预约演示

更新于:2025-09-13

FP-01

更新于:2025-09-13

概要

基本信息

原研机构 |

在研机构- |

权益机构- |

最高研发阶段无进展临床2期 |

首次获批日期- |

最高研发阶段(中国)- |

特殊审评- |

登录后查看时间轴

关联

6

项与 FP-01 相关的临床试验NCT01703923

An Exploratory, Randomized, Placebo-Controlled, Double-Blind, Crossover Study of FP01 Lozenges in Subjects With Chronic Refractory Cough

The purpose of this study is to determine the antitussive effect size and dose response of FP01 lozenges in subjects with chronic cough and to demonstrate the safety and tolerability of FP01 lozenges in subjects with chronic cough.

开始日期2012-11-01 |

申办/合作机构 |

NCT01701752

A Randomised, Double Blind, Double Observer Study to Assess Repeated Administration of a Single Dose of an Influenza A Vaccine (FP-01.1) Formulated With and Without Adjuvant, in the Presence or Absence of a Single Dose of a Trivalent Inactivated Influenza Virus Vaccine in Subjects 65 to 74 Years of Age.

This study will evaluate the safety and immunogenicity of FP-01.1 and FP-01.1 reformulated with an adjuvant (FP-01.1-Adjuvant) in relatively healthy subjects 65 to 74 years of age, subjects that are more representative of the target population. Both formulations will be administered alone or concomitantly with the Trivalent Inactivated Influenza Virus (TIV) vaccine.

开始日期2012-09-01 |

申办/合作机构 |

NCT01597349

An Exploratory, Randomized, Placebo Controlled, Double Blind, Parallel Arm Dose Ranging Study to Determine the Antitussive Effects of FP01 Lozenges in Subjects With Cough Due to Upper Respiratory Tract Infection

The purpose of this research study is to learn how effective and safe FP01 lozenges are when given to subjects with a cough due to an upper respiratory tract infection. The study will include subjects who have an upper respiratory tract infection, with a cough of less than six weeks duration.

开始日期2012-05-01 |

申办/合作机构 |

100 项与 FP-01 相关的临床结果

登录后查看更多信息

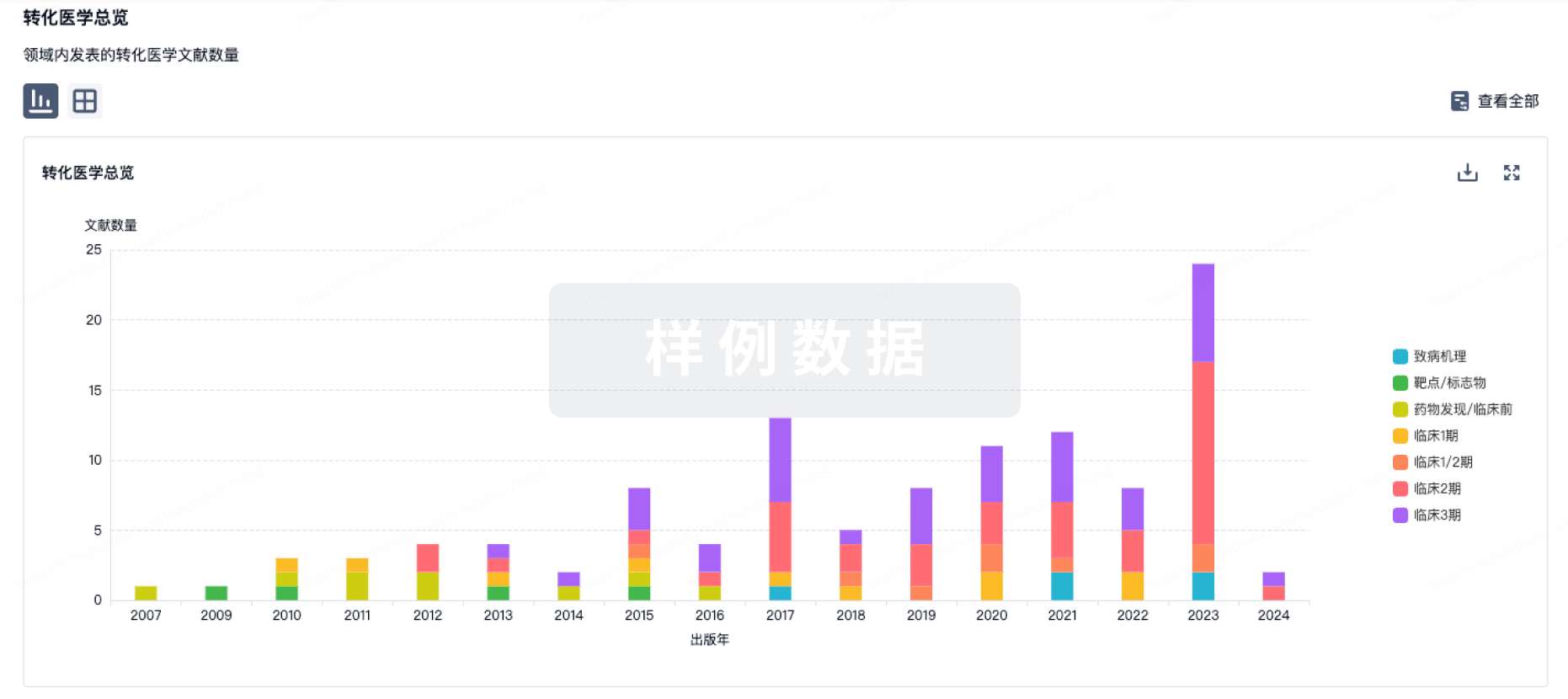

100 项与 FP-01 相关的转化医学

登录后查看更多信息

100 项与 FP-01 相关的专利(医药)

登录后查看更多信息

15

项与 FP-01 相关的文献(医药)2024-09-02·MOLECULAR PHARMACEUTICS

Elucidation of the Reversible Self-Association Interface of a Diabody–Interleukin Fusion Protein Using Hydrogen-Exchange Mass Spectrometry and In Silico Modeling

Article

作者: Hentze, Nikolai ; Eisinger, Martin ; Fernandes, Melissa ; Tavella, Davide ; Lin, Zhiyi ; Chen, Yong ; Rahn, Harri ; Moussa, Ehab M.

Reversible self-association (RSA) of therapeutic proteins presents major challenges in the development of high-concentration formulations, especially those intended for subcutaneous administration. Understanding self-association mechanisms is therefore critical to the design and selection of candidates with acceptable developability to advance to clinical trials. The combination of experiments and in silico modeling presents a powerful tool to elucidate the interface of self-association. RSA of monoclonal antibodies has been studied extensively under different solution conditions and have been shown to involve interactions for both the antigen-binding fragment and the crystallizable fragment. Novel modalities such as bispecific antibodies, antigen-binding fragments, single-chain-variable fragments, and diabodies constitute a fast-growing class of antibody-based therapeutics that have unique physiochemical properties compared to monoclonal antibodies. In this study, the RSA interface of a diabody-interleukin 22 fusion protein (FP-1) was studied using hydrogen-deuterium exchange coupled with mass spectrometry (HDX-MS) in combination with in silico modeling. Taken together, the results show that a complex solution behavior underlies the self-association of FP-1 and that the interface thereof can be attributed to a specific segment in the variable light chain of the diabody. These findings also demonstrate that the combination of HDX-MS with in silico modeling is a powerful tool to guide the design and candidate selection of novel biotherapeutic modalities.

2023-02-01·Luminescence : the journal of biological and chemical luminescence

A highly sensitive ratiometric fluorescent probe based on fluorescein coumarin for detecting hydrazine in actual water and biological samples

Article

作者: Li, Tiechun ; Luo, Weiwei ; Ma, Pinyi ; Lv, Linlin ; Diao, Quanping ; Zhou, Yixiao ; Song, Daqian

Abstract:

Hydrazine (N2H4) is a highly toxic and harmful chemical reagent. Fluorescent probes are simple and efficient tools for sensitive monitoring of N2H4 enrichment in the environment, humans, animals, and plants. In this work, a ratiometric fluorescent probe (FP‐1) containing coumarin was used for hydrazine detection. The proposed FP‐1 probe had a linear detection range of 0–250 μM and a limit of detection (LOD) of 0.059 μM (1.89 ppb). A large red Stokes shift was observed in fluorescence and UV–vis absorption spectra due to the hydrolysis of ester bonds between FP‐1 and hydrazine. The hydrazine detection mechanism of FP‐1 was also investigated using density functional theory (DFT) calculations. Finally, FP‐1 could sensitively and selectively monitor hydrazine in actual water samples and BEAS‐2B cells. Therefore, it has great application potential in environmental monitoring and disease diagnosis.

2022-09-01·Journal of molecular recognition : JMR4区 · 生物学

Computational design of immunogenic peptide constructs comprising multiple human leukocyte antigen restricted dengue virus envelope epitopes

4区 · 生物学

Article

作者: Jain, Sahil ; Kaushal, Neha ; Baranwal, Manoj

Abstract:

Dengue virus (DENV) is endemic in 100 countries with the ability to impact nearly 50% of world population. DENV envelope (E) protein is responsible for viral attachment to host cells and has been target of various countermeasure development efforts. The current study focuses on a consensus computational approach to identify cross‐reactive, immunogenic DENV‐2 E peptides displaying promiscuity with a wide array of human leukocyte antigen (HLA) molecules. Four conserved peptides (FP‐1, FP‐2, FP‐3 and FP‐4) containing multiple CD8+ and CD4+ T cell epitopes were identified by employment of various immunoinformatics tools. FP‐1, FP‐2, FP‐3 and FP‐4 were estimated to bind with 227, 1787, 1008 and 834 HLA alleles, respectively. Root mean square deviation (RMSD) values obtained by molecular docking (CABS‐Dock) with 20 HLA alleles (10 each of HLA classes I and II) resulted into comparable RMSD values of identified epitopes with native peptides, which represents the natural presentation of epitopes to HLA molecules. These peptides were also found to be part of previous experimentally validated immunogenic peptides. Further, a dengue immunogenic peptide construct was generated by linking the four peptides, an adjuvant and a 6× histidine tag. The construct showed strong binding and stability with Toll‐like receptor. Collectively, these results provide strong evidence in the support of the immunogenic potential of the dengue immunogenic peptide construct.

1

项与 FP-01 相关的新闻(医药)2023-09-11

摘要传统流感疫苗产生毒株特异性抗体,不能提供针对不同流感病毒毒株的保护。此外,由于流感病毒频繁的抗原变化和漂移,需要每年重新配制和重新接种以匹配流行的毒株。因此,通用流感疫苗(UIV)的开发对于针对所有季节性流感病毒株的长期保护以及针对潜在疫情病毒的保护至关重要。开发UIV的最重要策略之一是选择最佳靶向抗原,以产生针对不同流感病毒株的广泛交叉反应性中和抗体或交叉反应性T细胞应答。然而,每种类型的UIV靶抗原对于产生针对不同流感病毒的足够免疫应答都有优点和局限性。在此,我们回顾了目前关于抗原使用的策略和前景,包括血凝素、神经氨酸酶、基质蛋白和内部蛋白,用于通用流感疫苗的开发。关键词:流感,通用疫苗,抗原,免疫应答。1.介绍流感病毒是属于正粘病毒科的包膜RNA病毒。根据抗原差异划分,流感病毒有四个属,A、B、C和D。在流感类型中,人类甲型流感病毒和乙型流感病毒都引起季节性流感,而甲型流感病毒(IAVs)是唯一引起大流行的病毒。IAVs分为两个系统发育类群,1和2。类群1病毒包括H1、H2、H5、H6、H8、H9、H11、H12、H13、H16、H17和H18,而类群2病毒包括H3、H4、H7、H10、H14和H15。乙型流感病毒分为两个谱系,B/Yamagata样和B/Victoria 。C型流感病毒不太流行,据报道仅在人类中引起轻微疾病,而D型流感病毒尚未感染人类,但会感染牛、猪、反刍动物、马和骆驼。接种疫苗被认为是控制流感感染的最有效方法,尽管现有的流感疫苗有一些局限性。目前,季节性流感疫苗主要有三种类型:减毒活疫苗、灭活疫苗和重组疫苗。减毒活流感疫苗(LAIV)被认为是传统灭活流感疫苗的替代品,因为它们能够模拟自然感染并诱导体液、细胞和粘膜免疫反应。40多年前,LAIV首次在俄罗斯使用,2003年在美国获得许可,2012年在欧洲获得许可,并已被证明对甲型流感病毒的抗原变种具有保护作用。季节性疫苗针对的流感病毒株是根据世界卫生组织协调的全球监测来选择的;因此,疫苗的有效性很大程度上取决于疫苗株与流行病毒之间的匹配。由于流感血凝素(HA)和神经氨酸酶(NA)糖蛋白的抗原快速转移和漂移,每年都需要重新配制和重新接种疫苗。尽管季节性流感疫苗每年更新以匹配流行毒株,但2004-2020年流感季节的疫苗有效性仅为10%至60%[10](图1),据世界卫生组织估计,每年导致25万至50万人死亡。根据初步的季末估计,2019-2020年流感季节的流感疫苗有效性估计仅为39%[10]。除了季节性流行之外,流感大流行也是不可预测的重大全球威胁。1918年西班牙(H1N1病毒)、1957年亚洲(H2N1病毒)、1968年香港(H3N2病毒)和2009年猪(H1N1大流行病毒)流感这四场20世纪和21世纪最大的流行病造成了全球卫生危机,造成了巨大的死亡率和发病率和巨大的经济负担。2009年最近的流感大流行清楚地表明,流感疫苗不足以控制潜在的大流行和季节性流行病。因此,有必要提高目前流感疫苗的免疫原性和效力。此外,由SARS-CoV-2病毒引起并于2019年12月底首次出现的新冠肺炎仍在威胁全球健康,感染患者和死亡人数不断增加。此外,合并感染流感会使新冠肺炎患者的死亡风险增加一倍以上。因此,当新冠肺炎合并感染时,有效的流感疫苗对于限制严重后果至关重要。图1 2010-2020年流感季节的估计疫苗效力(VE)。数据改编自疾病控制和预防中心季节性流感疫苗有效性研究。疫苗效力的定义是,与未接种疫苗的人相比,接种疫苗的人患流感疾病的频率减少了百分比,这是使用美国疫苗效力网络的数据进行估计的。数据显示为调整后的总体VE(%),可信区间为95%。已经做出了许多努力来开发通用流感疫苗(UIV),这种疫苗能够对由类群1和类群2流感病毒引起的症状性疾病提供至少75%的效力,并在所有人群中持续保护至少12个月;然而,目前还没有商业UIV可用。已经探索了许多方法,包括靶向保守的抗原,如HA、NA、基质和内部蛋白,以及多个疫苗平台的应用,包括重组抗原/蛋白质疫苗、重组/重组流感病毒疫苗、病毒载体疫苗、病毒样颗粒(VLP)疫苗、纳米颗粒疫苗、DNA/RNA疫苗和多平台疫苗。由于需要针对不同的季节性和潜在的大流行流感病毒株产生广泛的免疫反应,因此慎重选择UIV开发的靶向抗原是当务之急。在这篇综述中,我们总结了目前抗原靶向策略在UIV开发中的优势和局限性。2.基于HA的通用流感疫苗流感HA分子由两个不同的结构域组成,一个是由部分HA1组成的球形头部,另一个是由部分HA1和全部HA2组成的茎结构。传统的IAV疫苗依赖于针对可变HA头部结构域的中和抗体(Abs)的产生,因此该疫苗具有毒株特异性。目前的策略针对变化较小的HA区域,包括茎结构域或/和头部结构域内的保守表位。这些方法包括使用无头HA、嵌合HA、镶嵌HA、计算优化的广谱反应抗原(COBRA)和“呼吸”HA。2.1 无头HA针对保守的茎结构域的广泛中和抗体的发现促进了基于茎结构域的UIVs的发展。Graves等人于1983年首次尝试通过化学去除免疫优势的HA全球头部结构域来生产免疫优势的无头HA。然而,这种处理导致HA2茎结构域的构象变化和HA1茎结构域中构象表位的移除,这是结合广泛活性的抗茎抗体所必需的。其他努力,包括基因治疗和在大肠杆菌或昆虫细胞中表达无头HA;然而,无头HA的构象可能远不是最佳的,尽管它在病毒攻击后提供了同源、异源和异亚型保护。2015年,Imagliazzo等人和Yassine等人通过在分子的膜近端引入稳定元件,独立生成了稳定且正确折叠的无头HA。无头HA通过Fc依赖的机制,如抗原依赖的细胞毒性(ADCC),诱导茎特异性抗体并保护动物免受H5N1病毒的异亚型攻击,而没有强大的中和抗体效价。这些发现不仅显示了无头HA在UIV发展中的潜在重要性,而且还表明了一种克服该分子构象变化的方法。然而,基于H1 HA柄的构建只提供了对类群1 IAV的保护。2016年,潘的研究小组首次报道,第1组无头HA微茎对类群1(H1和H5)和类群2(H3)流感病毒具有保护作用。此外,邓等人最近的一项研究表明,将由四聚体M2e配制的无头HA用于蛋白质纳米颗粒可以诱导持久的免疫反应,并保护小鼠免受同一组或两组不同IAV的挑战。虽然不断努力开发基于无头HA的UIV,但也有一些人担心HA干细胞特异性抗体诱导抗体依赖增强(ADE)。尽管上述研究值得进一步探索基于HA的无头UIV,但仔细评估无头HA诱导的抗体是否可以增强ADE,从而增加疾病严重程度是一个先决条件。2.2 嵌合HA除了无头HA外,另一种将免疫反应从HA头部转向HA茎的策略是使用嵌合HA(cHA)。这种方法包括通过与共享相同的茎结构域但不同的头部结构域的cHA连续接种来诱导抗茎抗体(图2)。cHA包括来自当前季节性IAV的HA茎结构域,例如H1、H3或B型流感病毒,以及来自外来禽流感病毒的HA头部结构域。第一次接种cHA可诱导出针对头和茎两个区域的抗体。用包含与第一次接种相同的茎域和不同的头域的另一cHA进行免疫导致对新的头域的初级响应和对固定的茎域的召回响应。用另一种由固定的HA茎结构域和不同的HA头部结构域组成的cHA进行额外的免疫可以进一步增强茎的反应。在不同的疫苗配方中接种cHA,如重组蛋白、病毒载体或基于核苷酸的疫苗,已被证明能诱导高茎反应性抗体,从而保护小鼠免受不同IAV的攻击。此外,连续接种CHA疫苗(CH8/1和CH5/1)在兔身上被证明是局部和系统耐受性良好的。由于这一策略同时诱导抗头和抗茎反应抗体,CHA提供的保护既通过中和抗体又通过非中和抗体(如ADCC活性)。用以CHA为基础的疫苗治疗雪貂可预防大流行性H1N1病毒感染。在雪貂模型中,连续接种CHA疫苗和减毒活疫苗还可以诱导HA茎特异的体液反应,授予针对不同IAV的保护性异型免疫,并诱导针对大流行H1N1病毒感染的长期免疫反应。最近,使用基于CHA的UIV的I期临床试验(NCT03300050)显示,该疫苗对人类使用是安全的(表1)。接种疫苗的健康成年人表现出非常高的抗茎抗体效价和持久的免疫反应图2 嵌合HA疫苗接种方法。在这个例子中,CHA疫苗包含来自H1 HA的茎结构域和来自外来禽类HA亚型的头部结构域。CHA可诱导对杆状H1HA的低抗体反应。然而,用含有相同茎H1HA结构域的其他CHA加强免疫,但外来禽亚型的不同HA头域增加了对H1HA茎结构域的抗体应答。CHA提供的保护是由中和抗体和非中和抗体(如ADCC)介导的。HA的结构采用瑞士模型(2021年4月5日访问https://www.swissmodel.expasy.org/,)。具有代表性的H1 Has来自甲型流感病毒(A/California/07/2009H1N1),序列来自GenBank(ACQ55359.1),或来自A型流感病毒(A/GOOSE/广东/1/1996(H5N1),序列来自GenBank(YP_529486.1)。表1 临床试验中的多种通用流感疫苗。尽管基于CHA的疫苗可以诱导产生抗茎HA的抗体,并对同源和异种病毒攻击提供保护,但这种疫苗的保护效果可能仍然有限,这取决于嵌合抗原亚型。此外,需要对不同的嵌合疫苗进行多剂量疫苗接种,以诱导广谱的疫苗效力。因此,进一步的研究需要有计划的抗原选择和简化的疫苗策略。2.3 马赛克HA马赛克HAS(MHAs)的设计思想是不仅针对保守的茎区,而且针对主要抗原位点外的头部区域的表位产生抗体。鉴于一些单抗与不同流感毒株的HA头部结构域显示出交叉反应[46-48],MHA被开发来最大限度地交叉反应和最小化遗传差异。MHA可以诱导针对HA头部和茎结构域的免疫反应(图3)。这与替换整个HA头部区域的CHA不同。具体地说,MHA是通过仅将头部HA的主要抗原位点替换为外来禽流感HA亚型的抗原位点来构建的。因此,MHA的保守头部和茎结构域来自H1、H3或B型流感病毒HA。MHA可诱导大量针对HA头区抗原位点的抗体和少量针对HA茎区保守表位的抗体。然而,用另一种不同的MHA(不同的抗原部位)增强可诱导针对HA头部和茎部位的抗原部位和保守表位的抗体。在小鼠模型中,发现用B型马赛克流感血凝素连续免疫可以诱导对同源和异种B型流感病毒株的交叉保护。接种马赛克H5 HA可增强抗体和T细胞反应,为小鼠抵御H5N1和H1N1病毒提供保护。接种H1马赛克HA或H3马赛克HA的小鼠也对不同的流感病毒株表现出广泛的免疫保护反应。Kingstad-Bakkle及其同事表明,通过聚酸酐纳米颗粒或改良的病毒Ankara传递的马赛克H5疫苗抗原可以在无特定病原体(SPF)和商业鸡只中诱导体液和细胞免疫反应。Florek等人的一项研究表明,用马赛克H5 HA免疫猕猴可以增加病毒清除,并引发能够介导ADCC活性的交叉反应抗体。最近,美国国家过敏和传染病研究所疫苗研究中心开发了一种镶嵌受体结合结构域(RBD)纳米颗粒,该纳米颗粒显示了来自H1 HA抗原的8个不同HA头域的多个副本。用这些镶嵌RBD纳米颗粒接种小鼠引起交叉反应的B细胞反应。尽管与基于CHA的疫苗相似,基于MHA的疫苗可以针对同源和异种病毒挑战提供更广泛的交叉反应保护,但这种疫苗的保护效果可能仍然有限,这取决于多剂量疫苗接种和选定的抗原亚型。因此,需要有计划的抗原选择和简化的疫苗策略进行进一步研究。2.4 COBRA HACOBRA策略应用一种计算方法来生成来自某一HA亚型的所有菌株的一致序列[57]。这种疫苗策略的主要目的是产生广泛的抗HA-Head反应,并增强HI[血凝抑制]活性。眼镜蛇HA方法已被证明是一种有效的策略,通过在小鼠、雪貂和非人类灵长类动物中诱导广泛反应的抗体,开发针对H1N1、H5N1和H3N1病毒组的流感疫苗。Carter等人报道,COBRA H1 HA抗原可以产生针对自1918年以来分离的17种人类季节性和大流行性H1N1病毒的抗头抗体。最近的一项研究表明,使用使用人和猪H1 HA序列设计的COBRA HA抗原可以保护小鼠免受猪和人来源的病毒。此外,Giles BM等人的动物研究表明,COBRA H5 HA抗原诱导的广谱抗体对25株高致病性禽流感H5N1病毒株具有HI活性。COBRA H3HA抗原已经被证明可以诱导HI抗体来保护小鼠免受一组H3N2型流感病毒的共同变异。最近,Ross等人开发了一种COBRA H3HA疫苗,方法是从2002年至2015年收集的22,144株人A(H3N2)病毒中产生一个一致的序列。与野生型HA疫苗相比,该候选疫苗显示出更高的HI活性。眼镜蛇H2 HA抗原也是使用人和禽类H2 HA序列开发的,使用这种疫苗产生了广泛交叉反应的抗体,可以对抗历史上的人H2病毒、禽类和最近在小鼠中分离的哺乳动物H2病毒。图3 马赛克HA疫苗接种方法。MHA疫苗包含一个头部结构域,其中可变的免疫优势抗原位点被外来禽类HA亚型的抗原位点取代,同时保留了头部和茎部结构域的保守区(在本例中为H1 HA)。MHA诱导的抗体对保守的抗原部位有较强的抗体反应,但对保守的保留区域只有微弱的抗体反应。然而,用来自其他外来禽类HA亚型的抗原位点增强MHA头部结构域可以增强对头部和茎结构域的抗体反应。HA的结构是使用Swiss-Model(https://www.swissmod.expasy.org/,2021年4月5日访问)构建的。代表病毒为甲型流感病毒(A/California/07/2009(H1N1)),序列从GenBank(ACQ55359.1)获得。总体而言,COBRA HA方法是通过产生广泛反应的抗头HA抗体来预防广泛的流感病毒而开发UIV的有前景的策略之一。然而,有时产生的共识序列不能产生全功能的HA蛋白,因此它需要使用替代疫苗平台,如VLP。目前,眼镜蛇HA疫苗正处于临床前开发的后期阶段,需要进行临床试验研究,以调查其在人类身上的疫苗效果。2.5 “呼吸”HA基于HA的疫苗的最新进展是利用针对HA区域中隐藏的、保守的表位,称为“呼吸”HA策略[64]。Bangaru等人和Watanabe等人的研究表明,针对HA头部结构域界面中隐藏的、保守的表位的抗体可以提供对广谱IAV亚型的保护。例如,人类单抗fla-20识别位于220环和相邻90环的表位,这些表位通常埋藏在天然的HA三聚体中。这种抗体保护小鼠免受人类H1N1、H5N1、H3N2和H7N9病毒的亚致死和致命攻击。从灭活季节性流感疫苗免疫捐赠者的记忆B细胞中分离出的抗体(S5V2-19、H2214、S1V2-58、S8V2-17和S8V2-37)的集体广度针对HA结构域的界面上的新位点,并在小鼠中提供对第1组(H1、H2、H5和H9)和2组(H3、H7和H14)病毒的保护。然而,揭示隐藏表位的方法还需要进一步探索。据报道,HA结构域的糖基化参与了IAV的抗原漂移,使其能够逃避宿主的免疫反应。有趣的是,HA头部结构域的糖基化位点可以被修饰以暴露隐藏的保守表位,从而引导免疫反应到保守的HA结构域。以前的研究已经报道,接种高糖化HA头部结构域的小鼠表现出增强的、保守的茎结构域定向抗体,并且比接种野生型HA的小鼠具有更好的抗致命病毒攻击的保护。Lin等人的研究表明,以VLP、重组蛋白或腺病毒载体等不同剂型接种高糖化HA可诱导针对禽流感H5N1病毒的广泛中和抗体。另一项研究显示,接种CHO细胞克隆稳定表达的葡聚糖保护的HA抗原可以增加针对异源H5N1病毒的中和抗体的潜力。正如Bajic等人所报道的那样,HA结构域的高糖基化并不会抑制整体体液反应,而是会改变免疫优势模式并引发广泛的保护性抗体。综上所述,这些研究表明,高糖基化可能是一种很有前途的策略,可以在HA头部和茎结构域中发现隐藏的表位,从而促进未来新型UIV的开发。目前,流感疫苗设计中的糖基化仍在争论中。研究表明,糖基化对病毒感染性和宿主免疫反应具有重要作用。Wu等人报道,HA在N-142位的糖基化促进了H1N1流感病毒的传染性,糖位142对病毒逃避人类免疫反应是重要的。在血凝抑制试验和空斑减少中和试验中,在头部HA区域添加N-连接糖基化修饰也降低了抗体效价。因此,有必要确定流感疫苗开发所需的确切糖基。还应该进行各种研究,以更好地了解糖基化对疫苗效力的影响。3.基于NA的UIVs第二种主要糖蛋白NA通过其唾液酸酶和神经氨酸酶活性,在促进流感病毒粒子从感染细胞中释放方面发挥重要作用。NA的酶活性是奥司他韦和扎那米韦等抗病毒药物的关键靶点。与HA相似,NA也经历抗原性漂移,但速度较慢。此外,在小鼠和人类身上的研究表明,与抗HA抗体相比,抗NA抗体的衰退速度较慢。最近,流感病毒NA正在成为识别其活性部位的广泛保护性抗体的靶标。Stadlbauer等人描述了针对NA的人单抗,这种单抗可以中和甲型流感病毒,抑制神经氨酸酶活性,并在体内提供广泛的保护,防止与第1组(人N1和禽类N1、N4、N5和N8)、第2组(人N1、猪N3、禽类N2、N6、N7和N9)和B型流感病毒(B/Victoria/2/87谱系)在小鼠中的攻击。最近,Madsen等人发现,人单抗还可以中和不同的B型流感病毒(IBV),抑制NA神经氨酸酶活性,诱导ADCC活性,并保护小鼠免受IBV攻击[82]。有了这些新的发现,NA可能是UIV的一个有吸引力的目标。在灭活疫苗中,NA的质量和数量各不相同。此外,这些疫苗可诱导约30%血清转换率的抗NA反应。先前的一项研究报告,NA特异性抗体可以通过干扰病毒出口来抑制流感病毒的复制。此外,针对保守NA表位的单抗还可以诱导ADCC活性,有助于保护小鼠免受B型流感病毒感染。Doyle等人报道,针对IAV保守NA序列的mAb在受到致命剂量H1N1和H3N2病毒攻击的小鼠中提供了异型保护。最近,接种重组B型流感病毒NA的豚鼠表现出病毒滴度降低,抗NA抗体水平高,病毒传播率下降。此外,已经证明一些H3N2病毒使用NA而不是HA来进行细胞附着,这表明NA抗体可能有助于阻止病毒附着。需要进一步的研究来解决这一假设。尽管NA有很多好处,但作为疫苗开发的靶点,它经常被忽视,并且由于标准化问题而没有被批准为有效的疫苗抗原,包括不适合量化NA含量的方法,以及缺乏简单的NA抗体测定方法。值得注意的是,疫苗中NA的含量可能与抗NA抗体反应相关,尽管疫苗中免疫优势HA头域的存在可能导致NA成为免疫亚优势。增加疫苗中NA的含量,同时改进NA定量方法,有助于提高抗NA免疫力。此外,储存的疫苗批次中的神经氨酸酶活性随着时间的推移而下降,这取决于所使用的菌株;因此,需要特定的储存条件来保持其活性。据我们所知,到目前为止还没有开展甲型流感疫苗的临床试验;因此,疫苗的开发变得更具挑战性,需要做出更多努力才能使其可用。应进行甲型流感疫苗的临床试验和观察性研究,以评估其在人类身上的疫苗效果。4.基于M2e的UIVS基质蛋白2(M 2)是一种跨膜蛋白,可分为细胞外N末端结构域(M2e)、跨膜结构域和细胞内C末端结构域。M2蛋白对于甲型流感病毒的适合性是必不可少的,对于病毒进入后内体的脱壳过程也是至关重要的。由于M2e高度保守,它是UIV的潜在靶点。然而,与HA和NA相比,M2e较小,免疫原性较低,导致单独给药时免疫反应较低。为了解决这个问题,研究人员试图通过加入载体蛋白、使用纳米颗粒制剂、呈现在VLP上(包括其他流感蛋白)或添加佐剂来增加M2E的免疫原性。目前认为抗M2e单抗不能中和病毒,但抗M2e单抗可与感染细胞表达的M2e蛋白结合,通过抑制病毒萌发减少病毒复制。其他提供保护的机制包括抗M2e抗体介导的细胞杀伤,通过补体依赖的细胞溶解、ADCC和/或抗体依赖的细胞吞噬作用来消除流感病毒感染的细胞。M2E特异性T细胞也可以介导对流感感染的保护。在动物模型中,基于M2e的多种疫苗配方对不同的流感病毒株显示出交叉保护作用。在小鼠中,显示在重组大肠杆菌来源的外膜囊泡上的M2e疫苗可以诱导抗M2e免疫以控制甲型流感病毒的复制,并对H1N1和H3N2的致命攻击提供100%的保护。含有来自人、猪和禽类IAV的M2e序列串联重复的VLP疫苗诱导细胞(巨噬细胞、单核细胞、中性粒细胞和CD11b+树突状细胞)募集,并在感染部位产生炎性细胞因子和趋化因子,提供对H1N1、H3N2和H5N1 IAV亚型的保护。研究表明,含有M2e序列串联重复序列的融合蛋白与分枝杆菌HSP70佐剂片段的N端融合,可增强体液和细胞免疫,减少病毒脱落,保护小鼠免受H1N1、H3N2和H9N2病毒的攻击,并保护小鼠免受H9N2病毒的攻击。一种由乳酸乳球菌表面表达的M2e组成的活细菌疫苗降低了病毒负担,并延长了接种H5N2病毒攻击后的鸡的生存时间。此外,接种了不同M2e表位的鸡对H5N1表现出保护作用。虽然关于M2e疫苗在雪貂中的效力的研究很少,但M2e与携带者结合的免疫增加了抗M2e抗体,并减少了H1N1病毒攻击后雪貂肺内的病毒脱落。此外,最近发现,在大流行H1N1病毒攻击雪貂后,显示在大肠杆菌来源的外膜囊泡上的M2e疫苗可以降低肺病毒滴度。在人类中,M2e串联重复序列与乙肝核心蛋白(NCT00819013)融合的I期临床试验显示,尽管抗体效价随着时间的推移而下降,但可以诱导抗M2e抗体。重组M2e鞭毛蛋白流感疫苗(STF2.4xM2e或VAX102)已被证明是安全的,并在健康成年人(18-49岁)中诱导高水平的抗M2e抗体[114];然而,该候选疫苗已不再处于开发阶段。另一项研究表明,在H3N2病毒攻击24小时后,静脉注射抗M2e单抗(TCN-032)(NCT01719874)的健康志愿者与安慰剂组相比,症状评分和病毒复制都有所降低。除了使用M2e作为疫苗抗原的研究外,FluGen Inc.(美国)还开发了一种缺乏M2基因的减毒单复制活病毒疫苗(表1)。该疫苗在健康成人(NCT03999554,NCT02822105,NCT03553940,Clinicaltrials.gov)中进行了安全性和免疫原性调查,目前正在50-85岁的成年人(NCT04785794,Clinicaltrials.gov)中进行调查。尽管基于M2e的疫苗显示出一些有希望的结果,但还没有实现商业化。因此,仍然需要对基于M2e的疫苗的有效性进行更广泛的临床研究,以提供证据证明这些疫苗可以保护人类免受不同流感病毒的侵袭。以M2E为基础的疫苗有一些局限性。抗M2e抗体可以预防A型流感病毒,但不能预防B型流感病毒,因为IBV中的M2蛋白结构不同。此外,由于免疫原性低,M2e可能不是一种独立的、通用的疫苗,但可能需要与携带者一起接种或其他疫苗,如季节性疫苗。此外,已有研究表明,融合到载体蛋白上的M2e可以诱导针对载体蛋白的免疫反应,当高剂量给予人类时,这可能会引起意想不到的副作用,如局部和全身不良反应。此外,对人类的临床试验表明,抗体滴度随着时间的推移而下降,这表明M2e应该与其他甲型流感抗原或佐剂一起使用,以实现可持续的免疫反应。5.基于内部蛋白的UIVs流感病毒的内部蛋白,如基质蛋白1(M1)和核蛋白(NP)是高度保守的。与在感染细胞表面表达的HA、NA和M2e不同,M1和NP在感染细胞内产生,由主要的组织相容性复合体分子加工和呈递,用于T细胞识别。因此,靶向内部蛋白也是一种有希望的策略,通过增强T细胞的交叉反应来改进当前的流感疫苗。在小鼠中,用壳聚糖佐剂对大肠杆菌表达的M1蛋白进行鼻腔免疫,分别对异源H1N1和H5N1病毒提供了70%和30%的保护。Liu等人发现,接种含有M1的DNA疫苗并用来自禽类H9N2的重组M1蛋白加强免疫的小鼠,可诱导体液和细胞免疫反应,并对同源病毒感染提供完全保护,对异型H1N1病毒感染提供部分保护。此外,几十年前,基于NP的DNA疫苗在动物模型中被证明对同源和异种流感病毒都具有保护作用。近年来,基于NP的mRNA疫苗已成为一种有吸引力的方法。用编码NP的信使核糖核酸疫苗在小鼠中诱导对流感病毒的跨株免疫。此外,通过将人类免疫缺陷病毒1(HIV-1)的蛋白转导结构域TAT-NP整合到NP中而产生的重组蛋白TAT-NP,增强了细胞免疫反应,并增强了对同源PR8、异亚型H9N2和H3N2IAV在小鼠中的保护效力。坎波等人。证明用重组NP疫苗OVX836免疫的小鼠表现出对H1N1和H3N2IAV的T细胞反应和保护效力。用第二代脂质佐剂稳定乳剂(SLA-SE)佐剂的NP免疫老龄小鼠,在PR8病毒致死攻击后,病毒清除和存活率都有所提高。将NP+M1+热休克蛋白60与水包油佐剂混合接种,可诱导强大的体液、粘膜和细胞免疫反应,抑制肺部病毒复制,并完全保护小鼠免受H7N9攻击。另一项研究表明,编码NP和M1的改良痘苗病毒安卡拉病毒载体(MVA−NP+M1)可作为佐剂增强小鼠、鸡和猪的抗体和T细胞反应。MVA−NP+M1候选疫苗自2011年以来已在多个临床试验中进行了测试(表1)。接种MVA−NP+M1的志愿者表现出流感症状和病毒脱落时间的减少。另一项临床试验表明,MVA−NP+M1在人类中是安全的,并诱导抗原特异性T细胞反应。该疫苗的安全性和免疫原性也在50岁以上的成年人中得到证实,其增强记忆T细胞和诱导多功能细胞因子的能力。此外,这种疫苗与季节性流感疫苗的结合被证明能增加50-85岁成年人的流感病毒特异性抗体反应和记忆T细胞。MVA-NP+M1疫苗正处于IIb期临床试验(NCT03880474),以调查其对18岁及以上成年人的疗效。然而,这项试验因无效而被停止(2021年4月26日更新,Clinicaltrials.gov)。用一种新的重组猿腺病毒ChAdOx1NP+M1接种也被发现诱导T细胞免疫原性增加,(表1)。基于NP寡聚体的候选疫苗OVX836也在I期临床试验中进行了测试(NCT04192500和NCT03594890,Clinicaltrials.com,于2021年3月28日访问),尽管结果尚未报告(表1)。尽管基于内部蛋白的流感疫苗在诱导T细胞免疫反应和交叉保护方面显示出良好的结果,但基于内部蛋白的疫苗诱导的抗体反应较弱,这是阻断流感病毒感染所必需的。此外,开发基于内部蛋白的T细胞疫苗的一个主要挑战是负责抗原肽结合和T细胞呈递的人类白细胞抗原单倍型的多样性。因此,为了生产有效的内部蛋白质疫苗,为所有具有不同人类白细胞抗原多样性的个体提供足够的覆盖,有必要在种族背景下进一步评估反应[134]。6.基于多种蛋白/多肽的UIVs考虑到不同基于蛋白质的疫苗的潜力,包含多个蛋白质或表位多肽的疫苗具有增强广泛交叉反应抗体和T细胞反应的潜力。这一疫苗策略已经用许多不同的疫苗平台和蛋白质组合进行了研究。表达NP和M1的病毒载体疫苗(ChAdOx1 NP+M1)和CHA疫苗的组合免疫诱导了针对分歧组2 IAV的HA、NP和M1的抗体反应,增强了T细胞对NP和M1的反应,并保护小鼠免受H3N2病毒的攻击。Park等人报道了一种表达M2和CHA的重组减毒H3N2型病毒,该病毒可以保护小鼠免受广泛的IAV感染,包括H1N1、H3N2、H5N1、H7N9和H9N2。此外,含有保守的HA、M2e和NP蛋白的嵌合亚单位疫苗被证明可以保护小鼠免受同源和异种IAV的攻击。此外,用含有M2e和HA的双层蛋白纳米粒免疫的小鼠可以免受H1N1、H3N1、H5N1和H7N9病毒的攻击。此外,重组乳酸乳球菌表达的M1-HA2融合蛋白在鸡身上对H9N2病毒具有粘膜保护作用。使用这一策略开发的候选疫苗也在许多临床试验中进行了测试。多聚体-001(M-001)由以色列BiondVax制药有限公司开发,是一种基于多肽的疫苗,包含HA、M1和NP蛋白的B和T细胞表位。事实上,M-001已经在七个临床试验中进行了评估,结果令人振奋(表1)。M-001(NCT03450915)的II期试验表明,独立的M-001是HA疫苗的引爆剂,并提高了老年人的HI效价。此外,M-001可用作增强对三价流感疫苗的HI反应的引发剂,也可用作H5N1 IAV的引发剂或单独的疫苗。值得注意的是,在第三阶段临床试验中,M-001作为一种独立的尿路感染药物在50岁的成年人≥中也进行了安全性和临床疗效的评估。FP-01.1由免疫靶向系统有限公司(英国)开发,是一种以合成肽为基础的疫苗,含有6个来自甲型流感病毒NP、M和聚合酶碱性1和2蛋白的多肽(表1)。该疫苗在4个I期临床试验中进行了测试,显示出良好的安全性和耐受性。然而,FP-01.1已经不再处于开发阶段。Flu-v是由PepTcell(SEEK,英国)开发的由NP、M1和M2蛋白组成的合成肽疫苗(表1)。流感病毒已经在四个I期和II期临床试验中得到了彻底的研究。第一阶段研究的结果表明,Flu-v可以刺激细胞免疫,并减少症状和病毒脱落。临床第二阶段研究的结果表明,Flu-v减少了病毒的脱落和临床流感症状,并诱导了长期的细胞免疫。不过,这种疫苗的效力还有待进一步探索。总体而言,基于多种蛋白质/多肽的疫苗方法是通过多种蛋白质或多肽组合来开发UIVs的有前景的策略之一,但仍然存在局限性,如靶蛋白在亚型之间的序列差异。因此,应在设计的候选疫苗中筛选靶蛋白序列,以提供对不同毒株的广泛保护。还应选择好免疫优势区域,以获得最适合疫苗构建的表位。7.流感疫苗佐剂提高流感疫苗效力的一种方法是加入佐剂。三种主要佐剂,铝盐(明矾)、MF59和AS03,被纳入获得许可的流感疫苗。自20世纪20年代以来,明矾在美国和欧洲被广泛用于疫苗。先前的研究表明,明矾通过仓库效应、NLRF3炎症激活、CD4+T细胞的刺激和分化、树突状细胞膜的扰动和补体激活等机制刺激Th2偏向反应。众所周知,明矾能激发强大的体液免疫反应;然而,它只能最低限度地诱导ADCC。此外,明矾只能微弱地引起细胞免疫反应。MF59于1997年在意大利获得许可,被开发为老年人流感疫苗接种的佐剂。获得许可的流感疫苗,包括Focetria、Celtura和Fluad以及季节性流感疫苗,都包括MF59。研究表明,MF59显著增强了抗原特异性抗体的产生,并增强了Th1和Th2偏向的反应。然而,MF59可引起注射部位的疼痛、反应性,并可诱发炎症性关节炎。AS03佐剂已用于获得许可的疫苗Pandemrix、Arepanrix、Prepanrix和Q-PanH5N1。以往的研究表明,AS03可诱导注射肌肉和引流淋巴结产生炎性细胞因子和趋化因子,并促进单核细胞和树突状细胞向引流淋巴结的迁移。此外,AS03的包含会导致持续产生中和抗体和高频率的记忆B细胞。然而,研究报告称,AS03佐剂疫苗在接种后可能会导致睡眠障碍和发作性睡病。此外,已经测试了几种策略,例如使用Toll样受体激动剂或不同的佐剂组合,以克服常见佐剂的局限性。综上所述,每种佐剂都有独特的优点和缺点。因此,流感疫苗佐剂的选择对于提高疫苗抗原的免疫原性和提高疫苗效力至关重要。然而,需要更安全和更有效的佐剂来有效地改善针对疫苗抗原的体液和细胞免疫反应。8.总结流感大流行的持续威胁显著表明,有必要开发具有比现行流感疫苗更广泛和更强的保护效力的新型UIV,以抵御季节性和潜在的大流行毒株。然而,尽管作出了不断的努力,目前仍没有商用UIV可用。虽然各种流感抗原正在为UIV的开发进行测试,但不同的疫苗抗原有独特的优点和缺点。以HA为基础的疫苗主要诱导抗体应答,无头和嵌合HA疫苗主要针对保守的HA干区,而嵌合疫苗则同时针对头部和保守的HA区域。此外,计算优化的广谱反应抗原(COBRA)策略产生了一致的序列,允许激发针对不同病毒株的广谱反应抗体。针对隐藏的HA区域的呼吸性HA方法也显示出希望。目前的季节性流感疫苗使用NA和HA作为抗原。尽管基于NA的疫苗已显示出诱导免疫反应的作用,但由于其局限性,如标准化问题,NA目前在流感疫苗开发中作为抗原靶标被忽视。应对基于NA的流感疫苗进行进一步研究,以证明NA作为流感疫苗抗原的重要作用。此外,应该开发先进的技术来量化NA的绝对量,准确地测量NA抗体的反应,并在储存期间保持NA疫苗的神经氨酸酶活性。虽然M2e是一种保守的流感病毒蛋白,很有希望成为UIV的靶标,但它的免疫原性很低。因此,为了诱导强大的免疫反应,它应该与其他病毒蛋白或佐剂一起使用。此外,基于内部蛋白的疫苗主要诱导T细胞反应,促进流感感染细胞的杀伤,是利用多种蛋白质或多肽组合开发UIV的有前景的策略之一,但这些疫苗诱导的抗体反应较弱,应适当选择其中的免疫优势区域,以获得最合适的疫苗构建表位。由于具有增强疫苗免疫原性的能力,佐剂已被广泛应用于各种流感疫苗的研究中。使用合适的佐剂,如铝基佐剂、水包油佐剂如MF59、佐剂系统03、(AS03)或以Toll样受体(TLR)为基础的佐剂(如针对TLR4的佐剂),或不同佐剂的组合,也有助于提高抗原免疫原性和疫苗效力。最后,针对以抗体为基础的传统疫苗的UIV将需要进行大规模的临床前和临床比较研究,以及用于商业UIV生产的疫苗生产和递送方案的标准化。参考资料:Nguyen QT, Choi YK. Targeting Antigens for Universal Influenza Vaccine Development. Viruses. 2021 May 24;13(6):973. doi: 10.3390/v13060973. PMID: 34073996; PMCID: PMC8225176.为推动我国生物制品全生命周期质量管理体系的建立,进一步提升生物制品的安全性和有效性,“2023生物制品全生命周期质量管理峰会”将于2023年9月22-23日在上海举办,主题为“质量为先、精益求精”。组委会将力邀知名制药企业质量专家、行业协会和监管部门领导、学术专家做精彩报告。将重点围绕抗体、ADC药物、疫苗、细胞和基因治疗药物、重组蛋白药物等领域的质量管理策略及要点进行探讨。会议内容时间:2023年9月22-23日(周五-周六)地点:上海(酒店定向通知)指导单位:上海市医药质量协会主办单位:四叶草会展、生物制品圈协办单位:奥星集团会议费用:为药企质量专家提供参会福利,报名FREE!(仅收取50元定金,含茶歇、会议资料等,定金概不退还)(如需用餐,2天午餐加收150元),先到先得,报完即止!请提前锁定!报名方式:扫描下方二维码或点击文章最底部“阅读原文”→ 填写表格 → 报名成功(报名志愿者,承担一定工作,请慎重考虑,免交定金)!组委会获得报名信息后,根据报名信息进行初筛,并进一步与报名者沟通确认,实现精准邀请。最终有机会进入大会微信群(严格审核通过)。识别微信二维码,添加生物制品圈小编,符合条件者即可加入生物制品微信群!请注明:姓名+研究方向!版权声明本公众号所有转载文章系出于传递更多信息之目的,且明确注明来源和作者,不希望被转载的媒体或个人可与我们联系(cbplib@163.com),我们将立即进行删除处理。所有文章仅代表作者观点,不代表本站立场。

疫苗

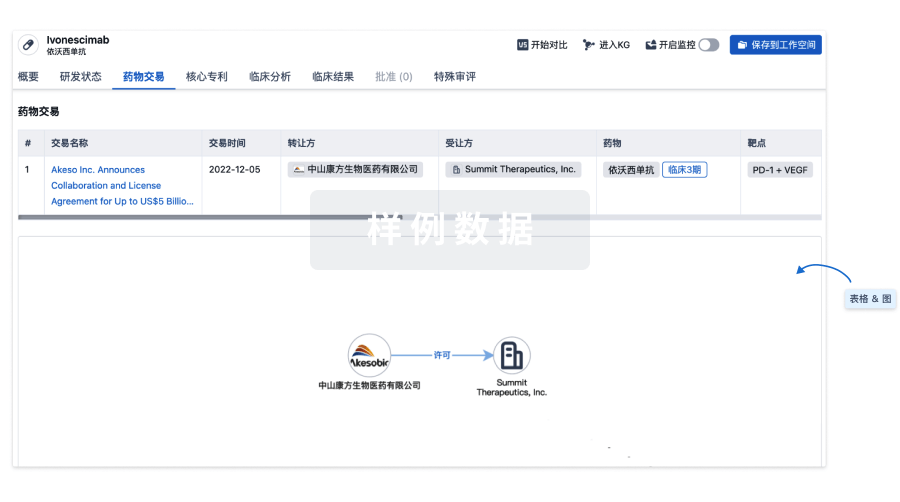

100 项与 FP-01 相关的药物交易

登录后查看更多信息

研发状态

10 条进展最快的记录, 后查看更多信息

登录

| 适应症 | 最高研发状态 | 国家/地区 | 公司 | 日期 |

|---|---|---|---|---|

| 难治性慢性咳嗽 | 临床2期 | 美国 | 2012-11-01 | |

| 急性咳嗽 | 临床2期 | 智利 | 2012-05-01 | |

| 急性咳嗽 | 临床2期 | 秘鲁 | 2012-05-01 | |

| 普通感冒 | 临床2期 | 智利 | 2012-05-01 | |

| 普通感冒 | 临床2期 | 秘鲁 | 2012-05-01 | |

| 咽炎 | 临床2期 | 智利 | 2012-05-01 | |

| 咽炎 | 临床2期 | 秘鲁 | 2012-05-01 | |

| 甲型流感病毒感染 | 临床1期 | 英国 | 2010-08-01 |

登录后查看更多信息

临床结果

临床结果

适应症

分期

评价

查看全部结果

| 研究 | 分期 | 人群特征 | 评价人数 | 分组 | 结果 | 评价 | 发布日期 |

|---|

No Data | |||||||

登录后查看更多信息

转化医学

使用我们的转化医学数据加速您的研究。

登录

或

药物交易

使用我们的药物交易数据加速您的研究。

登录

或

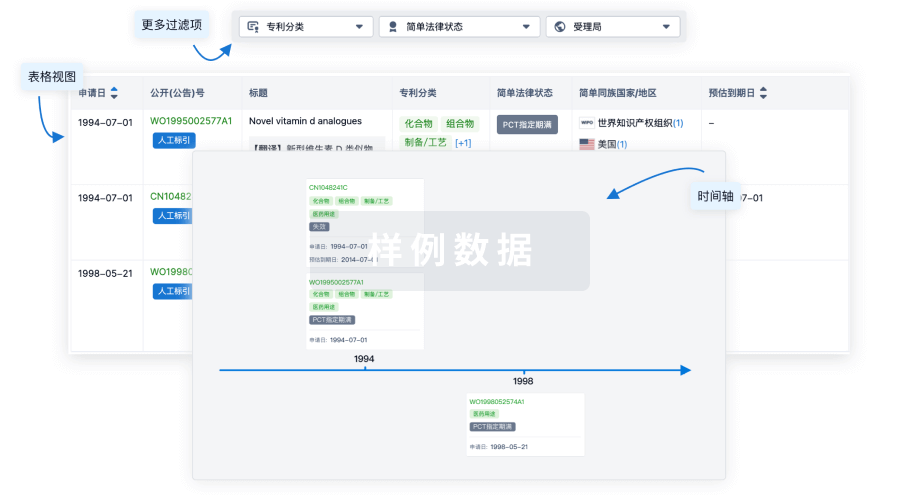

核心专利

使用我们的核心专利数据促进您的研究。

登录

或

临床分析

紧跟全球注册中心的最新临床试验。

登录

或

批准

利用最新的监管批准信息加速您的研究。

登录

或

特殊审评

只需点击几下即可了解关键药物信息。

登录

或

Eureka LS:

全新生物医药AI Agent 覆盖科研全链路,让突破性发现快人一步

立即开始免费试用!

智慧芽新药情报库是智慧芽专为生命科学人士构建的基于AI的创新药情报平台,助您全方位提升您的研发与决策效率。

立即开始数据试用!

智慧芽新药库数据也通过智慧芽数据服务平台,以API或者数据包形式对外开放,助您更加充分利用智慧芽新药情报信息。

生物序列数据库

生物药研发创新

免费使用

化学结构数据库

小分子化药研发创新

免费使用