预约演示

更新于:2025-09-09

Shanghai Cell Therapy Group Co., Ltd.

更新于:2025-09-09

概览

标签

肿瘤

免疫系统疾病

消化系统疾病

CAR-T

自体CAR-T

双特异性T细胞结合器

疾病领域得分

一眼洞穿机构专注的疾病领域

暂无数据

技术平台

公司药物应用最多的技术

暂无数据

靶点

公司最常开发的靶点

暂无数据

| 排名前五的药物类型 | 数量 |

|---|---|

| CAR-T | 4 |

| 自体CAR-T | 3 |

| 双特异性T细胞结合器 | 2 |

| 治疗性疫苗 | 2 |

| 生物药 | 1 |

关联

18

项与 上海细胞治疗集团股份有限公司 相关的药物作用机制 MSLN抑制剂 [+3] |

在研机构 |

原研机构 |

最高研发阶段临床1/2期 |

首次获批国家/地区- |

首次获批日期- |

作用机制 CD19抑制剂 [+1] |

在研机构 |

原研机构 |

在研适应症 |

非在研适应症- |

最高研发阶段临床1/2期 |

首次获批国家/地区- |

首次获批日期- |

作用机制 CTLA4调节剂 [+1] |

在研机构 |

原研机构 |

非在研适应症- |

最高研发阶段临床1/2期 |

首次获批国家/地区- |

首次获批日期- |

22

项与 上海细胞治疗集团股份有限公司 相关的临床试验NCT07146672

Exploratory Study of Super DC Cell Injection in Preventing Recurrence After Radical Surgery for Tumors

The study is a controlled, open-label exploratory clinical trial.

开始日期2025-07-31 |

申办/合作机构 |

NCT06732232

A Dose Escalating Study of CD19/CD22/BCMA Three Targets Autologous Chimeric Antigen Receptor T (CAR-T) Cell Therapy in Subjects With Relapsed/Refractory Multiple Myeloma

This is a single arm, open-label, dose escalation clinical study to evaluate the safety and tolerability of autologouschimeric antigen receptor T (CAR-T) cells targeting CD19/CD22/BCMA in patients with relapsed/refractory multiple myeloma.

开始日期2024-12-12 |

申办/合作机构 |

NCT06446128

A Dose Escalating Study of CD19/CD22/BCMA Three Targets Autologous Chimeric Antigen Receptor T (CAR-T) Cell Therapy in Subjects With Relapsed or Refractory B Cell Non-Hodgkin Lymphoma(NHL)

This is a single arm, open-label, dose escalation clinical study to evaluate the safety and tolerability of autologous chimeric antigen receptor T (CAR-T) cells targeting CD19/CD22/BCMA in patients with relapsed or refractory B cell non-Hodgkin lymphoma.

开始日期2024-05-07 |

申办/合作机构 |

100 项与 上海细胞治疗集团股份有限公司 相关的临床结果

登录后查看更多信息

0 项与 上海细胞治疗集团股份有限公司 相关的专利(医药)

登录后查看更多信息

18

项与 上海细胞治疗集团股份有限公司 相关的文献(医药)2025-08-14·Scientific Reports

Cryopreserved leukapheresis enables scalable and distributed CAR-T manufacturing: a multi-platform comparative study.

Article

作者: Ren, Menglin ; Liu, Tao ; Xu, Zenghui ; Sun, Yan ; Chen, Jiangrui ; Xu, Yuanjian ; Wang, Xiaodie ; Qian, Qijun

Cryopreserved leukapheresis is a scalable source for Chimeric antigen receptor T (CAR-T) manufacturing, yet it remains understudied (18.3% of 349 studies, 2010-2024). Current challenges include that cryopreserved leukapheresis lacks a standardized preparation process and has a low level of automation. Systematic validation of its clinical feasibility and platform compatibility is imperative. We carried out a series of optimizations, including the centrifugation procedure, the proportion of CS10, and the cryopreservation procedure. Eventually, a standardized cryopreserved leukapheresis process was established through a closed automated system. Subsequently, a systematic evaluation of the quality and functionality of cryopreserved leukapheresis was conducted. Results showed that cryopreserved leukapheresis achieved ≥ 90% post-thaw viability, with recovery and phenotypic profiles comparable to peripheral blood mononuclear cells (PBMCs). It exhibited a higher lymphocyte proportion than PBMCs (66.59% vs. 52.20%), correlating with enhanced CAR-T potential. Initial viability (91.0%) was lower than fresh samples (99.0%), but functional recovery post-electroporation and compatibility with both platforms were confirmed. In the non-viral CAR-T, lentiviral CAR-T, and Fast CAR-T platforms, cryopreserved leukapheresis and fresh leukapheresis were comparable in cell viability, expansion, cell phenotype, CAR + cell proportion, and cytotoxicity. This study comprehensively validated cryopreserved leukapheresis as a universal raw material for CAR-T manufacturing, preserving critical quality attributes (T-cell fitness, CAR functionality) without compromising consistency. Decoupling from fresh material logistics improves supply chain resilience. Protocol standardization and large-scale clinical validation remain critical next steps.

2025-08-11·Journal of Translational Medicine

Low-liver-accumulation lipid nanoparticles enhance the efficacy and safety of HPV therapeutic tumor vaccines.

Article

作者: Fang, Yuan ; Guo, Chuanxin ; Yang, Shuyan ; Bai, Xuesen ; Wang, Meng ; Zeng, Jianyao ; Liu, Tao ; Wang, Xiaodie ; Qian, Qijun ; Wang, Pei ; Cai, Xiaoru ; Sun, Yan ; Tian, Zhidan

BACKGROUND:

Lipid nanoparticles (LNPs) hold significant potential in vaccine and cancer therapy, but conventional LNPs often cause hepatotoxicity and reduced efficacy due to liver accumulation.

METHODS:

LNP molecules with varying tail lengths were synthesized in vitro. Transfection efficiency was assessed in vitro via flow cytometry. The BALB/c model was used to evaluate in vivo delivery efficiency of the LNPs. The C57BL/6 mouse model was used to evaluate in vivo anti-tumor pharmacodynamics, along with tumor-infiltrating immune cells and serum inflammatory cytokines. The Sprague Dawley (SD) rat model was used for toxicity testing of the candidate LNP.

RESULTS:

Lipid 7 demonstrated threefold higher mRNA expression efficiency at the injection site while minimizing liver retention. In an HPV tumor model, Lipid 7 achieved tumor suppression comparable to SM-102-based LNP but outperformed in remodeling the tumor microenvironment (dendritic cells: 12.1% vs. 5.1%; natural killer cells: 1.1% vs. 0.5%) and elevating serum immune cytokines (TNF-α, IL-1β, etc., 1.2-1.8-fold higher). Critically, Lipid 7 reduced off-target mRNA accumulation in the heart, liver, spleen, lungs, and kidneys, mitigating hepatotoxicity risks associated with traditional LNPs.

CONCLUSIONS:

By employing a novel, non-patented ionizable lipid design, this work balances delivery efficiency and biosafety, Lipid 7 offers a high-efficacy, low-toxicity therapeutic strategy for HPV-related cancers.

2025-01-01·DRUG DISCOVERY TODAY

Targeting spleen tyrosine kinase (SYK): structure, mechanisms and drug discovery

Review

作者: Lu, Yingying ; Wang, Lilin ; Zhang, Lan ; Zhang, Tongtong ; Guo, Chuanxin ; Zhang, Shuangqian

Spleen tyrosine kinase (SYK) is a crucial non-receptor tyrosine kinase involved in signaling pathways that regulate various cellular processes. It is primarily expressed in hematopoietic cells and myeloid cells, which are crucial for B-cell development, maturation and antibody production, and it is a key therapeutic target for autoimmune and allergic diseases. Overexpression of SYK is also associated with cancer and cardiovascular, cerebrovascular and neurodegenerative diseases, contributing to their initiation and progression. SYK is a promising target for drug development, and several inhibitors have already been reported. This review covers the structure and regulatory pathways of SYK, as well as its links to various diseases. It also highlights key small-molecule SYK inhibitors, their design strategies and their potential therapeutic benefits, aiming to enhance our understanding and aid in the discovery of more-effective SYK inhibitors.

439

项与 上海细胞治疗集团股份有限公司 相关的新闻(医药)13 小时之前

·同写意

9月9日,驯鹿生物与赛桥生物正式签署全球战略合作协议,共同推动国产先进细胞治疗药物产业链一体化出海。赛桥生物创始人、董事长兼首席执行官商院芳博士与驯鹿生物创始人、董事长兼首席执行官张金华共同出席签约仪式。

签约现场合影(前排左一驯鹿生物首席商务官张华,右一赛桥生物免疫细胞业务线总裁陈静,后排左四驯鹿生物创始人、董事长兼首席执行官张金华,右四赛桥生物创始人、董事长兼首席执行官商院芳博士,及双方管理团队代表)

秉持“让天下没有治不起的病”的发展愿景,赛桥生物聚焦细胞治疗领域“工艺即产品、工具即工艺”的行业特性,以及“交不出、用不起”的行业核心痛点,与行业客户深度协同。通过工艺-工具一体化技术创新,推动细胞制备从传统手工开放模式,逐步升级为单机自动封闭化、流程集成化、床旁智能化的全新生产范式,实现自体细胞药物生产成本降低5-10倍、异体细胞药物生产成本降低数十倍的突破。核心产品及解决方案已覆盖全球10余个国家、超100条细胞治疗管线,累计装机量近1000台,成功支撑中国首款MSC上市药物及多款CAR-T上市药物的研发与生产,成为全球前三覆盖早研、临床至商业化全阶段且具备完全自主知识产权的细胞治疗工具平台。

本次驯鹿生物与赛桥生物达成战略合作,标志着双方正式启动“驯鹿生物细胞生产工艺+赛桥生物智能制造”的全球协同模式,加速国产细胞治疗产业链一体化的输出,满足国际市场对先进治疗技术的需求。合作将从技术协同与市场拓展两个维度深入推进:在技术层面,双方将共同建立工艺开发机制,结合驯鹿生物在CAR-T药物研发方面的深厚经验与赛桥生物在高端装备适配领域的核心能力,协同提升细胞治疗产品的生产可行性;在市场层面,将整合彼此的国际渠道资源,推动整体解决方案在海外市场的落地与应用。此次合作不仅是两家企业之间的资源互补,更为中国细胞治疗产业链上下游协同出海提供了重要实践范例,有望进一步增强中国先进治疗技术在全球市场的影响力。

关于赛桥生物

赛桥生物成立于2020年3月,由清华大学精密仪器系博士、德国国家工程院院士张友明教授联合创办,核心团队曾负责国家生物仪器重大专项,拥有10+年仪器工程与生物相关技术积累,是国内最早深耕细胞处理与自动化装备的专业团队。

秉持“让天下没有治不起的病”的发展愿景,赛桥生物聚焦细胞治疗领域“工艺即产品、工具即工艺”的行业特性,以及“交不出、用不起”的行业核心痛点,与行业客户深度协同。通过工艺-工具一体化技术创新,推动细胞制备从传统手工开放模式,逐步升级为单机自动封闭化、流程集成化、床旁智能化的全新生产范式,实现自体细胞药物生产成本降低5-10倍、异体细胞药物生产成本降低数十倍的突破。核心产品及解决方案已覆盖全球10余个国家、超100条细胞治疗管线,累计装机量近1000台,成功支撑中国首款MSC上市药物及多款CAR-T上市药物的研发与生产,成为全球前三覆盖早研、临床至商业化全阶段且具备完全自主知识产权的细胞治疗工具平台。

关于驯鹿生物

驯鹿生物成立于2017年,是一家行业领先的专注于研发、生产和销售创新细胞疗法的生物制药公司。公司以开发血液肿瘤细胞类药物为创新基石,并向自身免疫性疾病领域和抗体类药物拓展,拥有完整的从早期药物发现、临床研发、注册申报到商业化的全流程能力。公司现有10余款处于不同研发阶段的创新药物品种,其中由驯鹿生物自主研发的全球首个全人源CAR-T产品,靶向BCMA的伊基奥仑赛注射液(福可苏®)已于2023年6月获中国国家药品监督管理局(NMPA)批准上市,用于治疗既往经过至少3线治疗后进展(至少使用过一种蛋白酶体抑制剂及免疫调节剂)的复发或难治性多发性骨髓瘤(R/R MM)成人患者。其前线适应症用于治疗2-3线多发性骨髓瘤(MM)已进入III期临床。此外,伊基奥仑赛注射液在中国和美国已获得多个自身免疫性疾病的新药临床试验申请(IND)许可。

同时,针对淋巴瘤的双靶点(CD19/CD22)产品CT120即将进入II期临床。另一款靶向GPRC5D用于治疗复发难治多发性骨髓瘤的产品IASO118已在中国获得IND许可。除细胞疗法产品外,公司的全人源靶向CD19抗体产品IASO-782,已在中国和美国获得治疗多个自身免疫性疾病的IND许可,同时仍在探索更多的自身免疫性疾病适应症。公司先后和海外细胞治疗公司Sana Therapeutics、Cabaletta Bio及Umoja Biopharma达成全球商业拓展授权或研发合作,积极探索新一代细胞疗法产品的开发。驯鹿生物依托其强大的管理团队、创新的产品管线、自有的GMP生产和先进的临床开发能力,全力以赴为中国及全球患者带来变革性、可及的创新疗法和治愈的希望。

关于同写意

同写意论坛是中国新药研发行业权威的多元化交流平台,二十一年来共举办会议论坛百余期。“同写意新药英才俱乐部”基于同写意论坛而成立,早已成为众多新药英才的精神家园和中国新药思想的重要发源地之一。同写意在北京、苏州、深圳、成都设立多个管理中心负责同写意活动的运营。

尊享多重企业/机构会员特权

● 分享庞大新药生态圈资源库;

● 同写意活动优享折扣;

● 会员专属坐席及专家交流机会;

● 同写意活动优先赞助权;

● 机构品牌活动策划与全方位推广;

● 秘书处一对一贴心服务。

入会请联系同写意秘书处

同写意创新链盟机构

(上下滑动查看更多)

瀚枢生物 | 深势科技 | 新天地药业 | 快舒尔医疗 | 华赛伯曼 | 艾里奥斯 | 药明合联 | 皓元医药 | 希格生科 | 纽瑞特医疗 | 夸克医药 | 石药集团 | 源生生物 | 君赛生物 | 达尔文生物 | 浩博工程 | 怀雅特 | 赛立维 | 科伦博泰 | 赛隽生物 | 安升达/金唯智 | 卡替医疗 | 达科为生物 | 沙利文 | 天广实 | 拜耳 | 楚天科技 | 三生制药 | 三启生物 | 国通新药 | 通瑞生物 | 科济药业丨立迪生物 | 森西赛智 | 汇芯生物 | 申科生物 | 方拓生物 | 东抗生物 | 科盛达 | 依利特 | 翊曼生物丨锐拓生物丨复百澳生物丨圆因生物丨普洛斯丨华润三九丨皓阳生物丨人福医药丨广生堂药业丨澳宗生物丨妙顺生物 | 荣捷生物丨行诚生物 | 宜联生物 | 生命资本 | 恒诺康丨斯丹姆 | 益诺思 | 深圳细胞谷丨佰诺达生物 | 沃臻生物 | 金仪盛世 | 朗信生物 | 亦笙科技 | 中健云康 | 九州通 | 劲帆医药 | 沙砾生物 | 裕策生物 | 同立海源 | 药明生基 | 奥浦迈 | 原启生物 | 百力司康 | 宁丹新药 | 上海细胞治疗集团 | 滨会生物 | FTA | 派真生物 | 希济生物 | 优睿赛思 | 血霁生物 | 优睿生物 | 邦耀生物 | 华大基因 | 银诺生物 | 百林科医药 | 纳微科技 | 可瑞生物 | 夏尔巴生物 | 金斯瑞蓬勃生物 | 健元医药 | 星眸生物 | 格兰科医药 | 莱羡科学仪器 | 明度智云 | 玮驰仪器 | 康源久远 | 易慕峰 | 茂行生物 | 济民可信 | 欣协生物 | 泰楚生物 | 泰澧生物 | 谱新生物 | 思鹏生物 | 领诺医药 | 宜明生物 | 爱科瑞思 | 阿思科力 | 博格隆生物 | 百吉生物 | 迈邦生物 | 多宁生物 | 万邦医药 | ASCT | 为度生物 | 比邻星创投 | 赛桥生物 | 吉美瑞生 | 荣泽生物 | 科金生物 | 汉超医药 | 康日百奥 | 汉腾生物 | 力品药业 | 安必生 | 博瑞策生物 | 中盛溯源 | 深研生物 | 东方略 | 赛赋医药 | 克睿基因 | 安润医药 | 镁伽科技 | 科锐迈德 | 和元生物 | 申基生物 |楷拓生物| 森松生命科技 | 凯理斯 | 尚德药缘 | 晟国医药 | 健新原力 | 纽福斯 | 华东医药 | 士泽生物 | 影研医疗科技 | 新格元生物 | 依生生物 | 腾迈医药 | 汉欣医药 | 恒驭生物 | 盛诺基 | 序祯达生物 | 乐纯生物 | 速石科技 | 耀海生物 | 新合生物 | 华龛生物 | 恺佧生物 | 成都凡微析 | 正帆科技 | 大橡科技 | 博雅辑因 | 因美纳 | 博雅控股集团 | 近岸蛋白 | 依科赛生物 | 利穗科技 | 东南科仪 | 倍谙基 | 辉诺医药 | 圣诺制药 | 埃格林医药 | 科镁信 | 爱思益普 | 复星医药 | 齐鲁制药 | 捷思英达丨荣昌生物丨泽璟制药丨奕安济世丨礼新医药丨维立志博丨派格生物丨赛生药业丨呈源生物丨启德医药丨双运生物丨宝船生物丨曙方医药丨澳斯康生物丨普莱医药丨维健医药丨海昶生物丨征祥医药丨智核生物丨望石智慧丨博生吉医药丨南京诺丹丨四星玻璃丨艾米能斯丨霁因生物丨普瑞康生物丨映恩生物丨康哲生物丨霍德生物丨海慈药业丨沃生生物丨睿健医药丨矩阵元丨斯微生物丨则正医药丨预立创投丨东立创新丨博安生物丨伟德杰生物丨星奕昂生物丨耀乘健康科技丨琅钰集团丨康德弘翼 | 原力生命科学丨上海科洲丨特瑞思丨药源丨健艾仕生物丨冠科美博丨微境生物丨天境生物丨合源生物丨泛生子丨创胜集团丨加科思药业丨丹诺医药丨凌科药业丨偶领生物丨凯斯艾生物丨成都圣诺丨松禾资本丨清普生物丨和其瑞丨开拓药业丨科兴制药丨玉森新药丨水木未来丨分享投资丨植德律所丨奥来恩丨乐明药业丨东曜药业丨君圣泰丨海创药业丨天汇资本丨再鼎医药丨济煜医药丨百英生物丨基石药业丨君实生物丨Sirnaomics,Inc.丨亦诺微丨博腾股份丨思路迪诊断丨艾博生物丨普瑞金生物丨未知君生物丨尚健生物丨阿诺医药丨有临医药丨赛业生物丨睿智医药丨博济医药丨晶泰科技丨药明康德丨创志科技丨奥星集团丨苏雅医药丨科贝源丨合全药业丨以岭药业丨科睿唯安丨DRG丨博瑞医药丨丽珠医药丨信立泰药业丨步长制药丨华素制药丨众生药业丨上海医药丨高博医疗集团丨药渡丨君联资本丨集萃药康丨诺思格丨精鼎医药丨百利药业丨Pfizer CentreOne丨默克中国创新中心丨奥来恩丨瑞博生物丨新通药物丨广东中润丨医普科诺丨诺唯赞丨康利华丨国信医药丨昆翎丨博纳西亚丨缔脉丨一品红丨和泽医药丨博志研新丨凯莱英医药丨汉佛莱丨英派药业丨京卫制药丨海思科药业丨宏韧医药丨开心生活科技丨哈三联丨Premier Research丨宣泰医药丨先声药业丨海金格丨普瑞盛医药丨Informa丨科特勒丨谋思医药丨HLT丨莱佛士丨辉瑞丨科林利康丨冠科生物丨科文斯丨卫信康丨龙沙(Lonza)丨美迪西丨阳光诺和丨润东医药丨勃林格殷格翰(中国)丨艾苏莱生物丨领晟医疗丨驯鹿医疗丨燃石医学丨中肽生化丨鸿运华宁丨泰格医药丨易迪希丨希麦迪丨百奥赛图丨迪纳利丨青云瑞晶丨鼎丰生科资本丨中源协和丨维亚生物丨青松医药丨中科谱研丨长风药业丨艾欣达伟丨鼎康生物丨中晟全肽丨海步医药丨勤浩医药丨奥萨医药丨太美医疗科技丨生特瑞丨东富龙丨Cytiva丨优辰实验室丨苏桥生物丨君达合创丨澎立生物丨南京澳健丨南京科默丨东阳光丨亚盛医药丨杰克森实验室丨上海科州丨三优生物丨三迭纪丨泰诺麦博丨Cell Signaling Technology丨PPC佳生丨澳斯康丨先为达丨智享生物丨锐得麦丨宜明昂科丨明济生物丨英百瑞丨六合宁远丨天津天诚丨百拓生物丨星药科技丨亓上生物丨真实生物丨引光医药丨方达医药丨高博医疗集团丨赞荣医药丨国投创新丨药明生物丨康哲药业丨高特佳投资丨普瑞基准丨臻格生物丨微谱医药丨和玉资本 | 倚锋资本

细胞疗法免疫疗法

23 小时之前

·同写意

关于同写意

同写意论坛是中国新药研发行业权威的多元化交流平台,二十一年来共举办会议论坛百余期。“同写意新药英才俱乐部”基于同写意论坛而成立,早已成为众多新药英才的精神家园和中国新药思想的重要发源地之一。同写意在北京、苏州、深圳、成都设立多个管理中心负责同写意活动的运营。

尊享多重企业/机构会员特权

● 分享庞大新药生态圈资源库;

● 同写意活动优享折扣;

● 会员专属坐席及专家交流机会;

● 同写意活动优先赞助权;

● 机构品牌活动策划与全方位推广;

● 秘书处一对一贴心服务。

入会请联系同写意秘书处

同写意创新链盟机构

(上下滑动查看更多)

瀚枢生物 | 深势科技 | 新天地药业 | 快舒尔医疗 | 华赛伯曼 | 艾里奥斯 | 药明合联 | 皓元医药 | 希格生科 | 纽瑞特医疗 | 夸克医药 | 石药集团 | 源生生物 | 君赛生物 | 达尔文生物 | 浩博工程 | 怀雅特 | 赛立维 | 科伦博泰 | 赛隽生物 | 安升达/金唯智 | 卡替医疗 | 达科为生物 | 沙利文 | 天广实 | 拜耳 | 楚天科技 | 三生制药 | 三启生物 | 国通新药 | 通瑞生物 | 科济药业丨立迪生物 | 森西赛智 | 汇芯生物 | 申科生物 | 方拓生物 | 东抗生物 | 科盛达 | 依利特 | 翊曼生物丨锐拓生物丨复百澳生物丨圆因生物丨普洛斯丨华润三九丨皓阳生物丨人福医药丨广生堂药业丨澳宗生物丨妙顺生物 | 荣捷生物丨行诚生物 | 宜联生物 | 生命资本 | 恒诺康丨斯丹姆 | 益诺思 | 深圳细胞谷丨佰诺达生物 | 沃臻生物 | 金仪盛世 | 朗信生物 | 亦笙科技 | 中健云康 | 九州通 | 劲帆医药 | 沙砾生物 | 裕策生物 | 同立海源 | 药明生基 | 奥浦迈 | 原启生物 | 百力司康 | 宁丹新药 | 上海细胞治疗集团 | 滨会生物 | FTA | 派真生物 | 希济生物 | 优睿赛思 | 血霁生物 | 优睿生物 | 邦耀生物 | 华大基因 | 银诺生物 | 百林科医药 | 纳微科技 | 可瑞生物 | 夏尔巴生物 | 金斯瑞蓬勃生物 | 健元医药 | 星眸生物 | 格兰科医药 | 莱羡科学仪器 | 明度智云 | 玮驰仪器 | 康源久远 | 易慕峰 | 茂行生物 | 济民可信 | 欣协生物 | 泰楚生物 | 泰澧生物 | 谱新生物 | 思鹏生物 | 领诺医药 | 宜明生物 | 爱科瑞思 | 阿思科力 | 博格隆生物 | 百吉生物 | 迈邦生物 | 多宁生物 | 万邦医药 | ASCT | 为度生物 | 比邻星创投 | 赛桥生物 | 吉美瑞生 | 荣泽生物 | 科金生物 | 汉超医药 | 康日百奥 | 汉腾生物 | 力品药业 | 安必生 | 博瑞策生物 | 中盛溯源 | 深研生物 | 东方略 | 赛赋医药 | 克睿基因 | 安润医药 | 镁伽科技 | 科锐迈德 | 和元生物 | 申基生物 |楷拓生物| 森松生命科技 | 凯理斯 | 尚德药缘 | 晟国医药 | 健新原力 | 纽福斯 | 华东医药 | 士泽生物 | 影研医疗科技 | 新格元生物 | 依生生物 | 腾迈医药 | 汉欣医药 | 恒驭生物 | 盛诺基 | 序祯达生物 | 乐纯生物 | 速石科技 | 耀海生物 | 新合生物 | 华龛生物 | 恺佧生物 | 成都凡微析 | 正帆科技 | 大橡科技 | 博雅辑因 | 因美纳 | 博雅控股集团 | 近岸蛋白 | 依科赛生物 | 利穗科技 | 东南科仪 | 倍谙基 | 辉诺医药 | 圣诺制药 | 埃格林医药 | 科镁信 | 爱思益普 | 复星医药 | 齐鲁制药 | 捷思英达丨荣昌生物丨泽璟制药丨奕安济世丨礼新医药丨维立志博丨派格生物丨赛生药业丨呈源生物丨启德医药丨双运生物丨宝船生物丨曙方医药丨澳斯康生物丨普莱医药丨维健医药丨海昶生物丨征祥医药丨智核生物丨望石智慧丨博生吉医药丨南京诺丹丨四星玻璃丨艾米能斯丨霁因生物丨普瑞康生物丨映恩生物丨康哲生物丨霍德生物丨海慈药业丨沃生生物丨睿健医药丨矩阵元丨斯微生物丨则正医药丨预立创投丨东立创新丨博安生物丨伟德杰生物丨星奕昂生物丨耀乘健康科技丨琅钰集团丨康德弘翼 | 原力生命科学丨上海科洲丨特瑞思丨药源丨健艾仕生物丨冠科美博丨微境生物丨天境生物丨合源生物丨泛生子丨创胜集团丨加科思药业丨丹诺医药丨凌科药业丨偶领生物丨凯斯艾生物丨成都圣诺丨松禾资本丨清普生物丨和其瑞丨开拓药业丨科兴制药丨玉森新药丨水木未来丨分享投资丨植德律所丨奥来恩丨乐明药业丨东曜药业丨君圣泰丨海创药业丨天汇资本丨再鼎医药丨济煜医药丨百英生物丨基石药业丨君实生物丨Sirnaomics,Inc.丨亦诺微丨博腾股份丨思路迪诊断丨艾博生物丨普瑞金生物丨未知君生物丨尚健生物丨阿诺医药丨有临医药丨赛业生物丨睿智医药丨博济医药丨晶泰科技丨药明康德丨创志科技丨奥星集团丨苏雅医药丨科贝源丨合全药业丨以岭药业丨科睿唯安丨DRG丨博瑞医药丨丽珠医药丨信立泰药业丨步长制药丨华素制药丨众生药业丨上海医药丨高博医疗集团丨药渡丨君联资本丨集萃药康丨诺思格丨精鼎医药丨百利药业丨Pfizer CentreOne丨默克中国创新中心丨奥来恩丨瑞博生物丨新通药物丨广东中润丨医普科诺丨诺唯赞丨康利华丨国信医药丨昆翎丨博纳西亚丨缔脉丨一品红丨和泽医药丨博志研新丨凯莱英医药丨汉佛莱丨英派药业丨京卫制药丨海思科药业丨宏韧医药丨开心生活科技丨哈三联丨Premier Research丨宣泰医药丨先声药业丨海金格丨普瑞盛医药丨Informa丨科特勒丨谋思医药丨HLT丨莱佛士丨辉瑞丨科林利康丨冠科生物丨科文斯丨卫信康丨龙沙(Lonza)丨美迪西丨阳光诺和丨润东医药丨勃林格殷格翰(中国)丨艾苏莱生物丨领晟医疗丨驯鹿医疗丨燃石医学丨中肽生化丨鸿运华宁丨泰格医药丨易迪希丨希麦迪丨百奥赛图丨迪纳利丨青云瑞晶丨鼎丰生科资本丨中源协和丨维亚生物丨青松医药丨中科谱研丨长风药业丨艾欣达伟丨鼎康生物丨中晟全肽丨海步医药丨勤浩医药丨奥萨医药丨太美医疗科技丨生特瑞丨东富龙丨Cytiva丨优辰实验室丨苏桥生物丨君达合创丨澎立生物丨南京澳健丨南京科默丨东阳光丨亚盛医药丨杰克森实验室丨上海科州丨三优生物丨三迭纪丨泰诺麦博丨Cell Signaling Technology丨PPC佳生丨澳斯康丨先为达丨智享生物丨锐得麦丨宜明昂科丨明济生物丨英百瑞丨六合宁远丨天津天诚丨百拓生物丨星药科技丨亓上生物丨真实生物丨引光医药丨方达医药丨高博医疗集团丨赞荣医药丨国投创新丨药明生物丨康哲药业丨高特佳投资丨普瑞基准丨臻格生物丨微谱医药丨和玉资本 | 倚锋资本

细胞疗法引进/卖出

2025-09-08

·同写意

智享生物(苏州)有限公司第9、10条产线预计将于2025年9月正式投产,此次投产将提升智享生物原液产能,加速赋能全球创新药企业多元化生物药的研发进程。此前已于2023年投产的第7、8原液生产线涵盖2条细胞培养线和2条蛋白纯化线,可以实现2000L到6000L规模生产,灵活匹配客户全流程需求。

智享生物成立于2018年,于2021年在常熟建立多模块集成化的生物药生产基地,并于2023年实现正式投产。随着新产线建成投运,总产能大幅提升至10.33万升。新投产产线具备年产2500公斤抗体类药物的能力,理论可满足约50万人次的临床用药需求。产品范围覆盖单抗、双抗、融合蛋白、抗体药物偶联物(ADC)及疫苗等大分子药物,重点聚焦肿瘤、自身免疫性疾病和代谢类疾病等治疗领域。

核心亮点解析:

01

绿色智能设计

全新投产产线的黑白分区设计,将洁净区体积压缩71%,空调能耗降低35%,践行绿色生产理念。

配套高效热回收系统,热水机组蒸汽消耗降低30%,推动厂区能源循环高效化。

02

安全与智能融合,保障卓越运营

常熟生产基地部署自动化物料传输系统,实现30秒内将多条产线样品精准送达IPC检测中心,最大程度降低转运风险,保障数据时效性。

采用艾默生DeltaV™分布式控制系统作为原液生产自控平台,对上下游工艺进行“集中监控、分散控制”。实现独立工艺流程控制, 确保单个环节异常不影响全局生产,大幅提升系统可靠性与安全性,实现智能化生产管理。

采用在线配液系统(CIP/SIP),根据预设配方自动、精准配液,按需实时补给,显著节省储存空间、减少人工干预与搬运风险、提升整体生产效率与批次一致性。

关于智享生物

智享生物(苏州)有限公司成立于2018年,是国内领先的一站式生物药CDMO服务商,专注于为抗体、双抗、融合蛋白、ADC、疫苗等大分子药物研发企业及科研机构提供从早期开发到商业化生产的全生命周期服务。凭借自主 知识产权 的核心技术平台与规模化产能优势,公司已成为国家级专精特新“小巨人”企业,累计获得生物医药领域专利超40项,国内CDMO产能规模前十强。

智享生物在7年内完成3大生产基地建设,拥有独特的模块化灵活排产系统,通过28个6000L反应器集群实现多线并行,可同时兼顾高产能和高灵活性。智享生物同时也是国内少数具有自主细胞株、自主化学限定组分培养基的CDMO企业,是国内少数具有核心技术、规模量产能力、商业化闭环综合能力的CDMO企业。

截止当前,智享生物累计签约40余亿元人民币,服务全球180多家生物药企业,通过3次国家级现场核查,总计客户项目约400余个,其中包括13个晚期临床项目,2个商业化项目已获批,临床许可数量已累积至89份,涵盖了中国、美国、澳洲、新西兰等国家。

关于同写意

同写意论坛是中国新药研发行业权威的多元化交流平台,二十一年来共举办会议论坛百余期。“同写意新药英才俱乐部”基于同写意论坛而成立,早已成为众多新药英才的精神家园和中国新药思想的重要发源地之一。同写意在北京、苏州、深圳、成都设立多个管理中心负责同写意活动的运营。

尊享多重企业/机构会员特权

● 分享庞大新药生态圈资源库;

● 同写意活动优享折扣;

● 会员专属坐席及专家交流机会;

● 同写意活动优先赞助权;

● 机构品牌活动策划与全方位推广;

● 秘书处一对一贴心服务。

入会请联系同写意秘书处

同写意创新链盟机构

(上下滑动查看更多)

瀚枢生物 | 深势科技 | 新天地药业 | 快舒尔医疗 | 华赛伯曼 | 艾里奥斯 | 药明合联 | 皓元医药 | 希格生科 | 纽瑞特医疗 | 夸克医药 | 石药集团 | 源生生物 | 君赛生物 | 达尔文生物 | 浩博工程 | 怀雅特 | 赛立维 | 科伦博泰 | 赛隽生物 | 安升达/金唯智 | 卡替医疗 | 达科为生物 | 沙利文 | 天广实 | 拜耳 | 楚天科技 | 三生制药 | 三启生物 | 国通新药 | 通瑞生物 | 科济药业丨立迪生物 | 森西赛智 | 汇芯生物 | 申科生物 | 方拓生物 | 东抗生物 | 科盛达 | 依利特 | 翊曼生物丨锐拓生物丨复百澳生物丨圆因生物丨普洛斯丨华润三九丨皓阳生物丨人福医药丨广生堂药业丨澳宗生物丨妙顺生物 | 荣捷生物丨行诚生物 | 宜联生物 | 生命资本 | 恒诺康丨斯丹姆 | 益诺思 | 深圳细胞谷丨佰诺达生物 | 沃臻生物 | 金仪盛世 | 朗信生物 | 亦笙科技 | 中健云康 | 九州通 | 劲帆医药 | 沙砾生物 | 裕策生物 | 同立海源 | 药明生基 | 奥浦迈 | 原启生物 | 百力司康 | 宁丹新药 | 上海细胞治疗集团 | 滨会生物 | FTA | 派真生物 | 希济生物 | 优睿赛思 | 血霁生物 | 优睿生物 | 邦耀生物 | 华大基因 | 银诺生物 | 百林科医药 | 纳微科技 | 可瑞生物 | 夏尔巴生物 | 金斯瑞蓬勃生物 | 健元医药 | 星眸生物 | 格兰科医药 | 莱羡科学仪器 | 明度智云 | 玮驰仪器 | 康源久远 | 易慕峰 | 茂行生物 | 济民可信 | 欣协生物 | 泰楚生物 | 泰澧生物 | 谱新生物 | 思鹏生物 | 领诺医药 | 宜明生物 | 爱科瑞思 | 阿思科力 | 博格隆生物 | 百吉生物 | 迈邦生物 | 多宁生物 | 万邦医药 | ASCT | 为度生物 | 比邻星创投 | 赛桥生物 | 吉美瑞生 | 荣泽生物 | 科金生物 | 汉超医药 | 康日百奥 | 汉腾生物 | 力品药业 | 安必生 | 博瑞策生物 | 中盛溯源 | 深研生物 | 东方略 | 赛赋医药 | 克睿基因 | 安润医药 | 镁伽科技 | 科锐迈德 | 和元生物 | 申基生物 |楷拓生物| 森松生命科技 | 凯理斯 | 尚德药缘 | 晟国医药 | 健新原力 | 纽福斯 | 华东医药 | 士泽生物 | 影研医疗科技 | 新格元生物 | 依生生物 | 腾迈医药 | 汉欣医药 | 恒驭生物 | 盛诺基 | 序祯达生物 | 乐纯生物 | 速石科技 | 耀海生物 | 新合生物 | 华龛生物 | 恺佧生物 | 成都凡微析 | 正帆科技 | 大橡科技 | 博雅辑因 | 因美纳 | 博雅控股集团 | 近岸蛋白 | 依科赛生物 | 利穗科技 | 东南科仪 | 倍谙基 | 辉诺医药 | 圣诺制药 | 埃格林医药 | 科镁信 | 爱思益普 | 复星医药 | 齐鲁制药 | 捷思英达丨荣昌生物丨泽璟制药丨奕安济世丨礼新医药丨维立志博丨派格生物丨赛生药业丨呈源生物丨启德医药丨双运生物丨宝船生物丨曙方医药丨澳斯康生物丨普莱医药丨维健医药丨海昶生物丨征祥医药丨智核生物丨望石智慧丨博生吉医药丨南京诺丹丨四星玻璃丨艾米能斯丨霁因生物丨普瑞康生物丨映恩生物丨康哲生物丨霍德生物丨海慈药业丨沃生生物丨睿健医药丨矩阵元丨斯微生物丨则正医药丨预立创投丨东立创新丨博安生物丨伟德杰生物丨星奕昂生物丨耀乘健康科技丨琅钰集团丨康德弘翼 | 原力生命科学丨上海科洲丨特瑞思丨药源丨健艾仕生物丨冠科美博丨微境生物丨天境生物丨合源生物丨泛生子丨创胜集团丨加科思药业丨丹诺医药丨凌科药业丨偶领生物丨凯斯艾生物丨成都圣诺丨松禾资本丨清普生物丨和其瑞丨开拓药业丨科兴制药丨玉森新药丨水木未来丨分享投资丨植德律所丨奥来恩丨乐明药业丨东曜药业丨君圣泰丨海创药业丨天汇资本丨再鼎医药丨济煜医药丨百英生物丨基石药业丨君实生物丨Sirnaomics,Inc.丨亦诺微丨博腾股份丨思路迪诊断丨艾博生物丨普瑞金生物丨未知君生物丨尚健生物丨阿诺医药丨有临医药丨赛业生物丨睿智医药丨博济医药丨晶泰科技丨药明康德丨创志科技丨奥星集团丨苏雅医药丨科贝源丨合全药业丨以岭药业丨科睿唯安丨DRG丨博瑞医药丨丽珠医药丨信立泰药业丨步长制药丨华素制药丨众生药业丨上海医药丨高博医疗集团丨药渡丨君联资本丨集萃药康丨诺思格丨精鼎医药丨百利药业丨Pfizer CentreOne丨默克中国创新中心丨奥来恩丨瑞博生物丨新通药物丨广东中润丨医普科诺丨诺唯赞丨康利华丨国信医药丨昆翎丨博纳西亚丨缔脉丨一品红丨和泽医药丨博志研新丨凯莱英医药丨汉佛莱丨英派药业丨京卫制药丨海思科药业丨宏韧医药丨开心生活科技丨哈三联丨Premier Research丨宣泰医药丨先声药业丨海金格丨普瑞盛医药丨Informa丨科特勒丨谋思医药丨HLT丨莱佛士丨辉瑞丨科林利康丨冠科生物丨科文斯丨卫信康丨龙沙(Lonza)丨美迪西丨阳光诺和丨润东医药丨勃林格殷格翰(中国)丨艾苏莱生物丨领晟医疗丨驯鹿医疗丨燃石医学丨中肽生化丨鸿运华宁丨泰格医药丨易迪希丨希麦迪丨百奥赛图丨迪纳利丨青云瑞晶丨鼎丰生科资本丨中源协和丨维亚生物丨青松医药丨中科谱研丨长风药业丨艾欣达伟丨鼎康生物丨中晟全肽丨海步医药丨勤浩医药丨奥萨医药丨太美医疗科技丨生特瑞丨东富龙丨Cytiva丨优辰实验室丨苏桥生物丨君达合创丨澎立生物丨南京澳健丨南京科默丨东阳光丨亚盛医药丨杰克森实验室丨上海科州丨三优生物丨三迭纪丨泰诺麦博丨Cell Signaling Technology丨PPC佳生丨澳斯康丨先为达丨智享生物丨锐得麦丨宜明昂科丨明济生物丨英百瑞丨六合宁远丨天津天诚丨百拓生物丨星药科技丨亓上生物丨真实生物丨引光医药丨方达医药丨高博医疗集团丨赞荣医药丨国投创新丨药明生物丨康哲药业丨高特佳投资丨普瑞基准丨臻格生物丨微谱医药丨和玉资本 | 倚锋资本

抗体药物偶联物疫苗

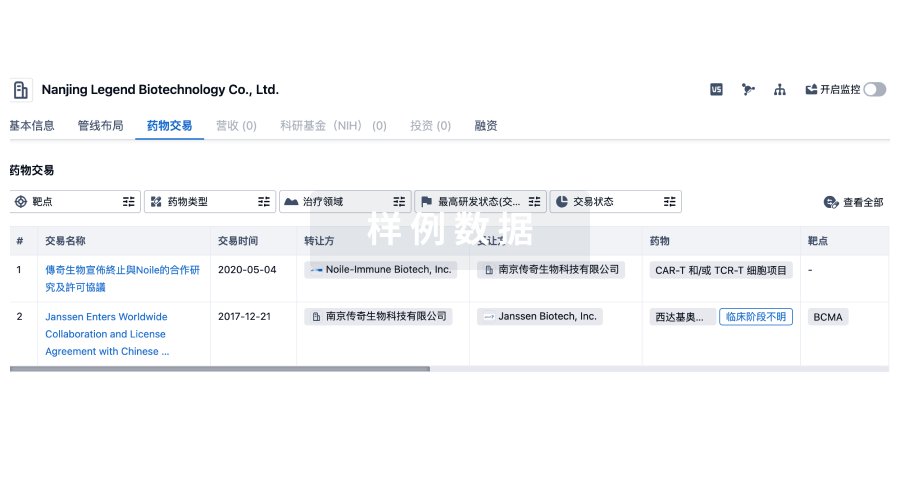

100 项与 上海细胞治疗集团股份有限公司 相关的药物交易

登录后查看更多信息

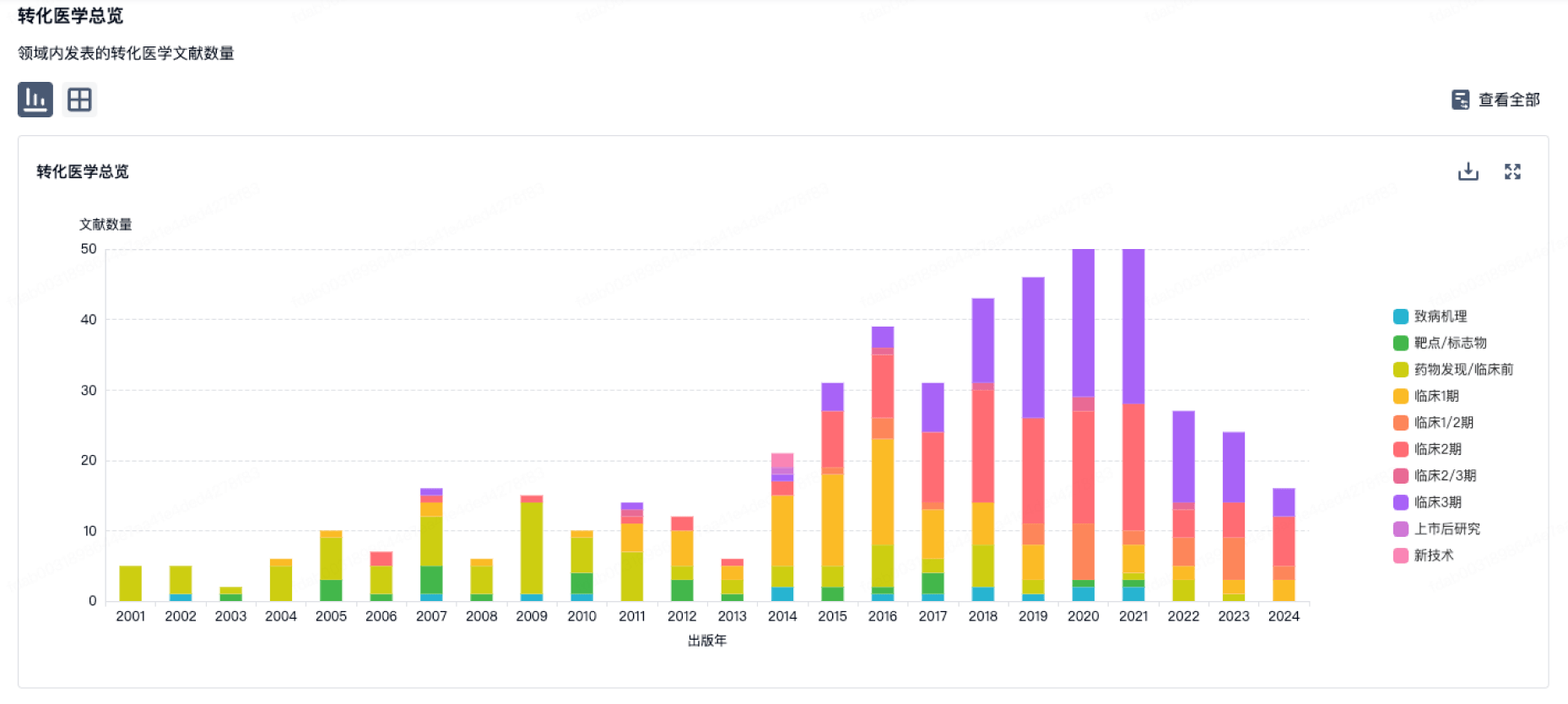

100 项与 上海细胞治疗集团股份有限公司 相关的转化医学

登录后查看更多信息

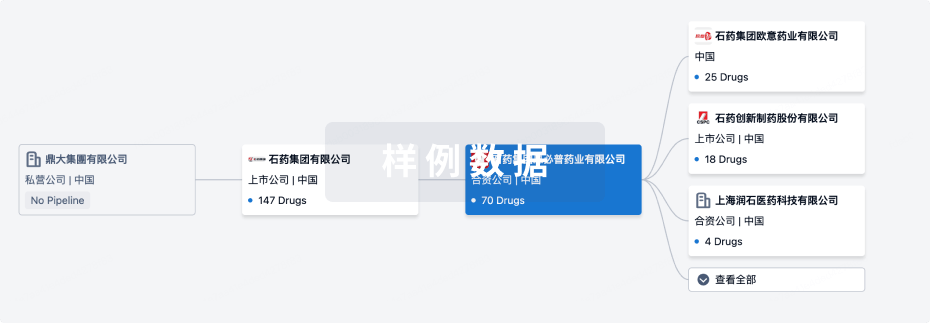

组织架构

使用我们的机构树数据加速您的研究。

登录

或

管线布局

2025年09月10日管线快照

管线布局中药物为当前组织机构及其子机构作为药物机构进行统计,早期临床1期并入临床1期,临床1/2期并入临床2期,临床2/3期并入临床3期

药物发现

6

5

临床前

早期临床1期

4

3

临床2期

其他

12

登录后查看更多信息

当前项目

| 药物(靶点) | 适应症 | 全球最高研发状态 |

|---|---|---|

自分泌PD1抗体靶向间皮素嵌合抗原受体T细胞(上海细胞治疗集团) ( MSLN x PD-1 ) | 间皮瘤 更多 | 临床1/2期 |

DC cells(Shanghai Cell Therapy Group) ( CTLA4 x PD-1 ) | 肝癌 更多 | 临床1/2期 |

PD-1 antibody CD19-CAR T therapy ( CD19 x PD-1 ) | B细胞淋巴瘤 更多 | 临床1/2期 |

BZE-2204 ( BCMA x CD19 x CD22 ) | 难治性B细胞淋巴瘤 更多 | 早期临床1期 |

BaizeDC ( CTLA4 x PD-1 x p53 x survivin ) | 实体瘤 更多 | 早期临床1期 |

登录后查看更多信息

药物交易

使用我们的药物交易数据加速您的研究。

登录

或

转化医学

使用我们的转化医学数据加速您的研究。

登录

或

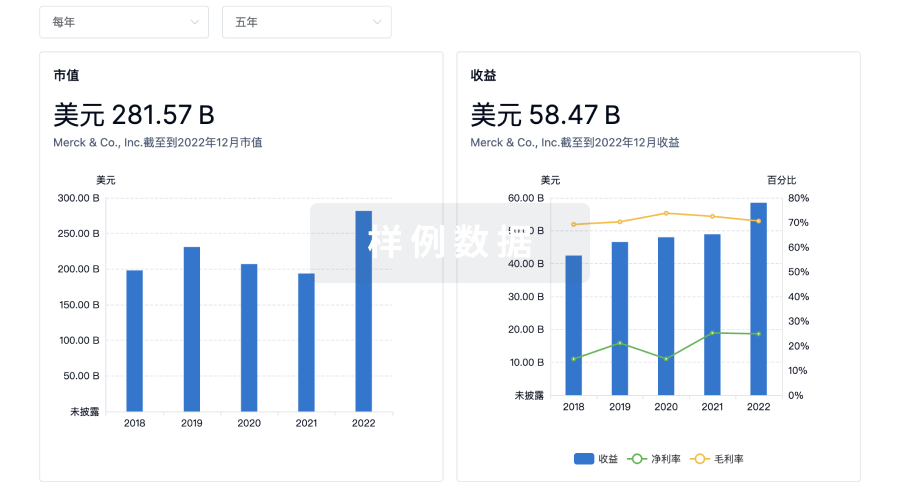

营收

使用 Synapse 探索超过 36 万个组织的财务状况。

登录

或

科研基金(NIH)

访问超过 200 万项资助和基金信息,以提升您的研究之旅。

登录

或

投资

深入了解从初创企业到成熟企业的最新公司投资动态。

登录

或

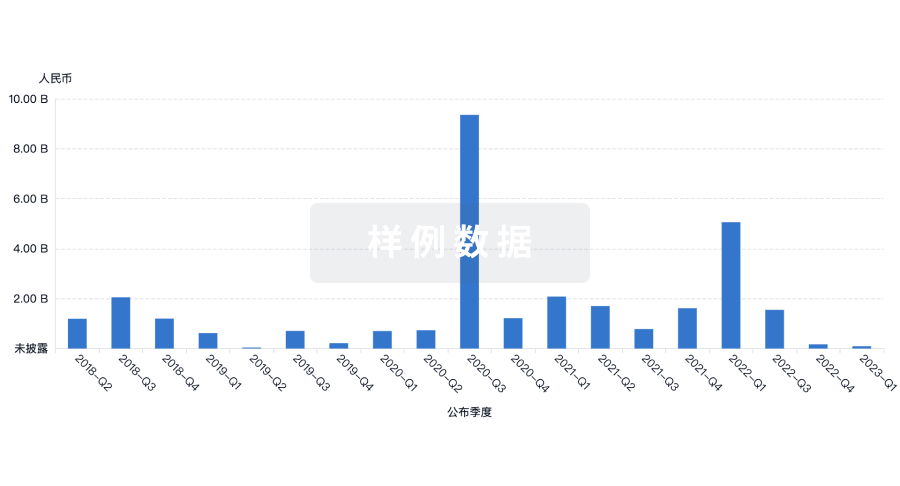

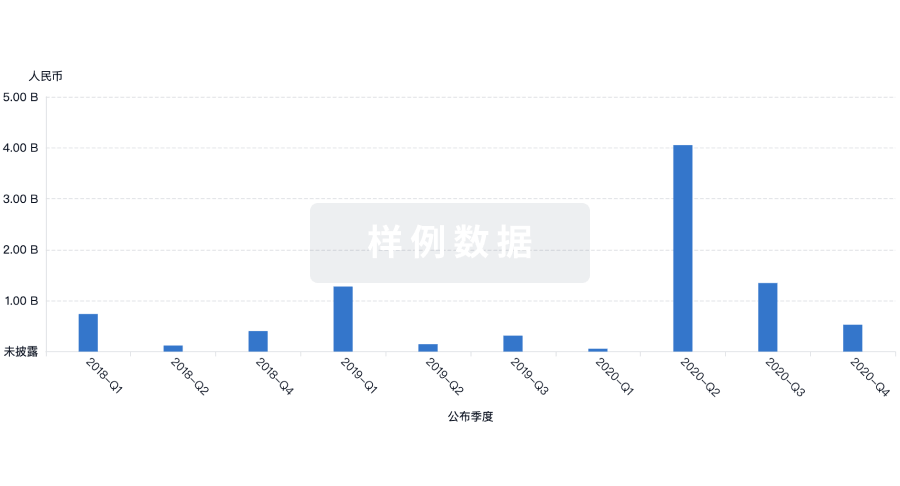

融资

发掘融资趋势以验证和推进您的投资机会。

登录

或

Eureka LS:

全新生物医药AI Agent 覆盖科研全链路,让突破性发现快人一步

立即开始免费试用!

智慧芽新药情报库是智慧芽专为生命科学人士构建的基于AI的创新药情报平台,助您全方位提升您的研发与决策效率。

立即开始数据试用!

智慧芽新药库数据也通过智慧芽数据服务平台,以API或者数据包形式对外开放,助您更加充分利用智慧芽新药情报信息。

生物序列数据库

生物药研发创新

免费使用

化学结构数据库

小分子化药研发创新

免费使用