预约演示

更新于:2025-05-07

Universidad Autónoma De San Luis Potosí

更新于:2025-05-07

概览

标签

免疫系统疾病

毒素

疾病领域得分

一眼洞穿机构专注的疾病领域

暂无数据

技术平台

公司药物应用最多的技术

暂无数据

靶点

公司最常开发的靶点

暂无数据

| 疾病领域 | 数量 |

|---|---|

| 免疫系统疾病 | 1 |

| 排名前五的药物类型 | 数量 |

|---|---|

| 毒素 | 1 |

| 排名前五的靶点 | 数量 |

|---|---|

| Kv1.3(电压门控性钾通道蛋白亚型Kv1.3) | 1 |

关联

1

项与 Universidad Autónoma De San Luis Potosí 相关的药物靶点 |

作用机制 Kv1.3阻滞剂 |

非在研适应症- |

最高研发阶段临床前 |

首次获批国家/地区- |

首次获批日期- |

48

项与 Universidad Autónoma De San Luis Potosí 相关的临床试验NCT06598072

Clinical Study to Evaluate the Efficacy of a Regimen Including Rinsing With an Alcohol Free Mouthwash Containing CPC+Zn as Compared to Dental Flossing and Brushing and a Regimen Including Rising With an Essential Oils Containing Alcohol Mouthwash in Reducing Dental Plaque and Gingivitis.

This is a Phase III, randomized, one-center, parallel group, double blinded, clinical study to evaluate the efficacy of an alcohol-free mouthwash containing CPC+Zn as compared to dental flossing and to rising with an essential oils containing alcohol mouthwash in reducing dental plaque and gingivitis. One hundred and twenty participants, aged between 18 and 65 years, will be included and followed for 12 weeks.

开始日期2024-09-17 |

申办/合作机构 |

NCT06528964

Expression of Proteinopathies in Skin Biopsies of Patients With Neurodegenerative Disorders

The goal of this observational study is to compare the aggregation pattern of proteinopathies (alpha-synuclein, amyloid-beta, phosphorylated tau and transactive response DNA -binding protein 43 [TDP43]) in skin biopsies of patients with a neurodegenerative disease like Alzheimer's disease, frontotemporal lobe dementia, Parkinson's disease, atypical Parkinsonism, amyotrophic lateral sclerosis or normal pressure hydrocephalus. The main question it aims to answer is:

* Is there a specific pattern of aggregation of proteinopathies in skin biopsies in each neurodegenerative disease in comparison to healthy control subjects?

Skin biopsies will be analyzed using immunohistochemistry and immunofluorescence for detection of alpha-synuclein, amyloid-beta, phosphorylated tau and TAR DNA binding protein 43, and the aggregation patterns will be compared between patients with a neurodegenerative disease vs patient with normal pressure hydrocephalus vs healthy control subjects.

* Is there a specific pattern of aggregation of proteinopathies in skin biopsies in each neurodegenerative disease in comparison to healthy control subjects?

Skin biopsies will be analyzed using immunohistochemistry and immunofluorescence for detection of alpha-synuclein, amyloid-beta, phosphorylated tau and TAR DNA binding protein 43, and the aggregation patterns will be compared between patients with a neurodegenerative disease vs patient with normal pressure hydrocephalus vs healthy control subjects.

开始日期2023-12-20 |

NCT06234839

Efficacy of Two Orally Administered Lactobacillus Reuteri Strains for Gingivitis Reduction in Young Adults: A Randomized Controlled Clinical Trial

The aim of the present study was to investigate the potential beneficial effects in volunteer young adults of orally administered L. reuteri (DSM 17938 and ATCC PTA 5289) on gingival inflammation. The null hypothesis was that no difference would be manifested by probiotic therapy regarding the conventional mechanical treatment (without probiotic administration).

开始日期2023-01-07 |

100 项与 Universidad Autónoma De San Luis Potosí 相关的临床结果

登录后查看更多信息

0 项与 Universidad Autónoma De San Luis Potosí 相关的专利(医药)

登录后查看更多信息

10,669

项与 Universidad Autónoma De San Luis Potosí 相关的文献(医药)2025-08-01·Colloids and Surfaces B: Biointerfaces

Solar-driven photochemical synthesis of bismuth-naringin nanoparticles with anticancer properties

Article

作者: Salado-Leza, Daniela ; Estrada-Loredo, Sarahí Josefina ; Rodríguez-Chávez, Victoria Nephertiti ; Meza-Pardo, Ingrid Guadalupe ; Castillo-Rivera, Francisco ; Silva-Melgarejo, Fernanda Abigail ; Sánchez-Campos, Daniel

2025-07-01·Separation and Purification Technology

Energy-economic purification of n-hexane from low benzene concentrations via extractive distillation with propylene carbonate as solvent: A comparative study with liquid–liquid extraction processes

作者: Barajas-Villarruel, Luis R. ; Cruz Valdez, Jesus Alonso ; Patino-Herrera, Rosalba ; Aviles Martinez, Adriana ; Perez, Elias

2025-06-01·Leukemia Research

Identification of ZNF384 as a regulator of epigenome in leukemia

Article

作者: Ávila-López, Pedro A ; Martínez, Yamelie A ; Rojas, Francisco I Torres ; Ortíz-Ortíz, Julio ; Vargas, Laura C Zárraga ; Viguri, Gabriela E Campos

100 项与 Universidad Autónoma De San Luis Potosí 相关的药物交易

登录后查看更多信息

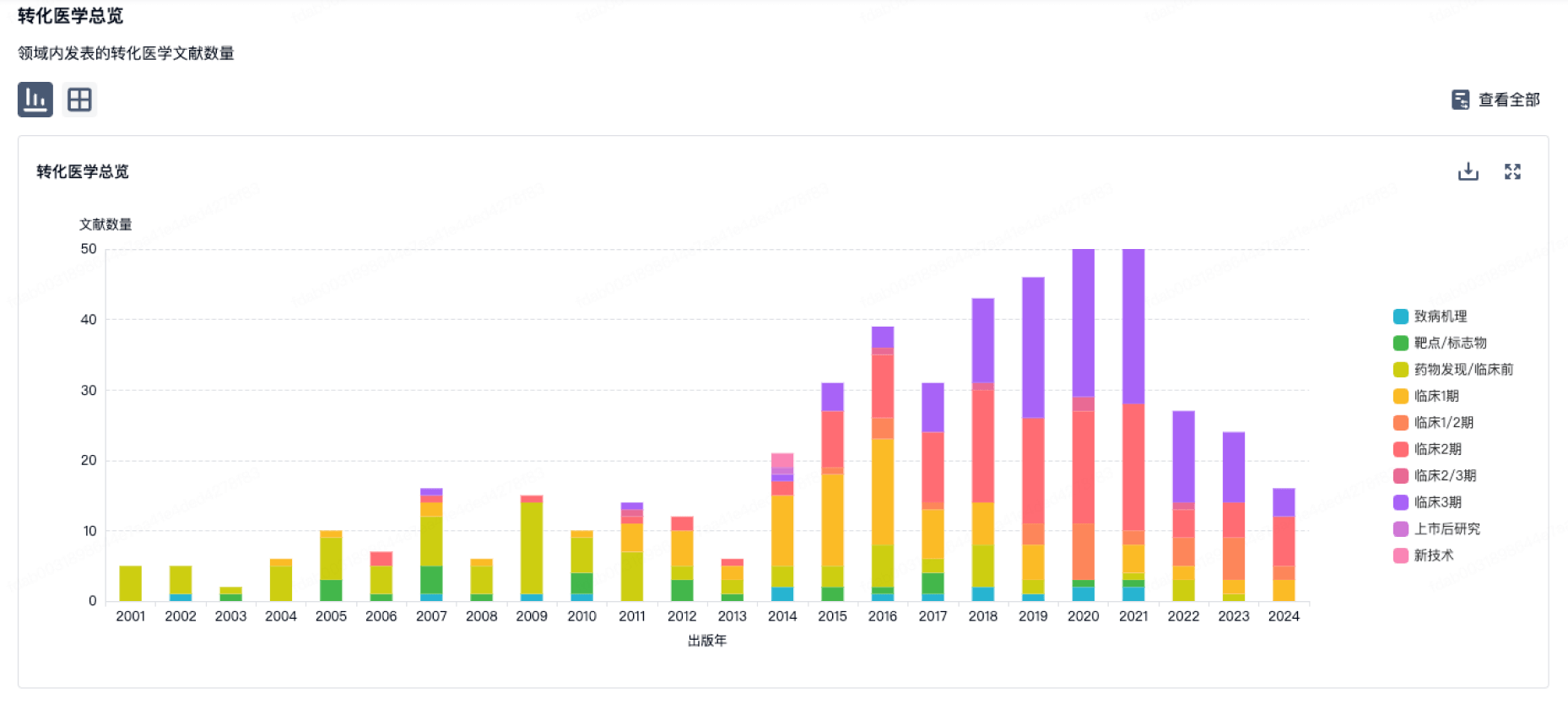

100 项与 Universidad Autónoma De San Luis Potosí 相关的转化医学

登录后查看更多信息

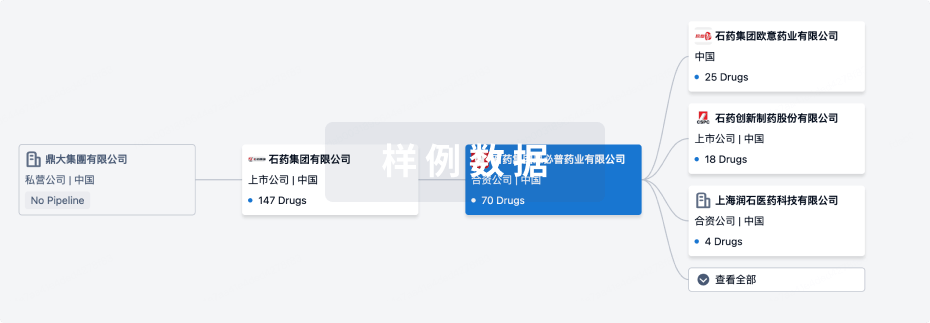

组织架构

使用我们的机构树数据加速您的研究。

登录

或

管线布局

2025年11月03日管线快照

管线布局中药物为当前组织机构及其子机构作为药物机构进行统计,早期临床1期并入临床1期,临床1/2期并入临床2期,临床2/3期并入临床3期

药物发现

1

登录后查看更多信息

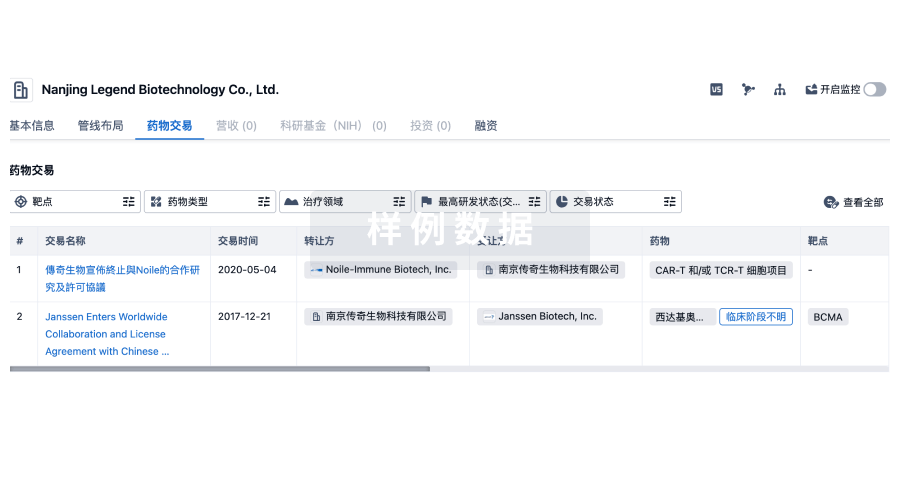

药物交易

使用我们的药物交易数据加速您的研究。

登录

或

转化医学

使用我们的转化医学数据加速您的研究。

登录

或

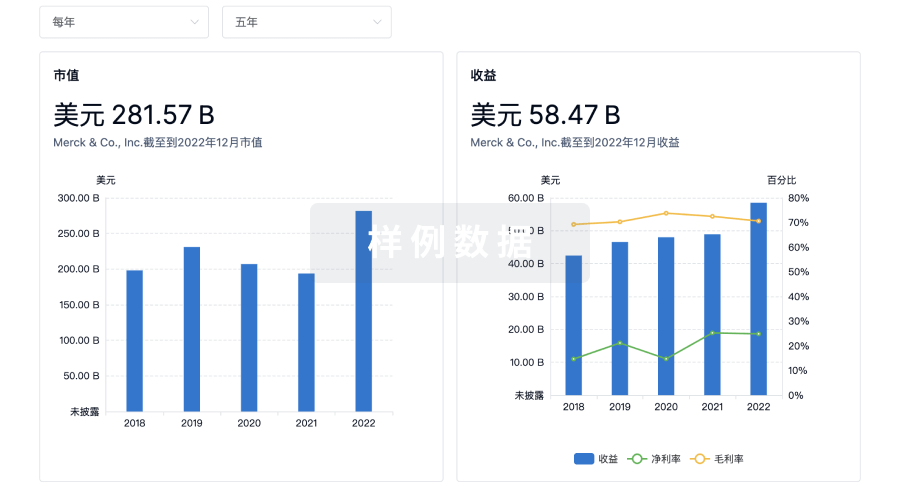

营收

使用 Synapse 探索超过 36 万个组织的财务状况。

登录

或

科研基金(NIH)

访问超过 200 万项资助和基金信息,以提升您的研究之旅。

登录

或

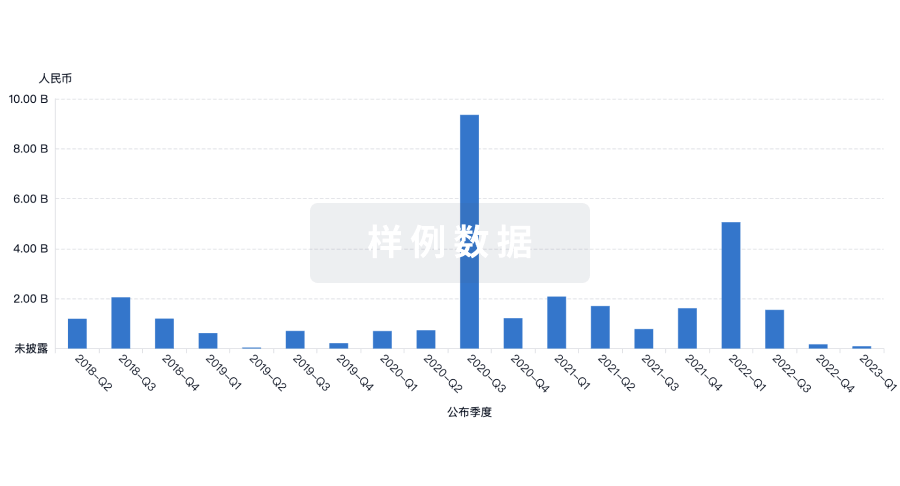

投资

深入了解从初创企业到成熟企业的最新公司投资动态。

登录

或

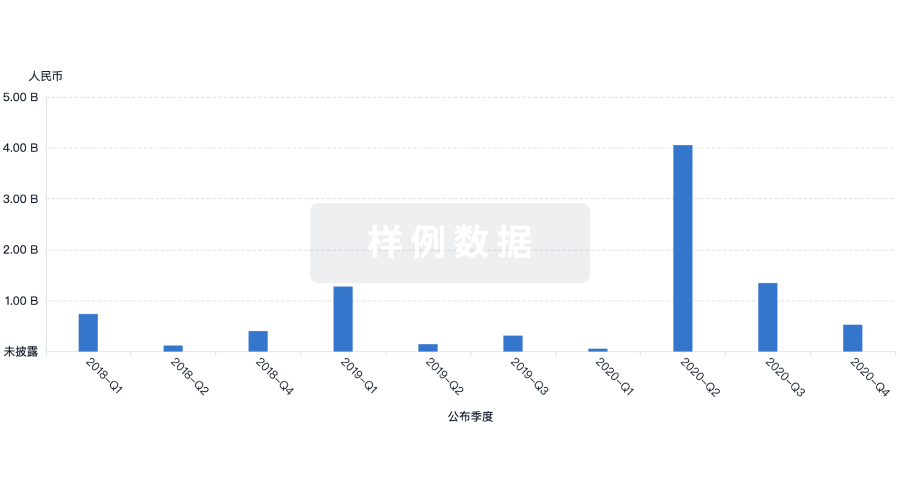

融资

发掘融资趋势以验证和推进您的投资机会。

登录

或

生物医药百科问答

全新生物医药AI Agent 覆盖科研全链路,让突破性发现快人一步

立即开始免费试用!

智慧芽新药情报库是智慧芽专为生命科学人士构建的基于AI的创新药情报平台,助您全方位提升您的研发与决策效率。

立即开始数据试用!

智慧芽新药库数据也通过智慧芽数据服务平台,以API或者数据包形式对外开放,助您更加充分利用智慧芽新药情报信息。

生物序列数据库

生物药研发创新

免费使用

化学结构数据库

小分子化药研发创新

免费使用