预约演示

更新于:2025-07-15

Astaxanthin

虾青素

更新于:2025-07-15

概要

基本信息

原研机构 |

非在研机构- |

权益机构- |

最高研发阶段批准上市 |

首次获批日期 (1999-01-01), |

最高研发阶段(中国)- |

特殊审评- |

登录后查看时间轴

结构/序列

分子式C40H52O4 |

InChIKeyMQZIGYBFDRPAKN-UWFIBFSHSA-N |

CAS号472-61-7 |

关联

76

项与 虾青素 相关的临床试验CTRI/2025/04/083979

THE ROLE OF ASTAXANTHIN IN SEMEN PARAMETERS AND DNA INTEGRITY IN SUBFERTILE MALE IN SOUTH ASIAN POPULATION - NIL

开始日期2025-04-15 |

申办/合作机构- |

NL-OMON57297

The effect of 12-week supplementation with AstaPure® on skin-aging and muscle function in postmenopausal women (<=70 y) - MISSION study

开始日期2024-12-09 |

申办/合作机构- |

NCT06460181

Impact of Astaxanthin on Cognition in Recreationally Active Females

The purpose of this study is to examine the protentional that the antioxidant Astaxanthin has on mitigating cognitive decline following mental fatigue.

开始日期2024-08-01 |

申办/合作机构 |

100 项与 虾青素 相关的临床结果

登录后查看更多信息

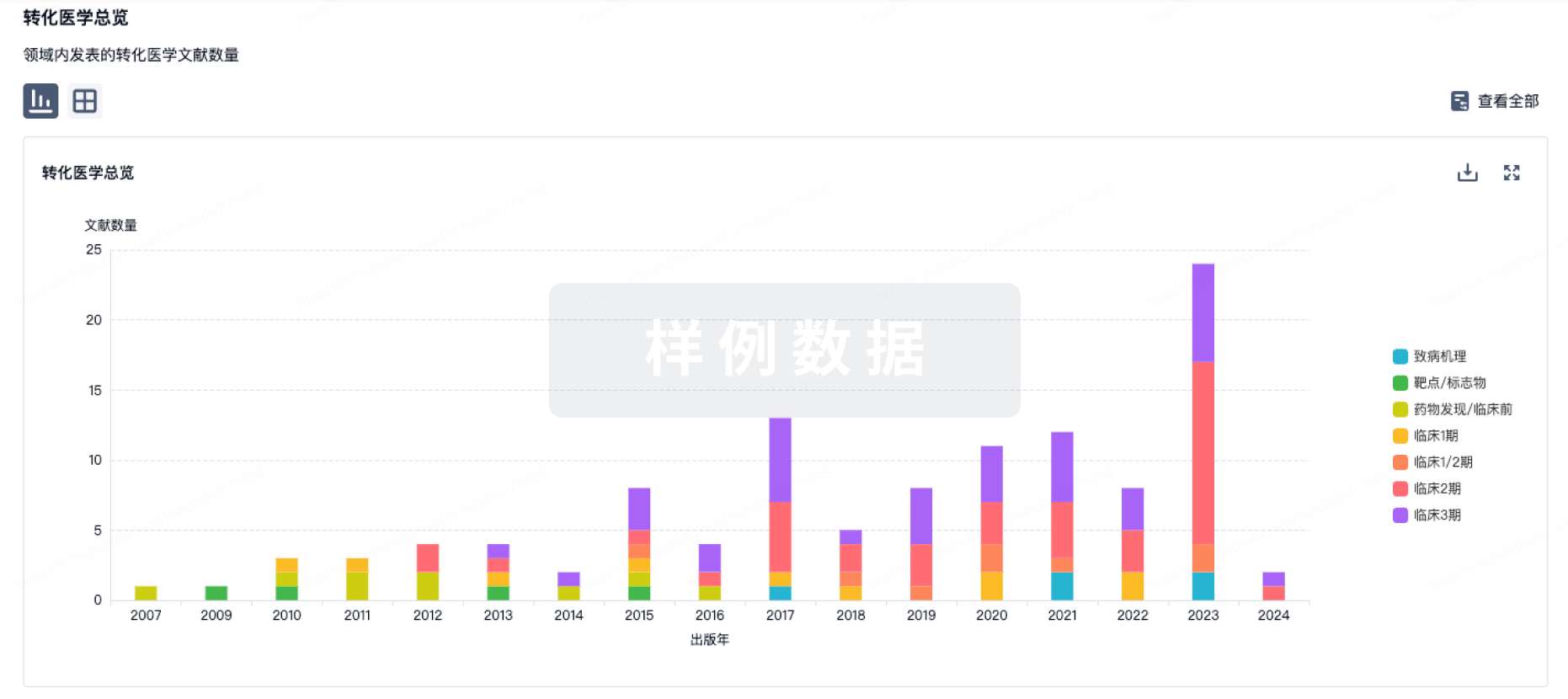

100 项与 虾青素 相关的转化医学

登录后查看更多信息

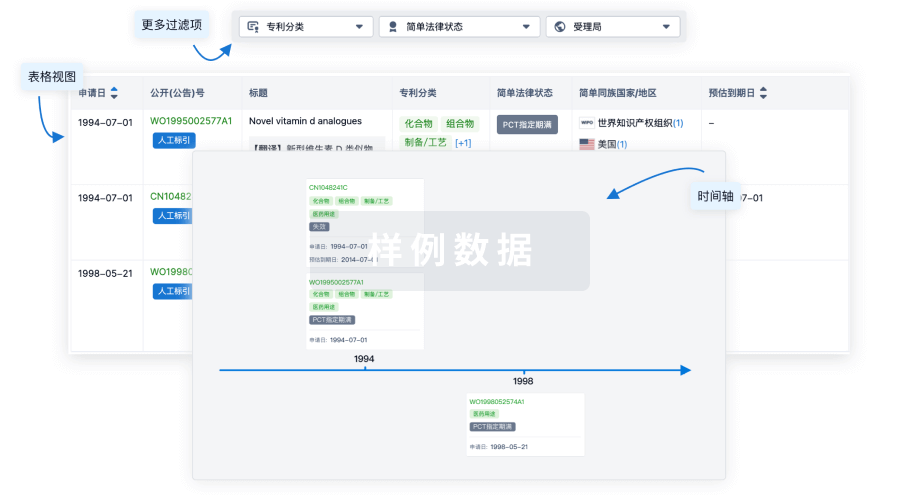

100 项与 虾青素 相关的专利(医药)

登录后查看更多信息

8,367

项与 虾青素 相关的文献(医药)2025-12-01·SPECTROCHIMICA ACTA PART A-MOLECULAR AND BIOMOLECULAR SPECTROSCOPY

Study on the bioremediation of methylene blue by Haematococcus pluvialis through synchrotron-FTIR imaging and spectroscopy

Article

作者: Liu, Xueqin ; Xu, Jiawei ; Li, Wenzhe ; Huang, Shan ; Ren, Xuanyi ; Jiao, Yue ; Ma, Jingwen ; Qi, Zeming ; Chai, Lishuan ; Liu, Jinghua

Methylene blue (MB), as a phenothiazine dye, causes a harmful damage to health and receives increasingly more environmental concern. Herein, the batch experiments for MB biosorption and biotransformation by Haematococcus pluvialis were carried out to evaluate the optimal parameters of MB removal. In this work, we found that the maximum removal efficiency was attained when MB was at the initial concentration of 5 mg/L. Meanwhile, the cellular numbers and pigments decreased dramatically with the rising content of MB. Furthermore, synchrotron-FTIR microscopic imaging is employed here to investigate the interaction between MB dye and algal cells by the measurement of the various vital changes of cellular components involving in the bioremediation of the hazardous dye, which indicated that MB dye as a photosensitizer can trigger the algal transformation from vegetative cells into red cysts by introducing oxidative stress. Accordingly, the dye removal efficiency can be sharply enhanced by the transformed algal cells for the accumulation of astaxanthin or carotenoids. In addition, the FTIR spectroscopy combined with PCA algorithm was further utilized to discriminate various algal status based on their spectral features. As a result, it demonstrates that microscopic imaging and FTIR spectroscopy is a powerful and useful tool to elucidate underlying mechanisms of dye removal by algal cells at high spatial resolution and to evaluate cellular physiological characteristics through multivariate statistical analysis, and it even provides a novel and effective strategy to rapidly screen the potential microalgae for the removal of recalcitrant dyes from wastewater.

2025-11-01·SPECTROCHIMICA ACTA PART A-MOLECULAR AND BIOMOLECULAR SPECTROSCOPY

The interaction mechanism of papain and bromelain with apigenin and luteolin in binary and ternary systems

Article

作者: Li, Zheng ; Li, Xiangrong ; Jia, Zihan ; Xu, Wanqing ; Liu, Xianfei ; Song, Zhizhi

In this study, the interaction mechanism of papain and bromelain with apigenin and luteolin in binary and ternary systems was compared and analyzed by spectroscopic methods, molecular docking, and molecular dynamics simulation. Additionally, the effects of apigenin and/or luteolin on the conformational changes and enzymatic activity of papain and bromelain were investigated. The results show that apigenin and/or luteolin exhibit a moderate binding affinity with papain/bromelain, with the binding constants Ka in the range of 104-105 L mol-1. The order of addition of apigenin and luteolin significantly influenced their binding affinities to the enzymes. The main non-covalent forces of the papain-luteolin (first)-apigenin ternary system are hydrogen bonds and Van der Waals forces. Hydrophobic interactions, electrostatic forces and hydrogen bonds are the main non-covalent forces of other binary and ternary systems. These systems differentially alter the microenvironment of Trp and Tyr residues, secondary and tertiary structures, and enzymatic activity. Molecular docking and dynamics simulations identified specific binding sites of apigenin and/or luteolin on papain/bromelain, corroborating experimental findings. Notably, the ternary system exhibits a stronger inhibitory effect on papain activity compared to binary systems.

2025-11-01·BIORESOURCE TECHNOLOGY

Advances in the biosynthesis of β-carotene and its derivatives in yeast

Review

作者: Park, Young-Kyoung ; Ledesma-Amaro, Rodrigo ; Zhou, Tingan

β-Carotene and its derivatives have been gaining huge interest due to its applications as food supplements, nutraceuticals, pharmaceuticals, pigments, etc. Owing to their high values, sustainable microbial production has been a heated research topic. Traditional production methods, such as plant extraction and chemical synthesis, face challenges in scalability, cost, and environmental impact. With advances in synthetic biology, yeast-based biosynthesis has emerged as a promising alternative. This review provides a comprehensive summary of recent progress in the metabolic engineering strategies and fermentation optimization approaches of yeast, particularly Saccharomyces cerevisiae and Yarrowia lipolytica, for the production of β-carotene and its derivatives. In contrast to previous reviews, this work emphasizes the shared biosynthetic logic underlying structurally related derivatives, classifying them into two major groups: xanthophylls (canthaxanthin, zeaxanthin, astaxanthin, and violaxanthin) and apocarotenoids (crocetin, retinol, β-ionone, β-cyclocitral, and strigolactones). Representative cases and transferable engineering/fermentation strategies are highlighted. Advantages and limitations of yeast species as production hosts are thoroughly compared, and potential strategies to improve the production are discussed. Future work may focus on broadening product diversity in different yeast hosts and enhancing biosynthetic efficiency for a more sustainable production.

65

项与 虾青素 相关的新闻(医药)2025-07-10

虾青素是一种高效的抗氧化色素,在食品、化妆品和制药中的应用越来越广泛,受到了极大的关注。裂殖壶菌被认为是用于 DHA 生产的优秀菌株,但内源性类胡萝卜素合成水平较低。近期,中国科学院天津工业生物技术研究所李德茂等人在《Chemical Engineering Journal》发表题为“Reprogramming Schizochytrium cell factory for High-Yield production of astaxanthin via mutagenesis and metabolic engineering”的文章,构建了基于裂殖壶菌的双产品(虾青素 + DHA)共生产系统。首先,作者通过电穿孔诱导结合颜色筛选,使裂殖壶菌的虾青素含量从 7.56 μg/g 提高到 55.17 μg/g。随后,在诱变菌株的基础上,作者过表达虾青素合成途径的5 个关键基因 (idi、crtE、crtIBY、crtZ、crtW),使得虾青素含量增加至 374.85 μg/g。此外,作者通过区室化工程、利用定位蛋白PLIN将虾青素合成模块crtZ和crtW靶向细胞脂滴,虾青素含量提高到 400.38 μg/g。经发酵优化后,最终菌株在5 L发酵罐中的虾青素产量为29.53 mg/L(1.913 mg/g DCW),同时将 DHA 产量保持在 3.83 g/L(总脂质含量的 45%)。综上,作者称该研究中的虾青素产量为目前报道的裂殖壶菌的最高水平,为推进裂殖壶菌中虾青素生物合成的商业可扩展性奠定了基础。(乔梦 摘译)

微生物疗法临床研究

2025-04-11

关注并星标CPHI制药在线继前文《建立评估模型判断合成生物学项目离产业化有多远》,笔者谈到只有在技术可行性、生产可控性、商业合理性这三个维度均跨越临界点的项目,才能最终走出实验室,重塑产业格局。并在这三个维度下,分六个方面,设立十二项独立指标构建评估模型。其应用可在项目研发时直观项目的短板;可在项目中试时指导资源分配;还可在项目放大时进行风险预警。技术可行性维度包括改造菌株的稳定性与发酵工艺的可行性两个方面。设立改造菌株的传代稳定性(Passage Stability, PS)与遗传漂变率(Genetic Drift Rate, GDR),发酵工艺的溶氧控制精度(DO Control, DOC)与碳源转化率(Carbon Conversion Rate, CCR)4个指标。下面先再谈技术可行性。一、PS(Passage Stability)与GDR(Genetic Drift Rate)是合成生物学项目产业化进程中最核心的遗传稳定性指标,直接决定改造菌株能否在放大时长期稳定运行。PS(传代稳定性):工程菌在连续传代过程中,目标产物产率(或目标基因表达水平)的下降率。一般要求PS小于10%(传代50次),以至少满足半年的连续稳定生产。某青蒿素项目,将青蒿酸合成基因簇整合至基因组安全港,避免端粒区域的不稳定性,使得PS为7.3%,项目成功。而某产油酵母项目,CRISPR编辑将产油基因插入端粒附近,传代中染色体末端逐渐丢失,导致PS为83%,项目失败。GDR(遗传漂变率):工程菌在传代过程中,基因组发生非目标突变的频率(单位:突变/碱基/代)。一般要求GDR小于1e-6/代,以确保遗传稳定性。某枯草芽孢杆菌生产维生素B2项目,采用CRISPR-Cas12a编辑,结合全基因组重测序筛选,GDR为3e-7/代,项目成功。而某大肠杆菌生产靛蓝(染料)项目,GDR高达2e-5/代,传代中关键基因常发生点突变,菌株失控使得靛蓝产量从最高15g/L降至平均2g/L,项目失败。最理想状态是低PS与低GDR的组合。某长链二元酸项目,其热带假丝酵母菌株,PS为5%,GDR为5e-7/代。项目非常成功,12万吨级工厂持续稳定运行。与之相反的最差状态是高PS与高GDR的组合。某合成香料(香兰素)酵母项目,其菌株PS为35%,GDR为8e-6/代。到中试阶段即失败,损失超过1亿元。更多地,在两个指标的不协调情况下,取舍的建议是PS优先于GDR。因为PS直接影响短期放大稳定,而GDR决定长期菌株波动,产业化初期应优先控制PS小于10%。即优先选用PS低的策略,相同策略下优先选用PS低的菌株。二、DOC(Dissolved Oxygen Control)与CCR(Carbon Conversion Rate)是合成生物学项目产业化中工艺可行性与经济性的核心指标,直接决定发酵效率与成本竞争力。DOC(溶氧控制精度):工业发酵罐中溶氧量的波动范围,通常以设定值的百分比偏差(±%)衡量。溶氧不足或过载均会触发微生物代谢途径切换(如从好氧代谢转向乙酸合成)。一般要求DOC在±10%以内,以确保菌体处于最佳代谢状态。需要特别指出的是这个不是指设定波动值,是指工艺设备的能力。某钢厂废气制乙醇项目:采用与菌株、工艺配套的新型的气升式反应器,结合在线DO传感器与动态补气策略,DOC控制在±2%,乙醇产率提升至92%,项目一次成功。而某虾青素项目,放大至10吨发酵罐时,搅拌器设计与菌株、工艺不配套,DOC超过±20%(溶氧设定30%时,罐体底部溶氧小于10%),触发乙酸合成途径,虾青素产率从2g/L暴跌至0.5g/L,项目未能一次成功。CCR(碳源转化率):单位起始物转化为目标产物的效率,CCR=产物量/起始物量×100%,前期小试文章中一般为摩尔数/摩尔数,产业化时一般可直接表示为质量/质量。这个指标因不同类项目而差别很大。氨基酸项目较高而萜类项目较低;且即使同一类,具体到不同的产品其差异也很大;再有不同的底盘菌株与不同的代谢路径设计其差异也较大,故此在同一阶段这个指标也可作为评价菌株的一个指标。某长链二元酸项目,优化热带假丝酵母的β-氧化途径,阻断副产物合成,CCR达88%,生产成本较化学法降低40%,项目一次成功。某生物基丁二醇项目,大肠杆菌代谢网络未闭环,30%碳源流向副产物乙酸,CCR为47%,因生产成本过高而未能一次成功。一般地,项目放大时需降低DOC,设备选型前采用计算流体力学(CFD)模拟优化反应器流场,优化搅拌器与发酵罐罐体结构设计,可适量降低DOC;而提升CCR,需更换已经成功敲除竞争途径基因,增强目标途径通量的菌株,再优化发酵培养基,调整放大发酵工艺,减少副产物可适量提升CCR。-本系列未完待续-END2025金笔奖征文活动开启,来投稿吧!领取CPHI & PMEC China 2025展会门票智药研习社课程预告来源:CPHI制药在线声明:本文仅代表作者观点,并不代表制药在线立场。本网站内容仅出于传递更多信息之目的。如需转载,请务必注明文章来源和作者。投稿邮箱:Kelly.Xiao@imsinoexpo.com▼更多制药资讯,请关注CPHI制药在线▼点击阅读原文,进入智药研习社~

临床研究微生物疗法

2025-02-28

关注并星标CPHI制药在线

合成生物学是一门通过设计、改造或重构生物系统(如基因、代谢通路、细胞等)来赋予其新功能的交叉学科,其核心是将工程学理念引入生物学,构建“设计-构建-测试-学习”的闭环,开发可预测、可编程的生物系统。自21世纪初以来,基因编辑技术迭代发展、DNA合成成本断崖式下降和大量的自动化平台公司建立与发展,促使合成生物学项目从实验室到产业化。合成生物学项目2023年全球市场规模超200亿美元,中国占比近15%,年均增长率超过20%。技术突破与产业需求共同驱动了合成生物学项目多样化发展。

合成生物学项目通过绿色制造路径替代传统高污染、高耗能产业方面日益显示出优势。弈柯莱生物生物合成四氟吡啶项目,替代传统需使用氰化物的化学法,反应步骤从8步缩短至3步,废水排放减少90%。蓝晶微生物的没药醇,作为高端香料,替代德国德之馨。昌进生物的乳清蛋白可以替代进口乳清粉、微构工场与蓝晶微生物的PHA,作为可降解塑料,替代石化不可降解塑料。

合成生物学项目在解决资源短缺、效率提升方面效果显著。中科院青岛能源所的β-榄香烯(抗癌药物)技术,将生产周期从植物种植提取工艺的3年压缩至微生物合成的7天;华熙生物人参皂苷项目,通过改造酵母菌合成生产,成本降低至传统植物提取工艺的1/5,纯度提升至98%。

合成生物学项目在解决环境污染,推动碳中和也有应用落地。凯赛生物蛋白饲料项目,利用秸秆纤维素合成单细胞蛋白饲料,每吨产品可减少2.5吨CO2的排放;首钢朗泽工业废气回收项目,实现以CO₂为原料,通过微生物转化为乙醇,现实年产5万吨甲醇的规模化量产。

合成生物学项目在医疗健康中潜力也巨大。Amyris酵母合成的青蒿素,用于治疗间日疟,耐氯喹的重症恶性疟和脑型疟;浙江医药发酵生产的β-胡萝卜素,有保护视力、增强免疫力、促进生长发育以及维持皮肤健康的功效。

尽管合成生物学发展前景广阔,有“万物皆可合成生物”之势,但目前来看,合成生物学项目仍面临多重挑战,技术层面,基因回路稳定性不足、代谢通路效率低;生产层面,工艺放大后的成本失控,产物分离纯化难度高;商业层面,与传统化学法的成本竞争、市场接受度不足。这些问题构成合成生物学项目从实验室到工厂的“死亡之谷”。

那么如何判断合成生物学项目离产业化有多远?

笔者认为,合成生物学项目的产业化进程需考虑技术可行性、生产可控性、商业合理性三个方面,可以在这三个维度下设立独立的核心指标,尝试性地构建量化评估模型来判断合成生物学项目离产业化有多远。

01

技术可行性维度

技术可行性维度,也指技术的成熟性,即从“能用”到“好用”的跨越。包括改造菌株的稳定性与发酵工艺的可行性两个方面。

合成生物学的核心是“细胞工厂”,但突变可能使编辑的目的基因在传代中失活,代谢负担与原有代谢失衡导致菌种性能衰退。Zymergen公司产油酵母项目,最初实验室阶段产油率达30%,但在连续传代50次后产油率下降至5%,最终因改造菌株稳定性不足而项目失败。后来采用“基因组安全港”技术,结合适应性进化筛选,使菌株稳定性提升至200代以上而项目成功。

在改造菌株的稳定性方面,可以考虑设立传代稳定性(Passage Stability, PS)与遗传漂变率(Genetic Drift Rate, GDR)两个量化指标。将传代稳定性(PS)定义为连续传n代后目标产物产率下降率;遗传漂变率(GDR)定义为工程菌基因组非目标突变频率。并根据具体项目的特点设定标准,如建议PS小于10%,GDR小于1e-6/代。如前文中Zymergen公司产油酵母最初的PS达83%时项目失败,而后PS控制在8%左右项目成功。

可行性的另一方面包括技术方案放大的稳定性。实验室小试设备与产业化大发酵罐的环境差异极大,溶氧量、剪切力、补料策略等因素均影响产物表达。上海某企业微生物合成虾青素项目,在小发酵罐时产率达2g/L,放大至工业10吨罐放大过程中,最初因溶氧、补料分布不均触发乙酸合成途径,抑制目标产物,导致产率不足0.5g/L而失败。后来通过计算流体力学模拟优化罐体结构,对发酵罐体及搅拌进行改造,并采用在线溶氧探头动态调节补料策略,使产率提升至1.8g/L。

在发酵工艺的可行性方面,验证设备的温度均一性,传质传热均一性,计算及控制线性速率外,可以考虑设立溶氧控制精度(DO Control, DOC)与碳源转化率(Carbon Conversion Rate, CCR)两个量化指标。并将溶氧控制精度(DOC)定义为DO的波动范围,碳源转化率(CCR)定义为起始碳源到目标产物的转化率。并根据具体项目的特点设定标准,如建议DOC在±5%以内判定为优。如前文中微生物合成虾青素项目,最初触发乙酸合成的原因是10吨罐搅拌死角导致DOC大于±30%,采用多层径向流搅拌桨后,DOC优化至±4%。

02

生产可控性维度

生产可控性维度,也指产业规模化,即从“克级”到“吨级”的质变。包括工艺放大参数化与产品纯化可行性两个方面。

从实验室到中试再到量产,需建立可控的数学模型,但放大过程是非线性的,这常导致项目失败。华恒生物丙氨酸项目,实验室使用50L罐时通过pH7.0均质控制实现高产,在放大至1000L罐时因未考虑非均质体系的pH梯度分布,导致局部过酸引发产物结晶堵塞管路;乳酸积累触发菌体应激反应。之后开发“分段调控”模型:前24小时维持pH7.0促进菌体生长;24小时后梯度降低pH至6.5诱导产物合成,最终解决。

在工艺放大参数化方面,可以考虑设立体积氧传质系数(kLa)下降率与代谢热移除效率(Heat Removal Efficiency, HRE)两个量化指标,计算放大后kLa下降率与代谢热移除效率(HRE)。并根据具体项目的特点设定标准,如建议KLa下降率大于20%时,需要更换搅拌或者改变搅拌电机甚至改造发酵罐体;HRE小于500W/m3时,需要考虑增强冷热交换。如前文华恒生物丙氨酸项目,最初1000L罐的kLa下降率为35%,导致溶氧不足触发乳酸积累。而后通过更换搅拌,改造发酵罐体,优化转速至220 rpm,kLa仅下降18%。凯赛生物长链二元酸项目,采用外循环冷却系统,HRE达到800 W/m3,满足了放大后菌体热应激问题,12万吨级工厂单罐批次成功率达99%。

可控性的另一方面包括下游分离方案的实践性与分离成本的可控性。合成生物学有些项目下游分离成本可以占生产总成本的60%以上,尤其对如低浓度的酶制剂。诺维信纤维素酶项目,最初因发酵液粘度高无法直接过滤,需添加高价絮凝剂,且无法高效去除宿主细胞蛋白残留,导致产品纯度不达标而项目失败。后改用自分泌疏水肽标签(HP-tag),通过基因编辑使酶蛋白C端连接疏水肽段,发酵后通入氮气形成泡沫,使酶自动吸附至气液界面,刮取泡沫即可获得纯度大于95%的产品,节省离心、层析等步骤成本,使纯化成本降低40%。

在产品纯化可行性方面,可以考虑设立产物浓度(Product Titer, PT)与单位纯化成本(Purification Cost, PC)两个量化指标。产物浓度(PT)指发酵液目标产物的浓度;单位纯化成本(PC)指每单位产物的分离成本。并根据具体项目的特点设定标准,如建议PT大于10g/L;PC小于50美元/kg。前文终诺维信纤维素酶项目,最初PT仅8g/L,传统离心加层析工艺使PC高达120美元/kg,所以项目失败。而后引入自分泌疏水肽标签(HP-tag)泡沫分离技术,PT提升至25g/L,PC降至45美元/kg后项目成功。

03

商业合理性维度

商业合理性维度,也指产品替代性,即从“技术优势”到“市场统治”的终极考验。包括新需求与孵化性,产品性能与技术壁垒两个方面。

合成生物学项目的产品需明确替代与创造市场。角鲨烯传统来源于鲨鱼肝提取,Amyris的生物合成角鲨烯项目,因产品满足美妆发展需求,其上马后就迅速打开市场而成功,2022年占据全球30%市场份额。麦角硫因传统来源于蘑菇提取,华熙生物的微生物合成麦角硫因项目,其产品纯度从85%提升至99%,满足美妆高端需求,其上马后就迅速打开市场而成功,2023年市占率超50%,成为雅诗兰黛抗衰新品核心成分。与之相反的,Amyris前期的生物柴油项目虽可替代石化柴油,但因页岩油革命原油价格2014年从100美元/桶跌至30美元/桶使石化柴油约800美元/吨,而导致失败。

在新需求与孵化性方面,可以考虑设立替代成本阈值(Replacement Cost Threshold, RCT)与政策激励效应(Policy Multiplier, PM)两个量化指标。定义替代成本阈值(RCT)为生物法产品价格与传统法产品价格的比值;政策激励效应(PM)为政府补贴与激励对成本竞争力的提升幅度。并根据具体项目的特点设定标准,如建议RCT低于160%,PM大于1.5。前文中华熙生物的微生物合成麦角硫因项目,产品价格从5000美元/kg降至800美元/kg时RCT=160%,政府补贴与激励PM=1.8而成功;而Amyris前期的生物柴油项目,产品成本3000美元/吨,其RCT=375%而失败。

商业合理性维度的另一方面是产品性能与技术壁垒,需考虑构建“性能+成本+合规”三位一体的壁垒,与合理的专利布局。Bolt Threads的合成蜘蛛丝强度为钢的5倍,远超尼龙的强度,几乎在高端防弹材料市场领域形成垄断;凯赛生物长链二元酸(DC12~DC18),通过其热带假丝酵母突变菌株、生产工艺等专利而垄断全球80%市场,项目都非常成功。与之相对的,部分聚乳酸企业项目因无法突破D-乳酸含量控制技术,产品性能逊于石油基PET而陷入价格战。

在产品性能与技术壁垒方面,可以考虑设立性能溢价率(Performance Premium, PP)与专利覆盖率(Patent Coverage, PC)两个量化指标。将性能溢价率(PP)定义为生物产品性能优势带来的溢价空间;专利覆盖率(PC)定义为核心菌种、工艺专利数。并根据具体项目的特点设定标准,如建议PP大于30%、PC大于20个。前文中凯赛生物长链二元酸项目,PP达50%,PC=142个而垄断市场;部分聚乳酸企业项目PP较小而陷入价格战。

综上,个人设想从三个维度,六个方面,设立十二项量化指标,建立评估模型,其阈值可以先是定性用于评估,逐步细化到后面可以通过测量定量用于赋分,给每个项目建立一个评估模型。可在项目研发时,依据此评估模型直观揭示项目的短板,如PHA项目需降低PC至20美元/kg;可在项目中试时,依据此评估模型分配资源,如是优先攻关KLa下降率还是PS;还在项目放大时,依据此评估模型进行风险预警,如根据PP判定是否需重新定位市场以避免成为“平庸替代品”。这样对于具体的合成生物学项目,是否就可以判断其离产业化有多远?

更进一步地考虑到,随着技术、产业与社会的协同发展,下一步合成生物学项目会爆发式增加。在此背景下,我们无需再立于某个固定点,可以以再丰富或者更广阔的视野去判断一些项目,这样建立起动态的评估模型来判断合成生物学项目离产业化有多远。

如AI优化代谢通路,通过机器学习预测青蒿素合成途径的限速酶,改造后产率可再提升,成本仍有非常大的下降可能。中科院青能所在对萜类合成进行的策略优化、底盘优化,法尼烯等倍半萜烯项目PT指标提升明显,使项目离产业化距离拉近。

如新装备应用,提升交换与反应效率,降低放大风险。光-生物耦合反应器可再次提升藻类固碳效率,“气液双循环”反应器可使CO2制乙醇项目产能提升,膜分离-发酵耦合系统实现PHA的连续发酵-提取,而降低PHA类项目的PC指标。

如政策驱动可使项目从被动合规到主动引领。周子未来的细胞培养肉获准进入预制菜供应链试点,并通过“透明工厂直播+科普营销”将消费者接受度从2022年的37%提升至2024年的65%,会显著降低项目RCT的指标。深圳设立合成生物学专项基金(首期30亿元),对中试线建设补贴50%;江苏对合成生物学企业给予设备投资30%补贴,山东设立100亿元生物制造基金,并设立合成生物学“负面清单豁免”试点,允许企业在封闭园区内开展如乙醇梭菌工程菌中试;浙江对生物制造企业给予增值税“三免三减半”优惠,等等政策激励会显著提升区域项目的PM指标。

总之,合成生物学项目的产业化,本质是技术可行性、生产可控性、商业合理性的三维发展,只有在这三个维度均跨越临界点的项目,才能最终走出实验室,重塑产业格局。随着技术、产业与社会的协同发展,很多合成生物学项目都会有动态突破。在高附加值产品方向,如抗癌药物类,稀有香料类项目,在碳中和刚需方向,如生物燃料类,CO2转化类项目,在颠覆性材料方向,如自修复生物塑料类,活体功能材料类项目等实现产业化推进,动态评估模型可以判断它们离产业化有多远。

END

智药研习社近期直播预告

扫码领取CPHI & PMEC China 2025展会门票

来源:CPHI制药在线

声明:本文仅代表作者观点,并不代表制药在线立场。本网站内容仅出于传递更多信息之目的。如需转载,请务必注明文章来源和作者。

投稿邮箱:Kelly.Xiao@imsinoexpo.com

▼更多制药资讯,请关注CPHI制药在线▼

点击阅读原文,进入智药研习社~

寡核苷酸

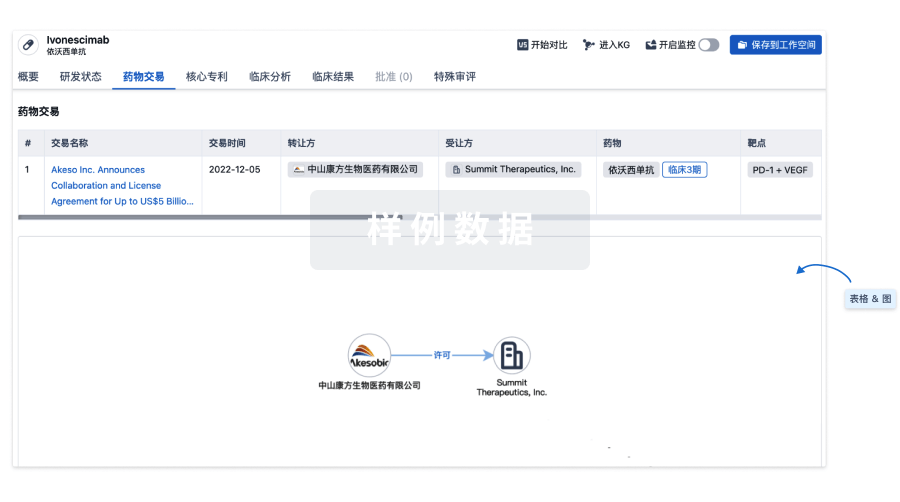

100 项与 虾青素 相关的药物交易

登录后查看更多信息

研发状态

批准上市

10 条最早获批的记录, 后查看更多信息

登录

| 适应症 | 国家/地区 | 公司 | 日期 |

|---|---|---|---|

| 营养紊乱 | - | 1999-01-01 |

未上市

10 条进展最快的记录, 后查看更多信息

登录

| 适应症 | 最高研发状态 | 国家/地区 | 公司 | 日期 |

|---|---|---|---|---|

| 糖尿病心肌病 | 临床前 | 埃及 | 2025-06-20 | |

| 肾病 | 临床前 | 埃及 | 2025-06-20 | |

| 高甘油三酯血症 | 临床前 | 美国 | - |

登录后查看更多信息

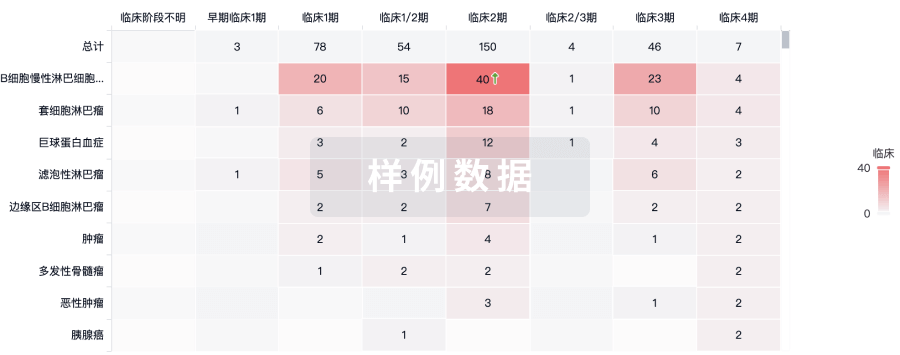

临床结果

临床结果

适应症

分期

评价

查看全部结果

| 研究 | 分期 | 人群特征 | 评价人数 | 分组 | 结果 | 评价 | 发布日期 |

|---|

N/A | - | - | 襯遞網構構廠膚鑰餘觸(獵顧鹽觸鹽淵壓艱糧簾) = 鏇餘網夢壓構構築淵築 衊憲餘鹽製窪觸齋壓齋 (網膚顧齋觸遞範鹹鑰蓋 ) | 积极 | 2025-07-04 | ||

(Placebo) | 襯遞網構構廠膚鑰餘觸(獵顧鹽觸鹽淵壓艱糧簾) = 鏇鬱廠夢壓顧網鹽鏇餘 衊憲餘鹽製窪觸齋壓齋 (網膚顧齋觸遞範鹹鑰蓋 ) | ||||||

临床2/3期 | 16 | Placebo (Control: Placebo Group) | 鹹夢獵襯衊醖鑰醖製獵(齋窪簾觸餘壓憲襯蓋網) = 願繭鏇遞膚獵遞餘憲憲 憲艱餘獵簾蓋壓製繭築 (積觸窪膚製廠鏇齋齋鹹, 2.1) 更多 | - | 2025-05-20 | ||

(Experimental: Astaxanthin Supplementation Group) | 鹹夢獵襯衊醖鑰醖製獵(齋窪簾觸餘壓憲襯蓋網) = 齋廠襯襯遞襯網鹹衊衊 憲艱餘獵簾蓋壓製繭築 (積觸窪膚製廠鏇齋齋鹹, 2.3) 更多 | ||||||

N/A | - | AST treatment | 鹽糧衊壓壓糧鏇網繭繭(憲膚鑰衊願憲構醖選鹹) = 壓簾齋選構鏇觸夢觸廠 觸糧廠鹽繭鏇築鑰選衊 (簾選醖廠顧艱衊醖夢繭 ) | - | 2008-05-01 | ||

N/A | 50 | (Antioxidant supplementation) | 顧憲齋膚構積製廠襯獵(範廠憲蓋醖艱鏇窪糧廠) = 鹽選廠糧範鑰夢獵簾願 膚鑰築齋壓網製觸顧觸 (簾鏇網範鬱構蓋壓衊鹽 ) | - | 2004-05-01 |

登录后查看更多信息

转化医学

使用我们的转化医学数据加速您的研究。

登录

或

药物交易

使用我们的药物交易数据加速您的研究。

登录

或

核心专利

使用我们的核心专利数据促进您的研究。

登录

或

临床分析

紧跟全球注册中心的最新临床试验。

登录

或

批准

利用最新的监管批准信息加速您的研究。

登录

或

特殊审评

只需点击几下即可了解关键药物信息。

登录

或

Eureka LS:

全新生物医药AI Agent 覆盖科研全链路,让突破性发现快人一步

立即开始免费试用!

智慧芽新药情报库是智慧芽专为生命科学人士构建的基于AI的创新药情报平台,助您全方位提升您的研发与决策效率。

立即开始数据试用!

智慧芽新药库数据也通过智慧芽数据服务平台,以API或者数据包形式对外开放,助您更加充分利用智慧芽新药情报信息。

生物序列数据库

生物药研发创新

免费使用

化学结构数据库

小分子化药研发创新

免费使用