预约演示

更新于:2025-08-30

APT Medical, Inc.

更新于:2025-08-30

概览

关联

1

项与 深圳惠泰医疗器械股份有限公司 相关的临床试验NCT02347358

Mechanical Opening Device Implantation Following Intravenous r-tPA and Recanalization Outcome Evaluation in Stroke Disease (MODIFIED) Trial

This study is to test a hypothesis that temporary implantation of JRecanTM blood flow recanalisation device within 6.5 hours of symptom onset of acute ischemic stroke due to a major intracranial artery occlusion following IV r-tPA can provide a greater rate of early successful recanalisation than treatment of IV r-tPA alone.

开始日期2015-02-01 |

申办/合作机构 |

100 项与 深圳惠泰医疗器械股份有限公司 相关的临床结果

登录后查看更多信息

0 项与 深圳惠泰医疗器械股份有限公司 相关的专利(医药)

登录后查看更多信息

6

项与 深圳惠泰医疗器械股份有限公司 相关的文献(医药)2025-05-01·Acta Biomaterialia

Negative mixing enthalpy medium-entropy Ti–Zr–Nb–Al alloys with ultrahigh elastic admissible strain, strength-elongation product, and biocompatibility for bone implant applications

Article

作者: Li, Yuncang ; Hua, Zhaolin ; Zhang, Xiaokai ; Guo, Lin ; Lin, Sihan ; Zhang, Dechuang ; Wen, Cuie

Beta-type Ti-Zr-Nb (TZN) medium-entropy alloys (MEAs) are being extensively investigated as orthopedic implants due to their metallic mechanical properties, corrosion resistance, and biocompatibility. However, improvements in elastic admissible strain, strength, and ductility are still needed to ensure their high performance in clinical applications. In this study, we designed a series of negative mixing enthalpy MEAs by adding 0, 3, 5, 7, and 10 at.% aluminum (Al) to equimolar TZN alloy (denoted TZNAx (x = 0, 3, 5, 7 and 10)). These alloys were fabricated by arc melting followed by cold-rolling and annealing, and their microstructure, mechanical properties, wear and corrosion resistance, and biocompatibility were systematically studied. In general, the TZNAx MEAs showed significantly improved elastic admissible strain and strength-elongation product compared with those of CP-Ti and Ti64; in particular, the TZNA5 exhibited the best combination of mechanical properties with an elastic modulus of ∼54.6 GPa, a yield strength of ∼1040 MPa, an ultimate strength of ∼1132 MPa, and an elongation of ∼21 %. The wear resistance of the TZNAx MEAs increased with increasing Al content. The TZNAx MEAs showed an extremely low corrosion rate of 124-587 nm /year in Hanks' solution due to the formation of a surface passivation film composed of TiO2, ZrO2, Nb2O5 and Al2O3 oxides. The TZNAx MEAs also showed a relative cell viability of more than 95 % toward MG-63 cells. Overall, the TZNA5 MEA has significant potential as an orthopedic implant material due to its exceptional and comprehensive mechanical properties, high wear and corrosion resistance, and adequate biocompatibility. STATEMENT OF SIGNIFICANCE: This work reports on negative mixing enthalpy Ti-Zr-Nb-Al medium-entropy alloys (MEAs) with superior elastic admissible strain, strength-elongation product, and biocompatibility. The TZNA5 MEA exhibited the best combination of biomechanical properties. The wear resistance of the TZNAx MEAs increased with increasing Al content. The TZNAx MEAs showed high corrosion resistance in Hanks' solution due to the formation of a surface passivation film composed of TiO2, ZrO2, Nb2O5 and Al2O3 oxides. The TZNAx MEAs showed a relative cell viability of more than 95 % toward MG-63 cells. Overall, the TZNA5 MEA has significant potential as an orthopedic implant material due to its exceptional and comprehensive mechanical properties, high wear and corrosion resistance, and adequate biocompatibility.

2025-05-01·Acta Biomaterialia

Elastic strain and strength–elongation performance of medium-entropy Zr–Nb–Ti–O alloys for bone implants

Article

作者: Li, Yuncang ; Zhang, Xiaokai ; Hua, Zhaolin ; Guo, Lin ; Lin, Sihan ; Zhang, Dechuang ; Wen, Cuie

Beta-type Zr-Nb-Ti (ZNT) medium-entropy alloys (MEAs) are receiving increasing research interest as orthopedic implants due to their appropriate mechanical properties, corrosion resistance, and biocompatibility. However, improvements in their elastic admissible strain, strength, and ductility are still required to ensure their high performance in clinical applications. In this study, a series of (ZrNbTi)100-xOx (x = 0, 0.5, 1.0, and 1.5; denoted ZNTO0, ZNTO0.5, ZNTO1.0, and ZNTO1.5) MEAs were fabricated by arc melting followed by cold-rolling and annealing. Their microstructures, mechanical properties, wear and corrosion resistance, and biocompatibility were systematically studied. The addition of oxygen could simultaneously enhance strength and ductility owing to interstitial solid-solution strengthening and strain-hardening. ZNTO0.5, ZNTO1.0, and ZNTO1.5 showed significantly improved elastic admissible strain and strength-elongation product compared to ZNTO0; in particular, ZNTO1.5 exhibited the best combination of mechanical properties with an admissible strain of ∼1.5 %, an ultimate strength of ∼1150 MPa, and an elongation of ∼22 %. The wear and corrosion resistance of the ZNTOx MEAs increased with increasing oxygen content. The ZNTOx MEAs showed better corrosion resistance than those of Ti-6Al-4V and Co-Cr-Mo alloys due to formation of surface passivation film composed of ZrO2, Nb2O5, and TiO2 oxides. The ZNTOx MEAs also showed cell viability of >97 % toward MG-63 cells. Overall, the ZNTO1.5 MEA has significant potential as an orthopedic implant material due to its comprehensive mechanical properties, high wear and corrosion resistance, and adequate biocompatibility. STATEMENT OF SIGNIFICANCE: This work reports on ZNTOx (x = 0, 0.5, 1.0, and 1.5) medium-entropy alloys (MEAs) with a comprehensive combination of biomechanical, corrosion, and biocompatibility properties. The addition of O to ZNT MEAs can significantly improve their elastic admissible strain, strength-elongation product, and wear and corrosion resistance. The ZNTOx MEAs showed better corrosion resistance in Hanks' solution than Ti-6Al-4V and Co-Cr-Mo alloys and cell viability of >97 % toward MG-63 cells. The results demonstrate that the ZNTO1.5 MEA has significant potential as an orthopedic implant material due to its best combination of elastic admissible strain and strength-elongation product, effective wear and corrosion resistance, and adequate biocompatibility.

2024-07-01·Cardiovascular pathology : the official journal of the Society for Cardiovascular Pathology

The distribution of the depth of aortic dissection and the correlation of the dissection depth index with other parameters

Article

作者: Qu, Wei ; Zhang, Zhenlu ; Wu, Yang ; Chen, Youping ; Li, Mengya

BACKGROUND:

In patients with aortic dissection, the aortic wall is separated into two layers along a dissection plane. In this study, a survey was performed to investigate the distribution of the depth of dissection plane and its correlation with other clinical and pathological parameters to help understand and expand the current knowledge of aortic dissection.

METHODS:

Pathology information system were searched for patients with aortic dissection who had undergone aortic replacement between 2019 and 2022 in Wuhan Asia General Hospital. The depth of dissection plane and dissection depth index were measured in the area around the edge of dissection plane. Correlation between parameters was calculated using Spearman's rank correlation coefficient.

RESULTS:

124 patients were included in this study. The depth of dissection plane ranged from 533 to 2335 microns, and the 5th percentile was 778 microns. The dissection depth index ranged from 0.320 to 0.972, and the 5th percentile was 0.503. The correlation coefficients were -0.305 (P=.0007), -0.259 (P=0.0111), 0.188 (P=0.0367), 0.189 (P=0.0359) respectively for male gender, the length of aortic dissection, atherosclerosis, and translamellar mucoid extracellular matrix accumulation.

CONCLUSIONS:

In 95% of patients with aortic dissection, the depth of dissection plane is larger than 778 microns, and the dissection depth index is greater than 0.503. In other words, aortic dissection rarely occurs in the inner 50.3% of the aortic media. The dissection depth index is negatively correlated with male gender and the length of aortic dissection, and positively correlated with atherosclerosis and translamellar mucoid extracellular matrix accumulation.

92

项与 深圳惠泰医疗器械股份有限公司 相关的新闻(医药)2025-08-21

·动脉网

本土电生理企业正在强势崛起。

近日,微创电生理正式发布2025年上半年业绩预告,预计归母净利润3000万元至3500万元,与去年同期相比增长76.34%至105.73%。同样作为国内电生理头部企业,惠泰医疗虽然目前还未发布半年报,但从今年一季度来看,其净利同比增长30.69%,延续了其一直以来的高增长态势。

图1.2025年上半年NMPA已获批电生理产品

(数据来源:国家药监局)

除了业绩层面,在产品端,国产电生理更是处于井喷状态。据国家药监局数据,今年上半年,我国共有45个创新医疗器械获批上市,其中电生理产品17个,数量高居细分领域第一,而在这之中,国产电生理产品多达13个,心诺普医疗、玄宇医疗、锦江电子、艾科脉医疗等企业的重磅产品都相继获批。

不过,在行业火爆背后,我们仍需清醒地认识到,我国电生理领域长期被进口产品垄断:强生、雅培、美敦力三大海外巨头共抢走90%以上的市场份额,留给国内企业的生存空间不到10%。

但巨大的差距,也意味着巨大的追赶空间,尤其是在政策不断的推动下,再叠加诸多国产产品当前已获批上市,这一潜力市场必将迎来一场行业洗牌。那么,作为“后起之秀”,国产电生理产品到底有多大的胜算?未来又会从外资抢走多少市场份额?这是一个充满机遇与挑战的长期课题。

01

净利连续暴增,究竟靠什么在“撑腰”?

作为国内首个业务高度聚焦且成功上市的电生理公司,微创电生理自2022年成功登陆科创板之后,就一直处于疯狂增长状态:上市第一年就扭亏为盈,2024年更是交出史上最强成绩单——全年归母净利润5207万元,同比增长815.36%,这使其成功摘“U”。

图2.2021-2025年一季度微创电生理净利润及增幅

(数据来源:企业财报)

进入2025年,微创电生理依旧延续高增长态势。今年一季度,其实现归母净利润1787.05万元,同比增长328.63%;上半年业绩预告预计预计归母净利润3000万元至3500万元,同比增长76.34%-105.73%。值得一提的是,这已经是微创电生理连续6个季度净利保持100%以上的增长。

事实上这并不容易,尤其是在三大海外巨头的持续压制下。那么在这背后,微创电生理到底在靠什么赚钱?

这得从两方面来看,一方面是基于国内市场,集采推动新产品迅速放量。以Columbus三维心脏电生理标测系统为例,在进入集采后,2024年上半年全球三维手术量累计突破7万例,市场份额迅速飙升至45%。另外还有TrueForce压力导管,其在2023年2月获批,到2024年年底就已在国内完成超4千例手术,覆盖医院400余家,这无疑为微创电生理创造了巨大营收。

另一方面则是依托于海外市场,通过布局东南亚、拉美等新兴板块,使其成为新的增长引擎。根据年报显示,2024年微创电生理海外业务收入1.12亿元,同比增长62.94%,而这主要是依赖于TrueForce压力监测射频消融导管、一次性星型磁电定位标测导管等产品在海外市场的大卖。据悉,压力监测磁定位射频消融导管在2024年的海外手术量已超过1000例,目前已覆盖超过30个国家和地区。

除此之外,微创电生理近年来还不断提升生产工艺,并持续优化市场渠道布局,这同时也为其赢得了更大的利润空间。

图3.2017-2024年惠泰医疗电生理业务及增幅

(数据来源:年报)

不同于微创电生理,惠泰医疗并非纯粹的电生理企业,它还有大量的血管介入业务,占总营收比例超过58%,而电生理业务只占22%。不过即便如此,作为惠泰医疗的发家产业,其电生理业务同样保持着较高的增长态势,2024年惠泰医疗电生理业务营收4.4亿元,同比增长19.73%。

而这依然是依托于国内市场的集采放量和海外市场的快速拓展。先说国内市场,2024年,惠泰医疗电生理产品新增入驻医院超200家,累计覆盖医院数量突破1360家,三维电生理手术量完成15000余例,相较2023年实现了50%的大幅增长。其中,可调弯十极冠状窦导管在细分市场中独占鳌头,年度使用量逾十万根,入院数量同比增长超100%。另外在海外市场,2024年惠泰医疗电生理自主品牌在海外市场同比增长63.04%,同样表现抢眼。

面向未来,惠泰医疗依然有着较高的增长势头。2024年12月,其电生理产品AForcePlusTM导管、PulstamperTM导管、心脏脉冲电场消融仪相继获批上市,这标志着惠泰医疗正式进入房颤治疗领域。此外,惠泰医疗在2025年初又获得磁定位压力感应导管的注册证,将打破海外企业在房颤治疗中的垄断地位。

02

市场份额不到10%,国产电生理到底卡在哪?

近十年来,我国医疗器械行业在技术进步和支付方式创新的推动下,多个前沿领域当前已成功实现国产替代,不少领域市场替代率甚至逼近90%。但即便如此,仍有一些细分器械板块当下依然被进口产品把持着,这其中的典型代表就包括电生理。

图4.2020年中国电生理市场竞争格局

(数据来源:微创电生理招股书)

根据东方证券2020年发布的研究报告显示,2020年中国电生理市场中占有率前三的均为外资品牌,分别是强生、雅培和美敦力,占比分别为58.8%、21.4%和6.7%,三者合计占比超过85%。与之形成鲜明对比的是,作为国内电生理双雄,惠泰医疗和微创电生理分别为3.1%和2.7%,合计不到6%。

不过,这一垄断局面近些年有所瓦解,国产电生理产品通过不断地技术创新以及市场推广,国产替代率已从之前的不足10%增长至2023年的15%到18%,2025年更是有望突破25%。但这仍然不够,相比于其他器械领域,电生理国产替代的进程相对缓慢。那么,到底卡在哪了?

首先一点还是技术层面存在明显短板。比如在设备上,磁电双定位技术是目前心脏电生理导航设备中最先进和最主流的技术,典型代表产品包括强生的CARTO 3系统和雅培的EnSite PRECISION系统,它们都已经过市场的验证,而国产第四代磁电三维导航产品近两年才获批,还处于刚获得入场券的初期阶段,因此无论是技术能力还是临床验证都还有很大的提升空间。

另外在耗材上,以关键的高密度导管和压力导管为例,因为工艺技术还不够成熟,再加上也没有进行足够的优化迭代,国产导管当前在批次间的一致性、长期使用的可靠性、以及在复杂解剖结构下反复弯折后的性能保持能力方面,与进口顶尖产品相比差距明显。

其次是在市场推广上,国内医生对于进口产品依赖性普遍较强,而对国产信任度不够。过去数十年,进口产品一直在我国电生理市场占据主导地位,三甲医院覆盖率超过90%。因此,当前绝大多数医生的操作习惯和临床认知都主要基于进口产品的培训体系,形成了较强的路径依赖,导致其对国产电生理产品的接受度和使用意愿都相对较低。

除了习惯性,国产电生理产品因为上市时间普遍较短,当前还缺乏一定数量的临床验证,医生并不愿意为之冒风险。对此,某资深投资人谈道,“电生理手术属于高风险手术,所以医生在选择品牌上会更加倾向更成熟、更具品牌效应的进口产品。而对于国产品牌,虽然其性能已经不差,但在产品获批上市后,依然需要相当长的时间去面对临床效果检验以及品牌的建立,逐步积累医生的信任度和市场认可度。”

最后一点则是在集采的推进上,降价力度和覆盖范围都还有很大的提升空间。2022年10月14日,福建省牵头的电生理类医用耗材27省联盟集采细则公布,采购周期为2年,2023年4月起正式执行,中选产品平均降幅49.35%。这是我国电生理领域首次集采,或许也正是因为如此,此次降价相对温和,据悉,只要企业降到最高申报价的40%以下就能中标,而“温柔一刀”显然对进口品牌的影响较小,国产替代效应并不明显。

此外,在电生理产品的覆盖上,集采当前也明显不够。目前,我国电生理集采共涉及11个大品种,包括房间隔穿刺鞘、电定位诊断导管、磁定位诊断导管、冷冻治疗导管等,而在三维标测系统、脉冲消融导管、神经电生理耗材等领域,当前还尚未形成大规模集采,这使得国产替代的进程仍面临较大阻力。

图5.中国心脏电生理市场规模变化

(图片来源:弗若斯特沙利文)

虽然如此,但不可忽视的是,电生理在我国仍然是一个巨大的潜力市场。根据弗若斯特沙利文数据,2021年中国心脏电生理器械市场规模达65.80亿元,2017-2021年的复合年增长率为28.36%;2025年预计将增至157.26亿元,2021-2025年期间复合年增长率为24.34%。2032年预计达到419.73亿元,2025-2032年的复合年增长率为15.06%。

面对这样一块巨大的蛋糕,国产电生理品牌到底要如何突围?

对此,某一线投资人表示,“首先一点是要通过技术迭代,提升现有产品的市场竞争力;其次是要瞄向以PFA为代表的创新技术,挖掘市场更多的可能性;然后是要加大集采推动力度,实现国产产品的进一步放量;最后是在审批上开通绿色通道,降低国产产品成本,在市场定价上掌握话语权。”

03

PFA:国产弯道超车的“黄金钥匙”

当前,全球电生理市场格局正在被PFA(脉冲电场消融)快速改写。

据悉,作为全球首个上市并且商业化的PFA产品,波士顿科学旗下产品Farapulse2024年全球销售额已突破10亿美元,这无疑验证了这一新兴技术领域的商业价值。回到国内视角,2023年12月,锦江电子的LEAD-PFA系统正式获批,成为国内首个PFA产品,而在第二年,其就完成超1000例商业化应用。近日,锦江电子第二代PFA导管刚投入市场便已接到百家医院订单,而惠泰医疗的Pulpstamper系统半年手术量当前也已突破3000台。

图6.目前全球已上市PFA产品的关键参数

(数据来源:公开资料整理)

商业化层面有如此抢眼表现,并非没有原因,这主要是基于PFA独特的临床优势。据悉,相比于射频、冷冻等消融术式,PFA技术拥有具备组织选择性、并发症少,消融速度快、手术效率高以及术式简单、术者学习周期短等优势,有效解决了现有心脏电生理术式的痛点。据临床数据显示,与传统射频消融相比,PFA能将房颤手术时间缩短40%,邻近组织损伤率降低至不足2%。

为此,不少行业人士表示,PFA将在一年内占据电生理30%的市场份额,这意味着冷冻消融和射频消融市场的大部分份额将被蚕食。惠泰医疗业务负责人也发表了相同看法,他在接受媒体采访时谈到,国内医生正加速转向PFA技术,尤其在房颤领域,射频消融或面临被迭代的趋势。

而在这一前沿技术领域上,国产电生理企业扎堆布局。2024年,德诺电生理、锦江电子以及惠泰医疗的PFA产品相继获批,并很快迈入商业化阶段;进入2025年上半年,又有多款国产PFA产品获批,45款创新器械中,13款属于脉冲电场消融系统及相关导管,占比接近三分之一。除此之外,洲瓴医疗、捍宇医疗、剑虎医疗等多家企业当前也都还在积极布局PFA产品,距离获批上市只差临门一脚。

因此,PFA被看做是国产电生理企业弯道超车的关键所在。这一方面是因为技术差距小,国产PFA与全球首款获批产品外资上市时间差仅为2-3年,且国内渗透率不足1%,本土企业可借临床合作快速迭代。另一方面则是可以依靠成本优势碾压,国产PFA单台手术耗材费用约3万元,仅为进口产品的50%,这为国产品牌成功突围增添了很多筹码。

而从“跟跑”到“并跑”,国产电生理显然已站在技术变革的潮头,有望在未来迎来一波新的业绩增长。

* 参考资料

1.《90%市场被海外巨头垄断,国产电生理玩家到底行不行?》——钛媒体;

2.《心脏电生理领域进入“脉冲时代”》——医药经济报;

3.《惠泰医疗:左手“国产替代”,右手“带量采购”》——Med空间站。

*封面图片来源:123rf

如果您认同文章中的观点、信息,或想进一步讨论,请与我们联系;也可加入动脉网行业社群,结交更多志同道合的好友。

近

期

推

荐

声明:动脉网所刊载内容之知识产权为动脉网及相关权利人专属所有或持有。未经许可,禁止进行转载、摘编、复制及建立镜像等任何使用。文中如果涉及企业信息和数据,均由受访者向分析师提供并确认。

动脉网,未来医疗服务平台

财报

2025-08-20

·动脉网

动脉网第一时间获悉,近日,蔚程医药有限公司(Vivatides Therapeutics, 以下简称“蔚程医药”)宣布完成杏泽资本领投,启明创投跟投的千万美金种子轮融资。本轮募资资金主要用于临床前肝外靶向小核酸平台及管线的开发。

随着一系列小核酸重磅品种商业化的不断突破,小核酸药物全球市场规模正快速增长,有望成为小分子和抗体后的第三大类药物。截至目前处于商业化阶段的siRNA药物均为肝靶向品种,肝外市场存在极大的未尽需求和可拓展空间。相较于肝靶向成熟的GalNac递送方式,肝外靶向递送在递送受体选择及配体偶联、目标组织吸收效率、安全性上都有较大的挑战,化学修饰仍在不断迭代中。蔚程医药自主研发的肝外递送平台,在底层设计上具备差异化创新,旨在突破肝外靶向的瓶颈。

蔚程医药成立于2025年,公司国际化核心团队成员创立公司前在小核酸行业头部公司包括Arrowhead、Ionis、Alnylam、Dicerna具有多年研发经验,曾主导或者深度参与多个肝外管线开发,多个项目当前处于临床开发阶段,是少数兼具肝外ASO和siRNA实际管线开发经验的技术领军团队。创始人周科明博士曾在Arrowhead、Ionis领导了多个肝外小核酸管线的开发和相关平台的建立。

蔚程医药创始人周科明博士表示:“肝外靶向递送是小核酸技术公认的下一代发展方向。我们创立蔚程医药的初心,是希望发展创新的递送技术平台,使小核酸药物能够更精准地作用于多种非肝脏组织,从而覆盖更广泛的疾病领域,让多元化的小核酸疗法惠及更多患者。衷心感谢杏泽资本和启明创投的信任与大力支持。公司团队正全力加速平台优化与管线布局,我们将持续在全球小核酸药物研发的前沿探索、前进,并贡献我们的力量。”

杏泽资本管理合伙人强静博士表示:“杏泽资本致力于支持能解决未被满足的重大临床需求的创新生物医药公司,小核酸赛道作为设立投资人参与了舶望制药和昂拓生物,小核酸肝外靶向递送方向一直是杏泽资本重点关注的方向。我们相信小核酸肝外递送技术突破,将为重大慢病和‘不可成药’靶点带来治疗范式革新。周科明博士及其团队在海外小核酸龙头企业深耕多年,积累了丰富的肝外小核酸药物的研发和工艺经验。公司成立数月以来,已在肝外递送平台与管线方面取得了令人振奋的阶段性成果,并在动物实验中实现了实质性进展。我们很高兴此次能和蔚程医药携手同行,支持公司完成前沿方向的种子轮融资,非常期待公司未来发展成为这个领域的引领者,推动生命科学产业的发展和进步。”

启明创投合伙人、医疗健康行业共同负责人陈侃博士表示:“我们非常高兴能够参与并支持蔚程医药的种子轮融资。公司团队在小核酸肝外靶向递送技术领域所取得的进展,令人印象深刻。该平台技术蕴含着巨大的潜力,有望为众多目前缺乏有效治疗手段的肝外组织疾病解锁全新的治疗机会。我们高度认可周科明博士及其团队卓越的执行力与持续的创新能力,将全力支持蔚程医药,加速其创新疗法的临床转化,最终让这些突破性成果能够惠及全球更广泛的、亟待新治疗方案的患者群体。”

关于蔚程医药

蔚程医药基于自主研发的肝外递送技术平台,主攻小核酸药物在非肝组织的靶向递送,旨在突破传统小核酸药物局限于肝内递送的技术瓶颈。核心使命是通过创新技术突破小核酸药物在肝外组织的递送,满足未尽的医疗需求。

关于杏泽资本

上海杏泽投资管理有限公司(“杏泽资本”) 成立于2015年,由全球20多位富有医疗健康领域投资经验的专业人士及顾问组成,取“杏泽”之名,意在通过股权投资,借资本之力整合大健康产业资源,促行业发展,以福泽人类。目前旗下管理6支人民币基金,管理资产总额近65亿元。

成立至今,杏泽资本专注于投资生命科学行业中早期和成长期的优秀企业,投资领域专注于创新生物医药、医疗器械(包括高端生命科学仪器)和创新服务产业链。已投资公司包括君实生物(1877.HK、688180.SH)、康方生物(9926.HK)、中国抗体(3681.HK)、荣昌生物(688331.SH、9995.HK)、心通医疗(2160.HK)、微创电生理(688351.SH)、Ambrx(NYSE:AMAM)、信诺维医药、六合宁远、宜联生物、齐禾生科、舶望制药、劲方医药、天泽云泰、亦诺微、拓创生物、申淇医疗、生生物流、医药魔方等70余家高速成长的明星企业。

关于启明创投

启明创投成立于2006年。目前,启明创投旗下管理11只美元基金,7只人民币基金,已募管理资产总额达到95亿美元。自成立至今,专注于投资科技(Technology)、医疗创新(Healthcare)等行业早期和成长期的优秀企业。

截至目前,启明创投已投资超过580家高速成长的创新企业,其中有超过210家分别在美国纽交所、纳斯达克,香港交易所,上交所及深交所等交易所上市,或通过并购等方式退出,有80多家企业成为行业公认的独角兽或超级独角兽企业。

启明创投投资企业中,很多已经成长为各自领域中最具影响力的公司,包括小米集团(01810.HK)、美团(03690.HK)、哔哩哔哩(NASDAQ:BILI, 09626.HK)、知乎(NYSE:ZH, 02390.HK)、石头科技(688169.SH)、优必选(09880.HK)、文远知行(NASDAQ:WRD)、影石创新(688775.SH)、甘李药业(603087.SH)、泰格医药(300347.SZ, 03347.HK)、再鼎医药(NASDAQ:ZLAB, 09688.HK)、康希诺生物(688185.SH, 06185.HK)、Schrödinger(NASDAQ:SDGR)、惠泰医疗(688617.SH)、三友医疗(688085.SH)、艾德生物(300685.SZ)、贝瑞基因(000710.SZ)、神州细胞(688520.SH)、圆心科技、英矽智能、宜联生物、礼新医药、智谱AI、阶跃星辰、壁仞科技等。

如果您想对接文章中提到的项目,或您的项目想被动脉网报道,或者发布融资新闻,请与我们联系;也可加入动脉网行业社群,结交更多志同道合的好友。

近

期

推

荐

声明:动脉网所刊载内容之知识产权为动脉网及相关权利人专属所有或持有。未经许可,禁止进行转载、摘编、复制及建立镜像等任何使用。文中如果涉及企业信息和数据,均由受访者向分析师提供并确认。

动脉网,未来医疗服务平台

核酸药物siRNA

2025-07-31

·药闻康策

☝ 点击上方 一键预约 ☝ 最新最热的医药健康新闻政策☝ ☝ 点击查看峰会活动议程 ☝ ☝ 过去十年间,中国医疗投资市场经历了巨大的起伏,从2015年行业融资额暴增,开启医疗投资的“元年”,到2021年达到3800余亿元的融资峰值,而后行业又进入沉寂。在这一波波投资热潮里,医疗健康行业里产生了数百家估值超十亿美元的医疗独角兽,分布在数字医疗、AI制药、手术机器人、互联网医院、慢病管理平台等各个领域。大家都一度风华正茂,头顶着技术创新、政策蓝海或美好的商业预期等各种光环,在不断加注的融资中走到独角兽的体量。幸运几乎是这一批医疗独角兽的共同特征,巨大的外部机遇让它们以极低的时间成本将成就最大化。但也正是在这一轮又一轮的资本热潮中,行业的“堰塞湖”悄然形成:高估值、大投入、慢转化。在漫漫创业长路里,许多项目因为不确定的商业回报兑现、冗长的客户转化周期与故事的一再切换,让公司处于持续亏损,通过上市来兑现“估值”变得遥遥无期,甚至要面临生存危机。医疗行业的一级市场,漂悬着众多的“梦”,太多创始人、高管团队、投资人皆身处其中。自2021年起,圆心科技五次递表仍未进入二级市场;英矽智能作为国内规模最大、发展最快的AI制药企业之一,也曾两度IPO折戟,不久前第三次赴港申请IPO;微医、医联、丁香园、春雨医生等一批互联网医疗企业早早凭借超高估值跻身独角兽之列,却至今仍滞留在一级市场,已经开始面临资本退出期的压力。随着行业红利逐渐褪去,美元基金撤出,国资LP主导的人民币基金趋于谨慎,资金属性发生了较大变化;行业政策也不断成熟——集采加剧、医保支付改革、注册制试点收紧。医疗创投圈像被按了暂停键,大量估值高企的医疗独角兽公司也陷入了沉寂。过去几年,融资难、退出难、套现难成为创业者和投资人共同面临的难题。但现如今,这一局面正在改善,今年上半年就有近40家医疗健康企业在港交所递交IPO文件,此外,诸如蚂蚁集团收购好大夫在线的收并购交易,创新药企的BD交易,这些都正在为困境中的独角兽们开启退出通道和“解套”之路。行业的春天又来临了吗?故事的转换:从“做梦”到活下去自2024年以来,医疗健康领域多起大额并购案进入大众视野,从华润三九62亿元控股收购天士力、阿斯利康12亿美元收购亘喜生物,再到蚂蚁集团收购好大夫在线,一些独角兽级别的企业不再执着于IPO,转而尝试通过并购“解套”及实现退出。港股医疗健康板块也逐渐开始回暖,更多的企业涌向港交所申请IPO,其中不乏独角兽级别的企业——去年12月,微医时隔三年重启IPO;今年5月,英矽智能三度递表;今年6月,镁信健康也赴港申请IPO。“其实不是行业变好了,是大家开始习惯了坏。”医疗行业资深从业者赵寻(化名)解释,资本退潮的这几年,是一场深刻的行业洗牌,更是一场集体心理的重新校准。在赵寻看来,现在市场上出现的一些“复苏迹象”,并不是真正的转暖,而是行业沉寂太久之后的反弹,是企业们在冲击里回过神来、在压抑中寻找出口的自然反应。过去几年,医疗独角兽普遍面临着高估值、高投入、低转化。尤其是To G、To F的项目,天然面临客户转化周期长、回款慢、采购复杂等问题,许多企业因此长期亏损,资金压力迅速放大。压力之下,一些独角兽求生失败,最终走到关停的地步,如平安医保科技。更多独角兽的“消失”实际则是失联,低调、无声地潜伏在水面之下,不再高调发布新品,也不再宣称要“重构医疗”。独角兽的天花板,并不是融资额,而是兑现路径。在现实的围困下,企业们各自踏上了不同的自救路径。一些具备平台价值和技术想象力的企业,在经历几轮重组、瘦身与战略调整后,仍在试图通过IPO实现阶段性出清。例如,英矽智能、镁信健康等企业递交招股书,选择登陆港交所,意在借助资本市场缓解融资压力,也为早期投资方打开退出通道。虽然很多公司估值相比高峰期大幅缩水,但这些公司仍具备一定市场号召力,背后机构愿意为其“冲一把”,以换回部分流动性。对于那些产品或技术难以独立撑起资本市场故事的企业,越来越多选择了“找个好人家”。尤其是具备医院端资源、医保对接能力、技术产品已部署的公司,成为了大平台并购整合的优先目标。比如,好大夫在线选择“卖身”蚂蚁集团,看重的正是其医疗支付、健康险、线上医疗服务之间的协同空间。这种交易对平台方而言是业务补充,对并购标的背后的投资人和创始团队来说则是一次体面“下车”。很多公司即便估值打折,也愿意卖——因为大家都明白,留在牌桌上,已经不一定意味着更高的回报。更多的企业处在“可继续但无增长”的尴尬阶段:现金流无法支撑研发和扩张,估值也无力支撑下一轮融资。在此情况下,公司只能做一件事——活下去。裁员、砍产品线、停止营销,转向盈利性更高但想象力更小的业务,是很多独角兽正在执行的生存策略。有公司甚至将业务一分为二,将不盈利的“科技故事线”彻底砍掉,集中人力维持基础营收。当潮水退去,先活下来的,才有资格去谈新的起点。独角兽们的沉寂,并不代表行业的终结。恰恰相反,这种低调求生状态,才是这个行业终于回归理性的开始。在这个阶段,谁能找到现金流、谁能搭上政策与产业的下沉通道、谁能与大平台融合,就意味着谁有资格进入下一轮博弈。而在这场全面认知重构的过程中,资本的逻辑也已彻底转变——从讲技术、讲想象力,到讲落地、讲变现。从“重构医疗”到“保本退出”在上一轮医疗创业热潮中,独角兽们的崛起离不开资本的推波助澜。从2018年到2021年,医疗投资行业曾迎来一轮空前活跃的繁荣期,美元基金集中加仓,人民币基金轮番下注,数字医疗、AI制药、远程医疗、慢病管理、医疗SaaS等几乎所有细分赛道都能讲出动人的故事。但如今再回头看,那更像是一场由“梦想”、“愿景”主导的资本游戏。政策利好、产业数字化升级等,这些大趋势为创业公司搭建了一个宏大的叙事舞台。在资本狂热的助推下,大量医疗企业走上“高估值、高烧钱、低兑现”的快车道,一边讲着“改变医疗”的理想故事,一边持续融资,烧钱扩张。当人们发现企业讲述的故事撑不起现实的商业前景,估值便开始集体缩水。2020年前后,“医疗行业数字化”的故事正处于高光时刻,不少创业公司并未真正跑通商业闭环,而是靠一轮又一轮融资“续命”,用讲故事的方式争取下一轮估值提升。但时代红利消退、注册制度趋严、医保控费加剧等多重因素叠加,让行业迅速进入“冷启动”状态。许多公司原本寄希望于的政策加持、用户增长或医院采购,并没有兑现到可持续营收上。一位投资人直言,“过去几年,有太多企业拿着PPT上门融资,背后没有实际产品,没有客户留存,更没有现金流。”资本市场对此做出了反应。自2022年开始,美元基金集体收缩,人民币基金进入“慢投”节奏,估值虚高的问题,在一级市场转化难、二级市场接盘冷淡的双重现实下暴露无遗。“投资人已经不愿意再为愿景买单了,他们只看现金流。”赵寻表示,“以前LP没那么急迫,但现在的LP要看到现金流,要看到退出的路径,心态变成‘别跟我讲未来10年,我只想知道你半年内能不能挣钱’。” 投资人们的判断标准发生了结构性变化,更加注重企业的盈利路径是否清晰、目标客户群体是否愿意长期付费、团队是否有成本意识与现金管理能力。技术因素反而在投资评估体系中退居次位。即便是AI制药、数字疗法这类曾经被视为“革命性”的技术创新,也开始被投资人用冷静的商业视角重新审视,一个不再盈利、客户流失严重、产品无复购的公司,只凭技术优势很难再打动投资人。对比五年前,当前行业的整体姿态也发生了微妙而深刻的变化。一级市场最火热时,创业者讲的是“重构医疗”的伟大命题,投资人追求的是“几十倍回报”的杠杆率,整个行业都相信医疗科技是下一个黄金十年。在商业化的过程中屡屡碰壁之后,企业们开始降低姿态,尝试用“降本增效”打动客户,投资人的预期也放低到“保本退出”。这一轮“独角兽解套潮”的背后,并非新一轮行业繁荣的开始,而是一场彻底的认知重塑。市场不再为“估值”欢呼,而是为“现金回报”结账;投资人不再豪赌未来,而是谨慎下注现在;创业者走出理想主义的叙事框架,重新学习如何在困境中活下去。如何上岸?IPO依然是企业们“解套”的上上选,但并非所有企业都有能力选择这条道路。“二级市场的环境变化并不是一家企业能否上市的决定性因素,真正的关键所在是企业本身。”医疗行业资深从业者张雨(化名)分析,不论二级市场是牛市还是熊市,企业进入二级市场的资格并没有发生变化,只是会影响公司发行价和发行量,因此一些企业觉得被低估时会主动推迟上市节奏,选择更合适的时机。而“内功不强”的企业,不论是在过去几年的低谷期,还是现阶段的“解套潮”中,都没有机会进入二级市场。在独立IPO之外,并购也是一些企业上市无望后的第二选择。但现实是,即便成功脱手,给投资人带来的也可能是亏损。过去几年间,国内出现的数十亿元级别的巨额并购案,几乎都出自医药或医疗器械领域,例如华润三九62亿元控股收购天士力、阿斯利康12亿美元收购亘喜生物、迈瑞医疗66.5亿元控股收购惠泰医疗等案例,支撑其价格的是医药、器械行业成熟的商业化模式、被收购公司进展迅速的研发管线,收购方看重的是可以预见的稳固收益。但国内的独角兽之中,有相当一部分公司诞生于兴起不过十几年的医疗科技赛道,又在一级市场繁荣期获得了过高的融资与估值,国内潜在的并购买家当中,鲜少有人能给出匹配独角兽估值的价格,因此,并购几乎就等于亏损。张雨透露,巅峰时期估值超百亿元的好大夫在线被蚂蚁集团收购时的价格,还远远达不到让投资人回本的水平。即便如此,并购也只是少部分企业能触摸到的解套机会。“首先要做好主营业务,其次尽快抓住AI重构业务的历史性机遇”,张雨指出渴望解套的独角兽们应该发力的方向,“二级市场回暖后,一部分钱会重新回到一级市场,趁着现阶段资本向好,尽快争取一轮新的融资。”当我们重新审视过去五年中被资本热捧、估值飞涨的医疗独角兽们,不难发现,那些真正能够穿越周期的公司,并非依赖一时的融资运气,而是建立在产品、技术与市场三者共振之上的稳健基本面。在当下这个充满变数的经济环境里,医疗独角兽不再是“讲好故事”的代名词,而是必须以可持续商业模式、真实收入能力和适应政策调整的弹性体质去面对市场考验。这些年,在经历了一次又一次的残酷考验后,痛苦带来了成长,医疗行业的大多数人已不再幻想过去那种颠覆式的变量,而更加理解了这个行业的客观规律。这个行业其实是很“慢”的,需要忍耐,需要等待,就像命运在无影灯下。(来源:健闻咨询 作者:乔燕薇 庞贝贝 )药闻康策新媒体矩阵微信公众号点击下方 一键关注【免责声明】1.“药闻康策”部分文章信息来源于网络转载是出于传递更多信息之目的,并不意味着赞同其观点或证实其内容的真实性。如对内容有疑议,请及时与我司联系。2.“药闻康策”致力于提供合理、准确、完整的资讯信息,但不保证信息的合理性、准确性和完整性,且不对因信息的不合理、不准确或遗漏导致的任何损失或损害承担责任。3.“药闻康策”所有信息仅供参考,不做任何商业交易或医疗服务的根据,如自行使用“药闻康策”内容发生偏差,我司不承担任何责任,包括但不限于法律责任,赔偿责任。欢迎转发分享、点赞、点在看

IPO并购

100 项与 深圳惠泰医疗器械股份有限公司 相关的药物交易

登录后查看更多信息

100 项与 深圳惠泰医疗器械股份有限公司 相关的转化医学

登录后查看更多信息

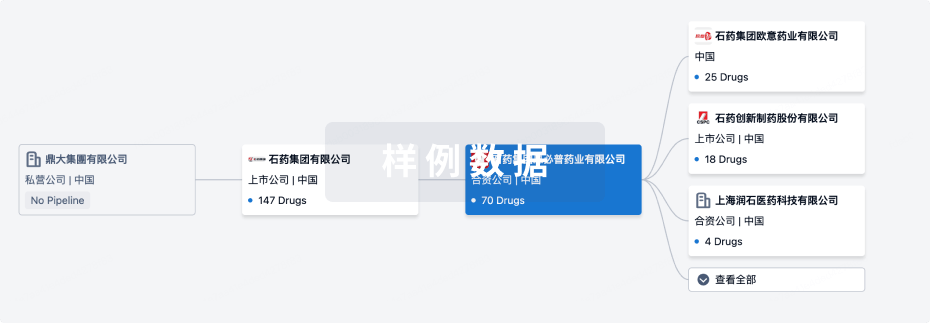

组织架构

使用我们的机构树数据加速您的研究。

登录

或

管线布局

2025年10月07日管线快照

无数据报导

登录后保持更新

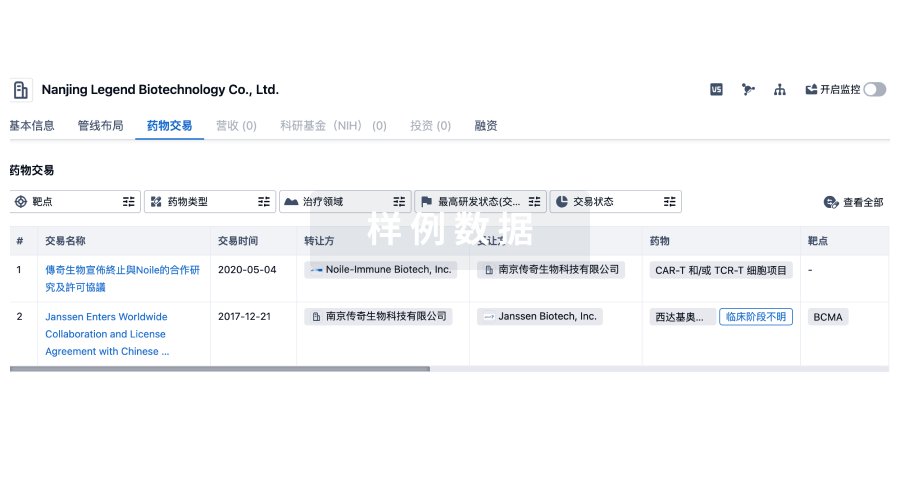

药物交易

使用我们的药物交易数据加速您的研究。

登录

或

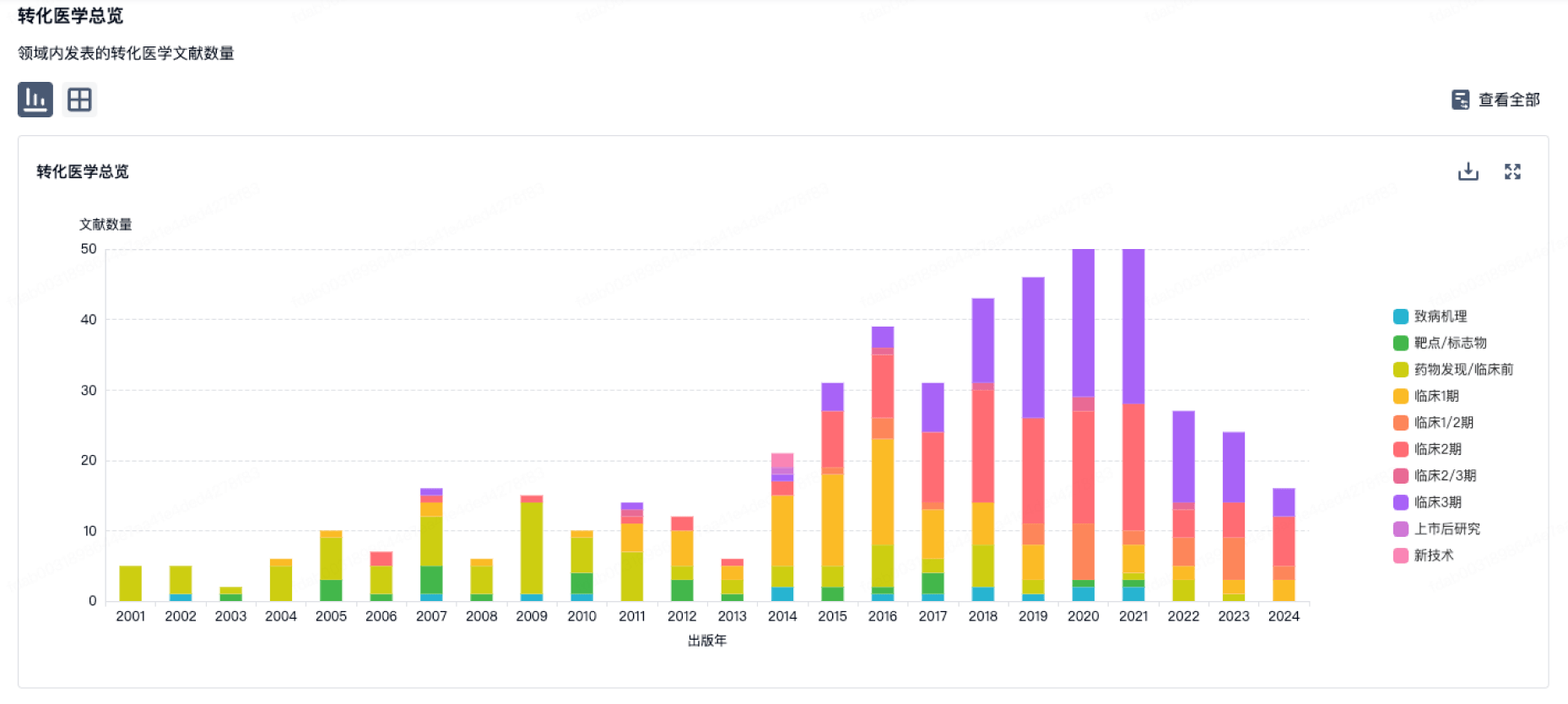

转化医学

使用我们的转化医学数据加速您的研究。

登录

或

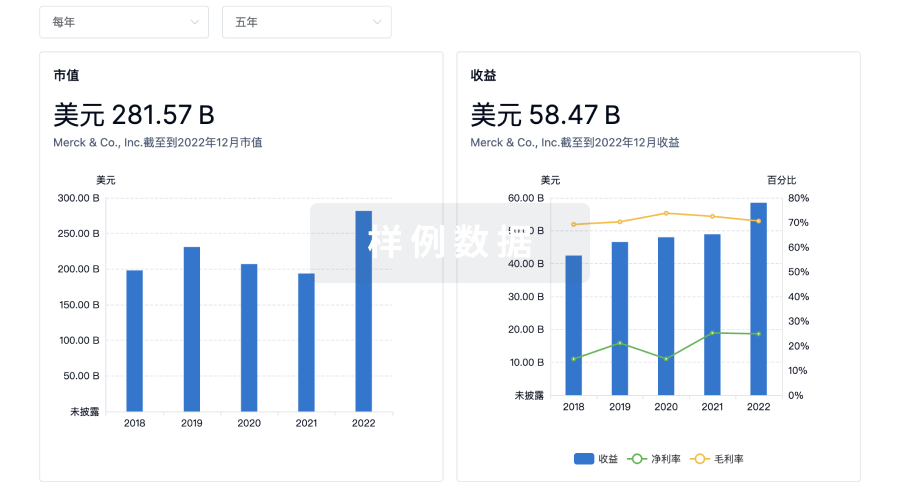

营收

使用 Synapse 探索超过 36 万个组织的财务状况。

登录

或

科研基金(NIH)

访问超过 200 万项资助和基金信息,以提升您的研究之旅。

登录

或

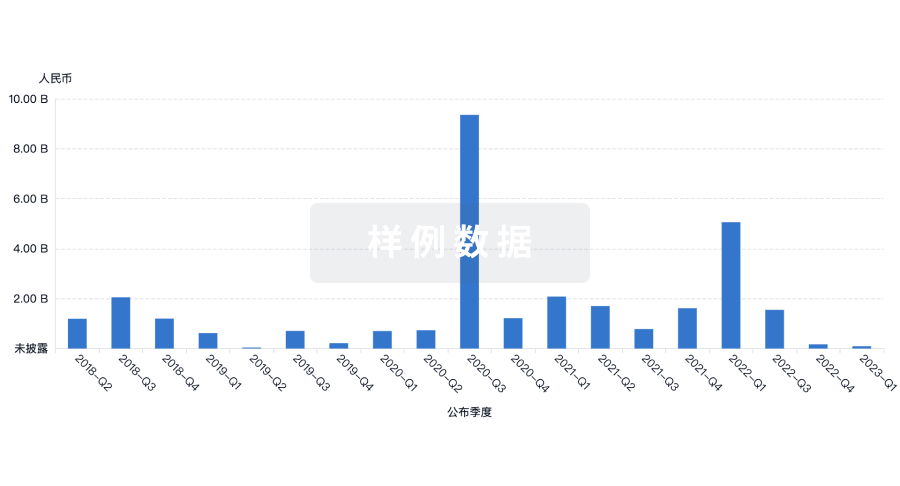

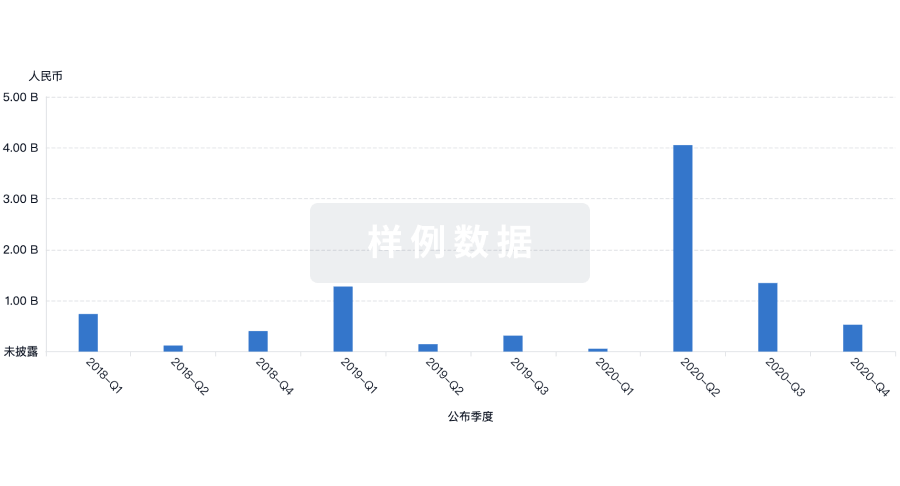

投资

深入了解从初创企业到成熟企业的最新公司投资动态。

登录

或

融资

发掘融资趋势以验证和推进您的投资机会。

登录

或

Eureka LS:

全新生物医药AI Agent 覆盖科研全链路,让突破性发现快人一步

立即开始免费试用!

智慧芽新药情报库是智慧芽专为生命科学人士构建的基于AI的创新药情报平台,助您全方位提升您的研发与决策效率。

立即开始数据试用!

智慧芽新药库数据也通过智慧芽数据服务平台,以API或者数据包形式对外开放,助您更加充分利用智慧芽新药情报信息。

生物序列数据库

生物药研发创新

免费使用

化学结构数据库

小分子化药研发创新

免费使用