预约演示

更新于:2025-05-07

Phenolphthalein

酚酞

更新于:2025-05-07

概要

基本信息

原研机构 |

非在研机构- |

权益机构- |

最高研发阶段批准上市 |

首次获批日期- |

最高研发阶段(中国)批准上市 |

特殊审评- |

登录后查看时间轴

结构/序列

分子式C20H14O4 |

InChIKeyKJFMBFZCATUALV-UHFFFAOYSA-N |

CAS号77-09-8 |

关联

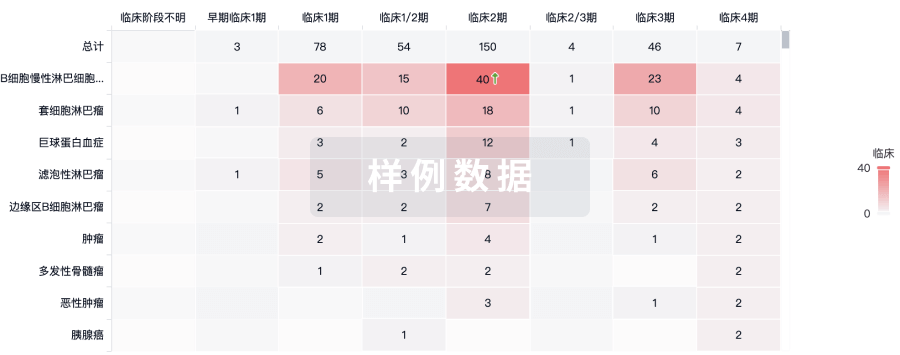

100 项与 酚酞 相关的临床结果

登录后查看更多信息

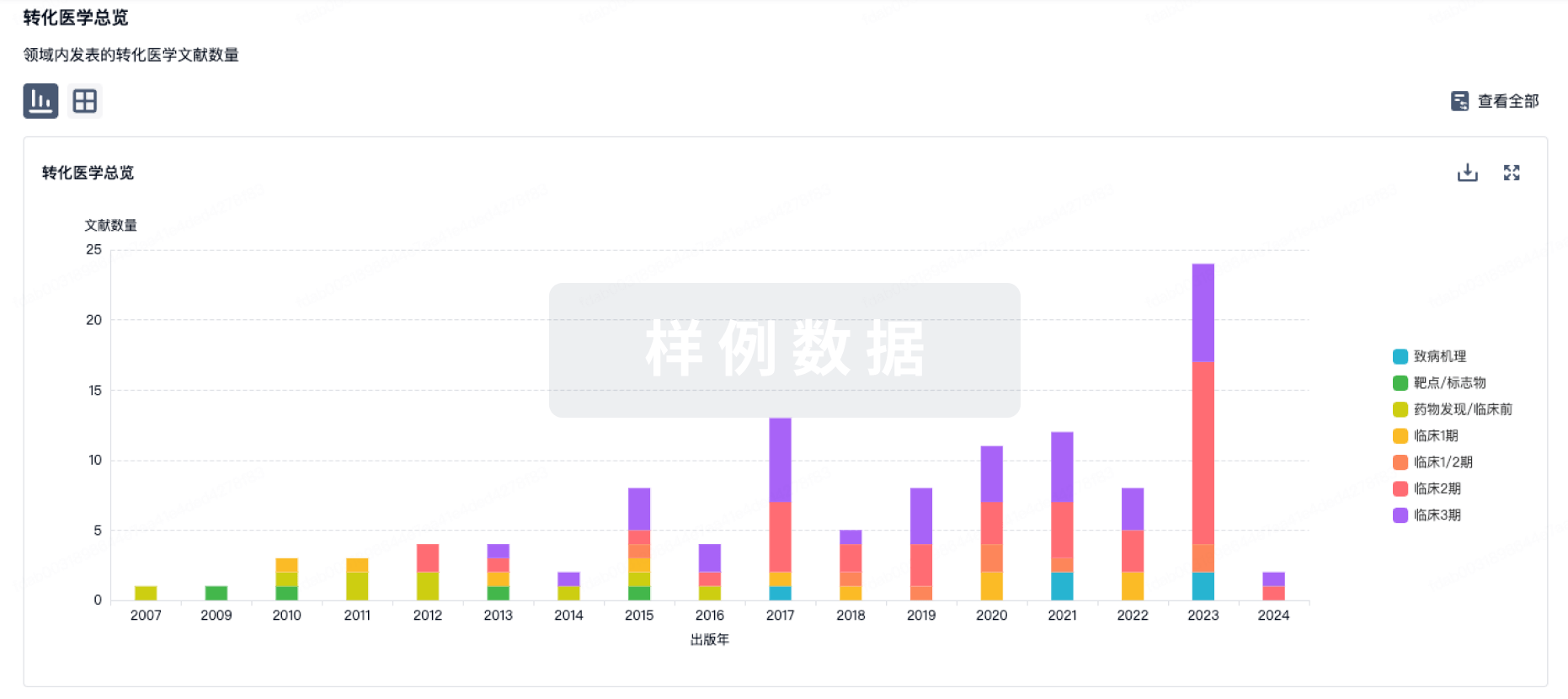

100 项与 酚酞 相关的转化医学

登录后查看更多信息

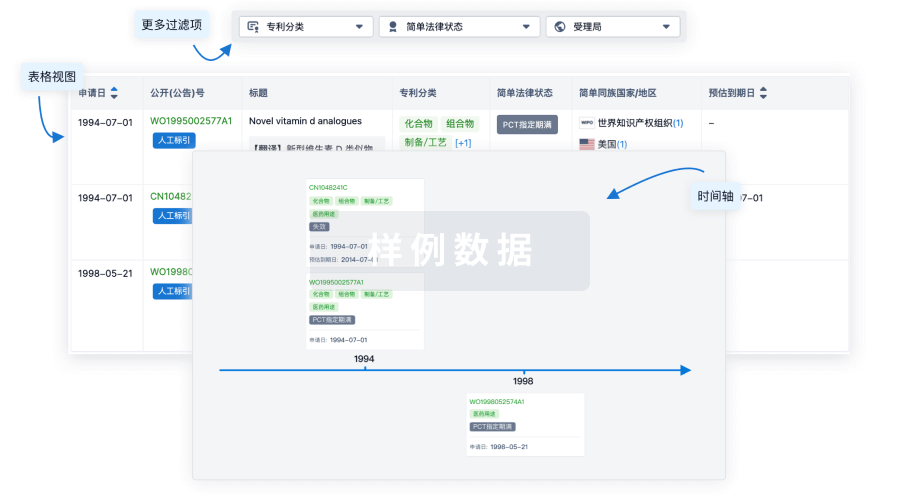

100 项与 酚酞 相关的专利(医药)

登录后查看更多信息

4,039

项与 酚酞 相关的文献(医药)2025-06-01·Reactive and Functional Polymers

Highly flexible β-cyclodextrin polymer surface-functionalized polyurethane membrane captures organic pollutant phenolphthalein from aqueous media

作者: Dong, Jiarui ; Zhang, Aiying ; Du, Jianxin ; Guo, Tianqing ; Wang, Xiang ; Zhao, Tianren ; Gong, Chenyue ; Feng, Zengguo ; Wang, Chengzhi

2025-04-08·Journal of Chemical Education

A New Proposal for Inquiry Activity Using a Low-Cost Remote Acid–Base Titration

作者: Cachichi, Ricardo Cenamo ; Aviles, Ivana Elena Camejo ; Morais, Carla Susana Lopes ; Barbosa, Mayara Ferreira ; Girotto Junior, Gildo ; Galembeck, Eduardo

2025-04-01·Construction and Building Materials

Effect of silica fume on Self-compacting Earth Concrete: Compressive strength, durability and microstructural studies

作者: Samimi, Kianoosh ; Azizi, Mehrzad

2

项与 酚酞 相关的新闻(医药)2023-12-14

悬浮细胞培养是一种将细胞培养在液体培养基中而不依赖于固体表面的培养方法。在悬浮细胞培养中,细胞以单个细胞或小团聚体的形式悬浮在培养基中,通过提供营养物质和适宜的环境条件,使细胞能够在体外快速增殖。悬浮细胞培养用培养基是专门设计用于支持细胞在悬浮状态下生长和增殖的培养基。它们通常包含以下组成部分:基础培养基:包括维持pH平衡的缓冲剂,如HEPES或Tris缓冲液,以及维持渗透压稳定的盐类和糖类成分。基础培养基还可以包含一些细胞生长和分裂所需的必要营养成分,如氨基酸、维生素和微量元素。补充物:悬浮细胞培养基通常需要添加一些额外的补充物来增强细胞的生长和增殖能力。这些补充物可以包括血清或血清替代物、生长因子、激素和胶原或基质组分等。抗生素:为了防止细菌和真菌等微生物的污染,悬浮细胞培养基中通常添加一些抗生素,如青霉素、链霉素或红霉素等。pH指示剂:为了方便检测和调节培养基的酸碱度,悬浮细胞培养基中通常添加pH指示剂,如酚红、溴酚蓝或酚酞。悬浮细胞培养用培养基的设计旨在提供细胞生长和增殖所需的适宜环境,以支持研究和生产领域中对悬浮细胞的培养和扩增需求。基础培养基基础培养基是悬浮细胞培养用培养基的重要组成部分,它提供了维持细胞生长和增殖所需的基本物质和适宜环境。基础培养基通常包含以下成分:缓冲剂:基础培养基中的缓冲剂用于维持培养基的pH稳定性,保持在细胞生长和代谢所需的适宜范围内。常用的缓冲剂有 Hepes (4-(2-羟乙基)-1-哌嗪乙磺酸) 和 Tris (三羟甲基氨基甲烷)。盐和糖:基础培养基中包含各种盐类和糖类,以提供细胞所需的营养物质和维持渗透压稳定。常见的盐类包括氯化钠、磷酸盐和碳酸盐,而糖类则通常是葡萄糖或乳糖。氨基酸、维生素和微量元素:基础培养基中通常添加适量的氨基酸、维生素和微量元素,以提供细胞合成蛋白质和生物活性分子所需的原料。这些成分可以通过来自胎牛血清等补充物中提供,也可以直接添加在培养基中。附加物:有时基础培养基还可能包含一些附加物,如氨水和胆酸盐等,它们可以提供细胞所需的额外营养支持或具有特定作用。基础培养基在悬浮细胞培养中的作用是为细胞提供一个合适的环境,其中包含必要的营养物质和适宜的生理条件,以促进细胞的生长和增殖。它们的配方将根据不同类型的细胞和实验目的进行调整和优化,以满足特定的生物学需求。补充物补充物是悬浮细胞培养基中的重要组成部分,用于增强细胞的生长和增殖能力,并提供细胞所需的特定营养物质和环境条件。以下是一些常见的补充物:血清或血清替代物:在传统的细胞培养中,常使用胎牛血清(Fetal Bovine Serum,FBS)作为补充物。血清可以提供多种生长因子、激素、细胞粘附分子和其他重要的细胞因子,促进细胞的增殖和分化。但是,使用血清存在一些缺点,如子代变异性和潜在的微生物污染。因此,近年来发展了许多血清替代物,如人血清Albumax、胎牛血清替代物和人血血小板等。生长因子:生长因子是一类具有调控细胞生命周期和功能的蛋白质。它们可以通过与细胞表面受体结合,激活信号转导途径,影响细胞的增殖、分化和存活。常见的生长因子包括表皮生长因子(EGF)、成纤维细胞生长因子(FGF)、血小板衍生生长因子(PDGF)、血管内皮生长因子(VEGF)等。激素:激素是一类内源性化合物,可以通过影响细胞的基因表达来调控细胞的生长和分化。在悬浮细胞培养中,常添加一些激素,如胰岛素、皮质醇、雌激素和睾酮等,以提供细胞所需的生长和分化信号。胶原或基质组分:在某些细胞类型的培养中,添加一些胶原或基质组分可以增强细胞的附着能力和生长。这些胶原或基质组分可以模拟体内细胞所处的基质环境,提供适宜的细胞-基质相互作用,促进细胞的增殖和功能维持。补充物在悬浮细胞培养中的作用是增强细胞生长和增殖的能力,提供细胞所需的特定营养物质和环境条件。根据不同细胞类型和实验需求,可以选择合适的补充物来优化培养条件,以满足细胞生长和实验目的的要求。抗生素抗生素是悬浮细胞培养中常用的添加物,用于抑制细菌和真菌等微生物的生长和繁殖,以防止细胞培养的污染。以下是一些常见的抗生素:青霉素(Penicillin):青霉素是一种广谱抗生素,可以抑制细菌细胞壁的合成,从而阻止细菌的生长。青霉素主要用于抑制革兰阳性细菌的生长,对革兰阴性菌的作用较小。链霉素(Streptomycin):链霉素是一种氨基糖苷类抗生素,可以抑制细菌蛋白质的合成。链霉素主要用于抑制革兰阴性细菌的生长,对革兰阳性细菌和放线菌的作用较小。红霉素(Erythromycin):红霉素是一种大环内酯类抗生素,可以通过阻断细菌蛋白质合成中的终止步骤而抑制细菌的增殖。红霉素在培养中常用于抑制革兰阳性细菌和肺炎支原体等微生物。抗真菌剂(Antifungal agents):除了抗细菌抗生素,还有一些抗真菌剂可用于抑制细胞培养中真菌的生长。常见的抗真菌剂包括氨咖啡因(Amphotericin B)和氟康唑(Fluconazole)等。使用抗生素的目的是预防或减少细胞培养过程中的微生物污染,通常通过将抗生素加入培养基中,以确保培养物的纯度和可靠性。在使用抗生素时,需要注意以下几点:浓度:针对不同微生物的抑制功效,需要选择合适的抗生素浓度。过高的浓度可能对细胞生长产生不良影响,而过低的浓度可能无法完全抑制细菌或真菌的生长。持续时间:为了保持培养的纯度,抗生素应该在整个培养期间持续添加。通常可以根据实验需要和抗生素的稳定性来确定添加的时间点和间隔。选择合适的抗生素:根据具体的微生物污染情况,选用适当的抗生素,考虑抗生素的作用机制和对目标微生物的敏感性。值得注意的是,抗生素的使用并不总是必要的,特别是当细胞来源于无菌的组织或已经经过严格的无菌处理时。因此,在选择使用抗生素时,需要根据实验的具体情况权衡利弊,并在可能的情况下采取无菌措施和合适的消毒操作。pH指示剂在悬浮细胞培养中,pH指示剂通常用于监测培养基的酸碱性质,以确保细胞在适宜的酸碱环境中进行生长和代谢。以下是pH指示剂在悬浮细胞培养中的应用:pH调节:pH指示剂可以用于调节培养基的pH值。在开始培养或更换培养基时,pH值通常是在理想范围内进行调节的重要步骤。根据pH指示剂的颜色变化,可以逐步添加酸性或碱性溶液,以达到所需的pH值。细胞生长监测:pH指示剂可以作为细胞生长的指标之一。细胞的代谢活动通常会改变培养基的酸碱平衡,导致pH值的变化。通过使用pH指示剂,可以观察和记录细胞生长过程中pH值的变化情况,并了解细胞代谢状态的变化。细胞培养条件优化:pH指示剂还可以用于优化细胞培养条件。不同的细胞类型对培养基中的pH值有不同的要求,因此通过监测和调整pH值,可以优化细胞培养条件,促进细胞生长和产物的合成。检测细胞培养中的污染:pH指示剂也可以用于检测细胞培养中的污染情况。一些微生物污染,如霉菌或细菌感染,会影响培养基的酸碱性质,并导致pH值的变化。通过使用pH指示剂,可以及时发现培养中的污染问题,并采取措施进行处理和预防。在使用pH指示剂时,需要注意以下几点:选择合适的pH指示剂:根据所用培养基的pH范围选择合适的pH指示剂,以确保它能在所需的pH范围内发生显色变化。遵循使用说明:根据pH指示剂的使用说明,正确使用和添加,以获得准确的pH测量结果。考虑指示剂对细胞的影响:某些pH指示剂对细胞有可能具有毒性或影响细胞生长。因此,在选择和使用pH指示剂时,应该考虑其对细胞的影响,并采取适当的浓度和使用方式。pH指示剂在悬浮细胞培养中具有重要的应用价值,用于监测培养基的酸碱性质,优化培养条件,监测细胞生长和检测细胞培养中的污染。通过正确使用pH指示剂,可以确保细胞在适宜的酸碱环境中进行生长、代谢和产物合成。参考文献Hu W.S., et al. Animal Cell Culture Media: History, Development and Prospects. Animal Cell Culture: Essential Methods, 2011, 12(1): 9-23.Martin H.S. et al. Suspension Cultures for the Production of Recombinant Proteins. Methods in Molecular Biology, 2017, 1666: 161-170.Georgiou, G., et al. Escherichia coli Physiology and Metabolism Dictate the Efficiency of Antibody Production in Antibody-Secreting Cells. Journal of Biological Chemistry, 1992, 267: 3425-3438.Thomas RJ. Animal Cell Culture Media: A Review. Biotechnology Progress, 1999, 15(2): 211-220.Mastrianni DM, et al. Development of a Chemically Defined Medium Supporting Long-Term Culture of Rabbit Marrow Cells Differentiating to Erythroid and Granulocytic Precursors. Blood, 1990, 75(2): 360-367.识别微信二维码,添加生物制品圈小编,符合条件者即可加入生物制品微信群!请注明:姓名+研究方向!版权声明本公众号所有转载文章系出于传递更多信息之目的,且明确注明来源和作者,不希望被转载的媒体或个人可与我们联系(cbplib@163.com),我们将立即进行删除处理。所有文章仅代表作者观点,不代表本站立场。

微生物疗法

2021-01-14

·药融圈

注:本文不构成任何投资意见和建议

国家药监局近日发布了《关于注销酚酞片和酚酞含片药品注册证书的公告》。

该公告称,根据《中华人民共和国药品管理法》第八十三条规定,国家药品监督管理局组织对酚酞片和酚酞含片进行了上市后评价,评价认为酚酞片和酚酞含片存在严重不良反应,在我国使用风险大于获益,决定自即日起停止酚酞片和酚酞含片在我国的生产、销售和使用,注销药品注册证书(药品批准文号)。已上市销售的酚酞片和酚酞含片由生产企业负责召回,召回产品由企业所在地药品监督管理部门监督销毁。

药融云数据查询可知,国内目前有数十家企业拥73个酚酞(含)片批文,批文涉及厂家包括欧意药业、特一药业、力生制药、正大天晴、北京中新药业、哈药、上海信谊九福、常山生化、仁和堂药业、远大医药等。其中,大部分药厂均已停产多年,根据药融云数据显示:市面在售酚酞片主要有:仁和堂药业、山西亨瑞达制药、力生制药、临汾宝珠、山西汾河制药,其中仁和堂药业2020年销售约83.81%市场,其次是力生制药和山西亨瑞达制药分别是约7.98%和6.9%。相信此公告发布对以上公司将会产生一定影响。

酚酞片,也叫果导片,是一种刺激性泻药,临床上常用于治疗顽固性便秘,或结肠镜检查前的肠道清洗,其价格低廉此前在一些基层医院的应用仍较为常见。由于该药能起到腹泻的作用,导致一些营养物质无法吸收,还被一些人拿来作为减肥药使用。市面在售主要以100mg规格的片剂,一盒100片的价格从几元至十几元不等。通过网上几个平台搜索发现,所有酚酞片全部下架。

【关于药融圈】药融圈围绕我国生物医药产业链,针对生物医药大数据、技术和资本投资、药融园(产业园)等开展系列系统性工作,促进我国生物医药产业健康发展,完善产业链,共同面对全球合作和竞争。

点分享

点点赞点在看

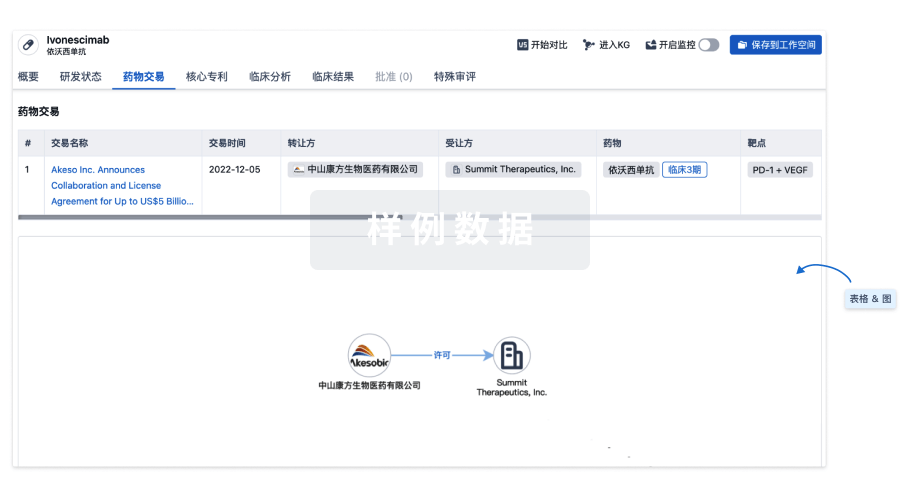

100 项与 酚酞 相关的药物交易

登录后查看更多信息

研发状态

10 条最早获批的记录, 后查看更多信息

登录

| 适应症 | 国家/地区 | 公司 | 日期 |

|---|---|---|---|

| 便秘 | 中国 | - | |

| 便秘 | 中国 | - |

登录后查看更多信息

临床结果

临床结果

适应症

分期

评价

查看全部结果

| 研究 | 分期 | 人群特征 | 评价人数 | 分组 | 结果 | 评价 | 发布日期 |

|---|

No Data | |||||||

登录后查看更多信息

转化医学

使用我们的转化医学数据加速您的研究。

登录

或

药物交易

使用我们的药物交易数据加速您的研究。

登录

或

核心专利

使用我们的核心专利数据促进您的研究。

登录

或

临床分析

紧跟全球注册中心的最新临床试验。

登录

或

批准

利用最新的监管批准信息加速您的研究。

登录

或

特殊审评

只需点击几下即可了解关键药物信息。

登录

或

生物医药百科问答

全新生物医药AI Agent 覆盖科研全链路,让突破性发现快人一步

立即开始免费试用!

智慧芽新药情报库是智慧芽专为生命科学人士构建的基于AI的创新药情报平台,助您全方位提升您的研发与决策效率。

立即开始数据试用!

智慧芽新药库数据也通过智慧芽数据服务平台,以API或者数据包形式对外开放,助您更加充分利用智慧芽新药情报信息。

生物序列数据库

生物药研发创新

免费使用

化学结构数据库

小分子化药研发创新

免费使用