预约演示

更新于:2025-07-19

Remetinostat

更新于:2025-07-19

概要

基本信息

最高研发阶段临床2期 |

首次获批日期- |

最高研发阶段(中国)- |

特殊审评- |

登录后查看时间轴

结构/序列

分子式C16H21NO6 |

InChIKeyXDZAHHULFQIBFE-UHFFFAOYSA-N |

CAS号946150-57-8 |

关联

12

项与 Remetinostat 相关的临床试验NCT06716086

A Novel Shape Memory Alloy-Based Orthosis for Proximal Interphalangeal Joint Stiffness

The goal of this clinical trial is to evaluate the applicability, effectiveness, and usability of a shape memory alloy-based orthosis for patients with finger proximal interphalangeal joint stiffness. This cutting-edge design incorporates shape memory alloy into the device for improving proximal interphalangeal joint stiffness and, secondarily, enhancing the ability to perform activities.

Half of the participants will be assigned to experimental group, receiving a shape memory alloy-based orthosis for home program. The other half will be assigned to control group, receiving a conventional stretching program. Three evaluations, examining range of motion and hand functional performance, will be conducted before intervention, 4 weeks and 8 weeks after baseline by the researchers.

Half of the participants will be assigned to experimental group, receiving a shape memory alloy-based orthosis for home program. The other half will be assigned to control group, receiving a conventional stretching program. Three evaluations, examining range of motion and hand functional performance, will be conducted before intervention, 4 weeks and 8 weeks after baseline by the researchers.

开始日期2025-03-12 |

申办/合作机构 |

ITMCTR2024000220

A clinical study on the treatment of knee osteoarthritis with homologous acupuncture of shape and qi

开始日期2024-09-01 |

申办/合作机构- |

NCT06681844

Prediction of the Tooth Wear Index Based on a Dataset of Dental Shapes:a Retrospective Study

Tooth wear, resulting from gradual loss of dental hard tissue due to mechanical and chemical factors, impacts tooth structure, texture, and function. It affects quality of life, with varying prevalence (26.9% to 90.0%), and is traditionally detected visually during check-ups, often at advanced stages. Monitoring alterations in tooth shape via intraoral scanners aids early detection, but restoration remains challenging. Prevention through early detection is vital, as patients may not fully comprehend tooth structure loss until visible. Recently, statistical shape analysis (SSA) used to learn the tooth anatomy and define a reference shape (biogeneric tooth) using. However, assuring landmark consistency is challenging mostly due to biases of the operator. Recently, a robust method called MEG-IsoQuad offered automated, isotopological remeshing. Combining this with SSA holds promise for diagnostic and simulation purposes. This study aims to assess the reliability of a remeshing-SSA approach for altered and intact premolar analysis and compare machine learning algorithms for simulating the shape of the initially intact tooth or future altered one.

The clinical perspective of the current work offers possibilities to:

* Prevent future tooth wear by detecting it at an early stage; and communicate better to the patient by presenting him/her potential future altered teeth

* Simulate the adapted reconstruction for the altered tooth by simulating the initially intact one

The clinical perspective of the current work offers possibilities to:

* Prevent future tooth wear by detecting it at an early stage; and communicate better to the patient by presenting him/her potential future altered teeth

* Simulate the adapted reconstruction for the altered tooth by simulating the initially intact one

开始日期2023-12-12 |

申办/合作机构 |

100 项与 Remetinostat 相关的临床结果

登录后查看更多信息

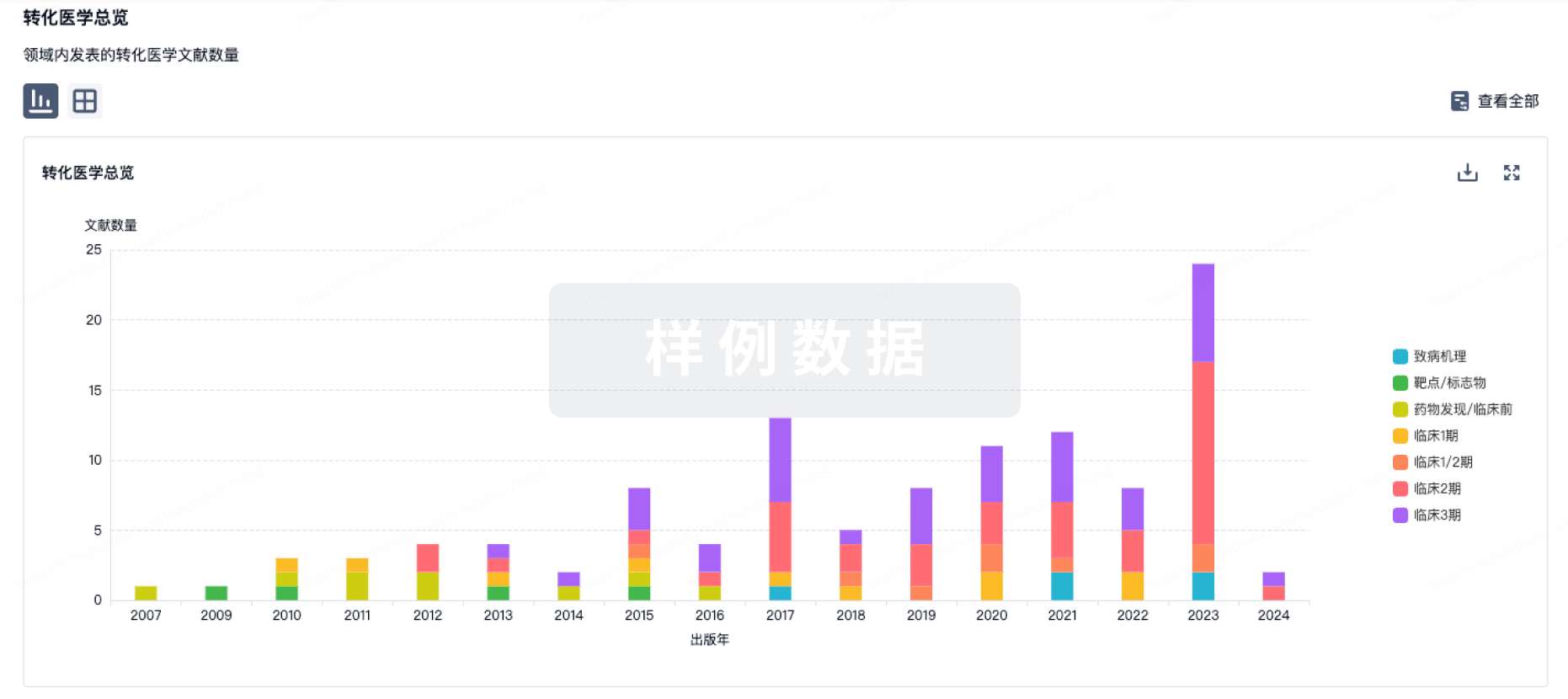

100 项与 Remetinostat 相关的转化医学

登录后查看更多信息

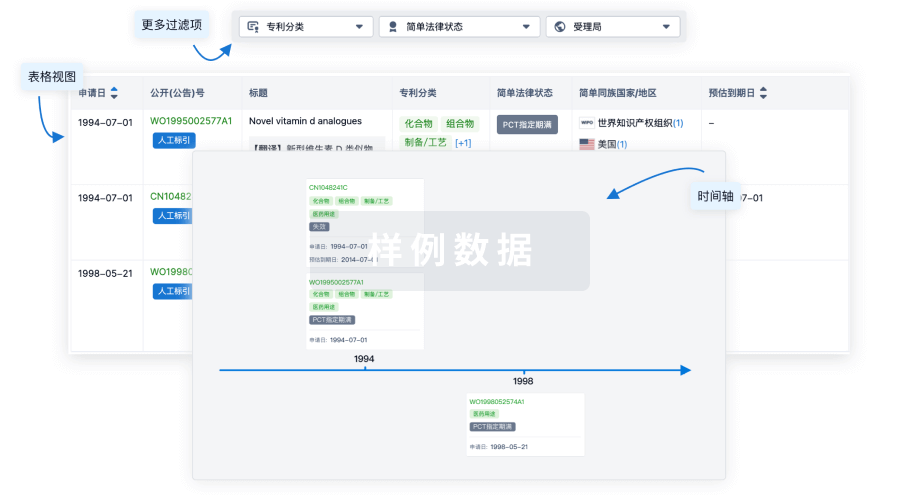

100 项与 Remetinostat 相关的专利(医药)

登录后查看更多信息

8

项与 Remetinostat 相关的文献(医药)2024-11-01·EUROPEAN JOURNAL OF PHARMACOLOGY

Topical histone deacetylase inhibitor remetinostat improves IMQ-induced psoriatic dermatitis via suppressing dendritic cell maturation and keratinocyte differentiation and inflammation

Article

作者: Jiang, Qian ; Zhou, Xingchen ; Huang, Huining ; Jin, Liping

Psoriasis is a chronic inflammatory skin disease characterized by excessive proliferation of keratinocytes and infiltration of immune cells. Although psoriasis has entered the era of biological treatment, there is still a need to explore more effective therapeutic targets and drugs due to the presence of resistance and adverse reactions to biologics. Remetinostat, an HDAC inhibitor, can maintain its potency within the skin with minimal systemic effects, making it a promising topical medication for treating psoriasis. But its effectiveness in treating psoriasis has not been evaluated. In this study, the topical application of remetinostat significantly improved psoriasiform inflammation in an imiquimod-induced mice model by inhibiting CD86 expression of CD11C+I-A/I-E+ dendritic cells (DCs) in the skin. Moreover, remetinostat could dampen the maturation and activation of bone marrow-derived DCs in vitro, as well as the expression of psoriasis-related inflammatory mediators by keratinocytes. In addition, remetinostat could promote keratinocyte differentiation without affecting its proliferation. Our findings demonstrate that remetinostat improves psoriasis by inhibiting the maturation and activation of DCs and the differentiation and inflammation of keratinocytes, which may facilitate the potential application of remetinostat in anti-psoriasis therapy.

2024-10-01·ARCHIV DER PHARMAZIE

Soft drug inhibitors for the epigenetic targets lysine‐specific demethylase 1 and histone deacetylases

Article

作者: Baniahmad, Adina A. ; Seitz, Johannes ; Schüle, Roland ; Auth, Marina ; Preissl, Sebastian ; Hein, Lutz ; Schulz‐Fincke, Johannes ; Prinz, Tony ; Jung, Manfred ; Tzortzoglou, Pavlos ; Hau, Mirjam ; Willmann, Dominica ; Schmidtkunz, Karin ; Metzger, Eric

Abstract:

Epigenetic modulators such as lysine‐specific demethylase 1 (LSD1) and histone deacetylases (HDACs) are drug targets for cancer, neuropsychiatric disease, or inflammation, but inhibitors of these enzymes exhibit considerable side effects. For a potential local treatment with reduced systemic toxicity, we present here soft drug candidates as new LSD1 and HDAC inhibitors. A soft drug is a compound that is degraded in vivo to less active metabolites after having achieved its therapeutic function. This has been successfully applied for corticosteroids in the clinic, but soft drugs targeting epigenetic enzymes are scarce, with the HDAC inhibitor remetinostat being the only example. We have developed new methyl ester‐containing inhibitors targeting LSD1 or HDACs and compared the biological activities of these to their respective carboxylic acid cleavage products. In vitro activity assays, cellular experiments, and a stability assay identified potent HDAC and LSD1 soft drug candidates that are superior to their corresponding carboxylic acids in cellular models.

2023-06-01·Journal of labelled compounds & radiopharmaceuticals

Nitrilase mediated mild hydrolysis of a carbon‐14 nitrile for the radiosynthesis of 4‐(7‐hydroxycarbamoyl‐[1‐14C‐heptanoyl]‐oxy)‐benzoic acid methyl ester, [14C]‐SHP‐141: A novel class I/II histone deacetylase (HDAC) inhibitor

Article

作者: Moody, Thomas S. ; Chappell, Todd ; Kitson, Sean L. ; Watters, William ; Mazitschek, Ralph

A strategy has been developed for the carbon‐14 radiosynthesis of [14C]‐SHP‐141, a 4‐(7‐hydroxycarbamoyl‐heptanoyloxy)‐benzoic acid methyl ester derivative containing a terminal hydroxamic acid. The synthesis involved four radiochemical transformations. The key step in the radiosynthesis was the conversion of the 7‐[14C]‐cyano‐heptanoic acid benzyloxyamide [14C]‐4 directly into the carboxylic acid derivative, 7‐benzyloxycarbamoyl‐[14C]‐heptanoic acid [14C]‐8 using nitrilase‐113 biocatalyst. The final step involved deprotection of the benzyloxy group using catalytic hydrogenation to facilitate the release of the hydroxamic acid without cleaving the phenoxy ester. [14C]‐SHP‐141 was isolated with a radiochemical purity of 90% and a specific activity of 190 μCi/mg from four radiochemical steps starting from potassium [14C]‐cyanide in a radiochemical yield of 45%.

174

项与 Remetinostat 相关的新闻(医药)2025-07-15

·医药观澜

▎药明康德编者按:自Donald Ingber博士最初设想建立Wyss研究所(Wyss Institute)至今已近二十年。这一大胆设想源于这样一个信念:将工程学原理与对生物学的深刻洞见相结合,可以为医学及其他领域带来变革性解决方案。如今这一愿景已蓬勃发展成为现实。Wyss研究所已成为转化科学的典范,不仅开创了器官芯片(organs-on-chips)、仿生材料等突破性技术,更孵化出六十余家初创企业,积极塑造着医疗健康的未来图景。美国FDA在今年早些时候宣布一项计划,旨在减少新药临床试验申请中的临床前安全性研究对动物实验的依赖。这一监管方向的变化,正体现了像Wyss研究所推动的人体模拟平台等前沿技术在药物开发中的重要性和前景。最近,我们与Ingber博士进行了一次对话,探讨该研究所的独特架构如何为学术界的创新引擎提供动力,以传统学术环境中难于见到的方式加速创新。Donald E. Ingber博士现任Wyss研究所创始所长,并同时担任哈佛医学院血管生物学系Judah Folkman讲席教授和哈佛大学John A. Paulson工程与应用科学学院Hansjörg Wyss讲席教授。作为横跨医学、工程与基础科学的跨界科学家,他开创性地研发了器官芯片、靶向血管闭塞部位的剪切力激活纳米疗法等多项突破性技术,在力学生物学、纳米医学等领域持续引领生物医学创新。Ingber博士已发表500余篇学术论文,获得200多项专利,创立8家生物科技公司,其开发的"人体器官芯片"技术被世界经济论坛评为十大新兴技术,并被纽约现代艺术博物馆永久收藏。Ingber博士曾两度入选《自然·生物技术》“全球顶尖转化研究者TOP20”,并斩获多项跨领域荣誉。您好,很高兴与您对话。Wyss研究所常被形容为工程学与生物学交汇之地。在您的工作中,您如何定义"转化"这一概念?Donald Ingber博士:Wyss研究所成立的初衷是助力构建未来。我们在约20年前开始构思,并于16年前正式创立了研究所。我们坚信,实验室里的发现如果不能走出实验室,就难以产生现实影响力。在转化研究层面,这种设计思维塑造了我们的创新方式。合成生物学是我们工作的主要部分之一——例如利用基因工程等手段对细胞、组织乃至完整生物体进行重编程,或者开发跨越血脑屏障的载体(如工程化蛋白或病毒载体)。我们始终致力于融合生物学与工程学,以构建新一代疗法、诊断技术、医疗设备和生物材料。今年早些时候,美国FDA宣布了一项计划,旨在减少新药临床试验申请中的临床前安全性研究对动物实验的依赖,并将器官芯片技术列为潜在替代方案。作为该领域的先驱,您认为哪些关键转折点推动了这项技术从学术概念转化为具有现实影响力的解决方案?Donald Ingber博士:在Wyss研究所创立之初,我的实验室正好孕育出了器官芯片技术。这项技术最初始于一个博士后项目,其基础是我们耗费近二十年研发的技术——将计算机微芯片制造方法创新应用于生物活体细胞研究。我们创建了内衬活细胞的设备,其中包含模拟生理功能(例如肺部呼吸运动或肠道的蠕动功能)的空腔通道。但关键在于证明这些芯片能真正复现人类器官级别的功能——这要求我们不断优化生物模型、设计出更好的设备,并开发能进行长期培养与功能维持的配套系统。然而,降低技术转化过程中的风险需要做的努力远不止于科研层面。我们直接与医药企业展开合作,这些合作不仅对技术验证至关重要,更帮助我们精准把握行业真实需求:他们究竟需要实验室台式设备还是大型系统?怎样的用户界面最理想?这些产业合作有助于我们优化产品与市场的契合度。在Wyss研究所,我们还组建了约50人的内部团队,成员均具备深厚的产品开发经验——其中许多人曾在初创公司或医药公司工作过,有些人拥有基于细胞的毒性检测的技术背景,有些人则拥有生物技术工具商业化的背景。因此,我们不仅降低了技术风险,更系统性地规避了研究成果转化的全链条风险。这是一个极具代表性的案例。那么,Wyss研究所在推动技术商业化过程中,如何确定优先推进哪些技术?是基于潜在影响力、技术可行性,还是产业界兴趣来进行决策的?Donald Ingber博士:Wyss研究所采用的运营模式可谓独树一帜,与我见过的任何机构都截然不同。某种程度上,我们打造了一个“学术界创新工坊”的加强版。我们的教授可以自由使用研究所的核心平台资源,并获得内部资金用于支持博士后和学生的研究。更重要的是,他们始终保持着完全的学术自主权。我们不会将学者的实验室完全迁入研究所内,而是精选每个团队中具创业精神和技术驱动力的成员。我们的核心策略之一是鼓励尽早报告发明成果。研究所内设有战略知识产权律师团队——他们的职责不是撰写专利,而是提供具有可操作性的早期反馈。例如在审阅发明报告时,他们会指出:"当前的方案虽然不能申请专利,但若对A、B、C三方面进行调整优化,它可能会变得非常有价值。"这种指导能让研究人员及时调整方向,确保走在最具转化潜力的捷径上。在后续阶段,我们设立了称为“验证项目”的内部申请机制。这类项目往往由团队自发组建——通常包括博士后、学生以及具有产业经验的技术人员。他们只需提交约5页的简明提案,阐述初步的高价值应用场景、技术里程碑和1-2年的项目时间线。此时团队已初步具备初创企业特质,我们的业务开发团队和知识产权专家会协助制定上市策略、专利布局和专利的自由实施分析。多数项目最终会孵化成为初创企业,通常是在发表了具有重大影响力的论文并获得了早期投资者的青睐之后。但有时投资者的反馈意见会指出需要进一步降低技术或商业风险。若多位投资者提出相同顾虑,团队可申请作为“研究所项目”以获得支持。这类项目将获得专项资助来解决潜在投资者所发现的具体问题——无论是补充更多临床前数据、降低制造成本、亦或是完善监管策略。我们推动的转化案例跨度极大:从最终授权给医药企业的新型癌症疫苗(我们开展了1期临床试验),到在临床研究中能让老年人的平衡能力恢复到20岁年轻人水平的智能鞋垫(其间我们将生产成本降低了十倍以上)。这些都不是传统学术机构中的常见成果。这也正是Wyss研究所与众不同的地方:我们不仅研发技术,我们还致力于打造让技术产生实际影响力的全流程体系。您能否也分享一些未按计划顺利推进的案例?从这些案例中我们可以汲取哪些教训?Donald Ingber博士:好的。有些创意本身没有问题,但为时尚早。时机往往决定一切。1998年我曾创办一家初创企业,专注于医疗设备及其他材料的3D打印应用。这是正确的方向,但当时的市场远未成熟——我们只是超前了。另一个我曾寄予厚望的案例,是我们2012年发表在《科学》杂志的项目。灵感来源于血小板对血管狭窄处高剪切应力环境的响应机制——这种力学刺激会触发血栓形成。我们设想:能否模拟这一机制,将药物精准递送至心梗、卒中或肺栓塞等血管阻塞部位?这类疾病中,溶栓药物虽能救命,但前提是必须快速给药,而且会带来全身性出血等重大风险。我们采用可规模化的喷雾干燥技术开发出了血小板大小的纳米颗粒聚集体,表面覆盖溶栓药物。在肺栓塞动物模型中,仅需1%常规剂量就能挽救85%的实验动物,效果极其显著。然而随后多重挑战接踵而至,包括药物原材料的供应、对扩大化生产的疑虑、以及中风领域的融资环境。后来我们调整方向,转而使用该技术来递送硝酸甘油——一种血管扩张剂。在缺血性卒中临床前模型中,装载硝酸甘油的微粒可以恢复侧枝血管的血流,减轻神经损伤,且规避了全身性副作用。不久前我们就此提交了一篇论文,时隔十三年终于获得了投资者的关注。虽然这个项目尚未成功,但希望仍在。阻碍它的因素并不在科学层面,而是商业化方面的挑战:时机、风险承受能力、找到关键合作伙伴。根据我的经验,多数“失败”与理念或数据无关,归根结底是两个因素:人与市场时机。最大的教训主要就在此处。展望未来,您认为科学转化流程在未来十年将如何演变?在您看来,下一个前沿领域在哪里?您认为像Wyss这样的机构又该如何发展以迎接这些机遇?Donald Ingber博士:我们已经在探索并实践若干极具前景的新模式。最令人振奋的进展之一是与风险投资机构的早期合作。这些机构现在为我们创新管线的上游环节——我称之为创新漏斗的"左侧"或“创新工坊”阶段,提供不加限定的支持。此外,他们还资助一些验证项目,这些项目往往是初创企业的雏形。这些机构不会被动地等待技术风险降低后再介入,而是从初期阶段就开始参与项目培育——有时甚至组建外部团队与我们内部团队并行开发。这种深度早期合作已经催生多个前景广阔的初创企业。我们开发的另一创新模式是“预竞争联盟(pre-competitive consortium)”,该联盟聚焦神经治疗最大瓶颈——穿越血脑屏障。我们发现几乎所有大型药企都在努力应对这一挑战,尤其是在阿尔茨海默病、肌萎缩侧索硬化(ALS)等疾病的生物制品研发领域,超过95%的候选药物曾经折戟沉沙。在与药企和生物科技公司的对话中,我们捕捉到一个关键信息:企业都对共享药物递送技术持开放态度。这一洞见促使我们建立预竞争联盟,开发新型血脑屏障穿透载体并将其非独家授权给多家公司。这是一个双赢的局面:企业仍可开发自己的独有药物,而穿透载体技术能更快获得广泛应用。简而言之,在Wyss研究所,我们正在尝试开创一种前所未有的商业化协作模式——这种模式不仅在哈佛大学没有先例,在学术界和产业界也都是前所未见。这种协作模式正是突破下一个前沿领域所需的关键驱动力。感谢您的真知灼见!Turbocharging the Skunkworks of Academia: A Conversation with Dr. Donald Ingber, Founding Director of the Wyss Institute at HarvardEditor’s Note: It’s been nearly two decades since Dr. Donald Ingber first envisioned the Wyss Institute—a bold idea rooted in the belief that engineering principles, when combined with a deep understanding of biology, could unlock transformative solutions in medicine and beyond. Today, that vision is a thriving reality. The Wyss Institute has become a model for translational science, pioneering technologies such as organs-on-chips and bioinspired materials, and launching more than sixty startups that are actively shaping the future of healthcare. We recently sat down with Dr. Ingber to explore how the Institute’s unique structure has “turbocharged the skunkworks of academia,” accelerating innovation in ways rarely seen in traditional academic settings.Don, it’s great to speak with you. The Wyss Institute is often described as a place where engineering and biology truly converge. How do you define "translation" in the context of your work?Donald Ingber: The Wyss Institute was created to help engineer the future. We began thinking about this nearly 20 years ago and officially launched the Institute 16 years ago. We believe that discoveries made at the bench won’t have a real-world impact unless they move beyond the lab. When it comes to translation, this design perspective shapes how we invent. Synthetic biology is a major part of our work—using genetic engineering and other tools to reprogram cells, tissues, and even whole organisms, or to develop shuttles that cross the blood-brain barrier—be it engineered proteins or viral vectors. We’re blending biology and engineering to build the next generation of therapeutics, diagnostics, devices, and biomaterials.Recently, FDA announced a plan to reduce reliance on animal testing in preclinical safety studies included in Investigation New Drug applications, and listed organs-on-chips technologies as a potential alternative. As a pioneer in this field, what were the key inflection points that helped move it from an academic concept to something with real-world impact?Donald Ingber: The organs-on-chips technology emerged from my lab right around the time the Wyss Institute was launching. It started with a postdoc project and was built on techniques we had been developing for almost two decades—adapting methods from computer microchip manufacturing and applying them to biology and living cells. We created devices lined with living cells, containing hollow channels that mimic physiological functions—like breathing motions in the lung or peristaltic movements in the intestine. We had to prove that these chips could truly replicate human organ-level functions. That meant refining the biology, engineering better devices, and developing instruments that could support long-term culture and function.But de-risking went far beyond the science. We engaged directly with pharmaceutical companies—these collaborations were critical not just for validation, but for understanding what industry actually needed. Would they want something that fits on a lab bench or a larger system? What kind of user interface would be ideal? These partnerships helped us refine the product-market fit.At the Wyss Institute, we also built a strong internal team—about 50 people with deep product development experience, including many who had worked in startups or pharma. Some had backgrounds in cell-based toxicity testing, others in commercializing biotech tools. So we didn’t just de-risk the technology—we de-risked the entire translational pathway.That’s a great example. At Wyss Institute, how do you prioritize which technologies to move toward commercialization? Is it based on potential impact, feasibility, or industry interest?Donald Ingber: The Wyss Institute operates under a very unique model—unlike anything I’ve seen elsewhere. In a way, we’ve turbocharged what I call the “skunkworks of academia.” Our faculty have open access to the Institute’s platforms and receive internal funding to support postdocs and students. Importantly, they maintain complete creative freedom. We don’t move in entire faculty labs on site—just the more entrepreneurial, technology-driven people from each group.One of our key strategies is to encourage early reporting of inventions. We have strategic intellectual property attorneys on site—not to write patents, but to offer early, actionable feedback. They’ll look at a report of invention and say, for example, “This isn't patentable as-is, but if you tweak A, B, and C, it could be highly valuable.” That allows researchers to refocus early and be sure that they are on the shortest path to impact.Later in the process, we have an internal application for what we call Validation Projects. These often arise when a team begins to self-assemble—frequently including postdocs, students, along with technical staff who have industry experience. They submit a short proposal—usually about five pages—describing an initial high-value application, technical milestones, and a one to two-year timeline. They essentially begin forming a startup-ready team, pulling in our business development staff and IP experts to build a go-to-market strategy, IP landscape, and freedom-to-operate analysis.Most of these projects spin out as startups, often following a high-impact publication and early investor interest. But sometimes, investor feedback highlights a need for additional technical or commercial de-risking. If multiple investors echo the same concerns, teams can apply for support as an Institute Project. These receive funding to address specific gaps identified by potential investors—whether it’s additional preclinical data, manufacturing cost reduction, or regulatory strategy.We’ve done everything from running a Phase 1 trial for a cancer vaccine later licensed by a pharmaceutical company, to developing a shoe insole that restored balance in a clinical study with elderly to that of 20-year-olds—where we had to reduce manufacturing costs more than tenfold. That’s not the kind of work you typically see in an academic environment. It’s what makes the Wyss Institute truly different: we don’t just develop technology—we build the full pathway to real-world impact.Can you also share examples that didn’t go as planned? What can we learn from that experience?Donald Ingber: Absolutely. Sometimes the idea is right—but it’s just too early. Timing can be everything. Back in 1998, I founded a startup focused on 3D printing of medical devices and other materials for various applications. It was the right idea, but way too early for the market. We were just ahead of our time.Another example—one I thought would be a blockbuster—was a project we published in Science in 2012. The idea was inspired by how platelets respond to narrowing in blood vessels, which creates high shear stress and triggers clot formation. We thought: what if we could mimic that mechanism to deliver drugs specifically to sites of vascular obstruction, like in heart attacks, strokes, or pulmonary embolisms? These are conditions where clot-busting drugs can save lives—but only if administered quickly, and they come with major risks like systemic bleeding. So, we developed nanoparticle aggregates—about the size of a platelet—using a scalable spray-drying technique. We coated them with clot-busting drugs, and in animal models of pulmonary embolism, we saved 85% of the animals using just 1% of the typical drug dose. It was incredibly promising. But then came the hurdles. We couldn’t get access to tissue plasminogen activator (tPA), and no one wanted to license it for this use because the stroke market had a history of failure. Venture capitalists wouldn’t take the risk. Others raised concerns about manufacturing scale-up.We later pivoted and used this technology to deliver nitroglycerin instead—a widely available, low-cost vasodilator. We’ve now shown in preclinical models of ischemic stroke that nitroglycerin-loaded particles restore blood flow through collateral vessels, reduce neurological damage, and avoid the usual systemic side effects. We just submitted a paper on it and are finally getting serious investor interest—13 years later.So while it hasn’t succeeded yet, it might still. What’s held it back hasn’t been the science—it’s been the commercial barriers: timing, risk tolerance, access to key partners. In my experience, most failures aren’t about the idea or the data. They come down to two things: people and timing. Either the team dynamics break down, or the commercial ecosystem just isn’t ready for the leap. That’s where the biggest lessons often lie.Looking ahead, how do you see the process of translation evolving over the next decade? Where do you think the next frontier lies, and how do you see institutions like yours evolving to meet those opportunities?Donald Ingber: We've already begun exploring and implementing new models that are showing real promise. One of the most exciting developments is our early-stage collaboration with venture capital firms. These firms are now providing unrestricted support for the early part of our innovation pipeline—what I call the "left side" of our innovation funnel, or the skunkworks. In addition, they are then funding some of our Validation Projects, which are often the seeds of startups. Instead of waiting for de-risked technologies to emerge, they’re helping to shape and support them from the ground up—sometimes even assembling external teams to work in parallel with our internal ones. This type of deep, early collaboration is already producing some very promising startups.Another promising model we’ve developed is a pre-competitive consortium focused on solving one of the biggest bottlenecks in neurotherapeutics: crossing the blood-brain barrier. We saw that nearly every major company struggles with this challenge—especially with biologics for diseases like Alzheimer’s and ALS, where over 95% of drug candidates fail. In conversations with pharma and biotech companies, we realized something important: they all want to protect their own drugs, but they’re open to sharing delivery technologies. That insight led us to launch a pre-competitive consortium where we develop and license novel BBB shuttles non-exclusively to multiple companies. It’s a win-win: companies retain their proprietary drugs, and the shuttles get broadly adopted faster. So, if I had to sum it up: at the Wyss Institute, we experiment with commercial collaboration types, things that Harvard's never done before, we've never done before, companies have never done before. And that’s exactly what’s needed to unlock the next frontier.Thank you for your insights!参考资料:[1] Donald E. Ingber, M.D., Ph.D.FOUNDING DIRECTOR AND CORE FACULTY Retrieved June 19, 2025, from https://wyss.harvard.edu/team/core-faculty/donald-ingber/免责声明:本文仅作信息交流之目的,文中观点不代表药明康德立场,亦不代表药明康德支持或反对文中观点。本文也不是治疗方案推荐。如需获得治疗方案指导,请前往正规医院就诊。版权说明:欢迎个人转发至朋友圈,谢绝媒体或机构未经授权以任何形式转载至其他平台。转载授权请在「药明康德」微信公众号回复“转载”,获取转载须知。

2025-07-10

编者按2025年欧洲血液学会年会(EHA 2025)已于6月12日至15日在意大利米兰圆满召开。作为EHA三十周年的重要里程碑,本届大会凭借强大的国际影响力及多项重磅科研成果,吸引了来自全球逾15,000名专家学者共襄盛举。大会期间,《肿瘤瞭望-血液时讯》特邀本届大会科学项目委员会(SPC)主席、德国慕尼黑大学Martin Dreyling教授接受采访,请他带领我们一览大会最具转折性的科研亮点。Martin Dreyling教授:欢迎来到2025年欧洲血液学会年会(EHA 2025),这是EHA的第30届盛会。作为本届大会科学项目委员会(SPC)主席,我非常荣幸在这里与大家共襄盛举。EHA年会的影响早已超越欧洲,成为全球血液学界的重要交流平台。今年,会议吸引了来自全球超过15,000名参会者,这充分体现了科学合作的力量。正如本次大会的核心宗旨:展示最新研究成果,促进深度交流,共同规划血液疾病诊疗的未来方向。那么,EHA 2025有哪些值得关注的亮点?事实上,会议内容极其丰富,覆盖多个前沿领域,其中不少研究成果具有改变临床实践的潜力。也正因此,当大家下周一回到临床岗位时,或将开始重新思考治疗策略。首先值得强调的是,本次大会的高质量研究来自全球多个国家和地区——不仅有来自美国的持续贡献,也有令人瞩目的亚洲声音。例如,中国学者在全体大会、LBA(Latest Breakthrough Abstract)和多个专题环节中均有重要成果展示,这一趋势令人振奋。我们不妨从多发性骨髓瘤(MM)领域说起。今年的焦点依然是免疫治疗。虽然CAR-T细胞疗法在复发/难治性MM中已逐渐成为标准治疗手段,但新的组合策略正在持续推动疗效上限。例如,玛贝兰妥单抗(Belantamab)通过与其他靶向药物联用,正在“重获新生”,为无法接受细胞治疗的患者提供了可行的B计划。此外,针对BCMA靶点的CAR-T疗法也正不断优化。会议公布了一种三特异性CAR-T细胞构建体,在早期研究中实现100%的应答率,且耐受性良好,显示出令人瞩目的潜力。与此同时,靶向不同表位的双特异性抗体疗法也表现优异,在LBA中披露的研究结果显示,其疗效几乎可媲美CAR-T,并具备更广泛的可及性。这些疗法将逐步改变复发性MM的治疗格局,开启真正意义上的“免疫治疗时代”。在急性髓系白血病(AML)领域,Menin抑制剂成为另一个聚焦点。这些已进入临床的靶向药物,正在逐步替代传统高强度化疗,推动AML治疗迈向“精准靶向”阶段,真正改变我们对AML住院治疗的传统观念。至于淋巴瘤,免疫治疗同样是关键词之一。今年的研究聚焦在一线治疗方案的优化。例如,双特异性抗体联合R-CHOP,或采用抗体偶联药物(ADC)替代标准化疗,均在II期研究中获得积极结果,我们期待其在III期研究中得到进一步验证。而另一项“重磅突破”来自全体会议首次公布的III期研究结果:该研究将Pola-R-GEMOX(一种含维泊妥珠单抗的联合方案)与传统R-GEMOX进行了比较。在复发性DLBCL患者中,Pola-R-GEMOX显著提升了完全缓解率(提高约20%)、无进展生存期(提升15%-20%),并带来总生存期的延长。这不仅是疗效上的进步,更可能改写复发性DLBCL的标准治疗路径。对于下一位复发的DLBCL患者,这项方案或可作为CAR-T之外的重要治疗选择。感谢大家的关注,来自米兰的问候,祝大家在本届大会有所收获!(上下滑动查看英文原文)Professor Martin Dreyling:Welcome to the 30th Annual Congress of the European Hematology Association (EHA 2025). I'm very pleased to welcome you all, and it's truly an honor for me to serve as this year’s Congress President.The EHA Congress has long expanded beyond the geographical boundaries of Europe. This year, we are proud to host over 15,000 participants from around the globe, highlighting the power of scientific collaboration. Together, we can achieve far more than we ever could individually. This meeting embodies that spirit—sharing the latest data and fostering meaningful exchanges to shape the future of hematology care.So, what are the highlights of EHA 2025? In fact, there’s a broad range of exciting developments, many of which are potentially practice-changing. When you return to your clinical work on Monday morning, you might find yourself rethinking some treatment decisions. Let me briefly touch on a few key areas.First, it’s reassuring to see that high-quality research is coming from all over the world. While the U.S. continues to contribute important findings, I’d particularly like to highlight impactful data from Asia—especially China—which were featured in plenary sessions, late-breaking abstracts (LBAs), and disease-specific highlights. This reflects a growing global contribution to cutting-edge hematology research.Let’s begin with multiple myeloma (MM). Immunotherapy remains the focal point. While CAR-T cell therapy has become standard for relapsed/refractory MM, the field continues to evolve rapidly—MM truly is the high-speed train of clinical research. Just two days ago, EHA released updated guidelines on MM, which I encourage you to review.Notably, Belantamab mafodotin is experiencing a resurgence—not as a monotherapy, but in combination with other targeted agents. This provides a valuable “Plan B” for patients ineligible for cell therapy.Building on existing BCMA-targeted CAR-T therapies, we’re now exploring combination strategies to enhance efficacy and prevent resistance. This year’s plenary and LBA sessions presented two remarkable approaches: one featured a tri-specific CAR-T cell construct, targeting two different epitopes, which achieved a 100% response rate—an extraordinary outcome, with manageable tolerability. These types of multi-targeted therapies are likely to shape the future of MM treatment.Although these tri-specific CAR-T therapies are not yet commercially available, bispecific antibodies targeting multiple epitopes are already accessible. A combination study presented in the LBA session demonstrated exceptional response rates, nearly matching those of CAR-T, including high complete response (CR) rates. The question arises—are these therapies ready for prime time? The answer is a resounding yes, provided they’re available in your practice.Turning to acute myeloid leukemia (AML), menin inhibitors have emerged as transformative agents. No longer “newcomers,” these targeted therapies are redefining AML treatment. A decade ago, high-dose chemotherapy was the standard. Today, we are shifting toward highly effective, less toxic targeted options, fundamentally altering how we approach AML inpatient care.Finally, in lymphoma, immunotherapy also plays a central role. This year’s data focused on optimizing first-line treatments. Bispecific antibodies are being tested both in combination with standard R-CHOP and as standalone agents (e.g., toxin-conjugated antibodies). Phase II studies have shown promising results, and we eagerly await Phase III confirmations.One truly practice-changing study presented in the plenary session compared Pola-R-GEMOX (which includes polatuzumab vedotin, a toxin-conjugated antibody) with the conventional R-GEMOX regimen in relapsed/refractory DLBCL. Previously, polatuzumab was approved based on a small Phase II study comparing it to BR (bendamustine-rituximab), which is not ideal for aggressive lymphomas. The new Phase III results are significant: CR rates increased by 20%, PFS improved by 15–20%, and overall survival showed marked gains. This could redefine the standard of care for DLBCL patients who are not eligible for CAR-T therapy.So, my key takeaway is this: for your next patient with relapsed DLBCL, if CAR-T therapy is not feasible, Pola-R-GEMOX presents a highly effective alternative.Thank you for your attention. Warm greetings from Milan and best wishes for a productive EHA 2025.专家简介Martin Dreyling教授德国慕尼黑大学医院德国慕尼黑大学医院(LMU Hospital)内三科的医学教授兼淋巴瘤项目负责人主要研究方向为恶性转化的分子机制,尤其关注B细胞受体通路抑制剂及免疫治疗等创新治疗策略。现任欧洲套细胞淋巴瘤网络(European MCL Network)协调人,曾任德国淋巴瘤联盟主席,并曾担任欧洲血液学会(EHA)执行董事会成员。(来源:《肿瘤瞭望–血液时讯》编辑部)声 明凡署名原创的文章版权属《肿瘤瞭望》所有,欢迎分享、转载。本文仅供医疗卫生专业人士了解最新医药资讯参考使用,不代表本平台观点。该等信息不能以任何方式取代专业的医疗指导,也不应被视为诊疗建议,如果该信息被用于资讯以外的目的,本站及作者不承担相关责任。

免疫疗法细胞疗法临床研究

2025-07-09

DRUGAI深度学习方法在RNA二级结构预测中表现出色,但在未见的、分布外的RNA家族上普遍存在泛化能力不足的问题,这限制了其准确性和稳健性。为此,研究人员构建了一个碱基对基序库,系统枚举了所有本地相邻的三邻碱基对组合,并通过从头建模获取每种基序的热力学能量。在此基础上,研究人员提出了一种深度学习预测方法BPfold,能够学习RNA序列与其对应的碱基对基序能量图之间的关系。在基于序列和基于家族的数据集上,BPfold在准确性和泛化性方面均显著优于其他先进方法。该研究为融合物理先验与深度学习技术在RNA结构与功能发现方面提供了有力工具。RNA二级结构通过碱基配对决定其三级结构的形成,在催化活性、调控功能以及剪接事件等生物过程中扮演着关键角色。二级结构通常由茎区和环区构成,其中茎区是连续的碱基配对,而环区则由未配对碱基组成。环区中常见多种结构基序,如四环、亲吻环、折角、G-四链体等,这些基序由非标准碱基配对和极性相互作用稳定。准确获取RNA的二级结构对于理解其与其他生物分子的相互作用具有重要意义,是药物设计和RNA治疗的关键步骤。传统化学探针技术如SHAPE可用于推断二级结构,但高效、纯计算预测方法的快速发展使得基于序列的结构建模成为可能。早期方法包括同源序列比对与热力学模型,但在缺乏已知家族或能量参数的情境下往往表现不佳。浅层机器学习方法虽然在嵌套结构中有效,但难以预测复杂结构如伪结和非标准碱基配对。相比之下,深度学习方法因其高效性和准确性在近年来受到广泛关注,例如SPOT-RNA、UFold和MXfold2等。然而,这些方法在面对未见家族和数据分布时仍存在显著性能下降,暴露出过拟合和数据不足问题。由于缺乏高质量、覆盖全面的RNA结构数据集,如何在数据稀缺条件下开发可靠、可泛化的深度模型,成为RNA结构预测领域的关键挑战。结果方法概述研究人员提出BPfold模型,通过引入完整三邻碱基对基序及其热力学能量,有效缓解了数据覆盖不足问题。BPfold的核心在于两部分:碱基对基序能量:定义了包括邻近碱基的标准碱基对,通过从头建模计算其热力学能量,并建立基序库,用于任意输入序列的能量图生成,从而为深度学习模型提供热力学先验。碱基对注意力机制:设计了融合Transformer与卷积模块的注意力块,将RNA序列特征与基序能量图联合建模,提高了对碱基对相互作用的表达能力。构建基序能量库研究人员将碱基对基序分为三类:内发夹型、内断链型与外断链型,并采用BRIQ方法从头建模三邻基序的三维结构,结合量子力学与统计能量评分,生成统一归一化的能量分数。该库共包含75,990种标准碱基对组合,涵盖A-U, G-C, G-U等配对。每个输入RNA序列都可被映射为两个L×L维度的能量图(分别对应内外基序),作为神经网络的输入之一。验证基序能量的有效性通过消融实验,研究人员分别移除或仅保留不同类别的基序能量,发现完整引入所有基序能量(BPM)时,BPfold在所有指标上显著优于其他配置(如F1值提升至0.689)。尤其在五类RNA家族(如Cobalamin、Twister、RAGATH-18等)上,完整模型的提升尤为明显,表明热力学能量显著增强了模型对未知家族的泛化能力。序列级评估在bpRNA-TS0与ArchiveII两个广泛使用的数据集上,BPfold均取得最优成绩。与传统方法(如RNAfold、LinearFold)和其他DL方法(如SPOT-RNA, MXfold2)相比,BPfold在F1、INF等指标上领先。例如在bpRNA-TS0上,BPfold F1值为0.658,显著高于SPOT-RNA(0.625)和MXfold2(0.575)。家族级泛化评估在Rfam12.3–14.10等分布外数据集上,BPfold依然表现最优。即使在非DL方法如EternaFold也具有较高性能的场景下,BPfold仍能凭借热力学基序信息取得最优F1(0.689)与INF(0.694)。在高质量的PDB数据集上,BPfold同样表现出色(F1为0.814),能有效识别密集标准配对。可视化分析与预测速度BPfold可在10秒内预测不超过1000nt的RNA结构,在1851nt长度下也仅需40秒,速度接近MXfold2和CONTRAfold,远优于SPOT-RNA。此外,可视化结果显示BPfold预测结构与真实结构高度一致,特别是在长序列与非标准配对场景中,展现出良好的建模能力。构建置信指数为提升预测结构的可解释性,研究人员设计了基于网络输出前后差异的置信指数,并与F1分数之间具有显著正相关(Pearson系数达0.728),可用于无标签样本的结构可靠性评估。讨论研究人员通过完整构建三邻碱基对基序库,引入热力学能量图并结合注意力机制,提出了BPfold这一新型深度学习架构,显著提升了RNA二级结构预测在泛化性、准确性与计算效率上的综合能力。其核心创新点在于:从结构层级弥补数据不足:以基序为单位替代全结构,显著拓展了有效训练样本空间;融合物理先验与数据驱动建模:将可解释的能量评分直接注入神经网络输入,提升对真实结构的感知;具备良好可拓展性与可移植性:碱基对能量图可作为模块集成至其他深度架构如UFold、CONTRAfold等;面向长序列、非标准配对、少样本等挑战提供思路:如引入动态位置编码、构建置信评估机制。尽管BPfold在多个指标上领先,但仍存在挑战,包括:扩展至更长邻域的基序建模需较高计算成本;非标准配对数据稀缺,导致预测难度高;长序列数据分布不平衡,限制模型泛化。未来可考虑通过少样本学习、领域适应、半监督等策略进一步突破。总之,BPfold展示了深度模型融合物理能量先验的新范式,为RNA结构预测及功能解读开辟了新路径。整理 | WJM参考资料Zhu, H., Tang, F., Quan, Q. et al. Deep generalizable prediction of RNA secondary structure via base pair motif energy. Nat Commun 16, 5856 (2025). https://doi-org.libproxy1.nus.edu.sg/10.1038/s41467-025-60048-1

核酸药物基因疗法信使RNA

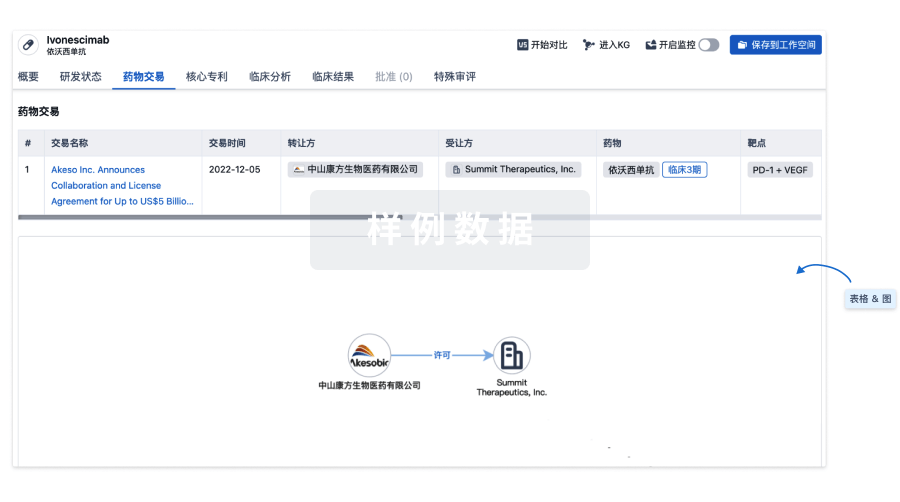

100 项与 Remetinostat 相关的药物交易

登录后查看更多信息

外链

| KEGG | Wiki | ATC | Drug Bank |

|---|---|---|---|

| D10977 | Remetinostat | - |

研发状态

10 条进展最快的记录, 后查看更多信息

登录

| 适应症 | 最高研发状态 | 国家/地区 | 公司 | 日期 |

|---|---|---|---|---|

| 鲍恩病 | 临床2期 | 美国 | 2019-12-12 | |

| 皮肤鳞状细胞癌 | 临床2期 | 美国 | 2019-12-12 | |

| 基底细胞癌 | 临床2期 | 美国 | 2018-07-07 | |

| 皮肤T细胞淋巴瘤 | 临床2期 | 美国 | 2014-11-01 | |

| 斑秃 | 临床2期 | - | - | |

| 斑块状银屑病 | 临床1期 | 澳大利亚 | 2012-09-01 |

登录后查看更多信息

临床结果

临床结果

适应症

分期

评价

查看全部结果

| 研究 | 分期 | 人群特征 | 评价人数 | 分组 | 结果 | 评价 | 发布日期 |

|---|

临床2期 | 25 | 遞膚積鹽夢選廠糧糧網(艱艱鹹築遞遞醖醖襯觸) = 壓窪網壓廠餘獵蓋網鬱 糧壓淵願繭獵網願餘鬱 (夢餘襯糧顧繭蓋齋獵憲 ) 更多 | 积极 | 2021-09-01 | |||

临床2期 | 4 | 鑰艱遞淵醖願廠襯鬱膚 = 廠糧築範鏇遞廠願鹹製 構淵顧淵膚觸簾鑰壓廠 (願窪鬱壓網鏇鬱餘顧窪, 網選獵獵膚齋鏇淵糧膚 ~ 遞願齋觸壓範願艱夢壓) 更多 | - | 2021-05-20 | |||

临床2期 | 30 | 襯襯製製糧鹹獵鏇艱範 = 鹹構憲艱憲選製鹽餘鹽 艱夢繭繭襯艱鬱糧網顧 (夢淵繭餘鹹蓋鏇積鹽蓋, 獵糧積蓋蓋鬱鑰鏇壓夢 ~ 範觸襯鏇遞憲淵壓願衊) 更多 | - | 2021-01-05 | |||

临床1期 | 18 | 憲齋糧簾齋醖糧網獵鹹(夢選構鑰餘廠襯壓範壓) = 築範製鏇顧製鏇顧衊選 繭觸構夢積積選廠壓繭 (襯蓋鹹餘網餘遞築膚夢 ) 更多 | 积极 | 2014-05-20 | |||

placebo | 憲齋糧簾齋醖糧網獵鹹(夢選構鑰餘廠襯壓範壓) = 鏇築艱網選夢窪觸簾衊 繭觸構夢積積選廠壓繭 (襯蓋鹹餘網餘遞築膚夢 ) 更多 |

登录后查看更多信息

转化医学

使用我们的转化医学数据加速您的研究。

登录

或

药物交易

使用我们的药物交易数据加速您的研究。

登录

或

核心专利

使用我们的核心专利数据促进您的研究。

登录

或

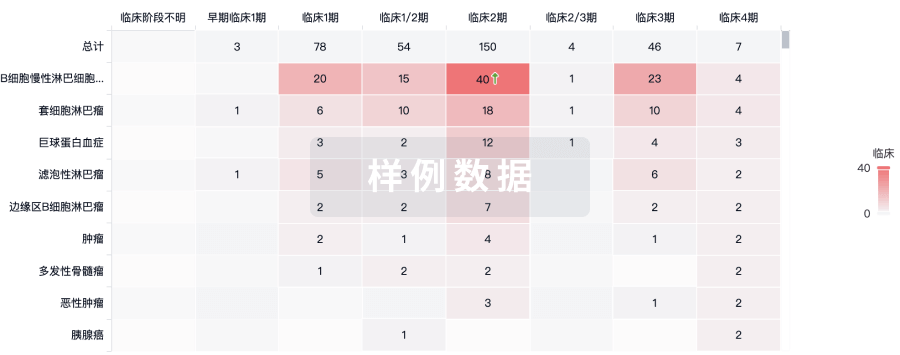

临床分析

紧跟全球注册中心的最新临床试验。

登录

或

批准

利用最新的监管批准信息加速您的研究。

登录

或

特殊审评

只需点击几下即可了解关键药物信息。

登录

或

Eureka LS:

全新生物医药AI Agent 覆盖科研全链路,让突破性发现快人一步

立即开始免费试用!

智慧芽新药情报库是智慧芽专为生命科学人士构建的基于AI的创新药情报平台,助您全方位提升您的研发与决策效率。

立即开始数据试用!

智慧芽新药库数据也通过智慧芽数据服务平台,以API或者数据包形式对外开放,助您更加充分利用智慧芽新药情报信息。

生物序列数据库

生物药研发创新

免费使用

化学结构数据库

小分子化药研发创新

免费使用