预约演示

更新于:2025-05-07

IFW Dresden eV

更新于:2025-05-07

概览

关联

100 项与 IFW Dresden eV 相关的临床结果

登录后查看更多信息

0 项与 IFW Dresden eV 相关的专利(医药)

登录后查看更多信息

2,082

项与 IFW Dresden eV 相关的文献(医药)2025-07-01·Corrosion Science

Pitting corrosion mechanisms of Ti-Cu-(Pd-) based metallic glasses in simulated physiological solution

作者: Shtefan, Viktoriia ; Kaban, Ivan ; Navas, Nora Fernandez ; Hantusch, Martin ; Gebert, Annett

2025-06-01·Electrochimica Acta

Downscaling magnetic field gradients for structured copper magnetoelectrodeposition on the micrometer scale

作者: Gebert, A. ; Neu, V. ; Sgarbi Stabellini, F. ; Mutschke, G. ; Soldatov, I. ; Leistner, K. ; Huang, M. ; Schaefer, R. ; Singh, A.

2025-05-01·Journal of Materials Research and Technology

Effect of aging treatments on mechanical, chemical, and antibacterial properties of a β-type Ti–Nb–Cu alloy for implant applications

作者: Gebert, Annett ; Vishnu, Jithin ; Hariharan, Avinash ; Calin, Mariana ; Alberta, Ludovico Andrea ; Palmquist, Anders ; Giraldo-Osorno, Paula Milena ; Voss, Andrea ; Trobos, Margarita ; Pilz, Stefan

2

项与 IFW Dresden eV 相关的新闻(医药)2023-09-18

Structural design of the newly developed carbon fiber chassis for the Krone Big X forage harvester. Photo Credit: IFW

In order to reduce CO2 emissions in the commercial vehicle and agricultural sector, the use of material concepts such as composites are being sought to reduce the weight of the machines, most of which weigh several tons. The Institute for Manufacturing Technology and Machine Tools (IFW) at Leibniz Universität Hannover (Germany), together with its German project partners Krone GmbH & Co. KG, M&D Composites Technology GmbH and the Institute for Polymer Materials and Plastics Technology (PuK) of the Clausthal University of Technology, has developed a carbon fiber chassis for the Krone Big X in the AgriLight research project.

Particular challenges arose from the different material properties of fiber-reinforced composites and metallic materials, the associated complexity in the design of thick-walled composite structures and the integration of the new, composite-compatible design into the existing vehicle structure.

However, the new design possibilities brought on by the carbon fiber-reinforced polymer (CFRP) monocoque construction were used to create additional benefits for the customer. Among them were larger, integrated tanks and simplified cleaning of the machine thanks to closed surfaces. For the chassis’ design, IFW and PuK jointly investigated a number of different resin systems for the out-of-autoclave vacuum infusion process. Ansys (Zurich, Switzerland and Canonsburg, Pa., U.S.) Composite PrePost was used to perform the finite element simulation. Shell models of the entire CFRP structure were created as well as detailed analyses using solid models. Based on a load spectrum newly developed by Krone, design adjustments as well as optimizations in the laminate structure were made.

In addition to the design and dimensioning of the frame structure, the IFW has also researched new approaches for the composite-compatible introduction of high loads into the frame structure of commercial vehicles. With the aid of a hybrid insert concept, significantly higher loads can be introduced into the composite structures — together with classic fasteners such as screws and bolts — removing the need for prestressing forces to be borne by the laminate. The resulting CFRP chassis reduced the machine’s weight by 50% compared to the original steel frame while simultaneously increasing torsional stiffness.

Next steps in the project include the production of a chassis prototype at M&D Composites Technology. Tooling is being developed, followed by production of the monocoque’s individual shell components. The completed prototype will be subjected to dynamic structural testing at Krone’s facility, where the developed load spectrum is run on the X-Poster, validating design results and the underlying finite element models. The main objective of this test is to ensure that the carbon fiber-based chassis and the hybrid inserts used in highly stressed areas do not suffer any damage over the entire lifetime of a vehicle. To record the loads and deformations of the chassis, IFW is also implementing a measurement concept that includes Rayleigh and strain gauge sensors as well as optical 3D measurements.

The project is funded by the German Federal Ministry of Economics and Climate Protection (BMWK) as part of the Technology Transfer Program Lightweight Construction (TTP LB).

2023-08-09

Photo Credit: IFW at Leibniz University

As part of the PräziLight project, the Institute of Production Engineering and Machine Tools (IFW) at Leibniz University (Hanover, Germany) is expanding its laser automated fiber placement (AFP) capabilities with the installation of AddComposites’ (Espoo, Finland) AFP system equipped with a Heraeus Noblelight (Gaithersburg, M.D., U.S.) humm3 Xenon flashlamp at the organization’s Stade and Garbsen facility.

IFW’s strategic expansion will enable the provision of practical R&D services to businesses, particularly in structural lightweight design and the production of complex components for aerospace, hydrogen and other industries using innovative material concepts such as thermoset and thermoplastic fiber-reinforced polymer (FRP) composite materials.

The IFW, particularly the Stade location, has dedicated extensive research efforts to explore AFP technologies over the past years. Its newly installed AFP system encompasses two innovative systems. One, at the Stade location, been augmented with an 8.5 × 6 × 4.5-meter laser protection cabin, complementing the existing experimental setup. This cabin houses a specially developed four-tow AFP system using a VCSEL diode laser from Trumpf (Ditzingen, Germany), operated on an industrial robot. This system can process a wide range of fiber-reinforced semi-finished products, from thermosets to high-performance thermoplastics (e.g., PEEK).

In addition, a second AFP system has been commissioned at the Garbsen location. Installed in the scale research building, this system features a horizontal positioner for producing rotationally symmetric components such as tanks, as well as a rotating-tilting table for fiber deposition on complex shapes. This system can realize components with a length of 2.6 meters and a diameter of 2 meters. Unlike the AFP system at the Stade location, the AddComposites AFP system in Garbsen is equipped with a Xenon flashlamp, eliminating the need for complex laser safety measures. The capability to process thermoset and thermoplastic semi-finished products remains.

In addition to the physical equipment, digital replicas of both systems are available, enabling simulation studies and offline programming before production begins.

The PräziLight project is funded by the State of Lower Saxony and the European Regional Development Fund (EFRE).

100 项与 IFW Dresden eV 相关的药物交易

登录后查看更多信息

100 项与 IFW Dresden eV 相关的转化医学

登录后查看更多信息

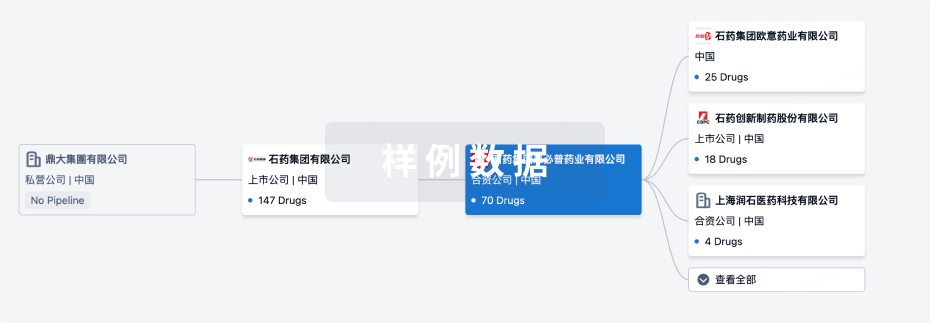

组织架构

使用我们的机构树数据加速您的研究。

登录

或

管线布局

2025年07月07日管线快照

无数据报导

登录后保持更新

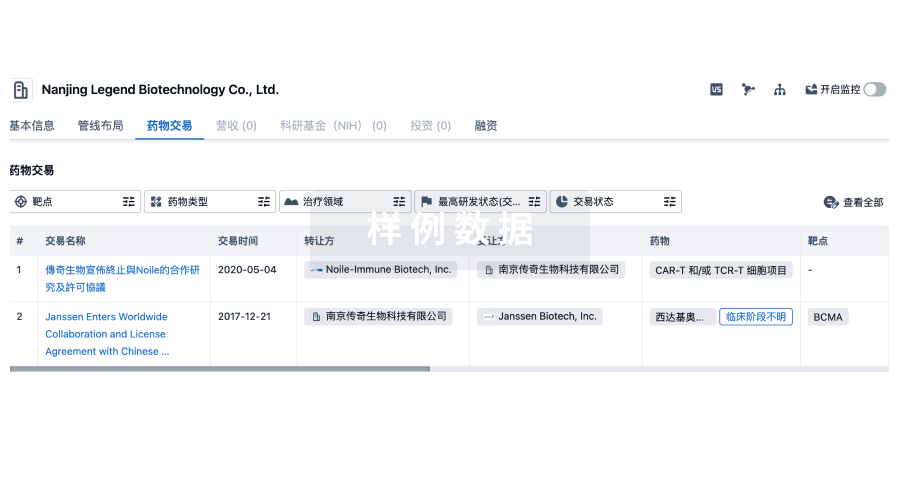

药物交易

使用我们的药物交易数据加速您的研究。

登录

或

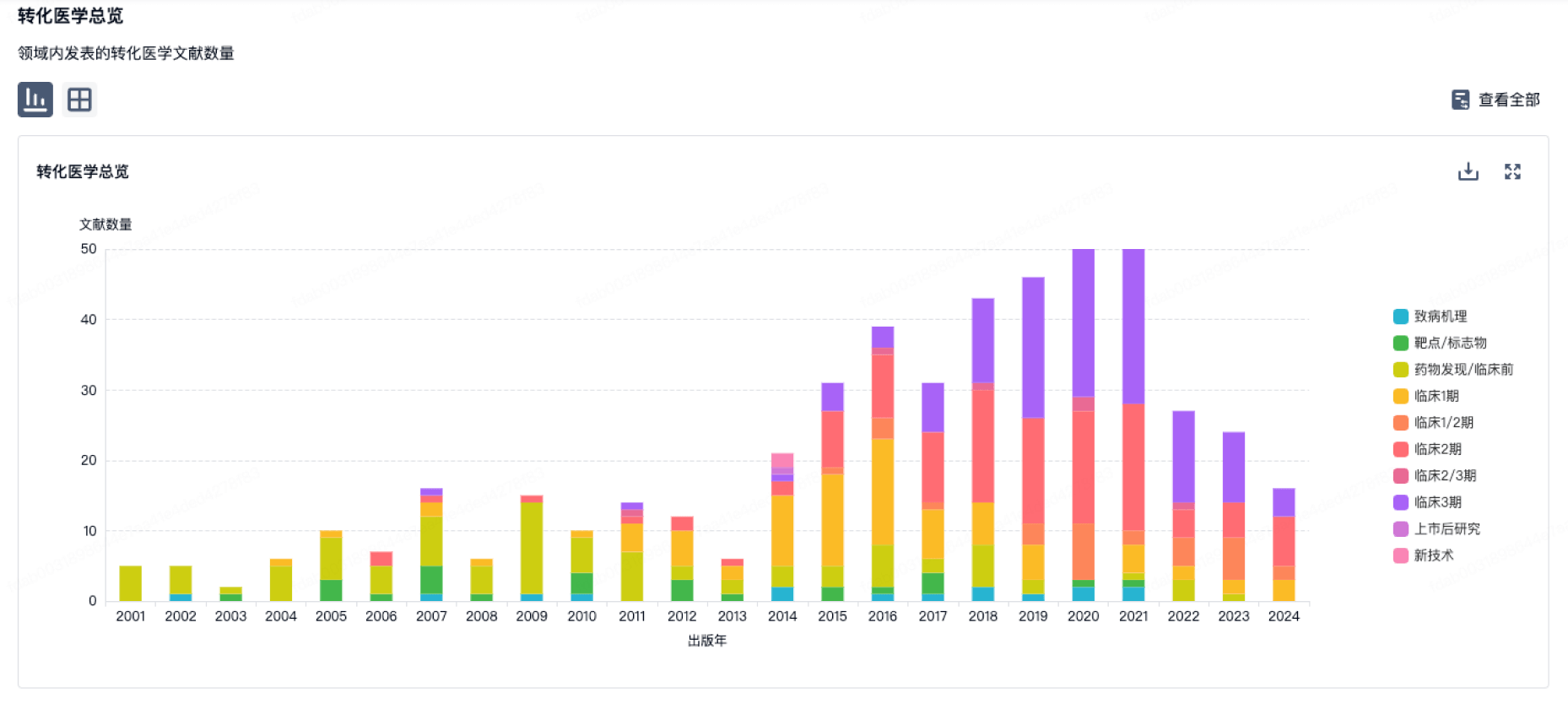

转化医学

使用我们的转化医学数据加速您的研究。

登录

或

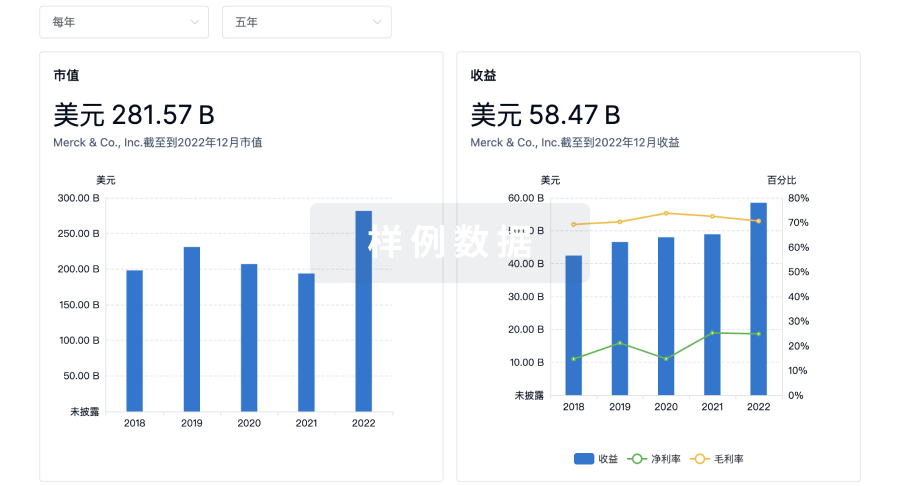

营收

使用 Synapse 探索超过 36 万个组织的财务状况。

登录

或

科研基金(NIH)

访问超过 200 万项资助和基金信息,以提升您的研究之旅。

登录

或

投资

深入了解从初创企业到成熟企业的最新公司投资动态。

登录

或

融资

发掘融资趋势以验证和推进您的投资机会。

登录

或

Eureka LS:

全新生物医药AI Agent 覆盖科研全链路,让突破性发现快人一步

立即开始免费试用!

智慧芽新药情报库是智慧芽专为生命科学人士构建的基于AI的创新药情报平台,助您全方位提升您的研发与决策效率。

立即开始数据试用!

智慧芽新药库数据也通过智慧芽数据服务平台,以API或者数据包形式对外开放,助您更加充分利用智慧芽新药情报信息。

生物序列数据库

生物药研发创新

免费使用

化学结构数据库

小分子化药研发创新

免费使用