预约演示

更新于:2025-09-09

Lappeenrannan-Lahden teknillinen yliopisto LUT

更新于:2025-09-09

概览

关联

100 项与 Lappeenrannan-Lahden teknillinen yliopisto LUT 相关的临床结果

登录后查看更多信息

0 项与 Lappeenrannan-Lahden teknillinen yliopisto LUT 相关的专利(医药)

登录后查看更多信息

3,113

项与 Lappeenrannan-Lahden teknillinen yliopisto LUT 相关的文献(医药)2025-12-01·COLLOIDS AND SURFACES B-BIOINTERFACES

Kraft lignin/polyurethane composites with enhanced mechanical strength, bioactive functionality, and superior wet wood adhesion

Article

作者: Layek, Rama ; Maiti, Pralay ; Parihar, Vijay Singh ; Uddin, Md Elias ; Kellomäki, Minna ; Arif, Maham ; Ahmed, Aleezay Anjum ; Choudhury, Avishek Mallick

Conventional additives used in composite resins, widely employed in various industrial and domestic applications particularly in polymer composite films and wood adhesives, pose significant environmental and health concerns due to their petrochemical origins. To address this challenge, we developed a novel polyurethane (LPU) composite resin integrated with kraft lignin (KL) as a bio-based additive, exhibiting excellent multifunctional properties. The synthesis involved reacting poly(ε-caprolactone) diol and citric acid with 2,4-toluene diisocyanate, followed by the incorporation of KL and castor oil (CO) as reactive bio-additives to enhance the functionality of the LPU. CO not only improved the bio-content of the LPU but also facilitated the processability of KL during synthesis. The LPU was characterized using FTIR, WAXS, X-FESEM, and SS-CP-MAS 13C NMR techniques. The LPU5 film exhibited a significantly higher tensile strength (8.1 ± 1.0 MPa) compared to the pure PU film (3.6 ± 1.5 MPa). The LPU15 wood adhesive demonstrated improved bio-content along with excellent shear strength and evident wood failure in wet environment, relative to pure PU. Furthermore, LPU composite resin mitigated the oxidative stress and also suppressed the proliferation of Escherichia coli (a Gram-negative bacterium), and Staphylococcus aureus (a Gram-positive bacterium) compared to pure PU. This study introduces a novel strategy for preparing LPU composite resin through the integration of bio-based additives, achieving enhanced bio-content, superior mechanical strength, wet wood-bonding ability, and improved bioactive properties such as antibacterial and antioxidant activity, thereby presenting a sustainable and reliable alternative to petrochemical-based constituents.

2025-09-02·WASTE MANAGEMENT

Systematic assessment of landfill mining potential in Zhejiang Province, China: Resource recovery and economic potential.

Article

作者: Lou, Fangfang ; Xiang, Xianchao ; Sima, Jingyuan ; Zhang, Hao ; Li, Xiaodong ; Feng, Shi ; Zhen, Zongao ; Huang, Qunxing ; Horttanainen, Mika

Landfilling has been the predominant municipal solid waste disposal method in recent decades. Recently, landfill mining has gained attention due to increasing raw material costs and environmental concerns. However, most research has focused on individual or limited specific cases, with insufficient studies on landfill mining potential at the regional or national level. This study established a regional-scale evaluation of the economic viability and environmental benefits of landfill mining in Zhejiang Province, China. Six representative landfills were selected based on an investigation of the status of landfills in the province. Using a waste age map, 316 waste samples weighing 816.56 kg were meticulously collected from 27 sampling points across the six landfills, covering waste generated from 1994 to 2020. The correlation analysis explored the relationship between landfill waste composition and landfill conditions/socio-economic factors, providing a basis for the preliminary assessment of waste composition based on landfill conditions and the socio-economic characteristics of the landfill service area. Additionally, the study evaluates the economic and environmental potential of landfill mining. The economic assessment highlighted the potential of landfill mining for societal actors, with potential NPV ranging from 26.2 to 47.8 USD/ton. Notable environmental benefits also be observed, with potential greenhouse gas emission reductions of 0.09-0.51 kg CO2-eq/ton and leachate reductions of 0.34-2.13 m3/ton. This study offers valuable insights into the resource recovery as well as the economic and environmental potential of landfill mining in Zhejiang Province, and serves as a useful reference for broader regional or national-scale assessments.

2025-09-01·MINERALS ENGINEERING

3D-printed polyamide-H2TiO3 composite for selective lithium adsorption: Insights from experimental and theoretical dynamic simulations studies

作者: Iurchenkova, Anna ; Bandina, Ekaterina ; Repo, Eveliina ; Elkabous, Mohammed ; Ouardi, Youssef El

Global decarbonization has increased the demand for lithium-ion batteries (LIBs), leading to a high demand for lithium a critical raw material in the EU.Efficient lithium recovery, especially from water sources, is essential due to the growing demand need for LIB recycling.Adsorption technol. is effective for this purpose, but traditional powder adsorbents present operational challenges.To overcome this, 3D printing allows for the preparation of solid monolith adsorbents with improved mech. stability and reusability.In this work, a polyamide-lithium titanium oxide composite (PA2200-Li2TiO3) was 3D-printed using selective laser sintering technol.The composite was characterized using SEM-EDS, TEM, XRD, Raman spectroscopy, TGA and XPS.The adsorbent exhibited up to 87% lithium adsorption efficiency at a concentration of 20 mg/L and showed high selectivity for lithium over sodium (Li/Na ≈ 37.4) and potassium (Li/K ≈ 60.5).A mechanism involving Li+ ion adsorption and transport through Li2TiO3's structural channels has been proposed, with dynamic simulations suggesting that lithium ions preferentially diffuse through these channels due to their geometric and energetic configuration.Thermodn. studies confirmed an endothermic adsorption process with enhanced performance at higher temperaturesRegeneration tests demonstrated only a 7% reduction in adsorption efficiency after three cycles, indicating structural stability and the potential for scalable application in lithium recovery processes.

100 项与 Lappeenrannan-Lahden teknillinen yliopisto LUT 相关的药物交易

登录后查看更多信息

100 项与 Lappeenrannan-Lahden teknillinen yliopisto LUT 相关的转化医学

登录后查看更多信息

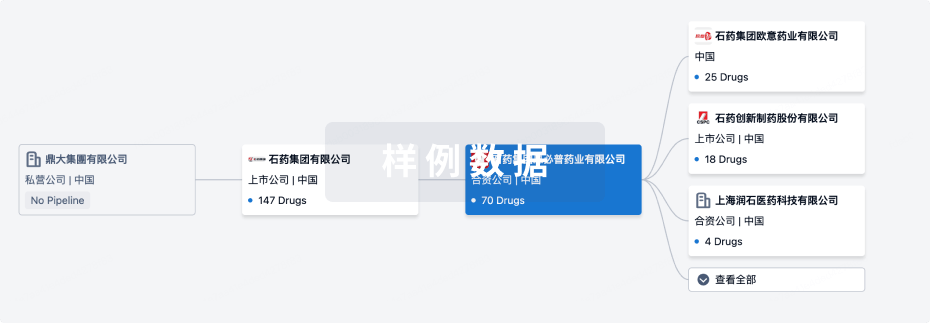

组织架构

使用我们的机构树数据加速您的研究。

登录

或

管线布局

2025年10月23日管线快照

无数据报导

登录后保持更新

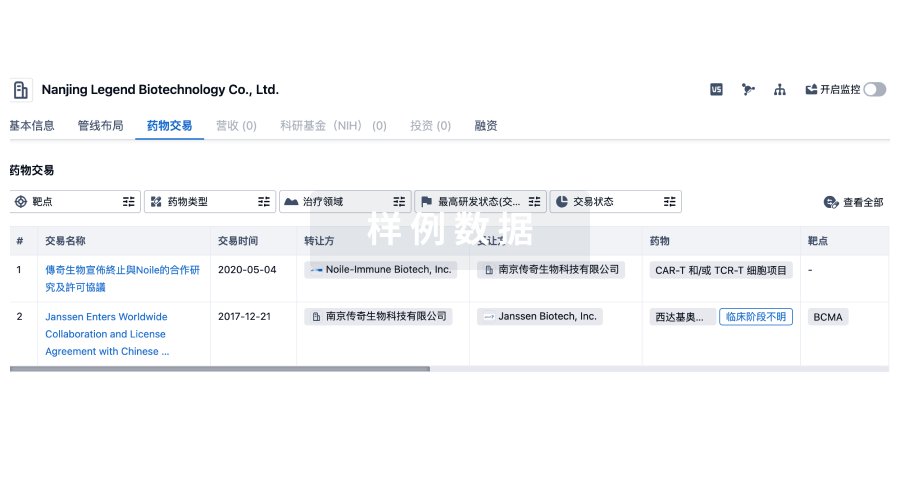

药物交易

使用我们的药物交易数据加速您的研究。

登录

或

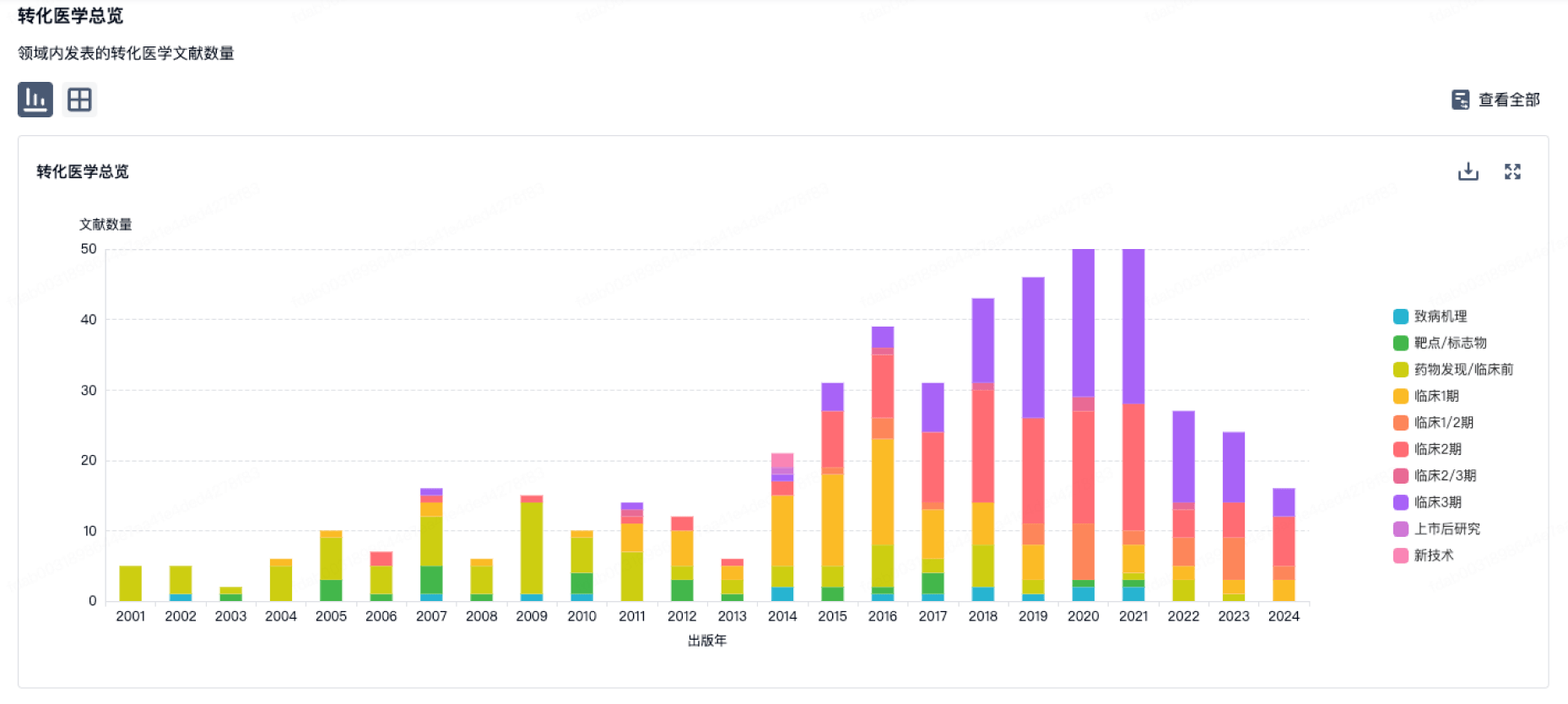

转化医学

使用我们的转化医学数据加速您的研究。

登录

或

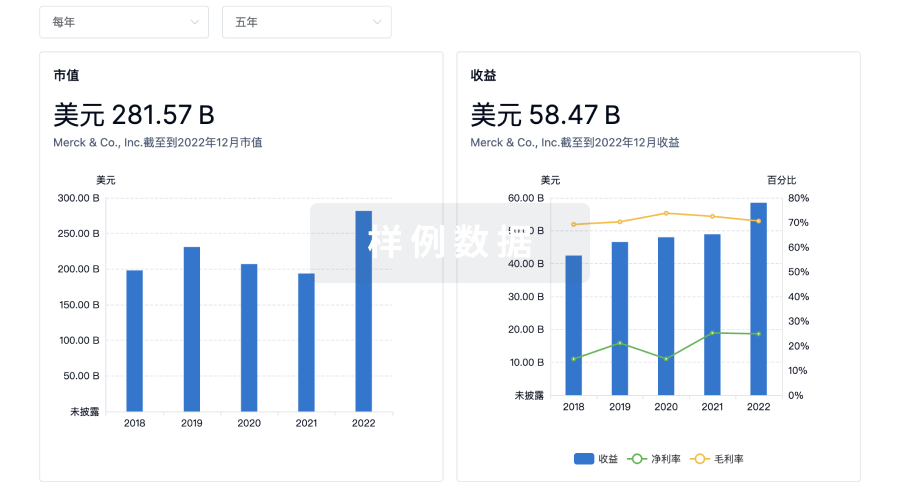

营收

使用 Synapse 探索超过 36 万个组织的财务状况。

登录

或

科研基金(NIH)

访问超过 200 万项资助和基金信息,以提升您的研究之旅。

登录

或

投资

深入了解从初创企业到成熟企业的最新公司投资动态。

登录

或

融资

发掘融资趋势以验证和推进您的投资机会。

登录

或

Eureka LS:

全新生物医药AI Agent 覆盖科研全链路,让突破性发现快人一步

立即开始免费试用!

智慧芽新药情报库是智慧芽专为生命科学人士构建的基于AI的创新药情报平台,助您全方位提升您的研发与决策效率。

立即开始数据试用!

智慧芽新药库数据也通过智慧芽数据服务平台,以API或者数据包形式对外开放,助您更加充分利用智慧芽新药情报信息。

生物序列数据库

生物药研发创新

免费使用

化学结构数据库

小分子化药研发创新

免费使用