预约演示

更新于:2025-05-07

P-1000

更新于:2025-05-07

概要

基本信息

非在研机构- |

权益机构- |

最高研发阶段临床前 |

首次获批日期- |

最高研发阶段(中国)- |

特殊审评- |

结构/序列

使用我们的ADC技术数据为新药研发加速。

登录

或

关联

100 项与 P-1000 相关的临床结果

登录后查看更多信息

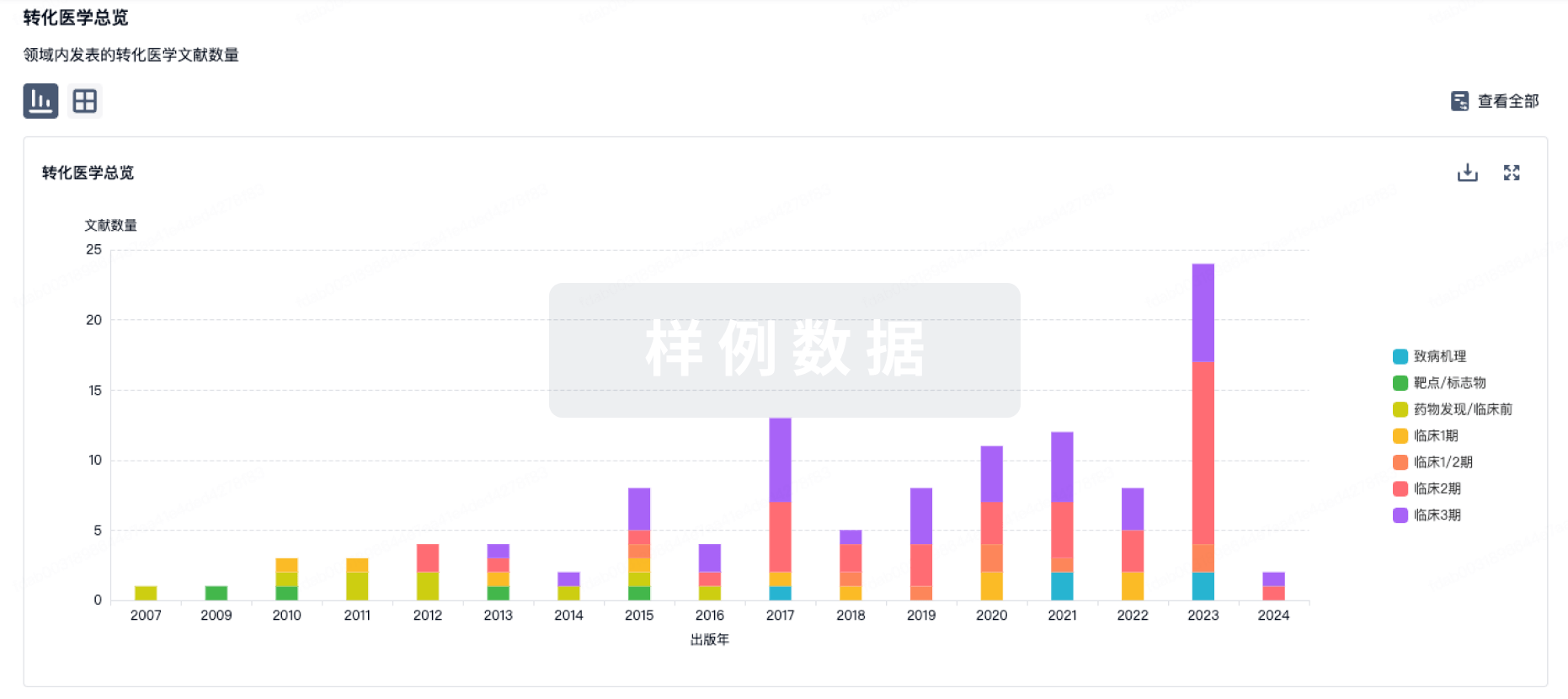

100 项与 P-1000 相关的转化医学

登录后查看更多信息

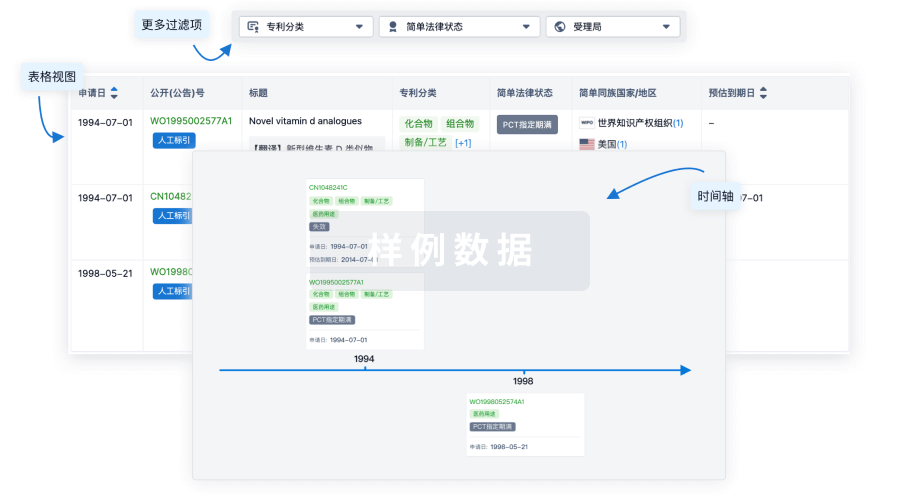

100 项与 P-1000 相关的专利(医药)

登录后查看更多信息

8

项与 P-1000 相关的文献(医药)2024-01-02·Regenerative Biomaterials

Bio-functional hydroxyapatite-coated 3D porous polyetherketoneketone scaffold for enhanced osteogenesis and osteointegration in orthopedic applications

Article

作者: Zhao, Yuwei ; Liu, Xiaoyin ; Yu, Haiyang ; Liu, Huanhuan ; Yin, Zhicheng ; Liu, Taiqing ; Tan, Ying

2019-12-01·BMC Anesthesiology4区 · 医学

Premedication with oral paracetamol for reduction of propofol injection pain: a randomized placebo-controlled trial

4区 · 医学

ArticleOA

作者: Jongjidpranitarn, Manasanun ; Prathep, Sumidtra ; Nimmaanrat, Sasikaan ; Oofuvong, Maliwan

2018-12-01·Nutrition Journal

High phosphorus intake and gut-related parameters – results of a randomized placebo-controlled human intervention study

Article

作者: Trautvetter, Ulrike ; Jahreis, Gerhard ; Glei, Michael ; Lorkowski, Stefan ; Camarinha-Silva, Amélia

1

项与 P-1000 相关的新闻(医药)2025-02-17

·循因缉药

环球视野,深度视角

各位亲爱的股东,大家早上好中午好晚上好。

赛纳新测序仪发布了,P1000和P1000X。

其实很好理解,就是当年的Illumina HiSeq X和X Ten的玩法。

发布会大部分人都会看,我这里主要跟大家掰扯掰扯几个感兴趣的点,全网独一份。

声明:本文所使用图片来自厂家PPT,内容来自发布会和我们的推论,如有错误,欢迎指正。

#01

“芯片重置”

测序仪芯片与测序化学、图像获取识别构成了NGS测序仪的核心三要素,也是成本三要素。

其中图像获取识别模块是软硬件构成,基本上是固定投入。

测序芯片(flow cell,FC)和测序化学(试剂)就是我们测序的主要成本。

曾经,非pattern玻璃基芯片其实是不贵的。

然而,为了追求更高的测序质量和芯片密度,现在大家选择的硅基芯片成本还是不便宜的。

这次赛纳发布会上推出了芯片重置功能真的吓到我了,而且可以重置10次...这不讲道理好吗。

在这之前,还没有人这么做过或者做到过。

所以,P1000X能做到50美元30X的人WGS测序我是相信的。

对,P1000暂时没开放哦,毕竟这是另外的价钱。

其实这事2010年就有人开过脑洞,只不过实诚的赛纳人给实现了...还拿出来了...

脑洞人的浪漫...我们不一样...

#02

“我们不一样”

好,我们来看第二个关键的东西:测序化学。

赛纳 P1000采用的测序化学与其桌面型S100的Fluorogenic技术并不相同,被称为LumoSeq技术。

当然,二者也有一些传承。

国产测序仪风云录之赛纳生物

我们此前在上文中有过详细描述Fluorogenic技术和ECC测序,这里节选一点:

1、直接在磷酸基团而不是碱基上进行荧光标记,但是由于跟磷酸基团连接,此时不发光。

2、聚合反应发生时,三磷酸酯与荧光基团脱落并被磷酸酶水解。

3、游离状态荧光基团被激光激发并发光。

这几条二者都是相同的,但是不同的是LumoSeq技术每轮延伸一个碱基直接图像识别。

并没有使用简并碱基测序和ECC纠错编码测序方式。

据说是图像识别技术与荧光强度又有了升级,不需要了。

但是,大家要注意,LumoSeq使用的是单色荧光,又是如何分辨四种碱基的呢?

一个可能的方式是通过4种碱基的荧光强度分级做到的,这点并没有资料支撑。

不然,不可能对吧?这不讲道理啊...

欢迎厂家解惑。

#03

“花活与花火”

P1000/X其实有不少“花活”,比如双芯片滚动上机、多点输出(意味着可以先出一份“报告草稿”)、现有文库的无缝衔接。

而这些“花活”赛纳都没多讲...好像很平常...

这没道理...直到我看到这张图。

自定义文库结构、自定义芯片表面引物...这是要干啥...

我瞬间能想到的就是,这货完全可以做空转啊...

自定义测序引物和读出模式:那我R1测19,R2测199也可以?甭管为什么,我就是这么任性,你就说可以不可以?

可以!!!!!!

这个被称为“OpenSeq开测”的计划,不仅仅是要送大家测100万Gb免费数据,还要激发出应用的花火、在市场上掀起应用开发的浪潮啊。

高,实在是高。

#04

最后

真的很开心,现在国内测序仪有这么多新的玩家。

因此,Illumina被送上《不可靠实体清单》其实大家一点都不担心。

信心,还是要有的。

更重要的是,我们的华大智造、真迈、赛陆和塞纳们,各有各的“花活”。

而这,也必将让行业诞生更多应用的“花火”。

哦对了,这货有两种规格芯片PT1(现货)、PT2(期货,2025Q4)。

二者就能够在PE150的规格下输出Q40>=85%的数据,运行时间36小时。

最后,LumoSeq大家是不是有点耳熟...

END

找小编,扫这里!

至此,各位股东星标了么?点赞了么?转发了么?在看了么?谢谢!

所有内容均不作为投资建议,信息均来自公开资料。

近期文章:

Bruker布鲁克:Q4超预期,中国刺激政策起效!

PacBio:营收下滑33%还盈利了???

诺辉健康:朱叶青时代终结

10x Genomics:2024下滑

PacBio脑子在想啥?

“置换”Illumina:方案遴选启动!

资料来源:官方ppt和发布会以及个人瞎猜

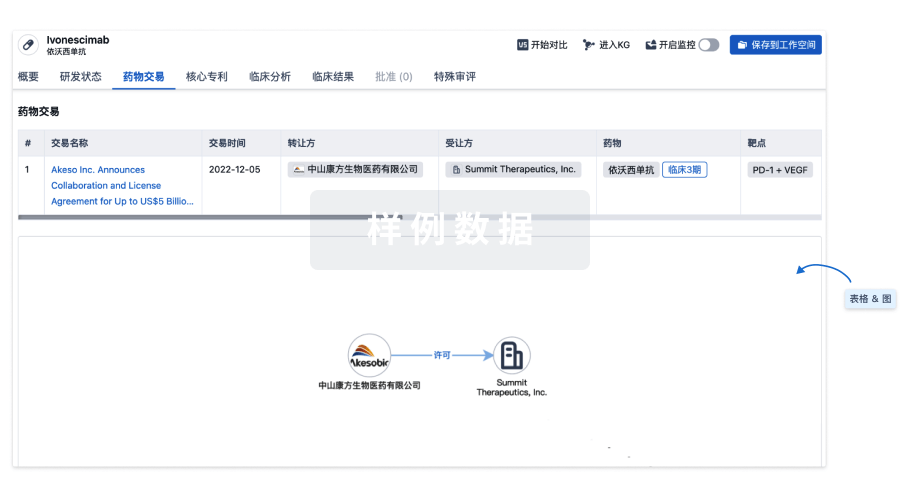

100 项与 P-1000 相关的药物交易

登录后查看更多信息

研发状态

10 条进展最快的记录, 后查看更多信息

登录

| 适应症 | 最高研发状态 | 国家/地区 | 公司 | 日期 |

|---|---|---|---|---|

| 肿瘤 | 临床前 | 德国 | - |

登录后查看更多信息

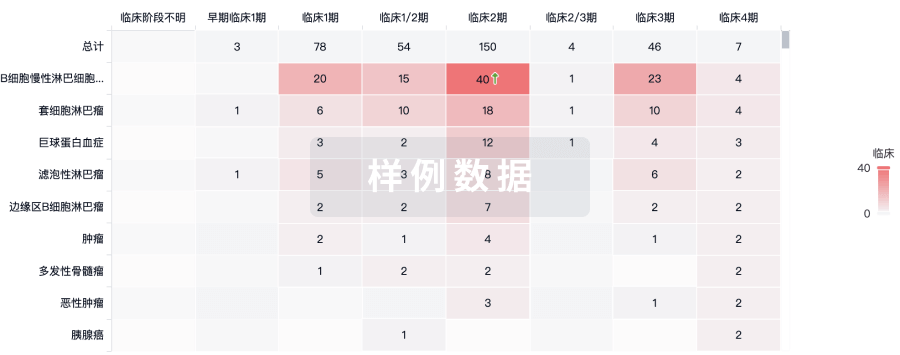

临床结果

临床结果

适应症

分期

评价

查看全部结果

| 研究 | 分期 | 人群特征 | 评价人数 | 分组 | 结果 | 评价 | 发布日期 |

|---|

No Data | |||||||

登录后查看更多信息

转化医学

使用我们的转化医学数据加速您的研究。

登录

或

药物交易

使用我们的药物交易数据加速您的研究。

登录

或

核心专利

使用我们的核心专利数据促进您的研究。

登录

或

临床分析

紧跟全球注册中心的最新临床试验。

登录

或

批准

利用最新的监管批准信息加速您的研究。

登录

或

生物类似药

生物类似药在不同国家/地区的竞争态势。请注意临床1/2期并入临床2期,临床2/3期并入临床3期

登录

或

特殊审评

只需点击几下即可了解关键药物信息。

登录

或

生物医药百科问答

全新生物医药AI Agent 覆盖科研全链路,让突破性发现快人一步

立即开始免费试用!

智慧芽新药情报库是智慧芽专为生命科学人士构建的基于AI的创新药情报平台,助您全方位提升您的研发与决策效率。

立即开始数据试用!

智慧芽新药库数据也通过智慧芽数据服务平台,以API或者数据包形式对外开放,助您更加充分利用智慧芽新药情报信息。

生物序列数据库

生物药研发创新

免费使用

化学结构数据库

小分子化药研发创新

免费使用