预约演示

更新于:2025-08-27

Farmak

更新于:2025-08-27

概览

标签

呼吸系统疾病

感染

小分子化药

关联

1

项与 Farmak 相关的药物12

项与 Farmak 相关的临床试验NCT05124730

Open, Comparative, Randomized, Crossover, Single Dose Bioequivalence Study of Metformin 500 mg Prolonged Release Tablets (JSC Farmak, Ukraine) vs Glucophage® XR 500 mg Prolonged Release Tablets in Healthy Subjects Under Fasting Conditions.

This study was designed to compare the bioavailability of the Test Product Metformin 500mg Prolonged Release Tablets (JSC Farmak, Ukraine) and Reference Product Glucophage® XR 500 mg Prolonged Release Tablets (Merck Serono Ltd, UK) in healthy male and female volunteers under fasting conditions.

开始日期2021-05-21 |

申办/合作机构 |

NCT05123976

A Comparative, Open-label, Randomized, Two-period Bioequivalence Study of Olanzapine Film-coated Tablets 5 mg (JSC Farmak, Ukraine) vs Zyprexa® Coated Tablets 5 mg (Eli Lilly, Nederland B V) in Healthy Subjects Under Fasted Conditions.

This study was designed to assess the bioequivalence of Olanzapine tablets of two different manufacturers and to investigate the safety and tolerability of Olanzapine tablets of two different manufacturers.

开始日期2020-10-21 |

申办/合作机构 |

NCT04682873

A Multi-centre, Double-blind, Randomised, Placebo-controlled, Trial to Assess the Efficacy and Safety of Amizon® Max, Manufactured by Farmak JSC, in Combination With Basic Treatment, in Subjects With Moderate Covid-19, Which is Caused by the SARS-CoV-2 Virus

Adult female and male patients, hospitalized with Covid-19 infection (confirmed by reverse transcription polymerase chain reaction [RT-PCR]), will be screened for participation in this prospective, multi-center, double-blind, randomised, placebo-controlled trial.

Enrolled patients will be randomized (1:1) into 2 treatment groups: Group 1 will receive the active treatment with Amizon® Max (international nonproprietary name enisamium iodide), one capsule (each containing 500 mg of enisamium iodide) 4 times daily every 6 hours for 7 days; patients in treatment Group 2 will receive a matching placebo capsule, 4 times daily every 6 hours for 7 days. Patient observation and follow-up are planned for 29 days, unless discharged before Day 29.

The effect of treatment on Covid-19 will be evaluated by time from day of randomization to an increase of at least two points (from the status at randomization) on the severity rating scale (SR), the Time to Clinical Recovery (TTCR) of main Covid-19 symptoms / complications and the Sum of Severity Rating from Day 2 to Day 15 (SSR-15). Safety and tolerability of the study drug will be evaluated based on the intensity and course of adverse events (Es).

Enisamium iodide is an antiviral small molecule. Enisamium inhibits replication of alpha- and beta- coronaviruses (human coronavirus NL63 and SARS-CoV-2, respectively) and influenza virus A and B. Mechanism of action against SARS-CoV-2 includes the direct inhibition of the viral RNA polymerase.

Enrolled patients will be randomized (1:1) into 2 treatment groups: Group 1 will receive the active treatment with Amizon® Max (international nonproprietary name enisamium iodide), one capsule (each containing 500 mg of enisamium iodide) 4 times daily every 6 hours for 7 days; patients in treatment Group 2 will receive a matching placebo capsule, 4 times daily every 6 hours for 7 days. Patient observation and follow-up are planned for 29 days, unless discharged before Day 29.

The effect of treatment on Covid-19 will be evaluated by time from day of randomization to an increase of at least two points (from the status at randomization) on the severity rating scale (SR), the Time to Clinical Recovery (TTCR) of main Covid-19 symptoms / complications and the Sum of Severity Rating from Day 2 to Day 15 (SSR-15). Safety and tolerability of the study drug will be evaluated based on the intensity and course of adverse events (Es).

Enisamium iodide is an antiviral small molecule. Enisamium inhibits replication of alpha- and beta- coronaviruses (human coronavirus NL63 and SARS-CoV-2, respectively) and influenza virus A and B. Mechanism of action against SARS-CoV-2 includes the direct inhibition of the viral RNA polymerase.

开始日期2020-05-15 |

申办/合作机构 |

100 项与 Farmak 相关的临床结果

登录后查看更多信息

0 项与 Farmak 相关的专利(医药)

登录后查看更多信息

15

项与 Farmak 相关的文献(医药)2025-02-01·Heliyon

Development and characterisation of polymeric solid dispersed systems of hesperidin, obtained by centrifugal fibre formation

Article

作者: Lisovyi, Vadym ; Bessarabov, Volodymyr ; Lyzhniuk, Viktoriia ; Yaremenko, Volodymyr ; Smishko, Roman ; Derkach, Tetiana ; Goy, Andriy ; Kostiuk, Viktor ; Gureyeva, Svitlana ; Kuzmina, Galina

The flavonoid hesperidin is a crucial, biologically active substance of great interest because of its polypharmacological properties and high safety profile. However, its widespread use of this bioflavonoid in remedies for the treatment and prevention of various diseases is limited by its low water solubility. This study reports on solid dispersed systems (SDSs) of hesperidin, fabricated for the first time via the method of centrifugal fibre. For one of the compositions of these SDSs, the solubility of the flavonoid in water is observed to be 150-170 times higher than that of the pure compound. Polyvinylpyrrolidones, with different molecular weights, was used as a fibre-forming polymer carrier, alongside sucrose and mannitol as auxiliary substances to enhance the yield of the composites. The SDSs of hesperidin in the form of fibres were characterised via differential scanning calorimetry (DSC), Fourier-transform infrared spectroscopy (FTIR) and powder X-ray diffraction (PXRD). DSC and PXRD results confirmed the amorphisation of hesperidin in the fibrous SDSs. FTIR results confirmed that the interaction of hesperidin with the components of the SDS composites occurs due to the formation of intermolecular hydrogen bonds. Studies of in vitro release kinetics in buffer media with pH = 1.2, 4.5 and 6.8 showed that the release rate of hesperidin from the centrifugally formed SDSs is considerably higher than the dissolution rate of pure hesperidin. Thus, the results of this study confirm that centrifugal fibre formation is a simple and effective method for fabricating highly soluble SDSs of hesperidin.

2021-05-28·ACTA POLONIAE PHARMACEUTICA

Development of the technology of a liposomal form of eye drops based on a peptide complex

作者: Borshchevsky, Gennady ; Rukhmakova, Olga ; Yarnykh, Tatyana ; Kruglov, Eugene

The aim of this work is to develop the stage of inclusion of the active pharmaceutical ingredient in liposomes, to study the effect of liposome composition on the degree of encapsulation and particle size in creating a liposomal eye drops based on a peptide complex used as a drug for ophthalmic diseases.Different concentrations of lipid membrane 80 mg/mL, 90 mg/mL, 100 mg/mL were studied.The influence of particle size on the degree of encapsulation of the peptide complex from 300 nm to 80 nm was studied.The highest degree of encapsulation of the peptide complex was determined for a liposomal sample with a lipid concentration of 100 mg/mL and a particle size of 120-140 nm or less.

2019-01-01·Methods and Objects of Chemical Analysis

Monitoring And Distribution Of Organochlorine Pesticides, Polychlorinated Biphenyls And Polycyclic Aromatic Hydrocarbons In Surface River Water And Suspended Particulate Matter

作者: Gorban, M.V. ; MILYUKIN, M.V. ; Skrynnyk, M.M.

The monitoring results of organochlorine pesticides (OCPs), polychlorinated biphenyls (PCBs) and polycyclic aromatic hydrocarbons (PAHs) in Ukranian and world surface river waters were summarized. Total concentrations of OCPs, PCBs and PAHs in surface waters of Ukrainian rivers (Dnieper and Dniester) were 1.4–17.1; 2.8–57.2; 7.5–378.6 ng/dm3 , respectively. These pollution levels are medium on a global scale. Higher concentrations were recorded in the surface water of China, India and other Asian countries. Distribution of these organic ecotoxicants between water and suspended particulate matter (dispersionphase distribution) was analyzed and it was shown that in the majority of river waters ≥50% of them are associated with suspended particles. By the case of River Dnieper antibate correlations between watersoluble parts of individual OCPs, PCBs and PAHs and coefficient of their hydrophobicity were recorded. These correlations were presented graphically. In addition, relevant correlation coefficients and criterions of probability were calculated. The clearest correlation was established for PCBs.

100 项与 Farmak 相关的药物交易

登录后查看更多信息

100 项与 Farmak 相关的转化医学

登录后查看更多信息

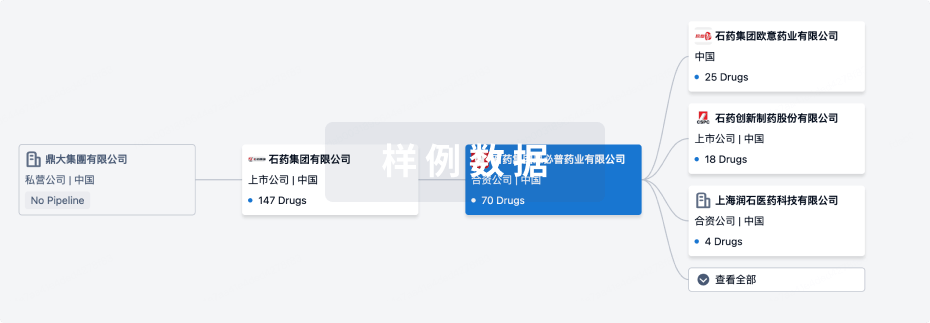

组织架构

使用我们的机构树数据加速您的研究。

登录

或

管线布局

2025年11月02日管线快照

管线布局中药物为当前组织机构及其子机构作为药物机构进行统计,早期临床1期并入临床1期,临床1/2期并入临床2期,临床2/3期并入临床3期

批准上市

1

登录后查看更多信息

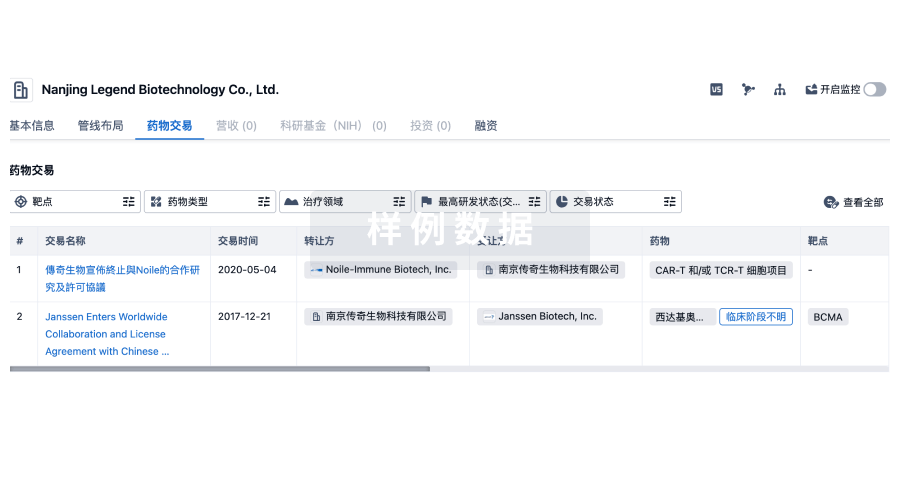

药物交易

使用我们的药物交易数据加速您的研究。

登录

或

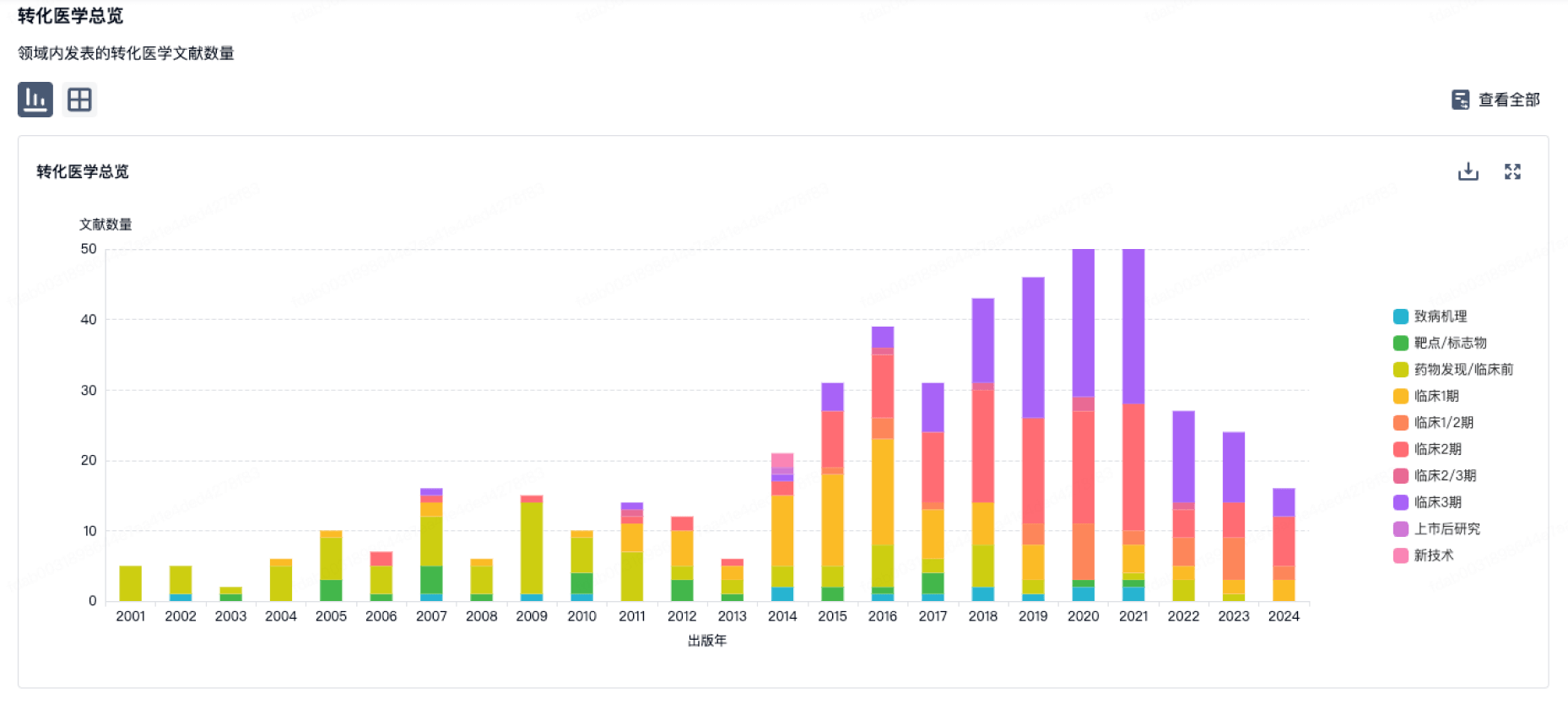

转化医学

使用我们的转化医学数据加速您的研究。

登录

或

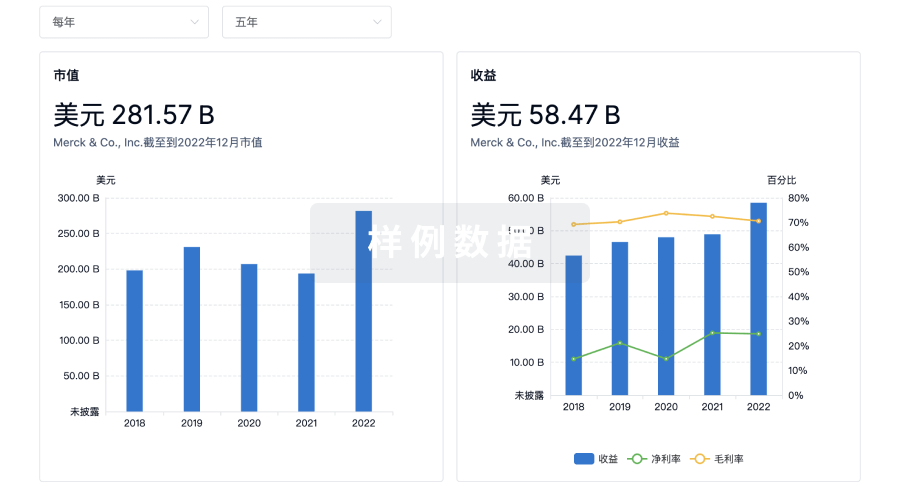

营收

使用 Synapse 探索超过 36 万个组织的财务状况。

登录

或

科研基金(NIH)

访问超过 200 万项资助和基金信息,以提升您的研究之旅。

登录

或

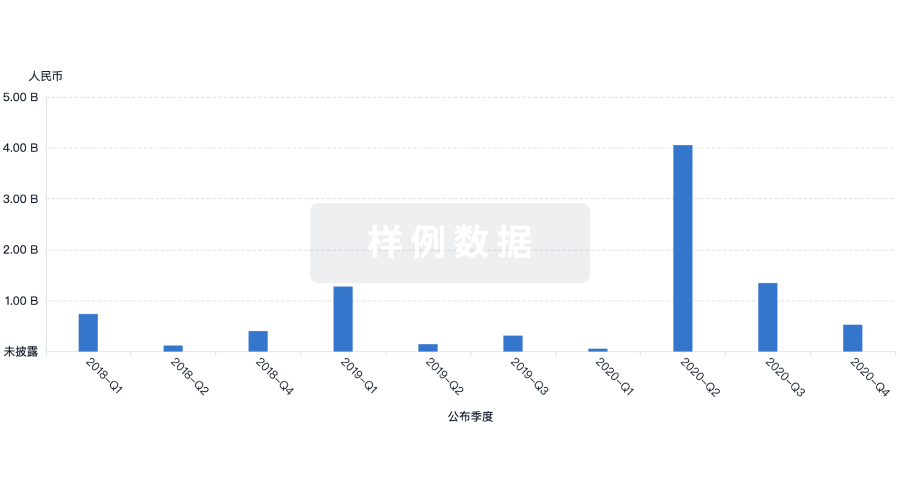

投资

深入了解从初创企业到成熟企业的最新公司投资动态。

登录

或

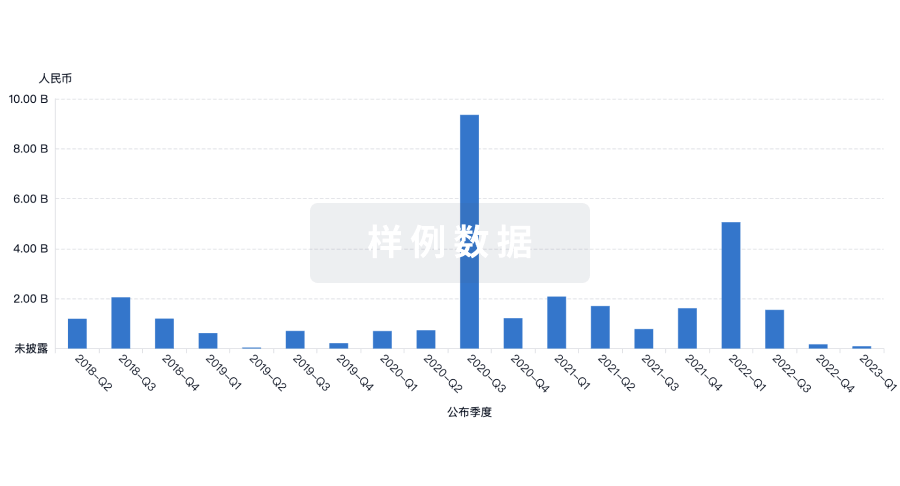

融资

发掘融资趋势以验证和推进您的投资机会。

登录

或

生物医药百科问答

全新生物医药AI Agent 覆盖科研全链路,让突破性发现快人一步

立即开始免费试用!

智慧芽新药情报库是智慧芽专为生命科学人士构建的基于AI的创新药情报平台,助您全方位提升您的研发与决策效率。

立即开始数据试用!

智慧芽新药库数据也通过智慧芽数据服务平台,以API或者数据包形式对外开放,助您更加充分利用智慧芽新药情报信息。

生物序列数据库

生物药研发创新

免费使用

化学结构数据库

小分子化药研发创新

免费使用