洛芬钠 相关的药物交易

登录后查看更多信息

研发状态

批准上市

10 条最早获批的记录, 后查看更多信息

登录

| 适应症 | 国家/地区 | 公司 | 日期 |

|---|---|---|---|

| 强直性脊柱炎 | 中国 | 1998-01-01 | |

| 骨关节炎 | 中国 | 1998-01-01 | |

| 疼痛 | 中国 | 1998-01-01 | |

| 类风湿关节炎 | 中国 | 1998-01-01 | |

| 瞳孔缩小 | 美国 | 1986-12-31 |

未上市

10 条进展最快的记录, 后查看更多信息

登录

| 适应症 | 最高研发状态 | 国家/地区 | 公司 | 日期 |

|---|---|---|---|---|

| 膝关节炎 | 临床3期 | 中国 | 2020-03-31 | |

| 膝关节炎 | 临床3期 | 中国 | 2020-03-31 |

登录后查看更多信息

临床结果

临床结果

适应症

分期

评价

查看全部结果

| 研究 | 分期 | 人群特征 | 评价人数 | 分组 | 结果 | 评价 | 发布日期 |

|---|

No Data | |||||||

登录后查看更多信息

转化医学

使用我们的转化医学数据加速您的研究。

登录

或

药物交易

使用我们的药物交易数据加速您的研究。

登录

或

核心专利

使用我们的核心专利数据促进您的研究。

登录

或

临床分析

紧跟全球注册中心的最新临床试验。

登录

或

批准

利用最新的监管批准信息加速您的研究。

登录

或

特殊审评

只需点击几下即可了解关键药物信息。

登录

或

Eureka LS:

全新生物医药AI Agent 覆盖科研全链路,让突破性发现快人一步

立即开始免费试用!

智慧芽新药情报库是智慧芽专为生命科学人士构建的基于AI的创新药情报平台,助您全方位提升您的研发与决策效率。

立即开始数据试用!

智慧芽新药库数据也通过智慧芽数据服务平台,以API或者数据包形式对外开放,助您更加充分利用智慧芽新药情报信息。

生物序列数据库

生物药研发创新

免费使用

化学结构数据库

小分子化药研发创新

免费使用